Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

3.2 Tests During Construction<br />

87<br />

<strong>Quality</strong> <strong>Assurance</strong> <strong>Handbook</strong> <strong>for</strong> <strong>Rural</strong> <strong>Roads</strong><br />

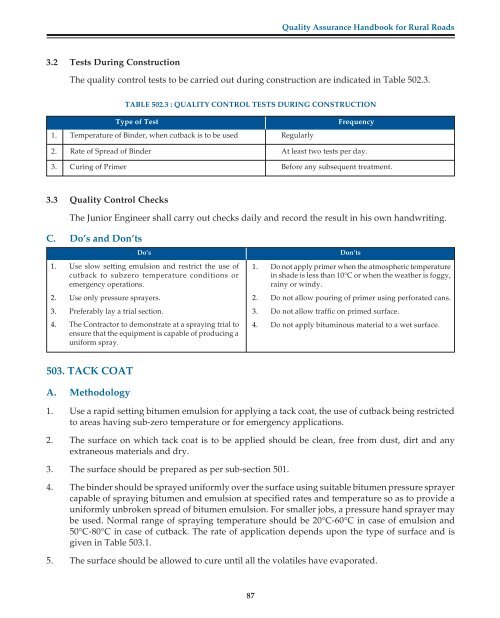

The quality control tests to be carried out during construction are indicated in Table 502.3.<br />

TABLE 502.3 : QUALITY CONTROL TESTS DURING CONSTRUCTION<br />

Type of Test Frequency<br />

1. Temperature of Binder, when cutback is to be used Regularly<br />

2. Rate of Spread of Binder At least two tests per day.<br />

3. Curing of Primer Be<strong>for</strong>e any subsequent treatment.<br />

3.3 <strong>Quality</strong> Control Checks<br />

The Junior Engineer shall carry out checks daily and record the result in his own handwriting.<br />

C. Do’s and Don’ts<br />

1. Use slow setting emulsion and restrict the use of<br />

cutback to subzero temperature conditions or<br />

emergency operations.<br />

2. Use only pressure sprayers.<br />

3. Preferably lay a trial section.<br />

4. The Contractor to demonstrate at a spraying trial to<br />

ensure that the equipment is capable of producing a<br />

uni<strong>for</strong>m spray.<br />

503. TACK COAT<br />

A. Methodology<br />

Do’s Don’ts<br />

1. Do not apply primer when the atmospheric temperature<br />

in shade is less than 10°C or when the weather is foggy,<br />

rainy or windy.<br />

2. Do not allow pouring of primer using per<strong>for</strong>ated cans.<br />

3. Do not allow traffic on primed surface.<br />

4. Do not apply bituminous material to a wet surface.<br />

1. Use a rapid setting bitumen emulsion <strong>for</strong> applying a tack coat, the use of cutback being restricted<br />

to areas having sub-zero temperature or <strong>for</strong> emergency applications.<br />

2. The surface on which tack coat is to be applied should be clean, free from dust, dirt and any<br />

extraneous materials and dry.<br />

3. The surface should be prepared as per sub-section 501.<br />

4. The binder should be sprayed uni<strong>for</strong>mly over the surface using suitable bitumen pressure sprayer<br />

capable of spraying bitumen and emulsion at specified rates and temperature so as to provide a<br />

uni<strong>for</strong>mly unbroken spread of bitumen emulsion. For smaller jobs, a pressure hand sprayer may<br />

be used. Normal range of spraying temperature should be 20°C-60°C in case of emulsion and<br />

50°C-80°C in case of cutback. The rate of application depends upon the type of surface and is<br />

given in Table 503.1.<br />

5. The surface should be allowed to cure until all the volatiles have evaporated.