Recycling Treated Municipal Wastewater for Industrial Water Use

Recycling Treated Municipal Wastewater for Industrial Water Use Recycling Treated Municipal Wastewater for Industrial Water Use

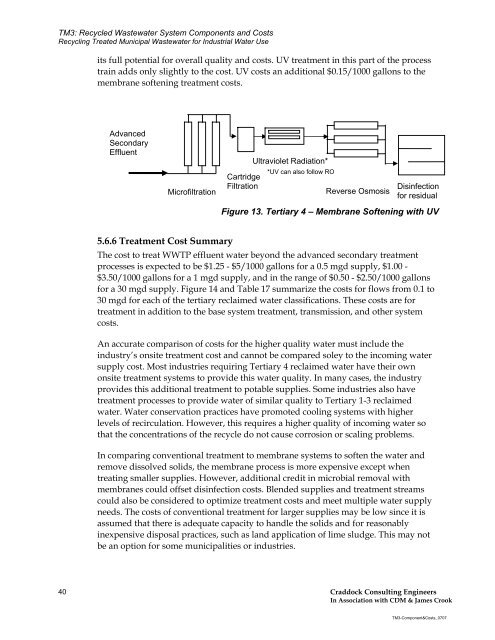

TM3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use This study assumed the need for carbon regeneration every 90 days, which is a conservative rate. The use of GAC following RO increases the treatment cost, expressed as cost of service, above the base system cost to $3.70/1000 gallons for a 1 mgd supply. At 30 mgd, the cost is approximately $2.30/1000 gallons. This process train provides the highest costs of the six treatment trains evaluated. Without RO, the treatment costs would drop by approximately $1.30/1000 gallons for a 1 mgd system, assuming that microfiltration is still required. Tertiary – 4 With Ion Exchange Ion exchange units are commonly used at many industries that require very low levels of dissolved minerals. Similar to GAC, the ion exchange reactors would follow reverse osmosis (Figure 12). Advanced Secondary Effluent Microfiltration Cartridge Filtration Ion Exchange Reverse Osmosis Disinfection Figure 12. Tertiary 4 – Membrane Softening with Ion Exchange Ion exchange annual costs are highly variable depending on the resin type and target constituent. The estimated cost, expressed as cost of service, for ion exchange following reverse osmosis is $3.30/1000 gallons for a 1 mgd supply and $3/1000 gallons for a 5 mgd supply. It is unlikely that larger volumes of this quality of water will be required; plus the annual costs would drive process requirements to use other technologies. Tertiary – 4 With Ultraviolet Radiation Additional treatment with ultraviolet radiation was included because some laboratory grade water quality is used by industry and UV provides additional pathogen protection. It can also be combined with hydrogen peroxide and other oxidants to remove persistent chemicals. In some cases, the UV and hydrogen peroxide can be used instead of reverse osmosis to target certain constituents rather than remove all constituents. UV can be pre or post-reverse osmosis, as shown in Figure 13. Disinfection prior to the membrane RO is used to minimize biofouling of the membrane. However, there could be constituents in the water that affect the transmittance and result in less economical performance of pathogen kill. Pilot testing is often performed to optimize the process train and use each unit process to Craddock Consulting Engineers 39 In Association with CDM & James Crook TM3-Component&Costs_0707

TM3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use its full potential for overall quality and costs. UV treatment in this part of the process train adds only slightly to the cost. UV costs an additional $0.15/1000 gallons to the membrane softening treatment costs. Advanced Secondary Effluent Microfiltration Cartridge Filtration Ultraviolet Radiation* *UV can also follow RO Reverse Osmosis Disinfection for residual Figure 13. Tertiary 4 – Membrane Softening with UV 5.6.6 Treatment Cost Summary The cost to treat WWTP effluent water beyond the advanced secondary treatment processes is expected to be $1.25 - $5/1000 gallons for a 0.5 mgd supply, $1.00 - $3.50/1000 gallons for a 1 mgd supply, and in the range of $0.50 - $2.50/1000 gallons for a 30 mgd supply. Figure 14 and Table 17 summarize the costs for flows from 0.1 to 30 mgd for each of the tertiary reclaimed water classifications. These costs are for treatment in addition to the base system treatment, transmission, and other system costs. An accurate comparison of costs for the higher quality water must include the industry’s onsite treatment cost and cannot be compared soley to the incoming water supply cost. Most industries requiring Tertiary 4 reclaimed water have their own onsite treatment systems to provide this water quality. In many cases, the industry provides this additional treatment to potable supplies. Some industries also have treatment processes to provide water of similar quality to Tertiary 1-3 reclaimed water. Water conservation practices have promoted cooling systems with higher levels of recirculation. However, this requires a higher quality of incoming water so that the concentrations of the recycle do not cause corrosion or scaling problems. In comparing conventional treatment to membrane systems to soften the water and remove dissolved solids, the membrane process is more expensive except when treating smaller supplies. However, additional credit in microbial removal with membranes could offset disinfection costs. Blended supplies and treatment streams could also be considered to optimize treatment costs and meet multiple water supply needs. The costs of conventional treatment for larger supplies may be low since it is assumed that there is adequate capacity to handle the solids and for reasonably inexpensive disposal practices, such as land application of lime sludge. This may not be an option for some municipalities or industries. 40 Craddock Consulting Engineers In Association with CDM & James Crook TM3-Component&Costs_0707

- Page 364 and 365: Date Day of Wk 10/8/06 Sunday 10/9/

- Page 366 and 367: Metropolitan Council Recycling Trea

- Page 368 and 369: Section 5 - Costs Table of Contents

- Page 370 and 371: TM3: Recycled Wastewater System Com

- Page 372 and 373: TM3: Recycled Wastewater System Com

- Page 374 and 375: WWTP 1 - 2 - 3 - 4 - 5 - 1 Treatmen

- Page 376 and 377: TM3: Recycled Wastewater System Com

- Page 378 and 379: TM3: Recycled Wastewater System Com

- Page 380 and 381: TM3: Recycled Wastewater System Com

- Page 382: o Synthetic medium o Two-stage Surf

- Page 385 and 386: TM3: Recycled Wastewater System Com

- Page 387 and 388: TM3: Recycled Wastewater System Com

- Page 389 and 390: TM3: Recycled Wastewater System Com

- Page 391 and 392: TM3: Recycled Wastewater System Com

- Page 393 and 394: TM3: Recycled Wastewater System Com

- Page 395 and 396: TM3: Recycled Wastewater System Com

- Page 397 and 398: TM3: Recycled Wastewater System Com

- Page 399 and 400: TM3: Recycled Wastewater System Com

- Page 401 and 402: TM3: Recycled Wastewater System Com

- Page 403 and 404: Table 13 WATER REUSE SYSTEM COST OF

- Page 405 and 406: TM3: Recycled Wastewater System Com

- Page 407 and 408: TM3: Recycled Wastewater System Com

- Page 409 and 410: Cost of Service, $/1000 gallon 1.00

- Page 411 and 412: TM3: Recycled Wastewater System Com

- Page 413: TM3: Recycled Wastewater System Com

- Page 417 and 418: TM3: Recycled Wastewater System Com

- Page 419 and 420: Cost of Service, $/1000 gallons 8.0

- Page 421 and 422: TM3: Recycled Wastewater System Com

- Page 423 and 424: Appendix A Water Reuse Regulatory E

- Page 425 and 426: Table A-1. 2000 California Water Re

- Page 427 and 428: California Department of Health Ser

- Page 429 and 430: Other Media Type Filters Fuzzy Filt

- Page 431 and 432: Appendix B TECHNICAL MEMORANDUM Rec

- Page 433 and 434: Appendix B Reclaimed Water Transmis

- Page 435 and 436: Exhibit 1 Transmission Main Cost To

- Page 437 and 438: Pipe Installation Data (DR 18 PVC P

- Page 439 and 440: Equipment Costs (with O&P) Item Des

- Page 441 and 442: Water Reuse Pipe Line Construction

- Page 443 and 444: Construction Unit Costs Item (2006

- Page 445 and 446: Crew Costs (with O&P) St. Paul Pres

- Page 447 and 448: Capital PROJECT Cost Curves for Rec

- Page 449 and 450: Diam (in) Annual Average Day Flow A

- Page 451 and 452: Diam (in) Annual Average Day Flow A

- Page 453 and 454: Pipe Capital Project Cost, $ Millio

- Page 455 and 456: Pipe Capital Project Cost, $/1000 g

- Page 457 and 458: Capital PROJECT Cost Curves for Rec

- Page 459 and 460: Capital PROJECT Cost Curves for Rec

- Page 461 and 462: Annual Pipe Average Annual Velocity

- Page 463 and 464: Pipe Capital Project Cost, $ Millio

TM3: Recycled <strong>Wastewater</strong> System Components and Costs<br />

<strong>Recycling</strong> <strong>Treated</strong> <strong>Municipal</strong> <strong>Wastewater</strong> <strong>for</strong> <strong>Industrial</strong> <strong>Water</strong> <strong>Use</strong><br />

its full potential <strong>for</strong> overall quality and costs. UV treatment in this part of the process<br />

train adds only slightly to the cost. UV costs an additional $0.15/1000 gallons to the<br />

membrane softening treatment costs.<br />

Advanced<br />

Secondary<br />

Effluent<br />

Microfiltration<br />

Cartridge<br />

Filtration<br />

Ultraviolet Radiation*<br />

*UV can also follow RO<br />

Reverse Osmosis<br />

Disinfection<br />

<strong>for</strong> residual<br />

Figure 13. Tertiary 4 – Membrane Softening with UV<br />

5.6.6 Treatment Cost Summary<br />

The cost to treat WWTP effluent water beyond the advanced secondary treatment<br />

processes is expected to be $1.25 - $5/1000 gallons <strong>for</strong> a 0.5 mgd supply, $1.00 -<br />

$3.50/1000 gallons <strong>for</strong> a 1 mgd supply, and in the range of $0.50 - $2.50/1000 gallons<br />

<strong>for</strong> a 30 mgd supply. Figure 14 and Table 17 summarize the costs <strong>for</strong> flows from 0.1 to<br />

30 mgd <strong>for</strong> each of the tertiary reclaimed water classifications. These costs are <strong>for</strong><br />

treatment in addition to the base system treatment, transmission, and other system<br />

costs.<br />

An accurate comparison of costs <strong>for</strong> the higher quality water must include the<br />

industry’s onsite treatment cost and cannot be compared soley to the incoming water<br />

supply cost. Most industries requiring Tertiary 4 reclaimed water have their own<br />

onsite treatment systems to provide this water quality. In many cases, the industry<br />

provides this additional treatment to potable supplies. Some industries also have<br />

treatment processes to provide water of similar quality to Tertiary 1-3 reclaimed<br />

water. <strong>Water</strong> conservation practices have promoted cooling systems with higher<br />

levels of recirculation. However, this requires a higher quality of incoming water so<br />

that the concentrations of the recycle do not cause corrosion or scaling problems.<br />

In comparing conventional treatment to membrane systems to soften the water and<br />

remove dissolved solids, the membrane process is more expensive except when<br />

treating smaller supplies. However, additional credit in microbial removal with<br />

membranes could offset disinfection costs. Blended supplies and treatment streams<br />

could also be considered to optimize treatment costs and meet multiple water supply<br />

needs. The costs of conventional treatment <strong>for</strong> larger supplies may be low since it is<br />

assumed that there is adequate capacity to handle the solids and <strong>for</strong> reasonably<br />

inexpensive disposal practices, such as land application of lime sludge. This may not<br />

be an option <strong>for</strong> some municipalities or industries.<br />

40 Craddock Consulting Engineers<br />

In Association with CDM & James Crook<br />

TM3-Component&Costs_0707