Mining_Methods_UnderGround_Mining - Mining and Blasting

Mining_Methods_UnderGround_Mining - Mining and Blasting

Mining_Methods_UnderGround_Mining - Mining and Blasting

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

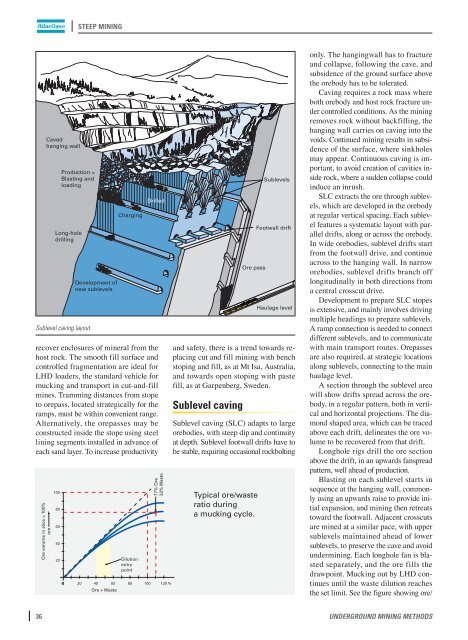

Sublevel caving layout.<br />

STeeP <strong>Mining</strong><br />

recover enclosures of mineral from the<br />

host rock. The smooth fill surface <strong>and</strong><br />

controlled fragmentation are ideal for<br />

LHD loaders, the st<strong>and</strong>ard vehicle for<br />

mucking <strong>and</strong> transport in cut-<strong>and</strong>-fill<br />

mines. Tramming distances from stope<br />

to orepass, located strategically for the<br />

ramps, must be within convenient range.<br />

Alternatively, the orepasses may be<br />

constructed inside the stope using steel<br />

lining segments installed in advance of<br />

each s<strong>and</strong> layer. To increase productivity<br />

Ore volume in slice = 100%<br />

ore<br />

Caved<br />

hanging wall<br />

Production =<br />

<strong>Blasting</strong> <strong>and</strong><br />

loading<br />

Long-hole<br />

drilling<br />

100<br />

80<br />

60<br />

40<br />

20<br />

Development of<br />

new sublevels<br />

Charging<br />

Dilution<br />

entry<br />

point<br />

Drilled<br />

77% Ore<br />

33% Waste<br />

0 20 40 60 80 100 120 %<br />

Ore + Waste<br />

<strong>and</strong> safety, there is a trend towards replacing<br />

cut <strong>and</strong> fill mining with bench<br />

stoping <strong>and</strong> fill, as at Mt Isa, Australia,<br />

<strong>and</strong> towards open stoping with paste<br />

fill, as at Garpenberg, Sweden.<br />

Sublevel caving<br />

Ore pass<br />

Sublevels<br />

Footwall drift<br />

Haulage level<br />

Sublevel caving (SLC) adapts to large<br />

orebodies, with steep dip <strong>and</strong> continuity<br />

at depth. Sublevel footwall drifts have to<br />

be stable, requiring occasional rockbolting<br />

Typical ore/waste<br />

ratio during<br />

a mucking cycle.<br />

only. The hangingwall has to fracture<br />

<strong>and</strong> collapse, following the cave, <strong>and</strong><br />

subsidence of the ground surface above<br />

the orebody has to be tolerated.<br />

Caving requires a rock mass where<br />

both orebody <strong>and</strong> host rock fracture un-<br />

der controlled conditions. As the mining<br />

removes rock without backfilling, the<br />

hanging wall carries on caving into the<br />

voids. Continued mining results in subsi-<br />

dence of the surface, where sinkholes<br />

may appear. Continuous caving is important,<br />

to avoid creation of cavities in-<br />

side rock, where a sudden collapse could<br />

induce an inrush.<br />

SLC extracts the ore through sublevels,<br />

which are developed in the orebody<br />

at regular vertical spacing. Each sublevel<br />

features a systematic layout with parallel<br />

drifts, along or across the orebody.<br />

In wide orebodies, sublevel drifts start<br />

from the footwall drive, <strong>and</strong> continue<br />

across to the hanging wall. In narrow<br />

orebodies, sublevel drifts branch off<br />

longitudinally in both directions from<br />

a central crosscut drive.<br />

Development to prepare SLC stopes<br />

is extensive, <strong>and</strong> mainly involves driving<br />

multiple headings to prepare sublevels.<br />

A ramp connection is needed to connect<br />

different sublevels, <strong>and</strong> to communicate<br />

with main transport routes. Orepasses<br />

are also required, at strategic locations<br />

along sublevels, connecting to the main<br />

haulage level.<br />

A section through the sublevel area<br />

will show drifts spread across the ore-<br />

body, in a regular pattern, both in vertical<br />

<strong>and</strong> horizontal projections. The dia-<br />

mond shaped area, which can be traced<br />

above each drift, delineates the ore volume<br />

to be recovered from that drift.<br />

Longhole rigs drill the ore section<br />

above the drift, in an upwards fanspread<br />

pattern, well ahead of production.<br />

<strong>Blasting</strong> on each sublevel starts in<br />

sequence at the hanging wall, commonly<br />

using an upwards raise to provide initial<br />

expansion, <strong>and</strong> mining then retreats<br />

toward the footwall. Adjacent crosscuts<br />

are mined at a similar pace, with upper<br />

sublevels maintained ahead of lower<br />

sublevels, to preserve the cave <strong>and</strong> avoid<br />

undermining. Each longhole fan is bla-<br />

sted separately, <strong>and</strong> the ore fills the<br />

drawpoint. Mucking out by LHD continues<br />

until the waste dilution reaches<br />

the set limit. See the figure showing ore/<br />

36 underground mining methods