Sales Guide HID Kit & Ballast - Laki Auto

Sales Guide HID Kit & Ballast - Laki Auto

Sales Guide HID Kit & Ballast - Laki Auto

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Sales</strong> <strong>Guide</strong><br />

<strong>HID</strong> <strong>Kit</strong> & <strong>Ballast</strong><br />

• EHWA TECHNOLOGIES INFORMATION

Company Profile<br />

1956. 1 : EHWA Electric Co. Establishment<br />

1994 : ISO9001<br />

(Voltage Regulator, UPS)<br />

1996. 7 : Listed in KOSDAQ<br />

2002.10 : <strong>HID</strong> <strong>Ballast</strong> R&D Project<br />

2003.12 : E-13 mark for <strong>HID</strong> <strong>Ballast</strong><br />

2003.12 : QS-9000<br />

• EHWA TECHNOLOGIES INFORMATION

Application fields of <strong>HID</strong><br />

Motorcycle; 12V Commercial Vehicle; 24V<br />

Passenger Car; 12V Heavy Equipment; 24V<br />

• EHWA TECHNOLOGIES INFORMATION

<strong>HID</strong> Bulb Type (1)<br />

H1 H3 H4 H7<br />

• EHWA TECHNOLOGIES INFORMATION

<strong>HID</strong> Bulb Type (2)<br />

9004 9005 9006 9007<br />

• EHWA TECHNOLOGIES INFORMATION

The Characteristics of ETI <strong>Ballast</strong><br />

- Durability<br />

You can make sure the quality of ETI <strong>Ballast</strong> in the aspects of durability as it has been used<br />

all the electronic components guaranteed in using under the 125 degrees.<br />

Even though the electronic components guaranteed 125 degrees are more expensive than<br />

85 degrees or 105 degrees in cost, ETI has not used the electronic components recommended in<br />

under using only just 85 degrees or 105 degrees for maintaining the quality of durability.<br />

- ETI’s <strong>Ballast</strong> has developed in considering all of conditions would be happened<br />

at the aftermarket fields.<br />

- The size of ETI <strong>Ballast</strong> is most compact enough to install easily comparing to the other ballasts.<br />

• EHWA TECHNOLOGIES INFORMATION

Auxiliary Parts<br />

Power Connecting Cable<br />

Polarity Adjusting Cable<br />

Double sided Tape<br />

Fuses<br />

Installation Manual<br />

Relay (H4 High Low Only)<br />

• EHWA TECHNOLOGIES INFORMATION

E-13 Certification<br />

Reference Number<br />

E13*10R00*10R02*2024*00<br />

Approval Mark<br />

10R-02 2024<br />

Place<br />

Luxembourg<br />

Date<br />

10 Dec. 2003<br />

• EHWA TECHNOLOGIES INFORMATION

QS-9000 Certification<br />

Certificate No.<br />

QSCQ30573<br />

Registered<br />

QS-9000:1998<br />

(Based ISO9001:1994)<br />

Validity ranges<br />

Design, R&D,<br />

Production & Services<br />

Date<br />

12 Dec. 2003<br />

• EHWA TECHNOLOGIES INFORMATION

Catalog(2)<br />

• EHWA TECHNOLOGIES INFORMATION

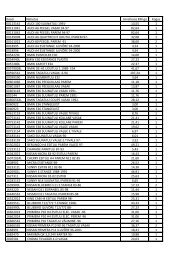

4. High temperature extremes can cause a malfunction by:<br />

1) Exceeding the dissociation temperature of surroundings polymer or other packing components.<br />

2) Carbonization of packing materials with eventual progressive failure of the associated passive or active<br />

components. In addition, non-catastrophic failure is possible due to electrical leakage in the resultant carbon paths.<br />

3) Changes in active device characteristics with increased heat including changes in gain, impedance, collector-base<br />

leakage, peak blocking voltage, collector-base junction second breakdown voltage, etc., with temperature.<br />

4) Changes in passive device characteristics such as permanent or temporary drift in resistor value and capacitor<br />

dielectric constants with increased temperature.<br />

5) Changes in interconnect and relay coil performance due to the conductivity temperature coefficient of copper.<br />

6) Changes in the properties of magnetic materials with increasing temperature, including Curie point effects and loss<br />

of permanent magnetism.<br />

7) Dimensional changes in packages and components leading to separation or subassemblies.<br />

5. Test Methods<br />

The effect of electric components caused by the temperature circumstances<br />

1) Operating Temperature<br />

Do not use Aluminum Electrolytic Capacitors at temperature on which exceeds the specified operating temperature<br />

range. Applying capacitors surpassing guaranteed conditions may cause destruction due to rapid characteristic<br />

deterioration. Where, temperature of a capacitor includes radiation heat of Power transistor, IC, Resistor, etc. and self<br />

heat by ripple current as well as ambient temperature of a set. (From the contents of sales guide published by Sam<br />

Young Electronics Co., Ltd.)<br />

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION

• EHWA TECHNOLOGIES INFORMATION