Recycling Treated Municipal Wastewater for Industrial Water Use

Recycling Treated Municipal Wastewater for Industrial Water Use Recycling Treated Municipal Wastewater for Industrial Water Use

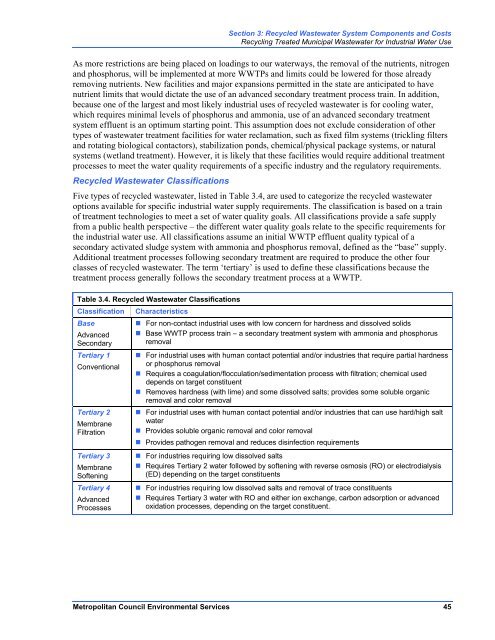

Section 3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use As more restrictions are being placed on loadings to our waterways, the removal of the nutrients, nitrogen and phosphorus, will be implemented at more WWTPs and limits could be lowered for those already removing nutrients. New facilities and major expansions permitted in the state are anticipated to have nutrient limits that would dictate the use of an advanced secondary treatment process train. In addition, because one of the largest and most likely industrial uses of recycled wastewater is for cooling water, which requires minimal levels of phosphorus and ammonia, use of an advanced secondary treatment system effluent is an optimum starting point. This assumption does not exclude consideration of other types of wastewater treatment facilities for water reclamation, such as fixed film systems (trickling filters and rotating biological contactors), stabilization ponds, chemical/physical package systems, or natural systems (wetland treatment). However, it is likely that these facilities would require additional treatment processes to meet the water quality requirements of a specific industry and the regulatory requirements. Recycled Wastewater Classifications Five types of recycled wastewater, listed in Table 3.4, are used to categorize the recycled wastewater options available for specific industrial water supply requirements. The classification is based on a train of treatment technologies to meet a set of water quality goals. All classifications provide a safe supply from a public health perspective – the different water quality goals relate to the specific requirements for the industrial water use. All classifications assume an initial WWTP effluent quality typical of a secondary activated sludge system with ammonia and phosphorus removal, defined as the “base” supply. Additional treatment processes following secondary treatment are required to produce the other four classes of recycled wastewater. The term ‘tertiary’ is used to define these classifications because the treatment process generally follows the secondary treatment process at a WWTP. Table 3.4. Recycled Wastewater Classifications Classification Characteristics Base For non-contact industrial uses with low concern for hardness and dissolved solids Advanced Base WWTP process train – a secondary treatment system with ammonia and phosphorus Secondary removal Tertiary 1 For industrial uses with human contact potential and/or industries that require partial hardness Conventional or phosphorus removal Requires a coagulation/flocculation/sedimentation process with filtration; chemical used depends on target constituent Removes hardness (with lime) and some dissolved salts; provides some soluble organic removal and color removal Tertiary 2 For industrial uses with human contact potential and/or industries that can use hard/high salt Membrane water Filtration Provides soluble organic removal and color removal Provides pathogen removal and reduces disinfection requirements Tertiary 3 Membrane Softening Tertiary 4 Advanced Processes For industries requiring low dissolved salts Requires Tertiary 2 water followed by softening with reverse osmosis (RO) or electrodialysis (ED) depending on the target constituents For industries requiring low dissolved salts and removal of trace constituents Requires Tertiary 3 water with RO and either ion exchange, carbon adsorption or advanced oxidation processes, depending on the target constituent. Metropolitan Council Environmental Services 45

Section 3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use Table 3.5 identifies the typical water quality constituent concentrations for the five classes of recycled wastewater. Table 3.5. Water Quality for Recycled Wastewater Classifications 1 Constituent Recycled Wastewater Concentration 2 Base Tertiary 1 Tertiary 2 Tertiary 3 Tertiary 4 Advanced Secondary Conventional Membrane Filtration Membrane Softening Advanced Processes BOD, mg/L 5-10 < 5

- Page 2 and 3: Acknowledgements This study was con

- Page 4 and 5: Contents Recycling Treated Municipa

- Page 6 and 7: Contents Recycling Treated Municipa

- Page 8 and 9: Executive Summary Vision Executive

- Page 10 and 11: Section 1: Introduction 1.1 Project

- Page 12 and 13: Table 1.2. Water Use in Minnesota,

- Page 14 and 15: Section 1: Introduction Recycling T

- Page 16 and 17: 1.5 Summary Section 1: Introduction

- Page 18 and 19: Section 2: Recycled Wastewater Dema

- Page 20 and 21: Section 2: Recycled Wastewater Dema

- Page 23 and 24: Section 2: Recycled Wastewater Dema

- Page 26 and 27: Figure 2.9. Ground Water Contaminat

- Page 28: Section 2: Recycled Wastewater Dema

- Page 31: Section 2: Recycled Wastewater Dema

- Page 35 and 36: Section 2: Recycled Wastewater Dema

- Page 38 and 39: Table 2.8. Ethanol Plant Capacity a

- Page 40 and 41: Section 2: Recycled Wastewater Dema

- Page 42 and 43: 2.7 References Section 2: Recycled

- Page 44 and 45: Section 3: Recycled Wastewater Syst

- Page 46 and 47: Water Quality Overview The total co

- Page 48 and 49: Industrial Water Quality Concerns S

- Page 50 and 51: Emerging Contaminants of Concern Se

- Page 54 and 55: Section 3: Recycled Wastewater Syst

- Page 56 and 57: 3.4 Storage and Transmission Overvi

- Page 58 and 59: Section 3: Recycled Wastewater Syst

- Page 60 and 61: Cost by Standard Industry Categorie

- Page 62 and 63: Costs and Planning Considerations S

- Page 64 and 65: Section 4: Implementation Considera

- Page 66 and 67: Economic Incentives and Risk Assess

- Page 68 and 69: Section 5: Summary and Potential Ne

- Page 70 and 71: Long-Term Vision Section 5: Summary

- Page 72: Exhibit A: California Water Recycli

- Page 75 and 76: Metropolitan Council Recycling Trea

- Page 77 and 78: Contents Section 1 - Introduction C

- Page 79 and 80: Craddock Consulting Engineers In As

- Page 81 and 82: Section 1 Introduction Craddock Con

- Page 83 and 84: Section 1 Introduction Craddock Con

- Page 85 and 86: Section 1 Introduction Craddock Con

- Page 87 and 88: Craddock Consulting Engineers 2-1 I

- Page 89 and 90: Section 2 Implementation Considerat

- Page 91 and 92: Section 2 Implementation Considerat

- Page 93 and 94: Section 2 Implementation Considerat

- Page 95 and 96: Table 2.4. Examples of State Water

- Page 97 and 98: Section 2 Implementation Considerat

- Page 99 and 100: Section 2 Implementation Considerat

- Page 101 and 102: Section 2 Implementation Considerat

Section 3: Recycled <strong>Wastewater</strong> System Components and Costs<br />

<strong>Recycling</strong> <strong>Treated</strong> <strong>Municipal</strong> <strong>Wastewater</strong> <strong>for</strong> <strong>Industrial</strong> <strong>Water</strong> <strong>Use</strong><br />

As more restrictions are being placed on loadings to our waterways, the removal of the nutrients, nitrogen<br />

and phosphorus, will be implemented at more WWTPs and limits could be lowered <strong>for</strong> those already<br />

removing nutrients. New facilities and major expansions permitted in the state are anticipated to have<br />

nutrient limits that would dictate the use of an advanced secondary treatment process train. In addition,<br />

because one of the largest and most likely industrial uses of recycled wastewater is <strong>for</strong> cooling water,<br />

which requires minimal levels of phosphorus and ammonia, use of an advanced secondary treatment<br />

system effluent is an optimum starting point. This assumption does not exclude consideration of other<br />

types of wastewater treatment facilities <strong>for</strong> water reclamation, such as fixed film systems (trickling filters<br />

and rotating biological contactors), stabilization ponds, chemical/physical package systems, or natural<br />

systems (wetland treatment). However, it is likely that these facilities would require additional treatment<br />

processes to meet the water quality requirements of a specific industry and the regulatory requirements.<br />

Recycled <strong>Wastewater</strong> Classifications<br />

Five types of recycled wastewater, listed in Table 3.4, are used to categorize the recycled wastewater<br />

options available <strong>for</strong> specific industrial water supply requirements. The classification is based on a train<br />

of treatment technologies to meet a set of water quality goals. All classifications provide a safe supply<br />

from a public health perspective – the different water quality goals relate to the specific requirements <strong>for</strong><br />

the industrial water use. All classifications assume an initial WWTP effluent quality typical of a<br />

secondary activated sludge system with ammonia and phosphorus removal, defined as the “base” supply.<br />

Additional treatment processes following secondary treatment are required to produce the other four<br />

classes of recycled wastewater. The term ‘tertiary’ is used to define these classifications because the<br />

treatment process generally follows the secondary treatment process at a WWTP.<br />

Table 3.4. Recycled <strong>Wastewater</strong> Classifications<br />

Classification Characteristics<br />

Base<br />

For non-contact industrial uses with low concern <strong>for</strong> hardness and dissolved solids<br />

Advanced Base WWTP process train – a secondary treatment system with ammonia and phosphorus<br />

Secondary removal<br />

Tertiary 1 For industrial uses with human contact potential and/or industries that require partial hardness<br />

Conventional<br />

or phosphorus removal<br />

Requires a coagulation/flocculation/sedimentation process with filtration; chemical used<br />

depends on target constituent<br />

Removes hardness (with lime) and some dissolved salts; provides some soluble organic<br />

removal and color removal<br />

Tertiary 2 For industrial uses with human contact potential and/or industries that can use hard/high salt<br />

Membrane<br />

water<br />

Filtration Provides soluble organic removal and color removal<br />

Provides pathogen removal and reduces disinfection requirements<br />

Tertiary 3<br />

Membrane<br />

Softening<br />

Tertiary 4<br />

Advanced<br />

Processes<br />

For industries requiring low dissolved salts<br />

Requires Tertiary 2 water followed by softening with reverse osmosis (RO) or electrodialysis<br />

(ED) depending on the target constituents<br />

For industries requiring low dissolved salts and removal of trace constituents<br />

Requires Tertiary 3 water with RO and either ion exchange, carbon adsorption or advanced<br />

oxidation processes, depending on the target constituent.<br />

Metropolitan Council Environmental Services 45