Recycling Treated Municipal Wastewater for Industrial Water Use

Recycling Treated Municipal Wastewater for Industrial Water Use Recycling Treated Municipal Wastewater for Industrial Water Use

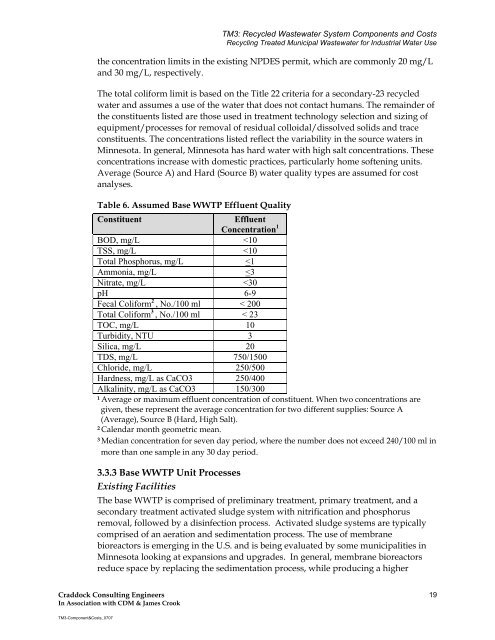

TM3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use the concentration limits in the existing NPDES permit, which are commonly 20 mg/L and 30 mg/L, respectively. The total coliform limit is based on the Title 22 criteria for a secondary-23 recycled water and assumes a use of the water that does not contact humans. The remainder of the constituents listed are those used in treatment technology selection and sizing of equipment/processes for removal of residual colloidal/dissolved solids and trace constituents. The concentrations listed reflect the variability in the source waters in Minnesota. In general, Minnesota has hard water with high salt concentrations. These concentrations increase with domestic practices, particularly home softening units. Average (Source A) and Hard (Source B) water quality types are assumed for cost analyses. Table 6. Assumed Base WWTP Effluent Quality Constituent Effluent Concentration 1 BOD, mg/L

TM3: Recycled Wastewater System Components and Costs Recycling Treated Municipal Wastewater for Industrial Water Use quality effluent. Membrane bioreactors are included in Figure 3, recognizing it as a future technology for Minnesota. The type of phosphorus removal is not identified in the Base WWTP. A facility could use chemical or biological phosphorus removal to achieve a 1 mg/L total phosphorus limit. Certain technologies could be selected because of benefits to the phosphorus removal mechanism. For example, if a facility uses chemical phosphorus removal, the use of a chemical softening process with coagulation, flocculation, and sedimentation could provide a more optimum use of chemicals for phosphorus removal, provide flexibility in chemical addition points, and reduce suspended solids and hardness. For example, the City of Mankato considered these benefits in the selection of their processes to produce reclaimed water for the cooling towers of the Mankato Energy Center. Additional Disinfection Requirements The base WWTP assumes the facility has disinfection equipment and structures to meet Minnesota’s seasonal fecal coliform limits. The majority of Minnesota’s WWTPS are permitted to disinfect from April through October and is the assumed period of disinfection for this study. There are three disinfection system improvements required to produce a reclaimed supply from WWTPs in Minnesota for a non-contact industrial water use: Year-round disinfection Higher levels of disinfection to meet reclaimed water pathogen limits Transmission system residual disinfection In Minnesota, disinfection for pathogens in WWTP effluent is required only from April through October. For a reclaimed supply, disinfection must occur year-round or any time during which reclaimed water is delivered to users. While the existing facilities will be adequate to disinfect the WWTP effluent year-round to the levels required by the NPDES permit limit (typically a fecal coliform limit of 200/100 ml) there will be additional O&M costs associated with the extra five months of disinfection a year. The California Water Recycling Criteria include a total coliform limit of 23/100 ml for the base system reclaimed supply. Most Minnesota WWTPs use chlorination or UV radiation for disinfection. In the case of chlorination systems, higher levels of disinfection can be achieved by increasing the concentration of chlorine in the effluent while using the same contact tanks. With UV radiation, the need to upgrade or add equipment will depend on the peaking factor criteria used to design the system and other flexibilities designed in the system. The other disinfection requirement is the presence of a residual disinfectant in the transmission system. The most common practice is the use of sodium hypochlorite which is the practice assumed for this study. While some systems may have adequate capacity to add a residual with their existing chlorination system, those with UV radiation processes will need new facilities and equipment. 20 Craddock Consulting Engineers In Association with CDM & James Crook TM3-Component&Costs_0707

- Page 340 and 341: MCES Empire Plant Final Effluent Sa

- Page 342 and 343: Date Day of Wk 10/24/06 Tuesday 10/

- Page 344 and 345: Date Day of Wk 10/24/06 Tuesday 10/

- Page 346 and 347: Date Day of Wk 10/24/06 Tuesday 10/

- Page 348 and 349: Exhibit D Metropolitan (Metro) WWTP

- Page 350 and 351: MCES Metropolitan Plant Final Efflu

- Page 352 and 353: Date Day of Wk 4/19/07 Thursday 4/2

- Page 354 and 355: Date Day of Wk 4/19/07 Thursday 4/2

- Page 356 and 357: Date Day of Wk 4/19/07 Thursday 4/2

- Page 358 and 359: MCES Seneca Plant Final Effluent Sa

- Page 360 and 361: Date Day of Wk 10/8/06 Sunday 10/9/

- Page 362 and 363: Date Day of Wk 10/8/06 Sunday 10/9/

- Page 364 and 365: Date Day of Wk 10/8/06 Sunday 10/9/

- Page 366 and 367: Metropolitan Council Recycling Trea

- Page 368 and 369: Section 5 - Costs Table of Contents

- Page 370 and 371: TM3: Recycled Wastewater System Com

- Page 372 and 373: TM3: Recycled Wastewater System Com

- Page 374 and 375: WWTP 1 - 2 - 3 - 4 - 5 - 1 Treatmen

- Page 376 and 377: TM3: Recycled Wastewater System Com

- Page 378 and 379: TM3: Recycled Wastewater System Com

- Page 380 and 381: TM3: Recycled Wastewater System Com

- Page 382: o Synthetic medium o Two-stage Surf

- Page 385 and 386: TM3: Recycled Wastewater System Com

- Page 387 and 388: TM3: Recycled Wastewater System Com

- Page 389: TM3: Recycled Wastewater System Com

- Page 393 and 394: TM3: Recycled Wastewater System Com

- Page 395 and 396: TM3: Recycled Wastewater System Com

- Page 397 and 398: TM3: Recycled Wastewater System Com

- Page 399 and 400: TM3: Recycled Wastewater System Com

- Page 401 and 402: TM3: Recycled Wastewater System Com

- Page 403 and 404: Table 13 WATER REUSE SYSTEM COST OF

- Page 405 and 406: TM3: Recycled Wastewater System Com

- Page 407 and 408: TM3: Recycled Wastewater System Com

- Page 409 and 410: Cost of Service, $/1000 gallon 1.00

- Page 411 and 412: TM3: Recycled Wastewater System Com

- Page 413 and 414: TM3: Recycled Wastewater System Com

- Page 415 and 416: TM3: Recycled Wastewater System Com

- Page 417 and 418: TM3: Recycled Wastewater System Com

- Page 419 and 420: Cost of Service, $/1000 gallons 8.0

- Page 421 and 422: TM3: Recycled Wastewater System Com

- Page 423 and 424: Appendix A Water Reuse Regulatory E

- Page 425 and 426: Table A-1. 2000 California Water Re

- Page 427 and 428: California Department of Health Ser

- Page 429 and 430: Other Media Type Filters Fuzzy Filt

- Page 431 and 432: Appendix B TECHNICAL MEMORANDUM Rec

- Page 433 and 434: Appendix B Reclaimed Water Transmis

- Page 435 and 436: Exhibit 1 Transmission Main Cost To

- Page 437 and 438: Pipe Installation Data (DR 18 PVC P

- Page 439 and 440: Equipment Costs (with O&P) Item Des

TM3: Recycled <strong>Wastewater</strong> System Components and Costs<br />

<strong>Recycling</strong> <strong>Treated</strong> <strong>Municipal</strong> <strong>Wastewater</strong> <strong>for</strong> <strong>Industrial</strong> <strong>Water</strong> <strong>Use</strong><br />

the concentration limits in the existing NPDES permit, which are commonly 20 mg/L<br />

and 30 mg/L, respectively.<br />

The total coli<strong>for</strong>m limit is based on the Title 22 criteria <strong>for</strong> a secondary-23 recycled<br />

water and assumes a use of the water that does not contact humans. The remainder of<br />

the constituents listed are those used in treatment technology selection and sizing of<br />

equipment/processes <strong>for</strong> removal of residual colloidal/dissolved solids and trace<br />

constituents. The concentrations listed reflect the variability in the source waters in<br />

Minnesota. In general, Minnesota has hard water with high salt concentrations. These<br />

concentrations increase with domestic practices, particularly home softening units.<br />

Average (Source A) and Hard (Source B) water quality types are assumed <strong>for</strong> cost<br />

analyses.<br />

Table 6. Assumed Base WWTP Effluent Quality<br />

Constituent Effluent<br />

Concentration 1<br />

BOD, mg/L