Recycling Treated Municipal Wastewater for Industrial Water Use

Recycling Treated Municipal Wastewater for Industrial Water Use Recycling Treated Municipal Wastewater for Industrial Water Use

3.4 Storage and Transmission Overview Section 3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use An integral part of the planning, operation, and maintenance of recycled wastewater systems is the transmission of the recycled wastewater to the customer. Transmission costs, both capital and O&M, are a significant cost component of recycled wastewater projects. Transmission systems typically include onsite storage, pump station(s), piping, off-site storage, diversion structures to off-site storage ponds, service connections, and metering. Wastewater recycling regulations and guidelines generally include standards for the design, installation, operation, and maintenance of the transmission systems. In addition, there are very specific guidelines and requirements for any cross-connections to other systems, use of backflow preventions devices and other plumbing features. Storage The conceptual recycled wastewater system, presented previously in Figure 3.1, provides for storage facilities on the WWTP site to meet a range of storage volumes. The base recycled wastewater system assumes that no storage is required, which is valid for a larger WWTP serving smaller industrial demands. The cost curves developed for this study do not include storage requirements, but cost information was developed to asses the impact of storage on system costs and is detailed in Section 5.5 of Appendix II-3. For purposes of this study, it is assumed that where storage is needed, it is for diurnal, daily, or weekly industrial demand patterns that the WWTP cannot meet with their continuous supply. Storage requirements for industrial applications can vary widely. Some industries may have adequate storage to meet peak hour requirements, but most would not have storage to handle significant volumes. Storage would likely be needed with smaller WWTPs where the diurnal flows could drop below the required demand of an industry or group of industries. Weekly demand patterns of industry could also change and should be accounted for when establishing storage requirements. This study does not consider any seasonal storage requirements for a reclaimed supply. Seasonal storage would be required for WWTPs that incorporate reuse practices to reduce their discharges to waterways and supply seasonal customers. These facilities would need to store and/or dampen peak flows to meet NPDES limits during periods when the seasonal recycled wastewater customers do not use water. Seasonal storage may also be required to meet a seasonal water demand, where peak demands cannot be consistently matched by the WWTP flow. The majority of Minnesota’s industries have year-round water demands. Some exceptions include: agricultural processing industries, which may depend on seasonal crops; industries that use recycled wastewater for landscape irrigation; and some cooling water applications. Seasonal storage facilities are common in recycled wastewater systems for irrigation practices. Recycled wastewater storage can also provide system reliability with a short-term supply if there is a process disruption as well as additional contact time for chlorine disinfection. Pumping This study assumes a pump station is located on the WWTP site and is owned by the municipality. The pump station is assumed to include standby and reliability features consistent with state water supply requirements. The pump station is sized for peak flow and a residual pressure at the end of the pipe line of 40 psi, assuming delivery at the same elevation as the WWTP. Transmission Pipelines The majority of recycled wastewater transmission piping is polyvinyl chloride pipe (PVC) or ductile iron pipe (DIP) meeting specific industry standards. For this study, the transmission system is assumed to be all force main with the following characteristics: pipe with a diameter of 24 inches or less is PVC, DR 18, Class 150 and greater than 24 inch diameter pipe is DIP, Class 51 with push-on joints. Pipelines are sized to carry the peak hour demand of a given industry at a target velocity of 5 to 7 feet per second (fps). Details assumed for the cost analysis are provided in Appendix II-3. Metropolitan Council Environmental Services 49

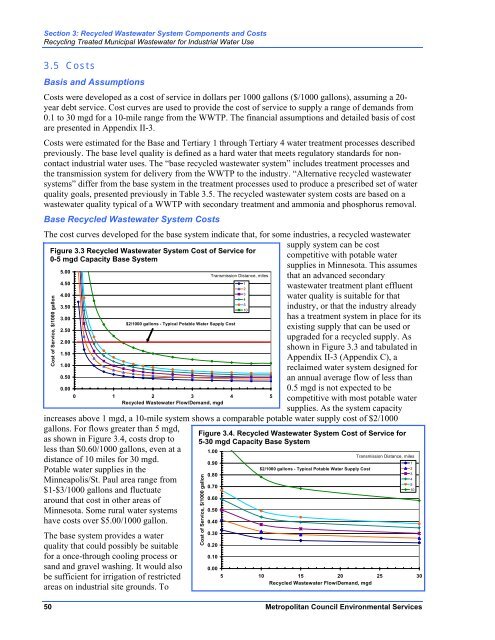

Section 3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use 3.5 Costs Basis and Assumptions Costs were developed as a cost of service in dollars per 1000 gallons ($/1000 gallons), assuming a 20year debt service. Cost curves are used to provide the cost of service to supply a range of demands from 0.1 to 30 mgd for a 10-mile range from the WWTP. The financial assumptions and detailed basis of cost are presented in Appendix II-3. Costs were estimated for the Base and Tertiary 1 through Tertiary 4 water treatment processes described previously. The base level quality is defined as a hard water that meets regulatory standards for noncontact industrial water uses. The “base recycled wastewater system” includes treatment processes and the transmission system for delivery from the WWTP to the industry. “Alternative recycled wastewater systems” differ from the base system in the treatment processes used to produce a prescribed set of water quality goals, presented previously in Table 3.5. The recycled wastewater system costs are based on a wastewater quality typical of a WWTP with secondary treatment and ammonia and phosphorus removal. Base Recycled Wastewater System Costs The cost curves developed for the base system indicate that, for some industries, a recycled wastewater Figure 3.3 Recycled Wastewater System Cost of Service for 0-5 mgd Capacity Base System Cost of Service, $/1000 gallon 5.00 4.50 4.00 3.50 3.00 2.50 2.00 1.50 1.00 0.50 0.00 $2/1000 gallons - Typical Potable Water Supply Cost 0 1 2 3 4 5 Recycled Wastewater Flow/Demand, mgd supply system can be cost competitive with potable water supplies in Minnesota. This assumes that an advanced secondary wastewater treatment plant effluent water quality is suitable for that industry, or that the industry already has a treatment system in place for its existing supply that can be used or upgraded for a recycled supply. As shown in Figure 3.3 and tabulated in Appendix II-3 (Appendix C), a reclaimed water system designed for an annual average flow of less than 0.5 mgd is not expected to be competitive with most potable water supplies. As the system capacity increases above 1 mgd, a 10-mile system shows a comparable potable water supply cost of $2/1000 gallons. For flows greater than 5 mgd, as shown in Figure 3.4, costs drop to less than $0.60/1000 gallons, even at a distance of 10 miles for 30 mgd. Potable water supplies in the Minneapolis/St. Paul area range from $1-$3/1000 gallons and fluctuate around that cost in other areas of Minnesota. Some rural water systems have costs over $5.00/1000 gallon. The base system provides a water quality that could possibly be suitable for a once-through cooling process or sand and gravel washing. It would also be sufficient for irrigation of restricted areas on industrial site grounds. To Transmission Distance, miles 1 2 3 4 5 10 Figure 3.4. Recycled Wastewater System Cost of Service for 5-30 mgd Capacity Base System Cost of Service, $/1000 gallon 1.00 0.90 0.80 0.70 0.60 0.50 0.40 0.30 0.20 0.10 0.00 $2/1000 gallons - Typical Potable Water Supply Cost 5 10 15 20 25 Recycled Wastewater Flow/Demand, mgd Transmission Distance, miles 50 Metropolitan Council Environmental Services 1 2 3 4 5 10 30

- Page 6 and 7: Contents Recycling Treated Municipa

- Page 8 and 9: Executive Summary Vision Executive

- Page 10 and 11: Section 1: Introduction 1.1 Project

- Page 12 and 13: Table 1.2. Water Use in Minnesota,

- Page 14 and 15: Section 1: Introduction Recycling T

- Page 16 and 17: 1.5 Summary Section 1: Introduction

- Page 18 and 19: Section 2: Recycled Wastewater Dema

- Page 20 and 21: Section 2: Recycled Wastewater Dema

- Page 23 and 24: Section 2: Recycled Wastewater Dema

- Page 26 and 27: Figure 2.9. Ground Water Contaminat

- Page 28: Section 2: Recycled Wastewater Dema

- Page 31: Section 2: Recycled Wastewater Dema

- Page 35 and 36: Section 2: Recycled Wastewater Dema

- Page 38 and 39: Table 2.8. Ethanol Plant Capacity a

- Page 40 and 41: Section 2: Recycled Wastewater Dema

- Page 42 and 43: 2.7 References Section 2: Recycled

- Page 44 and 45: Section 3: Recycled Wastewater Syst

- Page 46 and 47: Water Quality Overview The total co

- Page 48 and 49: Industrial Water Quality Concerns S

- Page 50 and 51: Emerging Contaminants of Concern Se

- Page 52 and 53: Section 3: Recycled Wastewater Syst

- Page 54 and 55: Section 3: Recycled Wastewater Syst

- Page 58 and 59: Section 3: Recycled Wastewater Syst

- Page 60 and 61: Cost by Standard Industry Categorie

- Page 62 and 63: Costs and Planning Considerations S

- Page 64 and 65: Section 4: Implementation Considera

- Page 66 and 67: Economic Incentives and Risk Assess

- Page 68 and 69: Section 5: Summary and Potential Ne

- Page 70 and 71: Long-Term Vision Section 5: Summary

- Page 72: Exhibit A: California Water Recycli

- Page 75 and 76: Metropolitan Council Recycling Trea

- Page 77 and 78: Contents Section 1 - Introduction C

- Page 79 and 80: Craddock Consulting Engineers In As

- Page 81 and 82: Section 1 Introduction Craddock Con

- Page 83 and 84: Section 1 Introduction Craddock Con

- Page 85 and 86: Section 1 Introduction Craddock Con

- Page 87 and 88: Craddock Consulting Engineers 2-1 I

- Page 89 and 90: Section 2 Implementation Considerat

- Page 91 and 92: Section 2 Implementation Considerat

- Page 93 and 94: Section 2 Implementation Considerat

- Page 95 and 96: Table 2.4. Examples of State Water

- Page 97 and 98: Section 2 Implementation Considerat

- Page 99 and 100: Section 2 Implementation Considerat

- Page 101 and 102: Section 2 Implementation Considerat

- Page 103 and 104: Section 2 Implementation Considerat

- Page 105 and 106: Section 2 Implementation Considerat

Section 3: Recycled <strong>Wastewater</strong> System Components and Costs<br />

<strong>Recycling</strong> <strong>Treated</strong> <strong>Municipal</strong> <strong>Wastewater</strong> <strong>for</strong> <strong>Industrial</strong> <strong>Water</strong> <strong>Use</strong><br />

3.5 Costs<br />

Basis and Assumptions<br />

Costs were developed as a cost of service in dollars per 1000 gallons ($/1000 gallons), assuming a 20year<br />

debt service. Cost curves are used to provide the cost of service to supply a range of demands from<br />

0.1 to 30 mgd <strong>for</strong> a 10-mile range from the WWTP. The financial assumptions and detailed basis of cost<br />

are presented in Appendix II-3.<br />

Costs were estimated <strong>for</strong> the Base and Tertiary 1 through Tertiary 4 water treatment processes described<br />

previously. The base level quality is defined as a hard water that meets regulatory standards <strong>for</strong> noncontact<br />

industrial water uses. The “base recycled wastewater system” includes treatment processes and<br />

the transmission system <strong>for</strong> delivery from the WWTP to the industry. “Alternative recycled wastewater<br />

systems” differ from the base system in the treatment processes used to produce a prescribed set of water<br />

quality goals, presented previously in Table 3.5. The recycled wastewater system costs are based on a<br />

wastewater quality typical of a WWTP with secondary treatment and ammonia and phosphorus removal.<br />

Base Recycled <strong>Wastewater</strong> System Costs<br />

The cost curves developed <strong>for</strong> the base system indicate that, <strong>for</strong> some industries, a recycled wastewater<br />

Figure 3.3 Recycled <strong>Wastewater</strong> System Cost of Service <strong>for</strong><br />

0-5 mgd Capacity Base System<br />

Cost of Service, $/1000 gallon<br />

5.00<br />

4.50<br />

4.00<br />

3.50<br />

3.00<br />

2.50<br />

2.00<br />

1.50<br />

1.00<br />

0.50<br />

0.00<br />

$2/1000 gallons - Typical Potable <strong>Water</strong> Supply Cost<br />

0 1 2 3 4 5<br />

Recycled <strong>Wastewater</strong> Flow/Demand, mgd<br />

supply system can be cost<br />

competitive with potable water<br />

supplies in Minnesota. This assumes<br />

that an advanced secondary<br />

wastewater treatment plant effluent<br />

water quality is suitable <strong>for</strong> that<br />

industry, or that the industry already<br />

has a treatment system in place <strong>for</strong> its<br />

existing supply that can be used or<br />

upgraded <strong>for</strong> a recycled supply. As<br />

shown in Figure 3.3 and tabulated in<br />

Appendix II-3 (Appendix C), a<br />

reclaimed water system designed <strong>for</strong><br />

an annual average flow of less than<br />

0.5 mgd is not expected to be<br />

competitive with most potable water<br />

supplies. As the system capacity<br />

increases above 1 mgd, a 10-mile system shows a comparable potable water supply cost of $2/1000<br />

gallons. For flows greater than 5 mgd,<br />

as shown in Figure 3.4, costs drop to<br />

less than $0.60/1000 gallons, even at a<br />

distance of 10 miles <strong>for</strong> 30 mgd.<br />

Potable water supplies in the<br />

Minneapolis/St. Paul area range from<br />

$1-$3/1000 gallons and fluctuate<br />

around that cost in other areas of<br />

Minnesota. Some rural water systems<br />

have costs over $5.00/1000 gallon.<br />

The base system provides a water<br />

quality that could possibly be suitable<br />

<strong>for</strong> a once-through cooling process or<br />

sand and gravel washing. It would also<br />

be sufficient <strong>for</strong> irrigation of restricted<br />

areas on industrial site grounds. To<br />

Transmission Distance, miles<br />

1<br />

2<br />

3<br />

4<br />

5<br />

10<br />

Figure 3.4. Recycled <strong>Wastewater</strong> System Cost of Service <strong>for</strong><br />

5-30 mgd Capacity Base System<br />

Cost of Service, $/1000 gallon<br />

1.00<br />

0.90<br />

0.80<br />

0.70<br />

0.60<br />

0.50<br />

0.40<br />

0.30<br />

0.20<br />

0.10<br />

0.00<br />

$2/1000 gallons - Typical Potable <strong>Water</strong> Supply Cost<br />

5 10 15 20 25<br />

Recycled <strong>Wastewater</strong> Flow/Demand, mgd<br />

Transmission Distance, miles<br />

50 Metropolitan Council Environmental Services<br />

1<br />

2<br />

3<br />

4<br />

5<br />

10<br />

30