Workplace transport safety An employers' guide - ARRI Lighting Rental

Workplace transport safety An employers' guide - ARRI Lighting Rental

Workplace transport safety An employers' guide - ARRI Lighting Rental

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Health and Safety<br />

Executive<br />

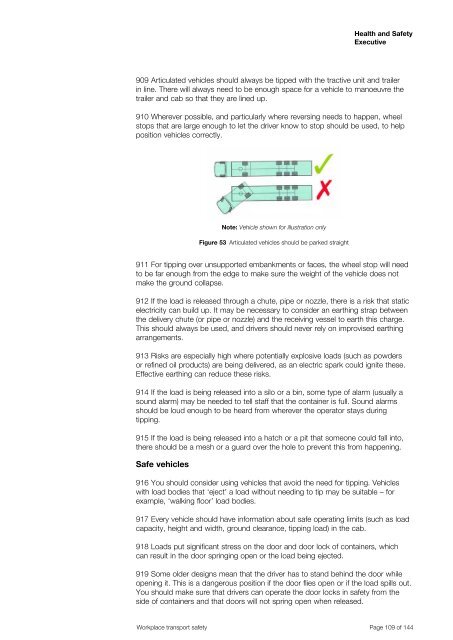

909 Articulated vehicles should always be tipped with the tractive unit and trailer<br />

in line. There will always need to be enough space for a vehicle to manoeuvre the<br />

trailer and cab so that they are lined up.<br />

910 Wherever possible, and particularly where reversing needs to happen, wheel<br />

stops that are large enough to let the driver know to stop should be used, to help<br />

position vehicles correctly.<br />

Note: Vehicle shown for illustration only<br />

Figure 53 Articulated vehicles should be parked straight<br />

911 For tipping over unsupported embankments or faces, the wheel stop will need<br />

to be far enough from the edge to make sure the weight of the vehicle does not<br />

make the ground collapse.<br />

912 If the load is released through a chute, pipe or nozzle, there is a risk that static<br />

electricity can build up. It may be necessary to consider an earthing strap between<br />

the delivery chute (or pipe or nozzle) and the receiving vessel to earth this charge.<br />

This should always be used, and drivers should never rely on improvised earthing<br />

arrangements.<br />

913 Risks are especially high where potentially explosive loads (such as powders<br />

or refined oil products) are being delivered, as an electric spark could ignite these.<br />

Effective earthing can reduce these risks.<br />

914 If the load is being released into a silo or a bin, some type of alarm (usually a<br />

sound alarm) may be needed to tell staff that the container is full. Sound alarms<br />

should be loud enough to be heard from wherever the operator stays during<br />

tipping.<br />

915 If the load is being released into a hatch or a pit that someone could fall into,<br />

there should be a mesh or a guard over the hole to prevent this from happening.<br />

Safe vehicles<br />

916 You should consider using vehicles that avoid the need for tipping. Vehicles<br />

with load bodies that ‘eject’ a load without needing to tip may be suitable – for<br />

example, ‘walking floor’ load bodies.<br />

917 Every vehicle should have information about safe operating limits (such as load<br />

capacity, height and width, ground clearance, tipping load) in the cab.<br />

918 Loads put significant stress on the door and door lock of containers, which<br />

can result in the door springing open or the load being ejected.<br />

919 Some older designs mean that the driver has to stand behind the door while<br />

opening it. This is a dangerous position if the door flies open or if the load spills out.<br />

You should make sure that drivers can operate the door locks in <strong>safety</strong> from the<br />

side of containers and that doors will not spring open when released.<br />

<strong>Workplace</strong> <strong>transport</strong> <strong>safety</strong> Page 109 of 144