Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

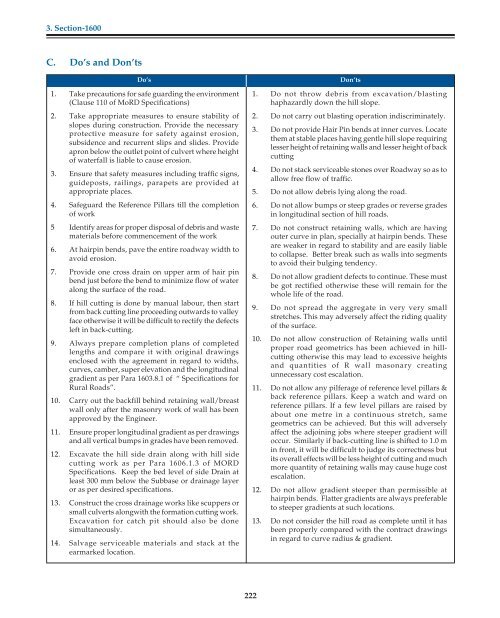

3. Section-1600 C. Do’s and Don’ts Do’s Don’ts 1. Take precautions for safe guarding the environment (Clause 110 of MoRD Specifications) 2. Take appropriate measures to ensure stability of slopes during construction. Provide the necessary protective measure for safety against erosion, subsidence and recurrent slips and slides. Provide apron below the outlet point of culvert where height of waterfall is liable to cause erosion. 3. Ensure that safety measures including traffic signs, guideposts, railings, parapets are provided at appropriate places. 4. Safeguard the Reference Pillars till the completion of work 5 Identify areas for proper disposal of debris and waste materials before commencement of the work 6. At hairpin bends, pave the entire roadway width to avoid erosion. 7. Provide one cross drain on upper arm of hair pin bend just before the bend to minimize flow of water along the surface of the road. 8. If hill cutting is done by manual labour, then start from back cutting line proceeding outwards to valley face otherwise it will be difficult to rectify the defects left in back-cutting. 9. Always prepare completion plans of completed lengths and compare it with original drawings enclosed with the agreement in regard to widths, curves, camber, super elevation and the longitudinal gradient as per Para 1603.8.1 of “ Specifications for Rural Roads”. 10. Carry out the backfill behind retaining wall/breast wall only after the masonry work of wall has been approved by the Engineer. 11. Ensure proper longitudinal gradient as per drawings and all vertical bumps in grades have been removed. 12. Excavate the hill side drain along with hill side cutting work as per Para 1606.1.3 of MORD Specifications. Keep the bed level of side Drain at least 300 mm below the Subbase or drainage layer or as per desired specifications. 13. Construct the cross drainage works like scuppers or small culverts alongwith the formation cutting work. Excavation for catch pit should also be done simultaneously. 14. Salvage serviceable materials and stack at the earmarked location. 1. Do not throw debris from excavation/blasting haphazardly down the hill slope. 2. Do not carry out blasting operation indiscriminately. 3. Do not provide Hair Pin bends at inner curves. Locate them at stable places having gentle hill slope requiring lesser height of retaining walls and lesser height of back cutting 4. Do not stack serviceable stones over Roadway so as to allow free flow of traffic. 5. Do not allow debris lying along the road. 6. Do not allow bumps or steep grades or reverse grades in longitudinal section of hill roads. 7. Do not construct retaining walls, which are having outer curve in plan, specially at hairpin bends. These are weaker in regard to stability and are easily liable to collapse. Better break such as walls into segments to avoid their bulging tendency. 8. Do not allow gradient defects to continue. These must be got rectified otherwise these will remain for the whole life of the road. 9. Do not spread the aggregate in very very small stretches. This may adversely affect the riding quality of the surface. 10. Do not allow construction of Retaining walls until proper road geometrics has been achieved in hillcutting otherwise this may lead to excessive heights and quantities of R wall masonary creating unnecessary cost escalation. 11. Do not allow any pilferage of reference level pillars & back reference pillars. Keep a watch and ward on reference pillars. If a few level pillars are raised by about one metre in a continuous stretch, same geometrics can be achieved. But this will adversely affect the adjoining jobs where steeper gradient will occur. Similarly if back-cutting line is shifted to 1.0 m in front, it will be difficult to judge its correctness but its overall effects will be less height of cutting and much more quantity of retaining walls may cause huge cost escalation. 12. Do not allow gradient steeper than permissible at hairpin bends. Flatter gradients are always preferable to steeper gradients at such locations. 13. Do not consider the hill road as complete until it has been properly compared with the contract drawings in regard to curve radius & gradient. 222

SECTION 1700 TRAFFIC SIGNS, 223 Quality Assurance Handbook for Rural Roads MARKINGS & OTHER ROAD APPURTENANCES

- Page 156 and 157: 1100: PIPE CULVERTS A. Methodology

- Page 158 and 159: 165 Quality Assurance Handbook for

- Page 160 and 161: SECTION 1200 167 Quality Assurance

- Page 162 and 163: 3. Section-1200 A2 Substructures Th

- Page 164 and 165: 3. Section-1200 4. Provide 75 mm ce

- Page 166 and 167: 3. Section-1200 (2) Tolerances 1200

- Page 168 and 169: 3. Section-1200 3.2 Tests / checks

- Page 170 and 171: SECTION 1300 179 Quality Assurance

- Page 172 and 173: 3. Section-1300 A-3 Toe Protection

- Page 174 and 175: 3. Section-1300 2. Stones for pitch

- Page 176 and 177: SECTION 1400 187 Quality Assurance

- Page 178 and 179: 3. Section-1400 3. Give streamline

- Page 180 and 181: 3. Section-1400 2. Tests during con

- Page 182 and 183: SECTION 1500 195 Quality Assurance

- Page 184 and 185: 3. Section-1500 5 Mark location and

- Page 186 and 187: 3. Section-1500 (iv) Water Water us

- Page 188 and 189: 3. Section-1500 TABLE 1501.3: QUALI

- Page 190 and 191: 3. Section-1500 2. Check the in-sit

- Page 192 and 193: 3. Section-1500 TABLE NO. 1502.3: P

- Page 194 and 195: 3. Section-1500 1503: RECTANGULAR C

- Page 196 and 197: 3. Section-1500 3.2 Tests during co

- Page 198 and 199: 3. Section-1500 1504: INTERLOCKING

- Page 200 and 201: 3. Section-1500 2. Quality Control

- Page 202 and 203: SECTION 1600 217 Quality Assurance

- Page 204 and 205: 3. Section-1600 The prescribed road

- Page 208 and 209: 1700. TRAFFIC SIGNS AND MARKINGS A.

- Page 210 and 211: 227 Quality Assurance Handbook for

- Page 212 and 213: 231 Quality Assurance Handbook for

- Page 214 and 215: 1904 : MAINTENANCE OF BITUMINOUS SU

- Page 216 and 217: 4.6 Settlement and Upheaval 235 Qua

- Page 218 and 219: 2. Surface Finish 237 Quality Assur

- Page 220 and 221: 1908 : MAINTENANCE OF CULVERTS AND

- Page 222 and 223: 241 Quality Assurance Handbook for

- Page 224 and 225: 4. Quality Monitoring only in excep

- Page 226 and 227: 1. SECTION 100: GENERAL 1.1: Qualit

- Page 228 and 229: 249 Quality Assurance Handbook for

- Page 230 and 231: 10 5R 60 106 25 DIA WELDED 21 DIA 1

- Page 232 and 233: 4. Section-300 (b) Carry out an ins

- Page 234 and 235: 4. Section-300 Photo 1. Visual Clas

- Page 236 and 237: 259 Quality Assurance Handbook for

- Page 238 and 239: Test 1 261 Quality Assurance Handbo

- Page 240 and 241: 4. Section-500 (iii) Check the aggr

- Page 242 and 243: 5. SECTION 1100:PIPE CULVERTS 267 Q

- Page 244 and 245: 6. SECTION 1300: PROTECTION WORKS A

- Page 246 and 247: 4. Section-1500 In case of cracked

- Page 248 and 249: 4. Section-1700 2. Road Markings C

- Page 250 and 251: Appendix-1 1.4 Estimating Plasticit

- Page 252 and 253: Appendix-1 1.8 Simple Gadgets for E

- Page 254 and 255: Appendix-1 (ii) Make two identical

3. Section-1600<br />

C. Do’s and Don’ts<br />

Do’s Don’ts<br />

1. Take precautions <strong>for</strong> safe guarding the environment<br />

(Clause 110 of MoRD Specifications)<br />

2. Take appropriate measures to ensure stability of<br />

slopes during construction. Provide the necessary<br />

protective measure <strong>for</strong> safety against erosion,<br />

subsidence and recurrent slips and slides. Provide<br />

apron below the outlet point of culvert where height<br />

of waterfall is liable to cause erosion.<br />

3. Ensure that safety measures including traffic signs,<br />

guideposts, railings, parapets are provided at<br />

appropriate places.<br />

4. Safeguard the Reference Pillars till the completion<br />

of work<br />

5 Identify areas <strong>for</strong> proper disposal of debris and waste<br />

materials be<strong>for</strong>e commencement of the work<br />

6. At hairpin bends, pave the entire roadway width to<br />

avoid erosion.<br />

7. Provide one cross drain on upper arm of hair pin<br />

bend just be<strong>for</strong>e the bend to minimize flow of water<br />

along the surface of the road.<br />

8. If hill cutting is done by manual labour, then start<br />

from back cutting line proceeding outwards to valley<br />

face otherwise it will be difficult to rectify the defects<br />

left in back-cutting.<br />

9. Always prepare completion plans of completed<br />

lengths and compare it with original drawings<br />

enclosed with the agreement in regard to widths,<br />

curves, camber, super elevation and the longitudinal<br />

gradient as per Para 1603.8.1 of “ Specifications <strong>for</strong><br />

<strong>Rural</strong> <strong>Roads</strong>”.<br />

10. Carry out the backfill behind retaining wall/breast<br />

wall only after the masonry work of wall has been<br />

approved by the Engineer.<br />

11. Ensure proper longitudinal gradient as per drawings<br />

and all vertical bumps in grades have been removed.<br />

12. Excavate the hill side drain along with hill side<br />

cutting work as per Para 1606.1.3 of MORD<br />

Specifications. Keep the bed level of side Drain at<br />

least 300 mm below the Subbase or drainage layer<br />

or as per desired specifications.<br />

13. Construct the cross drainage works like scuppers or<br />

small culverts alongwith the <strong>for</strong>mation cutting work.<br />

Excavation <strong>for</strong> catch pit should also be done<br />

simultaneously.<br />

14. Salvage serviceable materials and stack at the<br />

earmarked location.<br />

1. Do not throw debris from excavation/blasting<br />

haphazardly down the hill slope.<br />

2. Do not carry out blasting operation indiscriminately.<br />

3. Do not provide Hair Pin bends at inner curves. Locate<br />

them at stable places having gentle hill slope requiring<br />

lesser height of retaining walls and lesser height of back<br />

cutting<br />

4. Do not stack serviceable stones over Roadway so as to<br />

allow free flow of traffic.<br />

5. Do not allow debris lying along the road.<br />

6. Do not allow bumps or steep grades or reverse grades<br />

in longitudinal section of hill roads.<br />

7. Do not construct retaining walls, which are having<br />

outer curve in plan, specially at hairpin bends. These<br />

are weaker in regard to stability and are easily liable<br />

to collapse. Better break such as walls into segments<br />

to avoid their bulging tendency.<br />

8. Do not allow gradient defects to continue. These must<br />

be got rectified otherwise these will remain <strong>for</strong> the<br />

whole life of the road.<br />

9. Do not spread the aggregate in very very small<br />

stretches. This may adversely affect the riding quality<br />

of the surface.<br />

10. Do not allow construction of Retaining walls until<br />

proper road geometrics has been achieved in hillcutting<br />

otherwise this may lead to excessive heights<br />

and quantities of R wall masonary creating<br />

unnecessary cost escalation.<br />

11. Do not allow any pilferage of reference level pillars &<br />

back reference pillars. Keep a watch and ward on<br />

reference pillars. If a few level pillars are raised by<br />

about one metre in a continuous stretch, same<br />

geometrics can be achieved. But this will adversely<br />

affect the adjoining jobs where steeper gradient will<br />

occur. Similarly if back-cutting line is shifted to 1.0 m<br />

in front, it will be difficult to judge its correctness but<br />

its overall effects will be less height of cutting and much<br />

more quantity of retaining walls may cause huge cost<br />

escalation.<br />

12. Do not allow gradient steeper than permissible at<br />

hairpin bends. Flatter gradients are always preferable<br />

to steeper gradients at such locations.<br />

13. Do not consider the hill road as complete until it has<br />

been properly compared with the contract drawings<br />

in regard to curve radius & gradient.<br />

222