Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

89<br />

<strong>Quality</strong> <strong>Assurance</strong> <strong>Handbook</strong> <strong>for</strong> <strong>Rural</strong> <strong>Roads</strong><br />

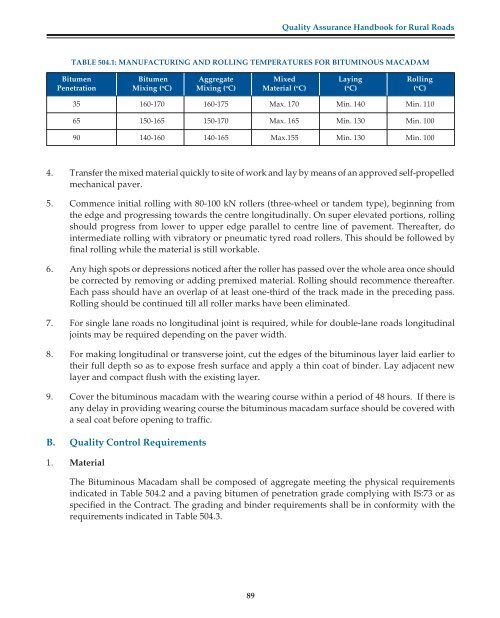

TABLE 504.1: MANUFACTURING AND ROLLING TEMPERATURES FOR BITUMINOUS MACADAM<br />

Bitumen Bitumen Aggregate Mixed Laying Rolling<br />

Penetration Mixing ( o C) Mixing ( o C) Material ( o C) ( o C) ( o C)<br />

35 160-170 160-175 Max. 170 Min. 140 Min. 110<br />

65 150-165 150-170 Max. 165 Min. 130 Min. 100<br />

90 140-160 140-165 Max.155 Min. 130 Min. 100<br />

4. Transfer the mixed material quickly to site of work and lay by means of an approved self-propelled<br />

mechanical paver.<br />

5. Commence initial rolling with 80-100 kN rollers (three-wheel or tandem type), beginning from<br />

the edge and progressing towards the centre longitudinally. On super elevated portions, rolling<br />

should progress from lower to upper edge parallel to centre line of pavement. Thereafter, do<br />

intermediate rolling with vibratory or pneumatic tyred road rollers. This should be followed by<br />

final rolling while the material is still workable.<br />

6. Any high spots or depressions noticed after the roller has passed over the whole area once should<br />

be corrected by removing or adding premixed material. Rolling should recommence thereafter.<br />

Each pass should have an overlap of at least one-third of the track made in the preceding pass.<br />

Rolling should be continued till all rolIer marks have been eliminated.<br />

7. For single lane roads no longitudinal joint is required, while <strong>for</strong> double-lane roads longitudinal<br />

joints may be required depending on the paver width.<br />

8. For making longitudinal or transverse joint, cut the edges of the bituminous layer laid earlier to<br />

their full depth so as to expose fresh surface and apply a thin coat of binder. Lay adjacent new<br />

layer and compact flush with the existing layer.<br />

9. Cover the bituminous macadam with the wearing course within a period of 48 hours. If there is<br />

any delay in providing wearing course the bituminous macadam surface should be covered with<br />

a seal coat be<strong>for</strong>e opening to traffic.<br />

B. <strong>Quality</strong> Control Requirements<br />

1. Material<br />

The Bituminous Macadam shall be composed of aggregate meeting the physical requirements<br />

indicated in Table 504.2 and a paving bitumen of penetration grade complying with IS:73 or as<br />

specified in the Contract. The grading and binder requirements shall be in con<strong>for</strong>mity with the<br />

requirements indicated in Table 504.3.