P0782 EN PFS-C Filling pump

P0782 EN PFS-C Filling pump

P0782 EN PFS-C Filling pump

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

- Subject to modifications -<br />

1290<br />

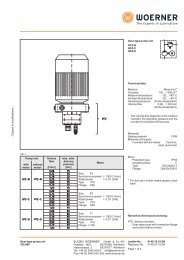

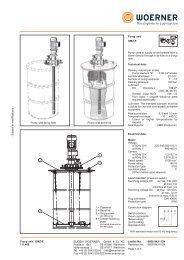

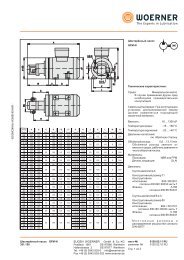

<strong>Filling</strong> <strong>pump</strong> <strong>PFS</strong>-C<br />

pneumatic actuation<br />

760<br />

800<br />

500 (430)<br />

620<br />

(600)<br />

1110 (960)<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

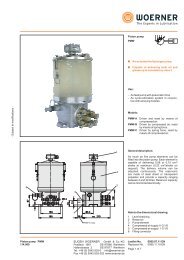

<strong>Filling</strong> <strong>pump</strong> <strong>PFS</strong>-C<br />

pneumatic actuation<br />

<br />

<br />

<br />

<br />

Technical data:<br />

Pressure ratio theor.: 60:1<br />

Air consumption: approx. 130 l/min<br />

Driving pressure: 3,5 ... 8,5 bar<br />

Delivery rate at 6 bar:<br />

1)<br />

max. 1600 g/min<br />

Noise level: 76 dB<br />

Air connection:<br />

Lubricant connection<br />

G 1/4i<br />

at <strong>pump</strong>: G 1/4a<br />

Drum size: 25, 50 or 180-200 kg<br />

Lubricants:<br />

Note:<br />

for 25 kg, 50 kg and 200 kg drums<br />

with drive vehicle<br />

maintenance-free<br />

easy drum change<br />

The unit is capable of processing greases<br />

up to NLGI class 2 (according to DIN<br />

51818). For pastes with no lubricating<br />

properties (with emery components) and<br />

silicone pastes, please turn to our technical<br />

support department.<br />

To limit the air pressure, increase the<br />

<strong>pump</strong>'s service life, and observe the<br />

warranty terms, it is necessary to install a<br />

maintenance unit upstream the <strong>pump</strong>.<br />

While taking the <strong>pump</strong>'s efficiency into<br />

account, the rule of thumb for the maximum<br />

delivery pressure is as follows:<br />

Leaflet-No. 0782.10.11 <strong>EN</strong><br />

Replaces No. 0782.11.10 <strong>EN</strong><br />

Page 1 of 3<br />

p p x 60-10 [bar]<br />

ab Air<br />

Example: At a driving pressure of 6 bar,<br />

a delivery pressure of approximately<br />

350 bar is yielded<br />

1)<br />

The delivery capacity depends on the<br />

lubricant to be delivered, temperature,<br />

driving pressure, and counter-pressure.<br />

Example:<br />

For grease of NLGI class 2, the delivery<br />

capacity at a temperature of 20 °C and<br />

a driving pressure of 6,5 bar at maximum,<br />

will amount to approximately 1,200<br />

g/min (in the absence of any counterpressure!)<br />

Due to the flow resistances of the<br />

components used and the counterpressure<br />

resulting therefrom, the delivery<br />

capacity may decrease considerably.

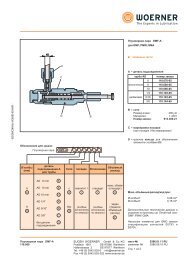

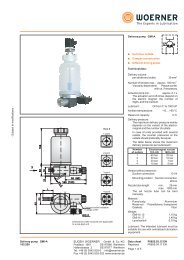

Order-designation:<br />

Drum size<br />

25 kg<br />

50 kg<br />

200 kg<br />

25<br />

50<br />

200<br />

Accessories:<br />

Ratio<br />

60:1<br />

Turning piece Z-joint:<br />

Turning piece axial joint:<br />

Handle for the <strong>pump</strong>:<br />

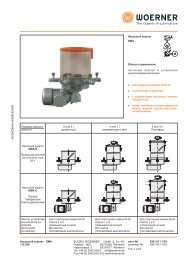

<strong>Filling</strong> <strong>pump</strong> <strong>PFS</strong>-C<br />

60<br />

other<br />

versions<br />

by request<br />

Examples for filling connections<br />

Drive<br />

vehicle<br />

with<br />

without<br />

Order-no.<br />

935.124-25<br />

935.124-26<br />

935.124-27<br />

<strong>Filling</strong> connection<br />

Cone grease nipple DIN 71412 - AG1/4<br />

A<br />

F<br />

0<br />

Follower plate<br />

25 kg<br />

for drum insideø<br />

250 … 280 mm<br />

without<br />

50 - 60 kg<br />

for drum insideø<br />

335 … 360 mm<br />

50 - 60 kg<br />

for drum insideø<br />

360 … 400 mm<br />

without<br />

180 - 200 kg<br />

for drum insideø<br />

540 … 580 mm<br />

without<br />

A<br />

0<br />

A<br />

B<br />

0<br />

A<br />

0<br />

Barrel cover<br />

25 kg<br />

for drum outsideø<br />

300 … 350 mm<br />

without<br />

50 - 60 kg<br />

for drum outsideø<br />

340 … 395 mm<br />

50 - 60 kg<br />

for drum outsideø<br />

370 … 420 mm<br />

without<br />

180 - 200 kg<br />

for drum outsideø<br />

550 … 600 mm<br />

without<br />

<strong>Filling</strong> connection<br />

Flat lubrication nipple DIN 3404 - M22<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

A<br />

0<br />

A<br />

B<br />

0<br />

A<br />

0<br />

Tube length<br />

1,5 m<br />

3 m<br />

5 m<br />

without<br />

Leaflet-No. 0782 <strong>EN</strong><br />

Page 2 of 3<br />

3<br />

5<br />

0<br />

<strong>Filling</strong> connection<br />

Lock nipple<br />

Transfer to<br />

lubrication point<br />

Gun with A<br />

connection "A"<br />

for cone grease nipple<br />

1,5 DIN 71412<br />

Gun with C<br />

connection "C"<br />

for flat lubrication nipple<br />

DIN 3404-M22<br />

Coupling with V<br />

connection "V"<br />

for filling connection "V"<br />

at GMF and "D" at<br />

GMA and GMG<br />

Coupling with W<br />

connection<br />

"G" and "W"<br />

for filling connection "W"<br />

and "G" at GMG<br />

without (G 1/4a)<br />

C G<br />

0<br />

- Subject to modifications -

- Subject to modifications -<br />

Important information on this publication<br />

Reproduction, also in extracts, only permitted with the approval of the firm of EUG<strong>EN</strong><br />

WOERNER GmbH & Co. KG.<br />

All the information in this publication has been examined for correctness with great care.<br />

Nevertheless, WOERNER cannot assume any liability for losses or damage resulting<br />

directly or indirectly from the application of the information contained in this publication.<br />

All products from WOERNER may only be used as intended and corresponding to the<br />

information in this publication.<br />

For products supplied with operating instructions, the additional directives and information<br />

contained in them are to be complied with.<br />

Materials deviating from those mentioned in this publication and the technical documents<br />

which further apply may only be poured into and processed in the appliances and systems<br />

manufactured and supplied by WOERNER by following agreement with and written<br />

approval by WOERNER.<br />

The safety and danger information stated in the safety data sheets of the substances used<br />

must be taken into account at all costs.<br />

Transportation of gases, liquefied gases, gases under pressure, vapours and liquids, the<br />

vapour pressure of which is more than 0,5 bar above normal atmospheric pressure<br />

(1013 mbar) at the maximum admissible temperature, of easy inflammable or explosive<br />

media as well as transportation of foodstuffs is forbidden.<br />

Information on EU Directive 2002/95/EC (RoHS)<br />

With Directive 2002/95/EC of January 27, 2003, for the limitation of the use of certain<br />

hazardous substances in electrical and electronic devices (RoHS) material bans come into<br />

effect from July 2006 for electrical and electronic devices newly placed on the market for<br />

lead, cadmium, hexavalent chromium, mercury and brominated flame retardants.<br />

In its controls and switching devices, WOERNER only uses materials which fulfil the criteria<br />

of EU Directive 2002/95/EC.<br />

To the extent that hexavalent chromium has been used as corrosion protection in the parts<br />

which we produce ourselves, it has already been replaced by other environmentally<br />

tolerable protective measures.<br />

The mechanical devices supplied by WOERNER are not affected by EU Directive<br />

2002/95/EC as they are appliances added or installed on "large-scale stationary industrial<br />

tools" (cf. EU Directive 2002/96/EC,Annex IA).<br />

But as WOERNER is conscious of its responsibility towards the environment, we shall also<br />

use materials fulfilling the requirements of the Directive for devices not covered by EU<br />

Directive 2002/95/EC as soon as they are generally available and their use is technically<br />

possible.<br />

EUG<strong>EN</strong> WOERNER GmbH & Co. KG<br />

Postfach 1661 DE-97866 Wertheim<br />

Hafenstrasse 2 DE-97877 Wertheim<br />

Tel. +49 (0) 9342 803-0 info@woerner.de<br />

Fax.+49 (0) 9342 803-202 www.woerner.de<br />

Leaflet-No. 0782 <strong>EN</strong><br />

Page 3 of 3