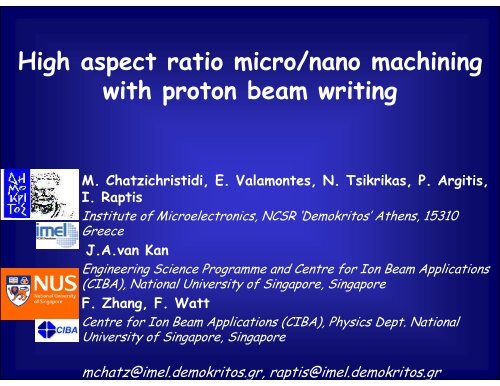

High aspect ratio micro/nano machining with proton beam writing

High aspect ratio micro/nano machining with proton beam writing

High aspect ratio micro/nano machining with proton beam writing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>High</strong> <strong>aspect</strong> <strong>ratio</strong> <strong>micro</strong>/<strong>nano</strong> <strong>machining</strong><br />

<strong>with</strong> <strong>proton</strong> <strong>beam</strong> <strong>writing</strong><br />

M. Chatzichristidi, E. Valamontes, N. Tsikrikas, P. Argitis,<br />

I. Raptis<br />

Institute of Microelectronics, NCSR ‘Demokritos’ Athens, 15310<br />

Greece<br />

J.A.van Kan<br />

Engineering Science Programme and Centre for Ion Beam Applications<br />

(CIBA), National University of Singapore, Singapore<br />

F. Zhang, F. Watt<br />

Centre for Ion Beam Applications (CIBA), Physics Dept. National<br />

University of Singapore, Singapore<br />

mchatz@imel.demokritos.gr, raptis@imel.demokritos.gr

Proposed approach<br />

Develop a resist formulation suitable for<br />

Formation of thick films<br />

<strong>High</strong> resolution structures<br />

<strong>High</strong> Aspect <strong>ratio</strong><br />

<strong>High</strong> sensitivity<br />

Processing compatible <strong>with</strong> Standard Silicon processes<br />

Stripping <strong>with</strong> conventional stripping schemes<br />

Develop a patterning technology suitable for<br />

Fast prototyping<br />

Thick polymer film structuring<br />

<strong>High</strong> resolution patterning<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Presentation Outline<br />

• Conventional HAR Patterning Technologies<br />

X-Ray lithography (XR-LIGA)<br />

I-line lithograpy (UV-LIGA)<br />

• Proton Beam Writing (PBW)<br />

Principle of ope<strong>ratio</strong>n<br />

Advantages & disadvantages<br />

Typical results<br />

• Typical HAR Resists<br />

PMMA<br />

SU-8<br />

• TADEP resist<br />

Formulation<br />

Physicochemical properties<br />

Formulation & processing optimization<br />

Lithographic results<br />

Electroplating<br />

• PBW simulation<br />

Simulation of Proton <strong>beam</strong> – Matter interaction<br />

Simulation of the thick polymeric films patterning<br />

• Conclusions<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Presentation Outline<br />

• Conventional HAR Patterning Technologies<br />

X-Ray lithography (XR-LIGA)<br />

I-line lithograpy (UV-LIGA)<br />

• Proton Beam Writing (PBW)<br />

Principle of ope<strong>ratio</strong>n<br />

Advantages & disadvantages<br />

Typical results<br />

• Typical HAR Resists<br />

PMMA<br />

SU-8<br />

• TADEP resist<br />

Formulation<br />

Physicochemical properties<br />

Formulation & processing optimization<br />

Lithographic results<br />

Electroplating<br />

• PBW simulation<br />

Simulation of Proton <strong>beam</strong> – Matter interaction<br />

Simulation of the thick polymeric films patterning<br />

• Conclusions

UV-LIGA (typical literature results)<br />

SEM photos of SU-8 <strong>micro</strong>structure <strong>with</strong><br />

thickness of 400 µm.<br />

Linewidth: 10 µm<br />

X. Tian, G. Liu, Y. Tian, P. Zhang, X. Zhang<br />

Micros. Techn. 11 265(2005)<br />

J. Liu, B. Cai, J. Zhu, G. Ding, X. Zhao, C. Yang, D. Chen<br />

Micros. Tech. 10 265(2004)<br />

SU-8 patterns <strong>with</strong><br />

thickness 210 µm, width 10 µm<br />

Aspect <strong>ratio</strong> is 21.<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

X-Ray LIGA (typical literature results)<br />

Three-level SU-8 structure <strong>with</strong> step heights<br />

of 300, 600 and 900 µm fabricated by X-ray<br />

lithography.<br />

J. Hormes, J. Göttert, K. Lian, Y. Desta, L.<br />

Jian Nucl. Instr. Meth. B 199 332(2003)<br />

1500 µm tall SU-8 gears.<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Proton Beam Writing (PBW) (I)<br />

Comparison between p-<strong>beam</strong> <strong>writing</strong>,<br />

FIB, and (c) e-<strong>beam</strong> <strong>writing</strong>. The p-<strong>beam</strong><br />

and e-<strong>beam</strong> images were simulated using<br />

SRIM and CASINO software packages,<br />

respectively.<br />

F.Watt, M.B.H.Breese, A.A.Bettiol, J.A.van Kan<br />

Materials Today 10(6) 20(2007)<br />

Schematic of the p-<strong>beam</strong> <strong>writing</strong> facility at<br />

CIBA. MeV <strong>proton</strong>s are produced in a <strong>proton</strong><br />

accelerator, and a demagnified image of the<br />

<strong>beam</strong> transmitted through an object<br />

aperture is focused onto the substrate<br />

material (resist) by means of a series of<br />

strong focusing magnetic quadrupole lenses.<br />

Beam scanning takes place using magnetic or<br />

electrostatic deflection before the focusing<br />

lenses.<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Proton Beam Writing (PBW) (II)<br />

Typical Application areas<br />

Photonics (waveguides, lens arrays, gratings, …)<br />

Microfluidic devices, biostructures, and biochips (imprinting, …)<br />

<strong>High</strong> resolution patterning (X-ray masks, …)<br />

Porous Si (patterning, Distributed Bragg reflectors, …)<br />

Advantages<br />

Maskless process (ideal for prototyping)<br />

Vertical side walls<br />

Ultra high resolution<br />

Ultra high <strong>aspect</strong> <strong>ratio</strong> pattering (provided the resist properties)<br />

Disadvantages<br />

Serial patterning process (moderate speed)<br />

Limited penet<strong>ratio</strong>n depth (50µm for 2MeV <strong>proton</strong> <strong>beam</strong>)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Proton Beam Writing (PBW) (III)<br />

<strong>High</strong> <strong>aspect</strong> <strong>ratio</strong> test<br />

structures in SU-8 (60 nm<br />

wide, 10µm deep structures).<br />

First exposure<br />

Parthenon’s copy <strong>with</strong> a<br />

reduction of 1 million times<br />

Second exposure<br />

I.Rajta, M.Chatzichristidi, E.Baradács, I.Raptis,<br />

Nucl. Instrum. Meth. B 260 414(2007)<br />

J. A. van Kan, P. G. Shao,<br />

K. Ansari, A. A. Bettiol,<br />

T. Osipowicz, F. Watt,<br />

Microsyst Technol 13 431(2007)<br />

Side view of the<br />

“lambda” structures.<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Typical resists for HAR structures<br />

Positive resists<br />

PMMA<br />

Novolak-diazonaphtoquinone resist platform<br />

Negative resists<br />

epoxy based, chemically amplified SU-8<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

PMMA (I)<br />

Advantages<br />

<strong>High</strong> resolution<br />

Stripping <strong>with</strong> conventional stripping schemes ( e.g. acetone)<br />

Disadvantages<br />

Limitation in the film thickness obtained by spin coating<br />

Low sensitivity<br />

Development in organic solvents (MIBK or MIBK/IPA)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

CH3 H2 C C<br />

n<br />

C O<br />

O<br />

CH 3<br />

PMMA<br />

PMMA thickness: 350 nm.<br />

Proton <strong>beam</strong>: 2MeV<br />

Structure’s width: 50nm<br />

PMMA (II)<br />

CH 3<br />

H 2<br />

C C<br />

C<br />

O<br />

OCH 3<br />

F. Watt, M.B.H. Breese, A.A. Bettiol, J.A.<br />

van Kan Materials Today 10(6) 20(2007)<br />

a)<br />

H 2<br />

C<br />

CH 3<br />

C<br />

C O<br />

OCH 3<br />

C<br />

H 2<br />

n<br />

CH 3<br />

C<br />

Chain Chain scission<br />

Cleavage Cleavage of methyl of methyl ester group<br />

CH 3<br />

hv H2 C C<br />

CH 3<br />

.<br />

Chain scission mechanism upon exposure<br />

H 2<br />

C<br />

CH 3<br />

C<br />

C O<br />

OCH 3<br />

CH2 + . C further reactions<br />

C O<br />

OCH 3<br />

n<br />

+<br />

Further reactions<br />

.<br />

C O<br />

OCH 3<br />

evolution of gaseous,<br />

volatile products:<br />

CO, CO2, . CH3, CH3O . Evolution of gaseous,<br />

Volatile products:<br />

CO, CO .<br />

2 , CH3 ,CH3O .<br />

SEM image of 5-μm thick PMMA by PBW<br />

at 1.7 MeV (fluence: 100 nC/mm 2 ) <strong>with</strong><br />

<strong>writing</strong> patterns of dots (1.25µm<br />

diameter).<br />

N. Uchiya, T. Harada, M. Murai,H. Nishikawa,<br />

J. Haga, T. Sato, Y. Ishii, T. Kamiya, Nucl.<br />

Instr. and Meth. in Phys. Res. B 260405(2007)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Advantages<br />

<strong>High</strong> sensitivity<br />

Thick films by spin coating<br />

Disadvantages<br />

Development in organic solvent<br />

SU-8 resist (I)<br />

Very difficult stripping by conventional<br />

stripping schemes (needs piranha etch,<br />

plasma ash e.t.c.)<br />

Absorption<br />

www.<strong>micro</strong>chem.com MNE 07 Copenhagen, Denmark<br />

25 September 2007

H 3C<br />

H 2C<br />

O<br />

O<br />

C<br />

H<br />

C CH 3<br />

O<br />

C<br />

H 2<br />

CH 2<br />

O<br />

C<br />

H<br />

H 2<br />

C<br />

CH 2<br />

H 3C<br />

H 2C<br />

O<br />

O<br />

C<br />

H<br />

C CH 3<br />

O<br />

CH 2<br />

O<br />

C C<br />

H2 H<br />

H 2<br />

C<br />

CH 2<br />

SU-8 resist (II)<br />

Chemical formulation of SU-8 resist<br />

H 3C<br />

H 2C<br />

O<br />

O<br />

C<br />

H<br />

C CH 3<br />

O<br />

C<br />

H 2<br />

CH 2<br />

O<br />

C<br />

H<br />

H 2<br />

C<br />

CH 2<br />

H 3C<br />

H 2C<br />

O<br />

O<br />

C<br />

H<br />

C CH 3<br />

O<br />

O<br />

C C<br />

H2 H<br />

CH 2<br />

CH 2<br />

Crosslinking mechanism<br />

+<br />

S +<br />

S<br />

F<br />

F<br />

F Sb F<br />

F F<br />

OPEN OF EPOXY RINGS<br />

AND BONDING

SU-8 resist (characteristic PBW results)<br />

1 mm 2 area of single pixel<br />

irradiation on SU-8 (top view).<br />

I.Rajta, M.Chatzichristidi, E.Baradács,<br />

I.Raptis, Nucl. Instrum. Meth. B 260<br />

414(2007)<br />

Side view of irradiation on SU-8.<br />

130 nm wide lines, 15 <strong>aspect</strong> <strong>ratio</strong><br />

J.A. van Kan, P.G. Shao, K. Ansari,<br />

A.A. Bettiol, T. Osipowicz F. Watt,<br />

Microsyst. Technol. 13 431(2007)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Presentation Outline<br />

• Conventional HAR Patterning Technologies<br />

X-Ray lithography (XR-LIGA)<br />

I-line lithograpy (UV-LIGA)<br />

• Proton Beam Writing (PBW)<br />

Principle of ope<strong>ratio</strong>n<br />

Advantages & disadvantages<br />

Typical results<br />

• Typical HAR Resists<br />

PMMA<br />

SU-8<br />

• TADEP resist<br />

Formulation<br />

Physicochemical properties<br />

Formulation & processing optimization<br />

Lithographic results<br />

Electroplating<br />

• PBW simulation<br />

Simulation of Proton <strong>beam</strong> – Matter interaction<br />

Simulation of the thick polymeric films patterning<br />

• Conclusions

Thick Aqueous Developable EPoxy resist<br />

TADEP formulation<br />

Goal:<br />

Develop a resist formulation suitable for<br />

•Formation of thick films<br />

•<strong>High</strong> resolution structures<br />

•<strong>High</strong> Aspect <strong>ratio</strong><br />

•<strong>High</strong> sensitivity<br />

•Processing compatible <strong>with</strong> Standard Silicon process<br />

•Stripping <strong>with</strong> conventional stripping schemes<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

[ CH CH2 ]<br />

OH<br />

TADEP formulation<br />

[ CH<br />

n CH2 ] m<br />

OH<br />

Partially Hydrogenated PHS<br />

from Maruzen Co.<br />

S +<br />

F<br />

F<br />

F Sb<br />

F F<br />

F<br />

Triphenyl Sulfonium Hexafluoro<br />

Antimonate (TPS-SbF 6 )<br />

[<br />

O<br />

Epoxy novolac<br />

Fractionation of EPICOTE 164 from Shell<br />

O<br />

F<br />

+<br />

S<br />

O<br />

S O<br />

F<br />

F<br />

CH 3<br />

OH<br />

1-(4-hydroxy-3-methylphenyl)<br />

tetrahydrothiophenium triflate<br />

(o-CS-triflate)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007<br />

O

TADEP Crosslinking mechanism<br />

OH OH OH OH OH OH OH OH<br />

* *<br />

n<br />

OH OH<br />

OH OH OH OH OH OH OH OH<br />

* *<br />

n<br />

OH OH<br />

OH<br />

OH<br />

*<br />

O<br />

O<br />

OH<br />

OH<br />

O<br />

OH<br />

O<br />

Unexposed Resist Areas: Soluble in<br />

aqueous base developers<br />

R 1<br />

O<br />

C<br />

H<br />

Crosslinking<br />

CH 2<br />

OH<br />

R 1<br />

n*<br />

CH<br />

OH<br />

OH<br />

H + SbF 6 -<br />

H<br />

O<br />

CH 2<br />

O + H<br />

R 2<br />

OH<br />

OH<br />

OH<br />

OH<br />

R 1<br />

H<br />

O<br />

CH2 +<br />

C<br />

H<br />

H + , heating<br />

R 1<br />

CH<br />

H<br />

O<br />

CH 2<br />

O<br />

R 2<br />

OH OH OH OH OH OH OH OH<br />

* *<br />

n<br />

R 2<br />

OH OH<br />

OH OH<br />

HO<br />

O<br />

OH OH OH OH OH<br />

* *<br />

n<br />

+<br />

OH<br />

OH OH<br />

OH OH O OH<br />

*<br />

OH<br />

O<br />

OH<br />

O<br />

n*<br />

Exposed Resist Areas: Insoluble in<br />

aqueous base developers<br />

R 1<br />

C<br />

H<br />

H<br />

H + SbF 6 -<br />

O<br />

CH2 +<br />

Lewis acid<br />

regene<strong>ratio</strong>n<br />

OH<br />

R 1<br />

OH<br />

OH<br />

CH<br />

H<br />

O<br />

CH 2<br />

OH<br />

O + H<br />

R 2<br />

OH<br />

OH<br />

OH<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Absorbance (A)<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

PAG’s UV spectra<br />

Thickness- Absorption data<br />

0.0<br />

300 320 340 360 380 400<br />

Wavelenght (nm)<br />

o-Cs Triflate<br />

TPS Antimonate<br />

365 nm<br />

It is shown that at 365nm, where<br />

the film is exposed, the TPSantimonate<br />

does not absorb<br />

whereas o-Cs triflate absorbs<br />

slightly.<br />

Film Thickness (μm)<br />

TADEP film thickness (after PAB)<br />

vs. spinning speed<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

0<br />

45% TADEP<br />

30% TADEP<br />

500 1000 1500 2000 2500 3000 3500 4000 4500 5000<br />

Spinning speed (rpm)<br />

55µm thick film can be achieved<br />

<strong>with</strong> one spinning<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Rev Heat Flow (W/g)<br />

0 .4<br />

0 .3<br />

0 .2<br />

0 .1<br />

0 .0<br />

-0 .1<br />

-0 .2<br />

-0 .3<br />

-0 .4<br />

Glass transition temperature studies<br />

23.5°C (H )<br />

0.2129J/g/°C<br />

38.51°C (I)<br />

108.6°C (I)<br />

95.75°C (I)<br />

88.74°C (I)<br />

Epoxy<br />

134.74°C (I)<br />

0 50 1 00 1 50 2 0 0 2 50 30 0<br />

Exo U p Tem perature (°C )<br />

U niversal V3.9A TA Instrum ents<br />

PHS<br />

PHS-EP<br />

PHS-EP TPS Ant.<br />

unexposed<br />

PHS-EP TPS Ant.<br />

exposed<br />

PHS-EP o-Cs trifl.<br />

unexposed PHS-EP o-Cs trifl.<br />

exposed<br />

SU-8<br />

The resist components are fully miscible<br />

The exposed areas are crosslinked and show no Tg<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Dissolution study (PAG molecule)<br />

Concept: Controlled development<br />

process<br />

Tool: White Light Reflectance<br />

Spectroscopy DRM<br />

Thickness (nm)<br />

0<br />

0 60 120 180 240 300 360<br />

Film thickness: ~2μm<br />

Developer: AZ-726 (AZ-EM) 0.26N TMAH<br />

In all cases dissolution proceeds linearly <strong>with</strong> time.<br />

NO swelling effect is observed except in the UVI case which is very<br />

hydrophobic.<br />

In the SU-8 resist case, the development is abrupt (impossible to monitor).<br />

2100<br />

1800<br />

1500<br />

1200<br />

900<br />

600<br />

300<br />

Development time (sec)<br />

P-RES-4 “Processing effects on the dissolution properties of<br />

thin chemically amplified photoresist films”<br />

no PAG<br />

o-Cs Triflate 3.4%<br />

TPS Antimonate 5%<br />

TPS Triflate 4%<br />

UVI 6%<br />

TPS Ant. 2%<br />

TPS Ant. 3,2% o-Cs1.1%<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Laser<br />

n 1<br />

θ 1<br />

Detector<br />

n 2 z1<br />

resist<br />

n 3<br />

substrate<br />

θ 2<br />

Operating principle<br />

Single Wavelength<br />

Interferometer Set-up<br />

PAB study<br />

Intereference Signal (a.u.)<br />

0.90<br />

0.88<br />

0.86<br />

0.84<br />

0.82<br />

0.80<br />

0.78<br />

0.76<br />

Temperature<br />

Interference signal<br />

50 100 150 200<br />

Time (min)<br />

Solvent evapo<strong>ratio</strong>n during the PAB step. Most of the solvent<br />

evaporates during the first 10min (heat up from RT to 95 o C). During<br />

the rest period (4h) ~0.8μm of resist thinning is observed.<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

40<br />

30<br />

Temperature ( o C)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

a<br />

100°C for 8 min<br />

exposure dose (238 nC/mm 2 )<br />

PEB study<br />

The increased PEB temperature helps<br />

significantly the crosslinking reaction<br />

b<br />

110°C for 8 min<br />

exposure dose (116 nC/mm 2 )<br />

Ι. Rajta, E. Baradacs, M. Chatzichristidi, E.S. Valamontes, I. Raptis,<br />

Nucl. Inst. Meth. B, 231 423 (2005)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Preliminary Lithographic evaluation (I)<br />

UV-LIGA<br />

Thickness = 11 µm<br />

Aspect Ratio = 7<br />

Substrate: Silicon wafer <strong>with</strong> plating base (Au surface)<br />

I-line lithography (MJB3 Karl-Suss)<br />

Thickness = 35 µm<br />

Layout = 5 µm L/S<br />

Linewidth = 5 µm<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Preliminary Lithographic evaluation (II)<br />

SINGLE PIXEL AND SINGLE LINE EXPOSURES<br />

The achieved smallest feature size was the same as the measured <strong>beam</strong> spot size (limited by<br />

the <strong>proton</strong> <strong>beam</strong> dimensions). The highest <strong>aspect</strong> <strong>ratio</strong> for this type of structures was 7<br />

(for the selected film thickness).<br />

Side view of single pixel<br />

irradiation on TADEP.<br />

Resolution 2.8µm<br />

Aspect <strong>ratio</strong> 7<br />

Top view of single line<br />

irradiation on TADEP.<br />

Beam size: ~ 3X3µm<br />

I.Rajta, M.Chatzichristidi, E.Baradács, I.Raptis,<br />

Nucl. Instrum. Meth. B 260 414(2007)<br />

MNE 07 Copenhagen, Denmark<br />

25 Sept. 2007

Lithographic Evaluation using fine p-<strong>beam</strong><br />

Top view of PBW double line<br />

irradiation on TADEP resist.<br />

Line width ~110nm in X-direction.<br />

Resist thickness ~2.0 µm<br />

Aspect <strong>ratio</strong>: 18<br />

Beam size: ~100X200nm<br />

Two pixels pass line<br />

Pitch: 1µm, 4µm<br />

110nm

Lithographic Evaluation (III)<br />

Side view of dense lines by<br />

2MeV PBW on TADEP resist.<br />

Resist thickness ~11.0 µm<br />

Beam size: ~100X200nm<br />

Two pixels pass line<br />

Pitch: 1µm, 4µm<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Lithographic Evaluation (IV)<br />

Top view of PBW double line<br />

irradiation on TADEP resist. Line<br />

width 280nm in X-direction.<br />

Side view of the pattern. Resist<br />

thickness 12µm, <strong>aspect</strong> <strong>ratio</strong>: 42.<br />

Beam size: 200nm in X-direction<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Electroplating results<br />

167nm<br />

Side view of Ni plated on gold features.<br />

Ni thickness 0.8µm<br />

On the right side the resist pattern<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Presentation Outline<br />

• Conventional HAR Patterning Technologies<br />

X-Ray lithography (XR-LIGA)<br />

I-line lithograpy (UV-LIGA)<br />

• Proton Beam Writing (PBW)<br />

Principle of ope<strong>ratio</strong>n<br />

Advantages & disadvantages<br />

Typical results<br />

• Typical HAR Resists<br />

PMMA<br />

SU-8<br />

• TADEP resist<br />

Formulation<br />

Physicochemical properties<br />

Formulation & processing optimization<br />

Lithographic results<br />

Electroplating<br />

• PBW simulation<br />

Simulation of Proton <strong>beam</strong> – Matter interaction<br />

Simulation of the thick polymeric films patterning<br />

• Conclusions

PBW simulation flow-chart<br />

Point <strong>proton</strong> <strong>beam</strong> simulation<br />

Convolution <strong>with</strong> Gaussian Profile<br />

Realistic <strong>proton</strong> <strong>beam</strong> simulation<br />

Convolution <strong>with</strong> Layout<br />

Thermal processing,<br />

PEB simulation (only for CARs*)<br />

* P-RES5 “Stochastic simulation studies of molecular<br />

resists for the 32nm technology node”<br />

Energy (KeV/cm 3 *electron)<br />

10 15<br />

10 14<br />

10 13<br />

10 12<br />

10 11<br />

10 10<br />

10 9<br />

10 8<br />

10 7<br />

Point Beam Energy Deposition<br />

0 500 1000 1500 2000<br />

Radial distance (nm)<br />

Point Beam<br />

exposure<br />

Layout<br />

(top view)<br />

Energy deposition on resist Energy deposition<br />

(cross section)<br />

Development simulation<br />

Resist Profile<br />

(development)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Proton Beam – matter interaction simulation<br />

The formalism adopted for simulating <strong>proton</strong>s propagation is that of TRIM /<br />

SRIM [1]. At high energies, we have decided, for the sake of the computer<br />

efficiency, to base the calculations on the Coulomb potential [2].<br />

Stopping powers at high energies were calculated according to Bethe’s<br />

theory<br />

At low energies, electronic stopping powers were obtained from experimental<br />

data, closely related to the empirical fitting formulas developed by Andersen<br />

and Ziegler.<br />

The nuclear stopping power, which is important only at very low energies, was<br />

obtained by the method of Everhart et al [3].<br />

[1] J. Biersack, L. Haggmark, Nucl. Instr. and Meth. 174 (1980) 257.<br />

[2] J. F. Ziegler, J. P. Biersack, U. Littmark, The Stopping and Range of Ions in Solids,<br />

The Stopping and Ranges of Ions in Matter, Vol. 1, Pergamon Press Inc., 1985.<br />

[3] Stopping Powers and Ranges for Protons and Alpha Particles, International<br />

Commission on Radiation Units and Measurements, Report 49, 1993.

Energy deposition (eV/Α)<br />

PBW simulation results (energy deposition)<br />

14<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Bulk PMMA<br />

10umPMMA/Si<br />

20umPMMA/Si<br />

30umPMMA/Si<br />

0<br />

0 5 10 15 20 25 30 35 40 45 50 55 60 65<br />

Depth (μm)<br />

Monte-Carlo (MC) simulation:<br />

Energy deposition vs. depth for<br />

various resist films.<br />

Proton <strong>beam</strong>: 2MeV<br />

Simulation Dz=50nm<br />

PMMA<br />

Si substrate<br />

Energy deposition (eV/Α)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

Literature<br />

SRIM<br />

Bulk PMMA<br />

0<br />

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70<br />

Depth (μm)<br />

Comparison of the MC simulation<br />

results in bulk <strong>with</strong> the literature<br />

and SRIM<br />

Proton <strong>beam</strong>: 2MeV<br />

Simulation Dz=50nm<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

PBW simulation results (convolution)<br />

Energy (KeV/cm 3 *electron)<br />

10 15<br />

10 14<br />

10 13<br />

10 12<br />

10 11<br />

10 10<br />

10 9<br />

10 8<br />

10 7<br />

Convoluted Energy Deposition<br />

Point Beam Energy Deposition<br />

0 500 1000 1500 2000<br />

Radial distance (nm)<br />

Energy deposition due to point <strong>beam</strong> and gaussian <strong>proton</strong> <strong>beam</strong> at<br />

the resist (10μm)/substrate interface (Beam diameter 100nm)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

PBW simulation results (layout level)<br />

Proton <strong>beam</strong> irradiated<br />

Unexposed area<br />

200nm lines / 400nm spaces<br />

Proton Beam Diameter 100nm<br />

Film Thickness 10µm<br />

Top view<br />

(layout)<br />

Si wafer Si wafer<br />

Threshold: 0.01 x G Threshold: 0.1 x G<br />

Energy deposition<br />

(cross section)<br />

Cross-section<br />

after development<br />

(simulation)<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Conclusions<br />

Proton Beam Writing proved a powerful <strong>micro</strong>/<strong>nano</strong> <strong>machining</strong><br />

tool, resolution depending on the <strong>beam</strong> size.<br />

The strippable, aqueous base developable TADEP resist proved<br />

adequate for high <strong>aspect</strong> <strong>ratio</strong> <strong>nano</strong><strong>machining</strong><br />

Dense features <strong>with</strong> vertical & smooth sidewalls were revealed:<br />

Thickness 2μμμμm, Linewidth 110nm, Aspect <strong>ratio</strong> 18<br />

Thickness 12μμμμm, Linewidth 280nm, Aspect Ratio 42<br />

Successful Ni electroplating is showed demonstrating the<br />

stripping capability of TADEP resist<br />

Simulation software for <strong>proton</strong> <strong>beam</strong> <strong>writing</strong> is under<br />

development<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007

Acknowledgments<br />

The work was financially supported by the<br />

PB.NANOCOMP project (funded by the Greek<br />

Secretariat for Research & Technology contract<br />

number 05-NONEU-467).<br />

THANK YOU FOR YOUR ATTENTION<br />

MNE 07 Copenhagen, Denmark<br />

25 September 2007