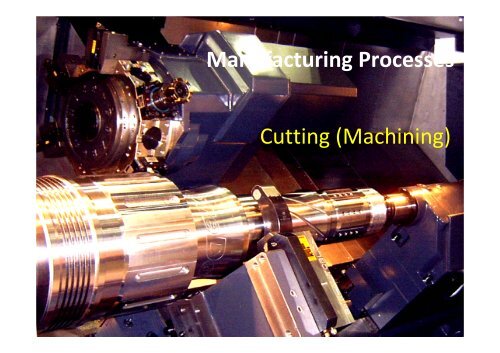

Manufacturing Processes Cutting (Machining)

Manufacturing Processes Cutting (Machining)

Manufacturing Processes Cutting (Machining)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

<strong>Cutting</strong> (<strong>Machining</strong>)

<strong>Cutting</strong><br />

1. <strong>Cutting</strong> mechanics<br />

2. Tool wear<br />

3. Tool material<br />

4. Turning, Turning center<br />

5. Milling, <strong>Machining</strong> center<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Cutting</strong> mechanics<br />

• Chip formation Shear break off<br />

• <strong>Cutting</strong> force = Specific energy x Area<br />

• Chatter (vibration)<br />

• <strong>Cutting</strong> temperature<br />

• Tool wear<br />

• Tool life equation<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Mechanics of Chip Formation<br />

• Chips are produced by the shearing taking place along a<br />

shear plane.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Cutting</strong> Force (Theory)<br />

• According to maximum‐shear‐stress criterion, yielding<br />

occurs when the max shear stress within an element is<br />

equal to or exceeds a critical value (shear yield stress).<br />

Stock<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Tool<br />

σ 1<br />

(Assume no friction)<br />

Fc<br />

σ 1<br />

τ<br />

Mohr’s circle<br />

σ<br />

τ<br />

Ф<br />

Shear angle<br />

Shear plane

<strong>Cutting</strong> Force (Theory)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

w<br />

t 0<br />

• Shear Area = Width x Depth / sin (Shear Angle)<br />

t0<br />

As w<br />

sin<br />

t 0 /sin(φ)<br />

φ<br />

F s<br />

• Shear Force = Shear Stress * Shear Area<br />

wt0<br />

Fs A<br />

s <br />

sin<br />

Tool

<strong>Cutting</strong> Force (Theory)<br />

• Resultant force<br />

= Shear force / cos (shear angle + friction angle –rake angle)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

R<br />

<br />

cos<br />

F<br />

s<br />

<br />

wt<br />

sin<br />

cos<br />

0

<strong>Cutting</strong> Force (Theory)<br />

• <strong>Cutting</strong> force<br />

= Resultant force x cos (friction angle –rake angle)<br />

• Shear angle<br />

= pi/4 + rake angle/2 –friction angle/2<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

F c<br />

R cos<br />

<br />

<br />

<br />

<br />

<br />

4 2 2

<strong>Cutting</strong> Force<br />

• Rake angle ↑ shear angle ↑, cutting force ↓ chip thickness ↓, cooler chip<br />

↓<br />

• Rake angle ↑ tool section ↓ strength at cutting edge ↓, heat conductivity<br />

↓<br />

• Relief angle ↑ friction ↓ tool life ↑, surface quality ↑<br />

• Relief angle ↑ strength at cutting edge ↓<br />

• Nose radius ↓ heat ↓, surface quality ↑<br />

• Force ↑< yield stress of stock ↑, cut depth ↑, cut width ↑<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Shear angle, φ<br />

Rake angle,α<br />

+<br />

Nose radius<br />

Relief angle,<br />

r

<strong>Cutting</strong> Force (Specific cutting energy)<br />

• <strong>Cutting</strong> force = Specific cutting energy x <strong>Cutting</strong> area<br />

Power c<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Fc ut<br />

Ac<br />

ut<br />

Tool<br />

Stock A c F c<br />

F V<br />

wt0<br />

Specific cutting energy (

Chip morphology<br />

• Type of chips produced<br />

influences surface finish<br />

and machining operation.<br />

1. Continuous chips<br />

Steel: http://www.youtube.com/watch?v=4bOzJiYAZD4<br />

Stainless: http://www.youtube.com/watch?v=DzAjpHFy4fw<br />

2. Built‐up‐edge chips<br />

3. Serrated chips<br />

4. Discontinuous chips<br />

Cast Iron: http://www.youtube.com/watch?v=RoooeTEEMxY&feature=related<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Chip morphology<br />

Chip curl<br />

• Chip breaker shorter chip<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Groove Chip breaker

Chatter (Self‐excited vibration)<br />

• Chatter vibrating with high frequency noise is caused by<br />

interaction of chip‐removal process with flexibility of the<br />

tool.<br />

• It could be avoided by increasing dynamic stiffness and<br />

damping, by decreasing depth of cut and proper<br />

selection of spindle speed .<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Safe<br />

Chatter<br />

http://www.youtube.com/watch?v=uv3yUCl27wM

Temperature<br />

• <strong>Cutting</strong> power P=FV Heat Increase the<br />

temperature of chip, work piece, and tool<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool wear<br />

• Mechanical wear<br />

1. Abrasive wear ‐ hardness<br />

2. Adhesive wear ‐ junction<br />

3. Fatigue wear ‐ crack<br />

• Thermo Chemical wear<br />

1. Diffusion wear (확산)<br />

2. Solution wear (용해)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool wear<br />

• The wear behaviour of cutting tools are flank<br />

wear(measure width of wear land), crater wear(at high<br />

speed, diffusion wear is the major reason, measure<br />

depth), nose wear, and chipping of the cutting edge.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool wear<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool life (F.W. Taylor)<br />

• Tool‐wear relationship for cutting various steels is<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

VT n <br />

C<br />

V = cutting speed<br />

T = time (min)<br />

C = constant.<br />

n = exponent depends on cutting conditions<br />

HSS 0.14-0.16, Uncoated carbides 0.21-0.25, TiC insert 0.30,<br />

Polydiamond 0.33, TiN insert 0.35, Ceramic coated insert 0.40

Tool life curve<br />

• Tool‐life is effected by depth and feed rate.<br />

VT<br />

• Tool wear is also depend on<br />

tool and workpiece material<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

n<br />

d<br />

x<br />

f<br />

y<br />

<br />

C<br />

d = depth of cut<br />

f = feed rate (in mm/rev) in turning

Ex<br />

Increasing tool life by reducing the cutting speed<br />

Given that n=0.5 and VT n =C, if the V reduced 50%, calculate the<br />

increase of tool life.<br />

Solution<br />

VT 0.5 =C (1)<br />

0.5VT 2 0.5 =C (2)<br />

(2)/(1)<br />

0.5(T 2/ T) 0.5 =1<br />

T 2 =4T<br />

Increase tool life 4 times.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Surface Finish and Surface Integrity<br />

Feed marks<br />

• In turning, peak‐to‐valley roughness is<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Stock<br />

R<br />

t<br />

<br />

2<br />

fr<br />

8R<br />

R<br />

Tool<br />

f r = feed per revolution<br />

R = nose radius<br />

f<br />

R t

<strong>Cutting</strong> Tool Materials<br />

• HSS<br />

• Carbide<br />

• Ceramic<br />

• Diamond<br />

• CBN<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Cutting</strong>‐Tool Materials<br />

• A cutting tool has the following characteristics:<br />

1. Hardness<br />

2. Toughness<br />

3. Wear resistance<br />

4. Chemical stability<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

HSS<br />

HSS (High‐speed steels)<br />

• HSS cuts faster than carbon tool steel, hence the name<br />

high speed steel, but slower than carbide tools.<br />

• It is often used in power saw blades and drill bits.<br />

TiN‐Coated HSS<br />

• PVD (physical vapor deposition), TiN coating reduces<br />

tool wear.<br />

HSS Drill: http://www.youtube.com/watch?v=98DvSQNHLMU<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Carbides<br />

Carbides (초경)<br />

• Better wear resistance, stiffness, hot hardness<br />

• Tungsten carbide: WC + Co(for toughness) powder<br />

metallurgy (sintered), suitable for non‐ferrous, grey cast<br />

iron<br />

• Titanium carbide: TiC + Co : TiC is suitable for steel and<br />

cast iron<br />

Coated Carbide<br />

• Carbide + TiC, TiN, Al 2O 3 coated<br />

by CVD (chemical vapor deposition)<br />

• Chemically stable greatly reduce crater wear<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Cermets<br />

Ceramics<br />

Aluminum oxide(Al 2O 3), Silicon‐nitride(SiN), cold pressed and<br />

hot sintered<br />

Hot hardness ↑, toughness ↓ (chipping), thermal shock<br />

Cermets<br />

Ceramic(Al 2O 3) + metal binder(TiC)<br />

Hot hardness ↑, toughness ↓, thermal expansion ↑<br />

http://www.youtube.com/watch?v=Om9gzgNPf80<br />

Insert: less thermal stress, eliminate grinding by user, less<br />

setting time<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Diamond, CBN<br />

Diamond (Poly crystal diamond)<br />

• Hardest material, Not good for steel<br />

http://www.youtube.com/watch?v=vAvfrrlMZg4<br />

CBN (polycrystalline cubic boron nitride)<br />

• 2nd hardest material, brittle, expensive<br />

http://www.youtube.com/watch?v=mKxX50OMBd4&p=9B6D9EAE75875D9D<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool materials<br />

Tool materials, feeds, and cutting speeds<br />

• Characteristics of cutting‐tool materials gives a range of<br />

cutting speeds and feeds for different applications.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Workpiece materials<br />

Workpiece materials and cutting speeds<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Cutting</strong> Tool Makers<br />

• www.taegutec.co.kr<br />

• www.yg1.co.kr<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Cutting</strong> Fluids<br />

• Also called lubricants and coolants, cutting fluids.<br />

• Used extensively in machining operations to:<br />

1. Cool the cutting zone<br />

2. Reduce friction and wear<br />

3. Reduce forces and energy consumption<br />

4. Wash away chips<br />

5. Protect surfaces from any environmental attack<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Turning<br />

• A piece of material is rotated and a single point cutting<br />

tool is traversed along 2 axes of motion to produce the<br />

cylinder, tubular components and various rotational<br />

geometries.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Lathe<br />

• Turning can be done manually, in a traditional form of<br />

lathe, which frequently requires continuous supervision<br />

by the operator.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Turning center (CNC Lathe)<br />

• Turning can be done by using a computer numerical<br />

control, known as CNC.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Turning process<br />

• Straight turning<br />

• Taper turning<br />

• Profiling (Couture turning)<br />

• External grooving<br />

http://www.youtube.com/watch?v=tDc0l9Gm8D4<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

http://www.youtube.com/watch?v=5AB_etoHesI&p=9B6D9EAE75875D9D

Math for Turning<br />

• <strong>Cutting</strong> speed(mm/min) = 3.14 x Diameter x Spindle<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

V = π D S<br />

• MRR (Material Removal Rate) = Volume / Time = 3.14 x<br />

Diameter x Depth x Feed per revolution x Spindle<br />

D<br />

df S<br />

MMR avg r<br />

• <strong>Cutting</strong> time = Distance / (Feed per revolution x Spindle)<br />

V<br />

S<br />

t<br />

<br />

l<br />

f S<br />

r<br />

S

TurnMill<br />

• Turning center has additional<br />

milling axis is called TurmMill<br />

(복합기)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

http://ma.gnu.ac.kr/vod/machining/TurnMill.AVI

Milling<br />

• <strong>Cutting</strong> tool is rotated and traversed along 3 axes of<br />

motion to produce from simple rectangular plane, slot,<br />

hole and complex contour.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Milling<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

<strong>Machining</strong> center (CNC Milling)<br />

C Type<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Horizontal M/C<br />

Bridge Type<br />

Vertical M/C<br />

http://www.youtube.com/user/GlacernMachineTools<br />

5AX M/C

Automatic Tool Changer (ATC)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Changer Arm<br />

Tool<br />

Spindle

Automatic Pallet Changer (APC)<br />

Pallet #1<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Pallet #2

Work holding Vise, Clamp<br />

• Work is fixed by vise or clamp on the table with T‐slot<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

http://www.youtube.com/user/GlacernMachineTools#p/u/5/J1VtofzVG24<br />

Flex clamp: http://ma.gnu.ac.kr/vod/<strong>Machining</strong>/Clamp.MP4

Tool holder, Tools<br />

Holder + Collet + Solid Endmill Insert Endmill<br />

http://www.youtube.com/watch?v=IPWGV_EGAHw&feature=related<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Tool holder, Tools<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Milling operations<br />

• Face cutter<br />

• Endmill : Flat, Ball, Rounded<br />

Face Cutter<br />

Basic: http://www.youtube.com/watch?v=j0vRYe9uvnI<br />

Face: http://www.youtube.com/watch?v=9OsNUi_o6C4<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Flat endmill (Slotting)<br />

Endmill: http://www.youtube.com/user/GlacernMachineTools#p/u/1/HfIaISnqHOk

Math for milling<br />

• <strong>Cutting</strong> speed(mm/min) = 3.14 x Diameter x Spindle<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

V = π D S<br />

• Feed per tooth = Feed / (Spindle x Number of teeth)<br />

F / Sn<br />

<br />

• MMR = Depth x Width x Feed<br />

MRR = d w F<br />

f t<br />

f t<br />

F (mm/min)<br />

w<br />

d

Huge 3+2 axis Milling<br />

• Has additional rotation BC axis on<br />

head.<br />

• Used for automobile door panel and<br />

bumper mold.<br />

http://ma.gnu.ac.kr/vod/machining/Huge_machine_tools.AVI<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

http://ma.gnu.ac.kr/vod/machining/Huge_5axis.AVI

5‐axis machining<br />

• Has 2 tinting A C or B C axis on table or head.<br />

Rotary table: http://ma.gnu.ac.kr/vod/<strong>Machining</strong>/Rotaty_table.MP4<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Impeller : http://ma.gnu.ac.kr/vod/<strong>Machining</strong>/5axis_machining_impeller.MP4

Drilling<br />

• Drills produces deep holes.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Drill<br />

Drilling machine<br />

Insert drill<br />

Max drill<br />

Drill: http://www.youtube.com/watch?v=ul20R32HJ3E<br />

Drill: http://ma.gnu.ac.kr/vod/<strong>Machining</strong>/Drill.MP4

Tapping<br />

• Tap produces thread inside the hold.<br />

• Tap Feed Rate = RPM x Pitch<br />

Ex) M6 x 1 at 2000 RPM = 2000 mm/min<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Tapping Tapping holder and tool<br />

http://www.youtube.com/watch?v=vCHQLFZHHJc

Reaming, Boring<br />

• Reamer enlarges an hole to the diameter of the tool.<br />

• Boring produce precise circular internal profiles.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Reaming<br />

Boring<br />

Drilling, Tapping, Boring: http://vimeo.com/8642433<br />

http://www.youtube.com/user/GlacernMachineTools#p/u/0/om6GQKfoS1g

Planer and Shaper<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Broaching<br />

• Linear broaching: the broach is run linearly against a<br />

surface of the workpiece to effect the cut.<br />

• Rotary broaching: the broach is rotated and pressed into<br />

the workpiece to cut an axis symmetric shape.<br />

Broaching gear<br />

http://www.youtube.com/watch?v=2K45B6tDqsg&p=9B6D9EAE75875D9D<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Rotary broaching:<br />

http://www.youtube.com/watch?v=gUEcagEmmZo&p=9B6D9EAE75875D9D

Sawing and saws<br />

• A cutting operation where the tool consists of a series<br />

of small teeth that removes material.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

Disk saw<br />

Belt saw

Gear Hobbing<br />

• A hob (cutter) is rotated one revolution to transfer each<br />

tooth profile onto a rotating gear blank.<br />

• Used very often for medium to high sizes of production<br />

runs.<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

http://www.youtube.com/watch?v=DwFssm9trSc

Design for <strong>Machining</strong><br />

• Geometric compatibility<br />

• Dimensional compatibility<br />

1. Availability of tools<br />

2. Drill dimensions, aspect ratio<br />

• Constraints<br />

1. Process physics<br />

2. Deep pocket<br />

3. <strong>Machining</strong> on inclined faces<br />

• Set up and fixturing<br />

1. Tolerancing is $$$<br />

2. Minimize setups<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU

Economics of <strong>Machining</strong><br />

Total cost per piece consists of four items:<br />

C<br />

m<br />

C<br />

C<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

s<br />

l<br />

t<br />

p<br />

where<br />

C<br />

C<br />

C<br />

C<br />

C<br />

p<br />

m<br />

C<br />

cost per piece<br />

s<br />

l<br />

C<br />

t<br />

machining cost<br />

cost of setting up for machining<br />

cost of loading, unloading and machine handling<br />

tooling cost

Example 8.4<br />

Material‐removal rate and cutting force in turning<br />

A 15.24-cm-long, 1.27-cm-diameter 304 stainless-steel rod is being reduced in<br />

diameter to 1.2192 cm by turning on a lathe. The spindle rotates at N=4000 rpm<br />

and the tool is travelling at an axial speed of 20.32 cm/min. Calculate the cutting<br />

speed, material-removal rate, cutting time, power dissipated, and cutting force.<br />

Solution<br />

Maximum cutting speed is<br />

<strong>Cutting</strong> speed at machined diameter is<br />

Depth of cut and feed is<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

V<br />

D N <br />

1.<br />

27 1.<br />

219<br />

20.<br />

32<br />

d<br />

0.<br />

0255 cm and f <br />

2<br />

400<br />

0<br />

1. 27400<br />

15.<br />

959 m/min<br />

V<br />

1. 2192400<br />

15.<br />

321m/min<br />

<br />

0.<br />

0508<br />

cm/rev

Example 8.4<br />

Material‐removal rate and cutting force in turning<br />

Solution<br />

Material-removal rate is<br />

MMR <br />

The torque and cutting force is<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU<br />

3<br />

1. 24450.<br />

02550.<br />

0508400<br />

2.<br />

02586 cm / min<br />

15.<br />

24<br />

Actual time taken to cut is t <br />

0.<br />

75 min<br />

0. 0508400<br />

Amount of power dissipated is<br />

3 410 Power 2. 02586<br />

135<br />

W<br />

82597<br />

T 32.<br />

8643 kg - cm and Fc<br />

<br />

4002 60<br />

32. 86432<br />

1. 2445<br />

<br />

52.<br />

8153<br />

kg

References: Machine Tool Makers<br />

• www.doosaninfracore.co.kr<br />

• www.wia.co.kr<br />

• www.hwacheon.co.kr<br />

• www.mazak.jp (Japan)<br />

• www.haascnc.com (USA)<br />

• www.deckelmaho.com (EU)<br />

<strong>Cutting</strong><br />

<strong>Manufacturing</strong> <strong>Processes</strong><br />

© 2011 Su-Jin Kim GNU