Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

Quality Assurance Handbook for Rural Roads Volume-I - pmgsy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

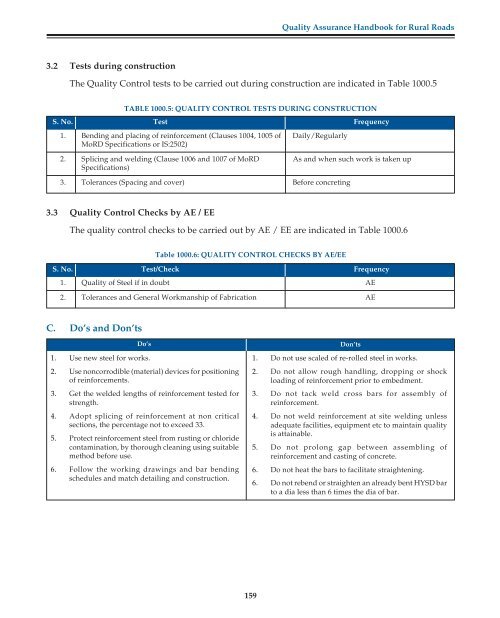

3.2 Tests during construction<br />

159<br />

<strong>Quality</strong> <strong>Assurance</strong> <strong>Handbook</strong> <strong>for</strong> <strong>Rural</strong> <strong>Roads</strong><br />

The <strong>Quality</strong> Control tests to be carried out during construction are indicated in Table 1000.5<br />

TABLE 1000.5: QUALITY CONTROL TESTS DURING CONSTRUCTION<br />

S. No. Test Frequency<br />

1. Bending and placing of rein<strong>for</strong>cement (Clauses 1004, 1005 of<br />

MoRD Specifications or IS:2502)<br />

Daily/Regularly<br />

2. Splicing and welding (Clause 1006 and 1007 of MoRD As and when such work is taken up<br />

Specifications)<br />

3. Tolerances (Spacing and cover) Be<strong>for</strong>e concreting<br />

3.3 <strong>Quality</strong> Control Checks by AE / EE<br />

The quality control checks to be carried out by AE / EE are indicated in Table 1000.6<br />

Table 1000.6: QUALITY CONTROL CHECKS BY AE/EE<br />

S. No. Test/Check Frequency<br />

1. <strong>Quality</strong> of Steel if in doubt AE<br />

2. Tolerances and General Workmanship of Fabrication AE<br />

C. Do’s and Don’ts<br />

Do’s Don’ts<br />

1. Use new steel <strong>for</strong> works.<br />

2. Use noncorrodible (material) devices <strong>for</strong> positioning<br />

of rein<strong>for</strong>cements.<br />

3. Get the welded lengths of rein<strong>for</strong>cement tested <strong>for</strong><br />

strength.<br />

4. Adopt splicing of rein<strong>for</strong>cement at non critical<br />

sections, the percentage not to exceed 33.<br />

5. Protect rein<strong>for</strong>cement steel from rusting or chloride<br />

contamination, by thorough cleaning using suitable<br />

method be<strong>for</strong>e use.<br />

6. Follow the working drawings and bar bending<br />

schedules and match detailing and construction.<br />

1. Do not use scaled of re-rolled steel in works.<br />

2. Do not allow rough handling, dropping or shock<br />

loading of rein<strong>for</strong>cement prior to embedment.<br />

3. Do not tack weld cross bars <strong>for</strong> assembly of<br />

rein<strong>for</strong>cement.<br />

4. Do not weld rein<strong>for</strong>cement at site welding unless<br />

adequate facilities, equipment etc to maintain quality<br />

is attainable.<br />

5. Do not prolong gap between assembling of<br />

rein<strong>for</strong>cement and casting of concrete.<br />

6. Do not heat the bars to facilitate straightening.<br />

6. Do not rebend or straighten an already bent HYSD bar<br />

to a dia less than 6 times the dia of bar.