SILAC® Siemens Industrial Linear Accelerator

SILAC® Siemens Industrial Linear Accelerator

SILAC® Siemens Industrial Linear Accelerator

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

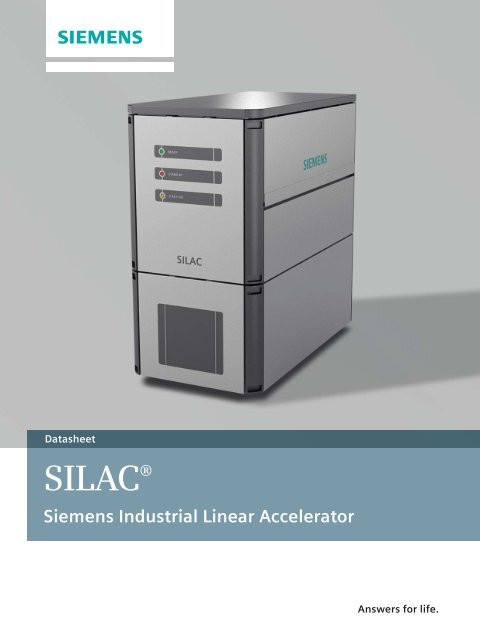

Datasheet<br />

SILAC ®<br />

<strong>Siemens</strong> <strong>Industrial</strong> <strong>Linear</strong> <strong>Accelerator</strong><br />

Answers for life.

<strong>SILAC®</strong><br />

<strong>Siemens</strong> <strong>Industrial</strong> <strong>Linear</strong> <strong>Accelerator</strong><br />

The <strong>SILAC®</strong> <strong>Linear</strong> <strong>Accelerator</strong> System is designed for<br />

special Non Destructive Testing (NDT) applications and for<br />

usage in scanning devices for cargo and vehicles in the<br />

security sector.<br />

Stationary and mobile types are available with a variable<br />

set of energies in the range of 1 to 9 MeV photon radiation.<br />

The <strong>SILAC®</strong> System is a compact module, which includes<br />

all necessary components like linear accelerator, shielding,<br />

magnetron, high frequency modulator, power supplies,<br />

interfaces.<br />

Additional and optional components such as external<br />

supplies for hot and cold environment, or a collimator, are<br />

available.<br />

General information<br />

The system can be equipped with 2 types of linear accelerator<br />

for a wide energy range (6 MeV, 9 MeV maximum<br />

Energy). The actual energy level can be varied by means<br />

of software.<br />

The energy is defined by the maximum electron energy of<br />

the selected mode and generates a spectrum of photons<br />

according to the corresponding Bremsstrahlung.<br />

The modular design allows customized installations in a<br />

stationary environment in bunkers or control areas as well<br />

as mobile setups on trucks and non-stationary equipment.<br />

2<br />

Three main components are combined in one module<br />

design:<br />

◾ An accelerator section<br />

◾ An HF-generation section<br />

◾ A control and interface section<br />

On request, it’s possible to include collimators or additional<br />

low leakage shielding.<br />

Control of the entire system is possible by an external<br />

user interface. This system software can be operated on<br />

any standard Windows-computer or by SPS system on<br />

customer site.<br />

It is possible to vary many parameters at the software<br />

control console like electron energy, pulse width, repetition<br />

rate or beam current.<br />

The integrated sensors for temperature, dose rate or<br />

water flow and the predefined software and mode tables<br />

supervise the status of the system at all times and produce<br />

warning messages or trigger system interlocks to avoid<br />

hazardous situations.

Scanned 6 MeV <strong>Accelerator</strong> (SW by Volume Graphics GmbH)<br />

<strong>SILAC®</strong><br />

<strong>Siemens</strong> <strong>Industrial</strong> <strong>Linear</strong> <strong>Accelerator</strong><br />

Application / example for use:<br />

◾ Cargo scanning<br />

Trucks<br />

Ships<br />

Rails<br />

◾ NDT<br />

QM in casting technology<br />

Material inspections<br />

Reverse engineering<br />

Measuring of complex assemblies<br />

◾ Various research fields<br />

Technical data<br />

A. Power parameter<br />

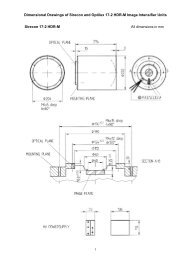

The system is equipped with a linear electron accelerator,<br />

which accelerates through 3 GHz radiofrequency standing<br />

waves until the maximum electron energy from 1 to 9 MeV<br />

is reached, depending on the type of accelerator (other<br />

energies on request) (Figure 1).<br />

B. Cone beam 6 MeV<br />

The following dose values characterize the beam angle:<br />

15°: Dose ~ 50 % of center beam line<br />

45°: Dose ~ 9 % of center beam line<br />

C. Image quality<br />

Distinguishable wire diameter and distance of the<br />

double-wire penetrameter Phantom 5D are 320 µm,<br />

which corresponds to an image blur of 640 µm<br />

(Figure 2).<br />

Scanned turbine blade (SW by Fraunhofer IIS)<br />

Figure 1: <strong>Linear</strong> <strong>Accelerator</strong> 6 MeV<br />

6 max.<br />

10 max.<br />

17<br />

5 4 3,5 4,5<br />

3 5 (= 15) 4 4 (= 16)<br />

Figure 2: Test device (parameter: extension ~3,<br />

distance focus-detector = 76 cm, energy = 6 MeV)<br />

70<br />

5 3,5 (= 17,5)<br />

15<br />

3

.75<br />

F<br />

4T Dia. 1T Dia.<br />

A<br />

E<br />

2T Dia.<br />

FE<br />

T<br />

±10%<br />

Figure 3: Test device acc. ASTM E1742-00 Diagram 1: Test result acc. ASTM E1742-00<br />

<strong>SILAC®</strong><br />

<strong>Siemens</strong> <strong>Industrial</strong> <strong>Linear</strong> <strong>Accelerator</strong><br />

ASTM E1742-00:<br />

The following unit mold is placed between 2 plates made<br />

on 80 mm thick steel (Figure 3).<br />

The diagram shows the result which is generated with the<br />

6 MeV <strong>SILAC®</strong> (Diagram 1).<br />

D. System interface<br />

Control of the whole system is possible via an external<br />

user interface. This system software can be operated on a<br />

standard Windows computer at the customer site or by<br />

SPS System (24V TTL).<br />

All relevant parameters like energy, dose, repetition rate<br />

or pulse length are variable within the system limits.<br />

In order to start the beam pulse the user can choose<br />

between external triggering and internal trigger control.<br />

The system control is fully integrated and shows the<br />

user all status messages regarding time stamps, status of<br />

system and safety loops and system errors (Figure 4).<br />

E. Safety circuits<br />

The “beam off“ safety switch is realized by an emergency<br />

stop switch of cat. 4, which has to be lined in the radiation<br />

safety loop at the user site.<br />

The system has an interlock system. When activated<br />

the errors are shown on the user monitor and the affected<br />

components stop operation.<br />

After solving the problem, the beam operation can be<br />

continued.<br />

D<br />

C<br />

B<br />

3.0 FE – 80 mm steel<br />

F. Mechanical design<br />

The main design elements are made of aluminum<br />

or stainless steel.<br />

The standard configuration can be operated in the<br />

horizontal position only.<br />

Cooling system<br />

The system needs a DI water supply. This can be provided<br />

at the user end or by the supplier. The recommended<br />

indoor cooling system has the following dimensions:<br />

Width 480 mm, length 510 mm, height 560 mm<br />

Figure 4: Screenshot of user interface<br />

4

Main Customer Benefits<br />

◾ Dual energy for enhanced material detection<br />

◾ Advanced energy selection for wide range of<br />

applications and samples<br />

◾ Adjustable operation scheme<br />

Pulse length<br />

Pulse repetition rate<br />

Dose rate<br />

Energy<br />

Configuration –<br />

Customizing<br />

Size H [cm]<br />

W [cm]<br />

D [cm]<br />

Leakage radiation weight Ratio 90° to central beam in<br />

1 m distance p weight [kg]<br />

Max. dose rate<br />

(measured in water,<br />

1 m distance)<br />

1 MeV [Gy/min]<br />

2 MeV [Gy/min]<br />

3 MeV [Gy/min]<br />

4 MeV [Gy/min]<br />

6 MeV [Gy/min]<br />

9 MeV [Gy/min]<br />

◾ Flexible customer design<br />

Separate accelerator section available<br />

“All in one box“ for easy installation<br />

◾ Compact size and optimized weight<br />

◾ Fully digital control with solid state power section<br />

◾ Variable shielding options<br />

◾ Different primary collimation options possible<br />

Stationary Compact<br />

6 MeV 9 MeV 6 MeV 9 MeV<br />

196<br />

101<br />

193<br />

10 -6 p On request<br />

10 -3 p 2600<br />

0.2<br />

0.5<br />

1.8<br />

3<br />

9<br />

–<br />

196<br />

101<br />

193<br />

10 -6 p On request<br />

2 x 10 -3 p 2200<br />

–<br />

–<br />

–<br />

3<br />

9<br />

16<br />

On request On request<br />

10 -6 p On request 10 -6 p On request<br />

Focal spot size [mm] < 2 < 2 < 2 < 2<br />

Variable pulse adjustment Repetition rate [Hz]<br />

Pulse length [µs]<br />

Environment for usage Temperature [°C]<br />

(other temperatures on request)<br />

Rel. humidity [%]<br />

Protection class [IP rating]<br />

Impact resistance<br />

Vibrations<br />

Interfaces to customer:<br />

• Electrical power<br />

TN-S supply with CEE plug<br />

stucked IP66<br />

• Communications<br />

for interlock-system<br />

status indication, 24 V<br />

TTL activation and<br />

triggering ethernet<br />

ext. control and<br />

trigger under reserve<br />

• Cooling system<br />

plugs<br />

(for customer equipment)<br />

Voltage [VAC]<br />

Current [A]<br />

1 x 15-pin SUB-D stucked IP66<br />

1 x 25-pin SUB-D stucked IP66<br />

1 x RJ45 Cat6 stucked IP66<br />

4 x 5V TNC stucked IP66<br />

1 x 9-pin SUB-D stucked IP66<br />

Pressure [bar]<br />

Temperature [°C]<br />

Water flow [l/min]<br />

Image quality DIN EN 462-5<br />

ASTM 1742-00<br />

20-300<br />

1-4 µs<br />

10-30<br />

10-85<br />

66<br />

20 g<br />

2 g<br />

400<br />

32<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

5-6<br />

16-30<br />

30-40<br />

See above<br />

See above<br />

20-300<br />

1-4 µs<br />

10-30<br />

10-85<br />

66<br />

20 g<br />

2 g<br />

400<br />

32<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

5-6<br />

16-30<br />

30-40<br />

See above<br />

See above<br />

0.2<br />

0.5<br />

1.8<br />

3<br />

9<br />

–<br />

20-300<br />

1-4 µs<br />

10-30<br />

10-85<br />

66<br />

20 g<br />

2 g<br />

400<br />

32<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

5-6<br />

On request<br />

On request<br />

See above<br />

See above<br />

Power consumption Power [kW] 15 15 15 15<br />

<strong>SILAC®</strong> <strong>SILAC®</strong> control and power unit<br />

<strong>SILAC®</strong> RF-unit<br />

<strong>SILAC®</strong> accelerator unit<br />

Mechanical components Collimator internal<br />

Adjusted aperture<br />

Controls and operation Dual energy switch – interlaced<br />

User interface and control software<br />

Others Installation and system integration<br />

R&D package<br />

Standards and Laws<br />

All <strong>SILAC®</strong> models are designed and manufactured<br />

in accordance with:<br />

All in One All in One<br />

On request<br />

On request<br />

On request<br />

Yes<br />

Yes<br />

On request<br />

On request<br />

On request<br />

On request<br />

Yes<br />

Yes<br />

On request<br />

Compact unit<br />

Separate<br />

radiation head<br />

On request<br />

On request<br />

Yes<br />

Yes<br />

Yes<br />

On request<br />

–<br />

–<br />

–<br />

3<br />

9<br />

16<br />

20-300<br />

1-4 µs<br />

10-30<br />

10-85<br />

66<br />

20 g<br />

2 g<br />

400<br />

32<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

Yes<br />

5-6<br />

On request<br />

On request<br />

See above<br />

See above<br />

Compact unit<br />

Separate<br />

radiation head<br />

On request<br />

On request<br />

Yes<br />

Yes<br />

Yes<br />

On request<br />

Low Voltage Directive 2006/95/EC and EMC<br />

Directive 2004/108/EC (EC Declaration of Conformity),<br />

other regulations on request<br />

5

The <strong>Siemens</strong> Healthcare Business<br />

Unit Components & Vacuum Technology<br />

is ISO 9001 and ISO 13485<br />

certified, manufactures in accordance<br />

with the Quality System Regulations<br />

(QSR) as defined by the U.S. Food<br />

and Drug Administration (FDA) and<br />

endeavors to comply with legal<br />

requirements concerning the environmental<br />

compatibility of its products.<br />

<strong>Siemens</strong> reserves the right to modify<br />

the design and specifications contained<br />

herein without prior notice.<br />

All rights reserved, particularly in<br />

connection with patent applications<br />

or registrations of utility model or<br />

design. This document is not considered<br />

to be a contractual specification.<br />

Kindly contact <strong>Siemens</strong> AG prior<br />

to using this information for equipment<br />

design.<br />

Local Contact Information<br />

<strong>Siemens</strong> AG<br />

Healthcare Sector<br />

H CP CV OEM<br />

Henkestr. 127<br />

DE-91052 Erlangen<br />

Germany<br />

Phone: +49 9131 84-6911<br />

Fax: +49 9131 84-2501<br />

oem.healthcare@siemens.com<br />

Global <strong>Siemens</strong> Headquarters<br />

<strong>Siemens</strong> AG<br />

Wittelsbacherplatz 2<br />

80333 Muenchen<br />

Germany<br />

These components and configurations<br />

are not finished devices. Compliance<br />

with all laws and regulations that are<br />

applicable to finished devices is the<br />

responsibility of the assembler/manufacturer<br />

of the finished device.<br />

The information in this document<br />

contains general descriptions of the<br />

technical options available, which do<br />

not always have to be present in<br />

individual cases. The required features<br />

should therefore be specified in each<br />

individual case at the time of closing<br />

the contract.<br />

Global <strong>Siemens</strong> Healthcare<br />

Headquarters<br />

<strong>Siemens</strong> AG<br />

Healthcare Sector<br />

Henkestrasse 127<br />

91052 Erlangen<br />

Germany<br />

Phone: +49 9131 84-0<br />

www.siemens.com/healthcare<br />

Legal Manufacturer<br />

<strong>Siemens</strong> AG<br />

Wittelsbacherplatz 2<br />

DE-80333 Muenchen<br />

Germany<br />

Printed in Germany | CC 230 04120.2 | 10306993_DS_SILAC 2012-04 | © 04.2012, <strong>Siemens</strong> AG<br />

www.siemens.com/healthcare<br />

Global Business Unit<br />

<strong>Siemens</strong> AG<br />

Medical Solutions<br />

Components and Vacuum Technology<br />

Henkestr. 127<br />

DE-91052 Erlangen<br />

Germany<br />

Phone: +49 9131 84-0<br />

www.siemens.com/oemproducts<br />

The components are labeled as<br />

“Manufactured by <strong>Siemens</strong>”.<br />

However, the buyer shall not market<br />

the components using the “<strong>Siemens</strong>”<br />

brand name and/or trademark. The<br />

buyer may integrate these components<br />

into a system using its own<br />

brands and labels. The product names<br />

and/or brands referred to are the<br />

property of their respective trademark<br />

holders.