The Alaska Contractor - Alaska Quality Publishing, Inc.

The Alaska Contractor - Alaska Quality Publishing, Inc.

The Alaska Contractor - Alaska Quality Publishing, Inc.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Associated General<br />

<strong>Contractor</strong>s of <strong>Alaska</strong><br />

8005 Schoon St.<br />

Anchorage, AK 99518<br />

(907) 561-5354<br />

Fax: (907) 562-6118<br />

www.agcak.org<br />

<strong>Contractor</strong>@agcak.org<br />

Editorial Board<br />

Dave Cruz<br />

Dick Cattanach<br />

Margaret Empie<br />

Mary Killorin<br />

John MacKinnon<br />

Brook Mayfield<br />

April Reilly<br />

Vicki Schneibel<br />

George Tuckness<br />

Lyn Whitley<br />

8537 Corbin Dr.<br />

Anchorage, AK 99507<br />

(907) 562-9300<br />

Fax: (907) 562-9311<br />

Toll Free: (866) 562-9300<br />

www.AQPpublishing.com<br />

Publisher<br />

Robert R. Ulin<br />

Editor<br />

Rachael Fisher<br />

Graphic Designer<br />

Justin Ritter<br />

Project Sales Manager<br />

Clem E. Mewmaw<br />

Advertising Coordinator<br />

Carol Choi<br />

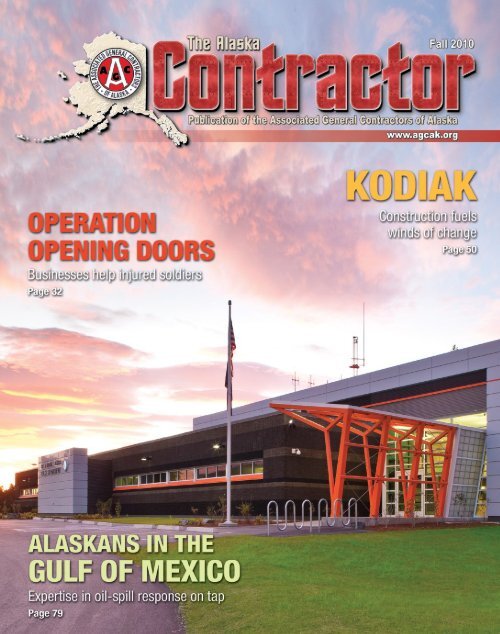

Th e n e w Ko d i aK p o l i c e s TaT i o n b u i lT<br />

by Ro g e R hi cK e l co n T R ac T i ng in c.<br />

cov e R p h oTo by<br />

ch R i s aR e n d<br />

Features<br />

Table of Contents<br />

12 Bonding Proposition B by J. Mark Dudick<br />

32 Smoothing the transition AGC members and community businesses help<br />

wounded warriors settle in<br />

37 Storm Water Pollution Prevention Plans<br />

38 Building the big picture <strong>Contractor</strong>s, Native Corporation and cinema chain<br />

create maximum entertainment<br />

46 Coming to the AGC of <strong>Alaska</strong> Convention in November: David Rabiner<br />

50 Changing face of Kodiak by Drew Herman<br />

59 In Memoriam – Senator Ted Stevens<br />

66 Anchorage and Fairbanks Annual AGC Golf Scrambles<br />

72 Traffic relief Lake Otis Parkway-Tudor Road intersection<br />

76 Kodiak Launch Complex<br />

79 Local contractors and cooperatives pitch in<br />

to salvage oily Gulf of Mexico by Drew Herman<br />

83 Project Update: Hiland Mountain Correctional Center,<br />

S.A.V.E. High School and more by Jessica Bowman<br />

86 Taking pride in what we do photo essay<br />

Pr o F i l e s<br />

22 Cruz Construction <strong>Inc</strong>. by Tracy Kalytiak<br />

40 H&K Sheetmetal Fabricators <strong>Inc</strong>. by Jamie Rogers<br />

60 Uresco Construction Materials <strong>Inc</strong>. by Rachael Fisher<br />

DePartments<br />

<strong>The</strong> <strong>Alaska</strong> Fall 2010<br />

<strong>The</strong> Official Publication of the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong><br />

www.agcak.org<br />

4 Winning Bids & Construction Activity<br />

8 President’s Message by Dave Cruz<br />

10 Executive Director’s Message by John MacKinnon<br />

18 Why join AGC of <strong>Alaska</strong>? by Barbara Rowland<br />

20 <strong>Alaska</strong> Construction Academies by Kathleen Castle<br />

28 Financial Services & <strong>Contractor</strong>s by Betsy Lawer<br />

35 Human Resources Update by Barbara Stallone<br />

48 AGC Annual Conference 2010 Registration<br />

64 <strong>Contractor</strong>s & the Law by Robert J. Dickson<br />

70 <strong>Contractor</strong>s & Ethical Contracting by Julia M. I. Holden<br />

74 Safety Report by Chris Ross<br />

78 WorkSafe by Matthew Fagnani<br />

92 Member News<br />

Correction: Christine M. West, <strong>The</strong>BusinessMD, is working on her PhD, thus the required designation of PhD-c.<br />

<strong>The</strong> <strong>Alaska</strong> <strong>Contractor</strong> is published by AQP <strong>Publishing</strong> <strong>Inc</strong>. for the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong>. Contents of the magazine are not necessarily endorsed by AGC of <strong>Alaska</strong> or AQP <strong>Publishing</strong> <strong>Inc</strong>. All rights reserved.<br />

Copyright 2010 by the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong>. For information about articles in this edition or for permission to reproduce any portion of it, contact AQP <strong>Publishing</strong> <strong>Inc</strong>.<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 3

Note: Winning Bids and<br />

Construction Activity<br />

1) Source from projects advertised<br />

in the AGC of <strong>Alaska</strong> Bulletin<br />

2) Calculations based<br />

on date of bid<br />

3) Supply/Service; Non-Construction<br />

bid results are not always<br />

advertised in the bulletin<br />

4) RFP results are not always<br />

advertised in the bulletin<br />

ArcTIc & WESTErn<br />

KIPNUK AIRPORT RELOC PHS II<br />

$13,477,354<br />

Knik Construction Co. <strong>Inc</strong>.<br />

NULATO AIRPORT IMPROVEMENTS<br />

$5,903,129<br />

Brice <strong>Inc</strong>.<br />

NAPASKIAK TEACHER HOUSING<br />

$1,976,310<br />

Bethel Services <strong>Inc</strong>.<br />

KING COVE AIRPORT FENCING<br />

$1,395,100<br />

D & L Construction Co. <strong>Inc</strong>.<br />

ATQASUK FIRE STATION FLOOR<br />

REPLACE<br />

$627,000<br />

Concor Construction <strong>Inc</strong>.<br />

InTErIor<br />

EIELSON FALL PROTECTION<br />

$10,000,000<br />

Weldin Construction <strong>Inc</strong>.<br />

NORTH POLE SEWER LIFT<br />

STATION REHAB<br />

$3,167,000<br />

Great Northwest <strong>Inc</strong>.<br />

DELTA HS BIOMASS HEATING SYSTEM<br />

$2,111,000<br />

Richard Stanton Construction <strong>Inc</strong>.<br />

FBKS UAF SKARLAND HALL SHOWER<br />

REPAIRS<br />

$1,598,000<br />

Richard Stanton Construction <strong>Inc</strong>.<br />

FBKS RESEARCH<br />

HEADHOUSE CONSTRUCT<br />

$1,210,593<br />

<strong>Alaska</strong> Commercial Construction<br />

COPPER CENTER SINGLE<br />

FAMILY HOMES<br />

$789,000<br />

W M Construction LLC<br />

SoUTHcEnTrAL<br />

ANCH 40TH AVENUE EXTENSION<br />

$9,070,013<br />

Pruhs Corporation<br />

MAT-SU SAFETY/<br />

SECURITY UPGRADES<br />

$4,940,000<br />

ATS <strong>Inc</strong>.<br />

ANCH 88TH AVE UPGRADES<br />

$3,037,097<br />

Roger Hickel Contracting <strong>Inc</strong>.<br />

EAGLE RIVER CIVIL/INFRASTRUCTURE<br />

$2,483,404<br />

Granite Construction Co.<br />

ANCH VAN BUREN ST/48TH AVE<br />

$ 2,179,798<br />

Southcentral Construction <strong>Inc</strong>.<br />

KODIAK CHEMICAL STORAGE BLDG<br />

$1,755,000<br />

Jay-Brant General <strong>Contractor</strong>s<br />

ANCH INDEPENDENCE DRIVE<br />

UPGRADE/EXT PHS I<br />

$1,468,387<br />

Southcentral Construction <strong>Inc</strong>.<br />

HOPE PORCUPINE CAMPGROUND<br />

RECONST<br />

$1,190,834<br />

Janssen Contracting <strong>Inc</strong>.<br />

ANCH SAND LAKE ROAD RECLAMATION<br />

$1,188,852<br />

Granite Construction Co.<br />

KODIAK ROOF REPLACE/LIBRARY<br />

PAINTING<br />

$1,043,400<br />

Brechan Enterprises <strong>Inc</strong>.<br />

MAT-SU BRIDGE REPLACEMENT<br />

$979,500<br />

Swalling Construction Co. <strong>Inc</strong>.<br />

4 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

ANCH PROVIDENCE/<br />

SPIRIT WAY SIGNAL<br />

$966,899<br />

Ancor <strong>Inc</strong>.<br />

ANCH S GAMBELL ST DRAINAGE<br />

$893,853<br />

Bristol Design Build Services LLC<br />

SoUTHEAST<br />

CORDOVA CENTER<br />

CONSTRUCT PHASE 1<br />

$8,305,653<br />

Dokoozian Construction LLC<br />

JUNEAU PORT CUSTOM/VISTOR CTR<br />

CONSTRUCT<br />

$8,039,869<br />

North Pacific Erectors<br />

SHAKWAK HWY SURFACE TREATMENT<br />

$5,862,520<br />

Yukon Engineering Services<br />

PETERSBURG FIRE/EMS<br />

FACILITY PHS II<br />

$4,222,400<br />

McGraw’s Custom Construction<br />

JUNEAU BRH MEDICAL EAST WING<br />

RENO<br />

$3,420,500<br />

McGraw’s Custom Construction<br />

KAKE JENNY CREEK BRIDGE INSTALL<br />

$3,088,458<br />

Southeast Road Builders<br />

KETCHIKAN RESEARCH FACILITY<br />

$2,650,000<br />

BAM LLC<br />

HAINES CHILKOOT DOCK<br />

IMPROVEMENTS<br />

$1,886,697<br />

Southeast Road Builders<br />

JUNEAU GLACIER SPUR RD REHAB<br />

$1,135,309<br />

Secon<br />

CRAIG PORT SAINT<br />

NICHOLAS ROAD PAVING<br />

$1,002,500<br />

Bicknell Construction <strong>Inc</strong>.<br />

OUZINKIE DOCK DEMOLITION<br />

$806,600<br />

Pacific Pile & Marine LP<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 5

$650,000,000<br />

$600,000,000<br />

$550,000,000<br />

$500,000,000<br />

$450,000,000<br />

$400,000,000<br />

$350,000,000<br />

$300,000,000<br />

$250,000,000<br />

$200,000,000<br />

$150,000,000<br />

$100,000,000<br />

$50,000,000<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

$450,000,000<br />

$400,000,000<br />

$350,000,000<br />

$300,000,000<br />

$250,000,000<br />

$200,000,000<br />

$150,000,000<br />

$100,000,000<br />

$50,000,000<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

$1,200,000,000<br />

$1,050,000,000<br />

$900,000,000<br />

$750,000,000<br />

$600,000,000<br />

$450,000,000<br />

$300,000,000<br />

$150,000,000<br />

2006<br />

2007<br />

2008<br />

2009<br />

2010<br />

$-0<br />

$-0<br />

$-0<br />

highway<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

building<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

annual<br />

TRENDS<br />

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC<br />

6 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

PrEsiDEnt’s MEssagE<br />

It’s Time to Walk the Talk<br />

I<br />

am using this venue for personal reasons as I am writing<br />

this with a heavy and troubled heart. In the past seven<br />

months fi ve people I knew well have been lost due to<br />

accidents. <strong>The</strong>se people were not only business associates,<br />

I considered them friends. As most of you <strong>Alaska</strong>ns well<br />

know, friends are an integral part of our livelihood.<br />

Jim Bowles with Conoco Phillips was not a typical president<br />

of an oil company. He was very down to earth and<br />

treated all people equally. It was easy to see that he did<br />

indeed have that “<strong>Alaska</strong>n Spirit.”<br />

Bill Michel – this guy, he was amazing. He was a bush<br />

pilot, but not your ordinary bush pilot. If you needed<br />

anything anywhere, he’d fi gure it out. If there wasn’t a safe<br />

place to land, he’d build it. He provided transportation to<br />

meet the demand for food, fuel, and cargo. He didn’t take<br />

short cuts; he took the time to ensure things<br />

were done right the fi rst time – safely and<br />

effi ciently.<br />

John Eshleman owned Steppers<br />

Construction. He was my competitor and<br />

my friend. He was a standup guy who will<br />

be truly missed. His participation in the Wolf<br />

Lake Airport is an example of the kind of<br />

man he was. He joined with other community<br />

members in the effort to develop this<br />

airport over the past 26 years. Up to 2008 all<br />

improvements and developments were done<br />

by and at the sole expense of the developers.<br />

No funds were received from the Mat-Su<br />

Borough, the State of <strong>Alaska</strong>, or the FAA for development.<br />

He used his own money, time and equipment to build and<br />

maintain a 3,800-foot paved runway. He was integral in<br />

helping the Wolf Lake community come together.<br />

Paul Quartly was not rough around the edges; he was<br />

rugged around the edges. He came to <strong>Alaska</strong> in 1975 working<br />

as a heavy equipment operator. Not many people know this,<br />

but he was run over by a log loader as a young man. This<br />

is something that would have killed or crippled most men.<br />

Not Paul - he was broken but he got back to work in a year’s<br />

time. And work he did. He was the Jack of All Trades and<br />

Master of Most. His communication skills would not pass<br />

the HR political correctness guide within the current work<br />

environment. His brutal truth would school the newbies as<br />

well as the experienced men on any crew. If you watched<br />

and listened, you learned. If he was assigned a task, he got<br />

it done on time and better than expected. He was my uncle,<br />

and I will miss him greatly.<br />

We need to<br />

help guide our<br />

great state to<br />

become what our<br />

forefathers had<br />

visions of –<br />

or better.<br />

DAV E CR U Z<br />

President<br />

Ted Stevens. I don’t think I can say anything that hasn’t<br />

already been said about Uncle Ted. He was my Scout Master<br />

in the Cub Scouts. And, I am proud to say that I was one of<br />

Ted’s Tigers.<br />

Each of these people leaves an individual void. However,<br />

combined that void is frightening.<br />

<strong>The</strong>ir untimely deaths make me think about their<br />

accomplishments.<br />

Each had faced unique challenges and great opportunities<br />

not given to every person. <strong>The</strong>y rose to their challenges and<br />

seized opportunities presented. <strong>The</strong>y made things happen.<br />

<strong>The</strong>y listened to the people around them. <strong>The</strong>y helped guide<br />

the younger generations as well as their peers – no matter<br />

their political point of view – mentoring them to recognize and<br />

seize their own opportunities. <strong>The</strong>y loved their families, and<br />

friends as well as their work and the people<br />

they represented. Whether as a senator for<br />

our state or the folks who depended on them<br />

to lead their companies into the future. <strong>The</strong>y<br />

cared. <strong>The</strong>y cared beyond their own worries<br />

and wanted to make our lives better.<br />

I’m afraid that we may never see the<br />

like of these folks again. I’m hoping to see<br />

better.<br />

Let’s hope that with our experience,<br />

we will help guide the next generation to<br />

become better than the last generation. Isn’t<br />

that the basic measure of success? <strong>The</strong> next<br />

generation learns from the prior and does at<br />

least one step better.<br />

So, current leaders of this state, it’s time that we, as a<br />

community, step up to the plate and learn from each of<br />

these gentlemen.<br />

We need to come together to put a stop to the palm up<br />

attitude that seems to be running rampant throughout our<br />

state and nation.<br />

We need to step up, as each of these people did, within our<br />

communities, groups or as individuals and walk the talk.<br />

We need to help guide our great state to become what<br />

our forefathers had visions of – or better.<br />

We need to regenerate that Can Do attitude that no<br />

matter how many failures there are, we pull ourselves up by<br />

the bootstraps and keep on keeping on until the goal is met.<br />

And then, together, set the next goal.<br />

We need to know when to throw the political b.s. to the<br />

side and get things done. Get it done right for the people of<br />

<strong>Alaska</strong>.<br />

8 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

EXECUtiVE DirECtor’s MEssagE<br />

Fiscal Certainty or an<br />

Adjustable Rate Mortgage?<br />

A<br />

few years ago, while the housing market boomed,<br />

people were sold adjustable-rate mortgages at<br />

“teaser” interest rates that ballooned after a few<br />

years. Houses were being fi nanced like some furniture<br />

store marketing ploys – “No payments for two years” – with<br />

promises to refi nance as the value goes up and interest<br />

rates go down.<br />

Unfortunately, the rates of those ARMs jumped at the<br />

same time that overbuilding softened the housing market,<br />

foreclosures skyrocketed and banks fl oundered, resulting<br />

in the bankruptcy or sale of many fi nancial institutions.<br />

Good sense dictates to you that one does not agree<br />

to unpredictable fi nancial terms. Imagine what it would<br />

be like if ARMs were the only kind available. What if your<br />

mortgage did not include information on when the interest<br />

rate would balloon, or what the new rate would be?<br />

What if lenders could change the terms of your loan<br />

anytime they wanted? That would make borrowing much<br />

riskier than it already is. While that proposition sounds<br />

absurd, it is not unlike what the North Slope producers<br />

face when they consider bidding their company’s future on<br />

the Gas Line Open Season.<br />

Why? To answer that question, it’s important to understand<br />

how pipelines are built and just who bears the risk.<br />

Much like any other project, a pipeline owner must line up<br />

adequate fi nancing to build the pipeline. Pipeline fi nancing,<br />

like most other projects, comes from the private fi nancial<br />

institutions that perform their due diligence, evaluate the<br />

risk in lending and set the terms. <strong>The</strong> higher the risk of not<br />

being paid back, the more costly the fi nancing; the lower<br />

the risk, the cheaper the fi nancing.<br />

For pipeline projects, lenders look to see if the pipeline<br />

owner has fi rm transportation commitments from gas<br />

shippers – in this case, the producers. Have gas producers<br />

committed to ship a suffi cient quantity of gas to allow the<br />

fi nancing to be paid back? <strong>The</strong> banks look to the producers<br />

and not the pipeline company to guarantee the debt. <strong>The</strong><br />

reason these are called fi rm transportation commitments<br />

is that the producers agree to pay the transportation cost<br />

of the gas through the pipeline regardless of the price of<br />

gas on the other end. By doing so, the producers agree<br />

to pay for the debt and operation of the pipeline whether<br />

they ship all or any of their gas. <strong>The</strong> fi rm commitment or<br />

JO H N MA CKI N N O N<br />

Executive Director<br />

risk taken by the producers gives the banks the confi dence<br />

they will be paid back and allows the pipeline company to<br />

leverage the producer’s risk to obtain adequate funding to<br />

construct the pipeline. <strong>The</strong> pipeline company passes most<br />

of the risk on to the shippers.<br />

So why is fi scal certainty so important? On a project<br />

this size ($30 billion to $40 billion) the fi rm transportation<br />

commitments are long-term and substantial. Because of<br />

the magnitude of the risks associated with a project of this<br />

size – over $100 billion of fi nancial commitments, potential<br />

construction delays and cost escalations (TAPS grew<br />

10-fold) and the risks associated with the commodity price<br />

of the gas – more than once in the last twenty years, the<br />

wholesale price of natural gas has fl uctuated up and down<br />

between $2 and $14 – fi rm fi scal terms that are predictable<br />

and durable are necessary. <strong>The</strong> state and the shipper need<br />

to agree on fi scal terms – how the revenue from the gas<br />

going through the pipeline is going to be shared.<br />

What the state is asking of the producers is little<br />

different from an adjustable rate mortgage where the<br />

terms and conditions aren’t known. Through the Open<br />

Season process, the North Slope producers must guarantee<br />

to fi nance North America’s single largest construction<br />

project and the single-most important project to the<br />

economic future of <strong>Alaska</strong>. <strong>The</strong> producers can manage the<br />

risk associated with their ability to supply the gas; they<br />

accept the risk associated with the commodity price of<br />

gas, confi dent in the increasing curve of U.S. natural gas<br />

consumption. But the unknown is what the state will do<br />

with industry taxes in the next few decades.<br />

In just 10 years, through statute and regulation, our<br />

politicians have increased oil and gas taxes fi ve times<br />

that I can think of, and there are probably more I don’t<br />

know about. One increase was even retroactive! That is<br />

a signifi cant increase every two years to prop up government<br />

spending!<br />

Now think about that adjustable rate mortgage.<br />

Would you be willing to invest your money in the pipeline<br />

under these conditions? <strong>The</strong> Permanent Fund sure<br />

wouldn’t. <strong>The</strong> producers of <strong>Alaska</strong>’s gas need fi scal<br />

certainty or they can’t make a reasoned investment decision<br />

and without reasoned investment decisions, <strong>Alaska</strong>ns<br />

don’t have a gas pipeline.<br />

10 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

Bonding Proposition B<br />

Nearly $400 million to renovate and build projects around<br />

the state is up to the voters in November<br />

By J. ma r K Du D i C K<br />

In the waning moments of the 2010<br />

session, state legislators came up<br />

with a bond issue to fi nance nearly<br />

$400 million to renovate and construct<br />

buildings throughout the state.<br />

<strong>The</strong> legislature passed and the<br />

governor signed the bill, but the voters<br />

will have the fi nal “yea” or “nay” on the<br />

Nov. 2, 2010, ballot under the heading<br />

of Bonding Proposition B: “Shall the<br />

State of <strong>Alaska</strong> issue its general obligation<br />

bonds in the principal amount<br />

of not more than $397,200,000 for the<br />

purpose of design and construction<br />

of library, education, and educational<br />

research facilities?”<br />

With many schools at or over<br />

capacity, educators view the bond<br />

as essential to the state’s future. In<br />

fact, six of the top-10 schools on<br />

the state’s renovation list are in the<br />

Lower Kuskokwim School District –<br />

two of which could benefi t from the<br />

bond, Kipnuk K-12 and Kwigillingok<br />

K-12, said Gary Baldwin, district<br />

superintendent.<br />

Chief Paul Memorial School in<br />

Kipnuk, for example, would receive<br />

$49.9 million to expand and renovate<br />

the K-12 school with 200 students.<br />

“We haven’t really added anything<br />

since the ‘80s,” said site administrator<br />

Jami Whedbee. “What we do have may<br />

help students go out in the world. But<br />

if we don’t stay cutting edge, we are<br />

robbing our students of their future,<br />

and that’s not fair.”<br />

Overall, the district is operating at<br />

200 percent above capacity, and most<br />

of the schools are “bare bones” at best,<br />

said Baldwin. <strong>The</strong> 30-year district<br />

resident described the evolution as:<br />

“You build a new school with plenty<br />

of specialized space, but as the school<br />

grows you do what you have to do to<br />

accommodate. You replace the library<br />

with a classroom. <strong>The</strong> shop becomes<br />

a classroom. Before you know it, the<br />

books sit in a corner and there’s no<br />

shop class anymore. In the end, it<br />

affects the kids.”<br />

12 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

An artist’s rendering of a KPC’s proposed tech center in Soldotna.<br />

Prop B will affect the state’s<br />

construction industry, as well, said John<br />

MacKinnon, the Associated General<br />

<strong>Contractor</strong>s of <strong>Alaska</strong>’s executive<br />

director. After consulting national and<br />

local trends and statistics, MacKinnon<br />

estimated that “the $400 million of<br />

projects in the bond issue should yield<br />

about 933 construction jobs a year for<br />

three years and 900 to 1,200 indirect<br />

and induced jobs.”<br />

Though state legislators agree on<br />

the need for renovation and new jobs,<br />

some contest the wisdom of borrowing<br />

money to fi nance the projects, especially<br />

when oil revenues are declining,<br />

warned Rep. Les Gara, D-Anchorage<br />

in the Juneau Empire.<br />

But the low interest rates are subsidized<br />

for these types of bonds, countered<br />

Sen. Bert Stedman, R-Sitka, co-chair<br />

of the Senate Finance Committee, in<br />

Details of Bonding<br />

Proposition B include:<br />

• $60 million for a new UAA<br />

sports arena in Anchorage<br />

• $128.5 million for schools in<br />

western <strong>Alaska</strong><br />

• $18.5 million for a state library,<br />

archives and museum in<br />

Juneau<br />

• $40 million for Dept. of Fish<br />

and Game research building in<br />

Kodiak<br />

• $23.5 million for a<br />

UAA-Mat-Su arts and learning<br />

center in Wasilla<br />

• $88 million for a UAF sciences<br />

classroom and lab in Fairbanks<br />

• $30.5 million for Kenai<br />

Peninsula College student<br />

housing and Tech-ed center<br />

• $5 million for Prince William<br />

Sound Community College<br />

campus renovations in Valdez<br />

• $3.2 million for Klawock Voc-ed<br />

center<br />

• $20 million for Mount<br />

Edgecumbe HS pool in Sitka<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 13

An artist’s rendering of UAA’s proposed sports complex in Anchorage.<br />

the same Juneau Empire article. Prop<br />

B would take advantage of a federal<br />

subsidy – Buy America Bonds.<br />

“<strong>The</strong>re’s some extremely low<br />

interest rates, with the Obama administration<br />

paying part of the interestrate<br />

costs.”<br />

With $12 billion in a savings account,<br />

not counting the permanent fund, the<br />

state could easily afford bond interest<br />

over the years, Stedman added.<br />

<strong>The</strong> University of <strong>Alaska</strong> system<br />

would benefi t considerably to the tune<br />

of $207 million, including a sports<br />

complex at UAA and a life science<br />

classroom and lab at UAF.<br />

<strong>The</strong> Wells Fargo Sports Complex,<br />

for example, is more than 30 years old<br />

and barely meets the university’s need<br />

for academic achievement, student<br />

recreation, varsity practices and spectator<br />

enjoyment, said UAA Alumni<br />

board director Lori Davey.<br />

“<strong>The</strong> new center is vital for<br />

Anchorage residents, UAA athletes<br />

and UAA students.”<br />

In UAF’s proposal to state legislators,<br />

Chancellor Brian Rogers echoed<br />

sentiments similar to other state<br />

educators.<br />

“Enrollment and research in this<br />

area has been surging, but we’ve packed<br />

too many people into too-small classrooms<br />

and laboratories for too long<br />

already,” he wrote of UAF, which ranks<br />

in the top 100 of the nearly 700 U.S.<br />

universities that conduct research.<br />

“Our students are not being served<br />

when we try to teach them in antiquated<br />

biology laboratories. Our state<br />

is not being served when we don’t have<br />

the proper space to conduct biological<br />

research in areas of vital importance<br />

to <strong>Alaska</strong>ns, from avian infl uenza to<br />

sudden infant death syndrome, and<br />

from climate change to emerging<br />

diseases.”<br />

Aside from the teaching and<br />

research advantages, according a recent<br />

McDowell Group study, every $1<br />

million invested by the state in university<br />

research creates 149 jobs with $4.8<br />

million in payroll and another $1.5 to<br />

$2 million in purchases.<br />

In the end, all of these new buildings<br />

and renovations are “needed now<br />

– for UAF, for UA, for all of <strong>Alaska</strong>,”<br />

Rogers concluded.<br />

An artist’s rendering of UAA-Mat-Su’s proposed arts and learning center in Wasilla.<br />

14 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

Scholarship testimonials<br />

How to<br />

apply<br />

Ryan Hammel<br />

In fall 2010, I will be returning to Gonzaga University<br />

in Spokane, WA, for my fi nal year of undergraduate<br />

classes. I greatly appreciate this generous scholarship from<br />

the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong>. This award<br />

helps to make it possible for me to fi nish my college career.<br />

As a civil engineering student, with a focus in structural<br />

design, I hope to eventually return to <strong>Alaska</strong> and enter the construction<br />

industry. Thanks again to AGC for helping to make this goal a reality.<br />

Pete Clements<br />

<strong>The</strong> decision to return to college and work toward<br />

my goals has been challenging in many ways. With the<br />

help of AGC, I was honored to receive a scholarship to<br />

help ease the fi nancial burden synonymous with higher<br />

education. <strong>The</strong> Construction Management Program at<br />

UAA is providing me with the knowledge and skills for<br />

success in the construction industry.<br />

Jacob Mathiesen<br />

As far back as I can remember, I’ve enjoyed<br />

attending the AGC Family Fun Night and I still fi nd it<br />

irresistible to cut the rigid insulation with a plastic saw!<br />

I am in my second year in the Construction Management<br />

Program at UAA. When I graduate, I will be the<br />

third generation of my family involved in construction<br />

in <strong>Alaska</strong>. I look forward to building <strong>Alaska</strong> along with AGC.<br />

Lyle Axelarris<br />

After working as a carpenter for several AGC of<br />

<strong>Alaska</strong> contractors in Fairbanks, I decided to study civil<br />

engineering at University of <strong>Alaska</strong> Fairbanks. Working<br />

on a civil engineering degree and raising a family is<br />

tough work. But AGC’s assistance has made it easier for<br />

me to focus on my studies and receive a 4.0 GPA. I am<br />

very excited to continue working in <strong>Alaska</strong>’s construction industry after I<br />

graduate. Thank you, AGC!<br />

<strong>The</strong> Construction Education Foundation is involved in all levels of construction education in <strong>Alaska</strong> – from<br />

students in secondary schools to older university students, to students looking to change careers or to take<br />

short courses to upgrade their skills. <strong>The</strong> foundation’s goal is to provide the next generation of construction<br />

workers in <strong>Alaska</strong>. To that end, CEF works with the Associated General <strong>Contractor</strong>s of <strong>Alaska</strong> to offer scholarships<br />

to students taking (or will be taking) classes toward a degree that will support the state’s construction<br />

industry. To apply, download the forms at www.alaskacef.org/scholarships.html and return by deadline to the<br />

CEF offi ce at 8005 Schoon St., Anchorage, AK 99518. For more information, call (907) 770-1826.

16 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 17

WHY JOIN AGC OF ALASKA?<br />

Leadership –<br />

How AGC pulls the parties together<br />

One of the benefi ts of AGC of <strong>Alaska</strong> membership<br />

that is very hard to quantify, yet which our members<br />

benefi t from, is leadership to effect positive<br />

change for the construction industry. By offering vision and<br />

bringing stakeholders together to solve industry problems,<br />

AGC allows members to go about their business doing what<br />

they do best – building <strong>Alaska</strong>.<br />

By the time I came on board seven years ago as membership<br />

coordinator, AGC of America and <strong>Alaska</strong> were already<br />

involved with the looming crisis of an aging workforce and<br />

lack of interested and qualifi ed youth to replace retiring<br />

baby-boomers. AGC of America had collected and tracked<br />

the necessary data to identify the problem and then set out<br />

to tackle it. First, they created “Build-Up!” and “On-Site!”<br />

programs to introduce construction to elementary and<br />

secondary classrooms in a<br />

fun and engaging way using<br />

volunteer members of the<br />

construction industry. Next,<br />

they promoted the National<br />

Center of Construction<br />

Education and Research<br />

curriculum to provide<br />

national standards and certifi<br />

cations for skilled trade<br />

education.<br />

AGC of <strong>Alaska</strong>’s former<br />

executive and training directors<br />

also tirelessly educated<br />

and lobbied legislators and<br />

school districts around the<br />

state to re-introduce and<br />

promote vocational education in the schools to motivate<br />

students to choose construction as a career path.<br />

To that end, AGC brought several members interested<br />

in reversing this downward trend together with representatives<br />

of organized labor unions to create the Construction<br />

Industry Progress Fund. This fund would use money from<br />

the negotiated “nickel-an-hour” employer contributions to<br />

the Welfare and Benefi ts packages. Next, AGC and the CIPF<br />

Board aggressively set out to change the negative image of<br />

the construction industry by creating cool TV commercials<br />

targeted at the “infl uencers” - parents and school counselors<br />

- of their youthful market.<br />

BA R BA R A RO W L A N D<br />

Membership Coordinator<br />

On another front, AGC’s Education Committee had<br />

long been giving university scholarships in Anchorage and<br />

Fairbanks with proceeds from the summer golf tournaments.<br />

But many students went out of state for construction<br />

management degrees and didn’t return, so the committee<br />

lobbied the University of <strong>Alaska</strong> Anchorage to introduce<br />

a Construction Management program. After they found a<br />

champion at UAA to anchor the program and raised a great<br />

deal of private money to fund it, a two-year degree program<br />

was launched! By the time the fi rst set of students neared<br />

graduation, a four-year degree curriculum was ready to go.<br />

And similar coursework soon opened at the University of<br />

<strong>Alaska</strong> Fairbanks, as well.<br />

As AGC was focusing on construction education and<br />

training, and with other new programs to launch, the<br />

Construction Education<br />

Foundation was formed<br />

to handle this huge multifaceted<br />

workforce development<br />

effort. Receiving<br />

grants from the Denali<br />

Commission and the <strong>Alaska</strong><br />

State Legislature, the CEF<br />

has worked closely with<br />

school districts throughout<br />

the state to create the <strong>Alaska</strong><br />

Construction Academies to<br />

develop a qualifi ed workforce<br />

for the next generation.<br />

With cooperation<br />

from the <strong>Alaska</strong> Department<br />

of Labor and such<br />

supporters as construction companies and labor unions,<br />

CEF has sponsored the successful Construction Career Days<br />

for high school students and invitational “hiring events” for<br />

the high school students who’ve shown serious interest and<br />

potential.<br />

We’ve come a very long way to insure a qualifi ed workforce<br />

for the years to come.<br />

Another leadership example involved the <strong>Alaska</strong><br />

Construction Industry Substance Abuse Program, also<br />

known as the AK Clean Card Program. Previously, contractors<br />

would plan signifi cantly ahead in hiring workers to allow<br />

time for pre-employment test results. In cases of hiring many<br />

18 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

new workers for weekend-closures<br />

of road intersections, for example,<br />

contractors spent a great deal of time<br />

and money on workers for only two to<br />

three days. Employees suffered terrible<br />

inefficiencies, as well, since many of<br />

them worked for multiple companies<br />

during a construction season and<br />

underwent a drug test each time they<br />

were dispatched and then lost wages<br />

waiting for the results.<br />

Listening to concerns of contractors<br />

and labor representatives, AGC<br />

brought the various parties together<br />

to create a workable program. Experts<br />

on drug-testing and a program “guru”<br />

from Spokane, WA rounded out the<br />

committee, and after about a year<br />

formed the AK Clean Card Program.<br />

As an employer-sponsored program<br />

endorsed by most of the local trade<br />

unions, it’s become a “win-win” solution<br />

for both parties.<br />

Yet another example is the certification<br />

program for handling erosion<br />

and storm water on construction<br />

sites, Certified Erosion and Sediment<br />

Control Lead and Storm Water Pollution<br />

Prevention Plan. When the Environmental<br />

Protection Agency began<br />

threatening contractors and owners for<br />

Clean Water Act violations a few years<br />

ago, AGC called in the Department of<br />

Transportation, the U.S. Army Corps of<br />

Engineers, the Department of Environmental<br />

Conservation, the Municipality<br />

of Anchorage, the <strong>Alaska</strong> Railroad and<br />

the Department of Natural Resources<br />

to determine a proper response to the<br />

EPA’s new enforcement efforts. Three<br />

years ago the CESCL certification<br />

course was created, instructors were<br />

certified to teach and AGC immediately<br />

began sponsoring classes. Soon<br />

thereafter the SWPPP class followed.<br />

Although open to anyone, AGC<br />

members receive significant discounts<br />

on these courses.<br />

I do not have the space to share<br />

all the leadership examples, but<br />

perhaps you see the point with these<br />

I’ve shared. AGC works very hard and<br />

effectively every day to connect the<br />

dots and act on behalf of the construction<br />

industry. It is unlikely you can<br />

put a dollar value on most of these<br />

membership benefits, but you know<br />

they are indeed invaluable.<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 19

<strong>Alaska</strong> Construction Academies<br />

Student survey yields positive results<br />

By Kat h l e e n Ca s t l e<br />

aKCa ex e C u t i v e Di r e C t o r<br />

Construction Education<br />

To make sure the <strong>Alaska</strong> Construction Academies are<br />

providing the best job training for high school students,<br />

the Construction Education Foundation, <strong>Inc</strong>. contracted<br />

LifeTrack Services <strong>Inc</strong>. to survey second-semester seniors<br />

registered in construction-related classes.<br />

<strong>The</strong> AkCA staff designed 17 questions to determine:<br />

• the student’s preliminary plans for the future<br />

• will the student choose a career in construction<br />

• will the student remain in <strong>Alaska</strong><br />

• how the student rates the construction classes<br />

• what/who influenced the student’s choice of classes<br />

What area(s) do you plan to pursue immediately<br />

after high school?<br />

In 2009-2010, more than 4,000 high- and middle-school<br />

students attended AkCA construction-related classes in<br />

Fairbanks, Mat-Su, Anchorage, Kenai Peninsula, Juneau and<br />

Ketchikan. Of those students, 260 second-semester seniors<br />

completed the survey in May 2010.<br />

Results indicate that the academies are following the<br />

right track. More than 80 percent of the seniors rated the<br />

classes’ influence on their self-confidence from “some” to<br />

“powerful,” and 90 percent landed in the same rating for<br />

helping to prepare for a career. <strong>The</strong> classes also increased the<br />

desire of 78 percent of the respondents to attend school.<br />

Immediately after high school you plan to . . .<br />

Other survey outcomes reveal:<br />

• 66 percent are “likely” to “absolutely likely” to choose a<br />

construction career<br />

• 75 percent are aware of construction jobs available after<br />

high school<br />

• 71 percent plan a career in <strong>Alaska</strong><br />

20 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

How would you rate your construction trade classes<br />

in preparing you for a career?<br />

As far as the biggest influence on their post-high-school<br />

plans, students indicated:<br />

• 43 percent – parents<br />

• 20 percent – friends<br />

• 12 percent – teachers<br />

<strong>Contractor</strong>s frequently emphasize nationally recognized<br />

certifications to increase the potential for landing an entrylevel<br />

job.<br />

Thanks to the academies’ classes, students received<br />

certificates in:<br />

• 29 percent – National Registry for the National Center for<br />

Construction Education and Research<br />

• 13 percent – an OSHA 10 class<br />

• 13 percent – HILTI Powder Actuated<br />

• 9 percent – First Aid/CPR<br />

• 8 percent – Forklift Driving<br />

To determine the program’s overall influence on their life<br />

paths, the Construction Education Foundation will survey<br />

these same students two and five years after they graduate.<br />

<strong>The</strong> CEF funds AkCA through grants from the <strong>Alaska</strong><br />

Department of Labor and Workforce Development and<br />

the <strong>Alaska</strong> Department of<br />

Commerce, Community and<br />

Economic Development. In<br />

late spring 2010, the Denali<br />

Commission also supported<br />

classes in the Bethel, Nome<br />

and Kodiak Regions.<br />

View the LifeTrack survey<br />

results at www.alaskaca.<br />

org. If you’d like to hire an<br />

AkCA graduate, contact<br />

your local <strong>Alaska</strong> Construction<br />

Academy or call AkCA<br />

Executive Director, Kathleen<br />

Castle at (907) 222-0999.<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 21

MEMBER PROFILE<br />

CRUZ CONSTRUCTION INC. By tr a C y Ka ly t i a K<br />

Cruz Control<br />

Palmer contractor acquires equipment,<br />

employees to accommodate almost any project<br />

F<br />

Four years ago, Cruz Construction fi nally<br />

found a way to put out fi res that for 40 years<br />

had been seething and moving underground<br />

near the abandoned Slipper Lake coal mines.<br />

Water couldn’t douse those fi res; they burned<br />

so hot the fl ames actually fed on oxygen molecules<br />

in the water. Workers instead dug up and<br />

cooled 81,000 dump-truck loads of smoldering<br />

coal waste, smothering the blaze.<br />

“<strong>The</strong>re would be no snow in that area, it<br />

was that warm on the surface,” said owner<br />

Dave Cruz about the subterranean confl agration.<br />

“It always had the potential for coming to<br />

the surface.”<br />

<strong>The</strong> coal fi re is just one example of the inge-<br />

nuity and drive the company has shown in its<br />

three decades of operation.<br />

“Any job, if you enjoy it, is not work,” Cruz,<br />

52, explained as his motivation for launching<br />

the business. “Getting to go out and do these<br />

projects, I don’t consider it work.”<br />

Hauling rig components on an exploration ice road.<br />

<strong>The</strong> endeavor that started with a sole employee<br />

now boasts 150 during peak season, with a core of 50<br />

year-round. Cruz’s partner and wife of 27 years, Dana,<br />

manages the company’s fi nances. <strong>The</strong>ir daughter,<br />

Heavy equipment hauls gravel from a barge on the Yukon River to<br />

Cruz Construction’s nearby worksite at the Grayling Airport.<br />

22 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010<br />

ph oTo s: co u R T e sT y o f cR u z co n sT Ru c T i o n in c.<br />

ph oTo: © sTephen no w e R s/al a s K a ph o To llc

Cruz Crusher Spread Operation<br />

Arianna, assists with takeoffs, bidding<br />

and logistics. <strong>The</strong>ir son, Ben, shares his<br />

father’s passion for construction but<br />

works as a certified crane operator for<br />

North Star Equipment.<br />

Able employees such as Jeff Miller,<br />

general manager, and Kevin Weiss,<br />

director of marine operations, anchor<br />

the business, Cruz said.<br />

“<strong>The</strong> two of them have been very<br />

instrumental in both those companies<br />

succeeding. Both of them move<br />

forward on their own initiative and<br />

they’re good at it.”<br />

<strong>The</strong> company originally concentrated<br />

on forestry-related jobs, such<br />

as building roads and campgrounds,<br />

but then ventured into land clearing,<br />

horizontal directional drilling and<br />

such heavy civil construction as roads,<br />

bridges, airports and runways, pipelines,<br />

excavation, erosion control and pads.<br />

“We are like the Marines because<br />

we do more with less, for example<br />

some of our competitors support their<br />

projects with twice the overhead staff,”<br />

he said.<br />

One of its first larger tasks came in<br />

1994 — the $1 million Palmer Industrial<br />

Park Phase 2.<br />

Five years later, the business landed<br />

a $2.2 million Chena River dredging<br />

undertaking in Fairbanks. That twowinter<br />

performance earned the<br />

Commander’s Medallion from the U.S.<br />

Army Corps of Engineers.<br />

Flood damage from a Mount Redoubt<br />

eruption created the next assignment<br />

– replacing 2,100 feet of 20-inch oil<br />

pipeline beneath the Drift River. That<br />

pursuit, combined with Cruz’s construction<br />

of Northern Intertie ice roads, won<br />

the Associated General <strong>Contractor</strong>s<br />

of <strong>Alaska</strong>’s Excellence in Construction<br />

Awards for 2002 and 2003.<br />

Next came the challenge of carving<br />

an access road to Teck Cominco’s Pogo<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 23

gold mine near Fairbanks.<br />

“<strong>The</strong>re were steep hills and 14 river<br />

crossings on that 50 miles of ice road,”<br />

Cruz said.<br />

Through the years, Cruz Construction<br />

has built lodgings, shops and<br />

other facilities on the North Slope and<br />

elsewhere in the state for ConocoPhillips,<br />

Chevron, BP, FEX, CH2M Hill,<br />

Anadarko, Pioneer Natural Resources<br />

<strong>Alaska</strong>, ENI, Jacobs Engineering and<br />

Aurora Energy.<br />

<strong>The</strong> general contractor expanded<br />

the scope of services after acquiring<br />

most of Western Geophysical’s equipment,<br />

vehicles and Prudhoe Bay shops,<br />

hoping to massage business from<br />

energy companies exploring in the<br />

NPR-A. That was a big step, Cruz said.<br />

“In oil-field work, the most important<br />

thing you can provide the client<br />

is service. We traditionally like the<br />

remote projects, so we increased the<br />

size of the company to accommodate<br />

the expanded workload, and added to<br />

our fleet of equipment.”<br />

<strong>The</strong>se days, massive tundra vehicles<br />

haul fuel, freight, drill rigs and<br />

other items to arctic work sites. <strong>The</strong><br />

company also builds ice roads and pads<br />

and rapidly sets up camps that feature<br />

maintenance and waste-management<br />

facilities. In the case of Pioneer Natural<br />

Resources <strong>Alaska</strong>, for instance, the outfit<br />

supported drilling a well in Anchor<br />

Point and exploring for oil and gas on<br />

the North Slope.<br />

“He’s a stand-up guy,” said Vance<br />

Hazzard, Pioneer Natural Resources<br />

<strong>Alaska</strong> drilling manager. “One thing<br />

about Dave Cruz is that what he works<br />

on, he delivers. It’s been my experience<br />

that with ice road construction,<br />

rig-site support, campsite and camp<br />

maintenance, he’s done a very good<br />

job of delivering to the customer.”<br />

As example of that “delivery” was a<br />

job for Chevron’s White Hills. For two<br />

consecutive years and 232,000 manhours<br />

without a recordable injury, the<br />

company maintained three main camps,<br />

built a 3,800-foot lighted, manned<br />

airstrip, paved 100 miles of ice road and<br />

erected five 5-acre drilling pads.<br />

“We manifested more than 5,000<br />

loads of freight to and from the project<br />

and handled over 2 million gallons of<br />

fuel without a spill,” Cruz said. Chevron<br />

recognized that accomplishment with<br />

24 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

ph o To s: ©sTephen no w e R s/al a s K a ph oTo llc<br />

Cruz Construction operations at the Franklin Bluffs and Musk Ox<br />

camps March, 2009.<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 25

Workers use a snow blower to clear an ice road.<br />

the Midcontinent Safety Achievement<br />

Award. And <strong>Alaska</strong> Business Monthly<br />

magazine featured Cruz Construction<br />

in its Top Corporate 100 for 2008, 2009<br />

and 2010.<br />

Recent and ongoing<br />

ventures include:<br />

• 28 miles of ice road to the<br />

eastern North Slope’s Badami<br />

unit for CH2M Hill<br />

• an access trail for Usibelli’s<br />

Wishbone Hill area.<br />

• resurfacing the Fort Yukon airport<br />

• new alignment built for the<br />

Grayling airport runway<br />

Because the Grayling airport undertaking<br />

required barging 130,000 yards<br />

of gravel seven miles down river, Cruz<br />

decided to bolster its marine fleet with<br />

a 92-foot tugboat. <strong>The</strong> triple-screw,<br />

1,800-horsepower craft dubbed “Dana<br />

Cruz” features a 45-inch draft good for<br />

river or coastal chores.<br />

“You won’t find a tug in the world<br />

that can do what that tug can do,” Cruz<br />

said. “It allows us to provide marine<br />

services with state-of-the-art equipment<br />

and support.”<br />

A second tug, the “Millie Cruz,” will<br />

join the fleet in April 2011.<br />

Among his many responsibilities,<br />

Cruz is serving a term as AGC of<br />

<strong>Alaska</strong>’s president for 2010. He joined<br />

the group to enhance his company’s<br />

productiveness and later gleaned a<br />

choice nugget of knowledge while<br />

participating in AGC’s training and<br />

political activities.<br />

“Competition is not your enemy,”<br />

Cruz said. “If you all work together<br />

with collective effort, you can get things<br />

done. AGC represents 650 companies.<br />

It has political clout. People listen.”<br />

Tracy Kalytiak is a writer who lives<br />

near Palmer.<br />

26 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

FINANCIAL SERVICES & CONTRACTORS<br />

For <strong>Alaska</strong>’s Economy,<br />

the Future is Now<br />

You’ve heard a lot about the future<br />

of <strong>Alaska</strong>’s economy lately, and I hope<br />

I can add something positive to the<br />

discussion. But before we look ahead,<br />

let’s take a look at the state’s economy<br />

50 years ago. Those of you who were<br />

here, as I was, know that life was good<br />

but much different than today, especially<br />

economics-wise.<br />

In 1960, the state depended on<br />

the federal government for half of<br />

its 90,000 jobs. And those jobs were<br />

extremely seasonal – the number of<br />

private sector summer jobs was double<br />

the amount in the winter. Household<br />

income was 10 percent to 20 percent<br />

below the U.S. average, and the fl edgling<br />

infrastructure was primitive by<br />

today’s standards.<br />

We all know that picture has brightened<br />

considerably. Today, the state<br />

boasts more than 350,000 jobs, income<br />

has risen from $3 billion in 1960 to $24<br />

billion, as has population from 230,<br />

000 to 660,000. So, what happened to<br />

fuel that growth?<br />

We all know the answer to that<br />

one, too. Prudhoe Bay happened.<br />

With the discovery of billions of<br />

barrels of oil on the North Slope in<br />

1967, <strong>Alaska</strong> entered a new era that<br />

signifi cantly and permanently changed<br />

the economy. With oil revenue fl owing<br />

into state coffers (85 percent of general<br />

fund revenue comes from oil), the<br />

economy became a dynamic engine<br />

for accelerated growth and increased<br />

income, with a certain stability, too.<br />

<strong>The</strong> petroleum industry became a<br />

key support in a “three-legged stool”<br />

economy, with federal spending<br />

another. All other basic industries<br />

combined, such as fi shing, tourism<br />

and mining, make up the third.<br />

We’ve been extremely fortunate to<br />

have that underpinning. For 40 years,<br />

we’ve enjoyed unparalleled prosperity<br />

in all corners of the state, in all<br />

sectors of our economy. Construction<br />

workers know that fact more than<br />

most, especially in building the state’s<br />

infrastructure.<br />

It’s a fact of life:<br />

a healthy petroleum<br />

industry is essential<br />

to a healthy <strong>Alaska</strong><br />

economy, which<br />

helps all sectors<br />

thrive, including<br />

the construction<br />

industry.<br />

But things are changing.<br />

<strong>The</strong> easy-to-reach oil is running<br />

out. Production has been declining<br />

for a number of years, a fact masked<br />

by the higher oil prices of recent years.<br />

As far as future investments, petroleum<br />

corporations have taken a waitand-see<br />

attitude due to uncertain<br />

tax structures and fi scal policies. This<br />

scenario isn’t new.<br />

In the 1980s, oil prices dropped<br />

precipitously, which in turn led to<br />

plummeting taxes and royalties from<br />

oil sales. An unprecedented fi scal crisis<br />

followed. That “three-legged stool”<br />

started wobbling uncontrollably and<br />

then thousands of jobs disappeared,<br />

income plunged and the bottom fell<br />

out of the housing market. Nearly 12<br />

percent of state’s population, more<br />

than 60,000 people, headed south.<br />

No one expects a repeat of those<br />

dramatic events but, if we don’t quickly<br />

By Be t s y la w e r<br />

vi C e Ch a i r<br />

Fi r s t na t i o n a l Ba n K al a s K a<br />

change our course, we’ll see a long, slow<br />

strangling of the economy, prompting<br />

conditions just as challenging as those<br />

of the late ‘80s.<br />

It’s a fact of life: a healthy petroleum<br />

industry is essential to a healthy <strong>Alaska</strong><br />

economy, which helps all sectors thrive,<br />

including the construction industry. To<br />

encourage continued investments, our<br />

state must become more businessfriendly.<br />

That’s an uphill battle considering<br />

CNBC’s “America’s Top States for<br />

Business” recently listed <strong>Alaska</strong> as last.<br />

So what can you do? AGC of<br />

<strong>Alaska</strong>’s executive director John<br />

MacKinnon put it well in the last issue<br />

of this magazine: “Your voice counts.”<br />

<strong>Alaska</strong>’s leaders need to know that it’s<br />

time to take defi nitive action on the<br />

future of the state’s economy. I suggest<br />

that you pose three specifi c questions<br />

to your elected offi cials and candidates<br />

in the November elections and<br />

demand specifi c answers.<br />

Ask them what<br />

steps we can take to:<br />

• Encourage new responsible investment<br />

in resource development<br />

that produces lasting benefi ts.<br />

• Build a fi scal plan that conserves<br />

assets and provides long-term<br />

stability.<br />

• Ensure that all <strong>Alaska</strong>ns share in a<br />

commitment to a stable economic<br />

future.<br />

Encourage everyone you know to<br />

pose these questions to candidates<br />

running for offi ce as well as elected<br />

state offi cials. Because it’s not just<br />

about us anymore – the decisions<br />

we make over the next few years will<br />

greatly affect future generations. We<br />

can wait no longer. That’s why I say,<br />

when it comes to our economy, the<br />

future is indeed now.<br />

28 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

30 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 31

Smoothing<br />

the transition<br />

AGC members and<br />

community community businesses<br />

help wounded<br />

warriors settle in<br />

When an eligible active-duty<br />

soldier from <strong>Alaska</strong> becomes<br />

disabled, the AGC of <strong>Alaska</strong><br />

is proud to provide support through<br />

Operation Opening Doors, our community<br />

project aimed at improving the<br />

livability of the home for soldiers and<br />

their families.<br />

To support disabled members<br />

of our military AGC partners with<br />

our members and the community,<br />

following the lead of the South Dakota<br />

AGC Chapter who successfully began<br />

their OOD program few years ago.<br />

<strong>The</strong> program is designed to provide<br />

accommodations for special needs<br />

caused by the injury – from installing<br />

ramps, to widening hallways and<br />

doors, to enlarging bathrooms and<br />

kitchens. <strong>The</strong> participating contractor,<br />

subcontractors and suppliers provide<br />

the labor and materials necessary to<br />

make life easier for wounded <strong>Alaska</strong><br />

service members.<br />

AGC oversees all volunteer and<br />

contribution efforts, and the general<br />

contractor for the OOD project<br />

provides coordination and performs<br />

some of the work.<br />

On August 12, John MacKinnon, the<br />

executive director of AGC <strong>Alaska</strong> and<br />

Gary Donnelly, the project’s manager<br />

from Neeser Construction <strong>Inc</strong>., cut the<br />

ribbon on the fi rst Operation Opening<br />

Doors project in <strong>Alaska</strong>. SFC David<br />

Waite was the program’s fi rst honoree.<br />

In less than a heartbeat, a barrage<br />

of Russian-made missiles shredded<br />

U.S. Army SFC David Waite’s usual<br />

“kicking-in-doors” routine while<br />

deployed to Afghanistan in 2004.<br />

“I tried to catch a 107 mm rocket<br />

without a whole lot of luck,” Waite<br />

recalled in typical understatement<br />

and humor about the explosion and<br />

shrapnel that ripped through his<br />

legs and back, shattered bones and<br />

joints and eventually took part of his<br />

stomach, spleen and intestines.<br />

As a member of the OOD board,<br />

32 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010<br />

ph oTo s: co u R T e sy o f az i m u T h ad v e n T u R e ph oTo g R a p h y

Gary Donnelly asked Jerry Neeser to<br />

volunteer Neeser Construction <strong>Inc</strong>. as<br />

the general contractor to oversee the fi rst<br />

project. Partnering with AGC, he then<br />

set out to fi nd like-minded businesses<br />

and was quickly overwhelmed with the<br />

outpouring of generosity, he said.<br />

“Everyone we asked said, ‘Just tell us<br />

what you need.’ Not what do you want<br />

or how much will it cost? ‘Just tell us<br />

what you need.’”<br />

<strong>The</strong> scope of work included hand<br />

rails in the entry way along the stairs<br />

and on the back deck; the installation<br />

of an energy-effi cient wood burning<br />

stove and new accessible toilets with<br />

grab rails in the bathrooms. Plus, a<br />

driveway redesign to level some of the<br />

steepness out so SFC Waite could park<br />

without concern that his vehicle might<br />

sled down into the street. When redesign<br />

was not a solution, because of<br />

limited space, the volunteers went to<br />

work tearing out the old driveway and<br />

installing a new heated driveway.<br />

“Neeser measured and installed<br />

carpentry work, tidied up and made<br />

sure everything was done,” Donnelly<br />

said. “Grazzini Brothers volunteered the<br />

tile materials and labor for the woodstove<br />

hearth, fi re wall and installed the<br />

chimney. Superior Plumbing & Heating<br />

installed the mechanical system for the<br />

snow melt on the driveway, Megawatt<br />

Electric handled the wiring and heating<br />

elements and Earth Stone <strong>Inc</strong>. made<br />

the forms and then placed and fi nished<br />

the concrete.”<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 33

<strong>Alaska</strong> Concrete Services provided<br />

equipment and the labor to pump<br />

the concrete. Material suppliers were<br />

Anchorage Sand and Gravel, Central<br />

Plumbing and Heating <strong>Inc</strong>., Ferguson<br />

Enterprises <strong>Inc</strong>., Insulfoam and<br />

Spenard Builders.<br />

<strong>The</strong> AGC Associates Council,<br />

Construction Industry Progress Fund,<br />

Eagleglen Golf Course, Golf of <strong>Alaska</strong><br />

and Juanita Kardell provided cash<br />

donations which gave the program<br />

seed money to get started.<br />

<strong>The</strong> volume of companies that<br />

participated was amazing in its own<br />

right; but when combined with the<br />

individuals that gave their time and<br />

expertise to this project it provided an<br />

outpouring of warmth and goodwill<br />

directed toward SFC David Waite and<br />

his family, and the <strong>Alaska</strong> military in<br />

general.<br />

“We sit over here with our comfortable<br />

lifestyle while all these men<br />

and women are over there risking<br />

their lives to make sure that lifestyles<br />

continue,” Donnelly said. “At the very<br />

least we’re honored to be able to give<br />

something back.”<br />

Military and civilian, community<br />

and contractor – together they’re<br />

mending the wounds of war. AGC<br />

members and volunteers have begun<br />

the program’s second project in<br />

Fairbanks. GHEMM Company has<br />

volunteered for the project that will<br />

honor SGT Tony Senecal. Operation<br />

Opening Doors looks forward to more<br />

successful projects in the future.<br />

34 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

hUMan rEsoUrCEs UPDatE<br />

Document and comply<br />

before you reply<br />

This column provides information<br />

about the law to help users competently<br />

cope with their legal needs. But legal information<br />

is not the same as legal advice –<br />

the application of law to an individual’s<br />

specifi c circumstances. Although we go to<br />

great lengths to ensure accurate and useful<br />

information, we recommend consulting a<br />

lawyer for professional assurance and your<br />

interpretation of a particular situation.<br />

I<br />

recently attended the 2010 Workplace<br />

Strategies Seminar sponsored<br />

by Ogletree, Deakins, Nash, Smoak<br />

& Stewart, P.C. law fi rm and thought I<br />

would pass on a few human-resource<br />

tips that may affect your business.<br />

First, the U.S. Department of Labor<br />

will increase its presence in the Offi ce of<br />

Federal Contract Compliance Programs,<br />

Occupational Safety & Health Administration,<br />

and the Wage and Hour Division.<br />

So you want to be prepared for a<br />

visit or other communications.<br />

To cover all your bases, audit all<br />

of your human resource compliance<br />

programs and then address any issues<br />

that arise. Too often employers conduct<br />

audits and then do nothing with the<br />

information. Good business sense calls<br />

for addressing audit items post haste<br />

and documenting how and when you<br />

corrected the defi ciencies.<br />

Key areas include compensation,<br />

record keeping, affi rmative action plans<br />

and compliance with federal contracts.<br />

Hardly a day goes by that the 6 o’clock<br />

news reports a workplace tragedy<br />

somewhere in the country. No employer<br />

is immune, so establish a catastrophe<br />

and/or fatality plan and make sure your<br />

employees from top management on<br />

down understand it.<br />

Also ensure that your workers know,<br />

understand and comply with such OSHA<br />

standards and regulations as process<br />

safety, combustible dust, machine<br />

guarding, and excavating and trenching.<br />

<strong>The</strong> new fi nes and penalties for violations<br />

will cause shudders to many construction<br />

companies’ bottom lines.<br />

A strong violence-in-the-workplace<br />

policy is also a major concern, as is making<br />

sure all employees live by it. To that<br />

extent, stress zero tolerance for violence<br />

and thoroughly investigate each allegation.<br />

Treat threats, for example, as actual<br />

acts of violence, and train your managers<br />

and supervisors on how to document all<br />

threats or acts of violence and how to<br />

respond to them in specifi c situations.<br />

By Ba r B a r a sta l l o n e<br />

Depending on the culture of your<br />

business, you may want to develop<br />

written standards of conduct for your<br />

workforce. If you do, make sure all<br />

employees understand the rules and<br />

the disciplinary process, and then train<br />

your managers how to document any<br />

violations.<br />

Even annual employee performance<br />

evaluations require a consistent<br />

company policy, effective communicators<br />

and honest feedback. If an<br />

employee loses their job, for example,<br />

based solely on poor performance but<br />

has a history of outstanding evalu-<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 35

ations, that employee may have legal<br />

grounds to take the employer to court.<br />

Failing to audit job classifications<br />

can also cause headaches in the form of<br />

violating the Fair Labor Standards Act.<br />

Make sure to specify policies for off-theclock<br />

work, travel time or use of company-owned<br />

Blackberry and cell phones on<br />

and off the clock.<br />

Some states have even banned cell<br />

phones while driving, but not <strong>Alaska</strong>,<br />

even though national statistics reflect cell<br />

phones are involved in 25 percent of all<br />

auto accidents. It’s frightening to watch<br />

drivers with cell phones pressed to their<br />

ears – weaving in and out of traffic at<br />

high rates of speed.<br />

In any case, if your employee causes<br />

an accident while driving a company<br />

car and talking on a cell phone, your<br />

company may be held liable. Even worse,<br />

the company could be held responsible if<br />

the employee’s driving their own car on<br />

company business. Given the possibility,<br />

many companies prohibit cell-phone use<br />

by any employee while driving a company<br />

or personal vehicle on the clock. If you<br />

don’t already have a cell-phone policy,<br />

establish one, train your managers to lead<br />

by example and then have each employee<br />

sign and acknowledge the policy.<br />

Another predicament looms in preemployment<br />

tests to determine a potential<br />

worker’s qualifications. Make sure the<br />

exams have been validated according to<br />

consistent industry standards because any<br />

off-the-cuff or one-of-a-kind tests could<br />

be grounds for discrimination.<br />

As these examples point out, employers<br />

need to establish and communicate<br />

specific human-resource policies and<br />

then train their managers and supervisors<br />

to adhere to and administer those policies,<br />

and lead by example. When infractions<br />

occur, employers must deal with them<br />

quickly and consistently and follow up on<br />

the outcome. You don’t want to be caught<br />

with your pants down if some regulatory<br />

agency starts asking questions.<br />

Barbara Stallone is a partner in<br />

<strong>The</strong> Human Resource Umbrella LLC,<br />

an Anchorage-based human resource<br />

consulting company and AGC member.<br />

Send questions about this column or<br />

suggestions for future columns to Barbara@<br />

HRUmbrella.com, or call (907) 727-2111<br />

or (888) 470-0903. Also check out the<br />

website at www.hrumbrella.com.<br />

36 <strong>The</strong> <strong>Alaska</strong> conTrAcTor Fall 2010

Storm Water<br />

Pollution<br />

Prevention<br />

Plans<br />

Polluted stormwater runoff pollutes<br />

nearly 40 percent of surveyed<br />

U.S. water bodies. If left untreated<br />

or uncontrolled, this pollution can<br />

destroy fi sh, wildlife and aquatic life<br />

habitats and threaten public health<br />

due to contaminated food, drinking<br />

water and recreational waterways.<br />

To prevent and control further<br />

contamination, Congress, under<br />

the Clean Water Act, established a<br />

comprehensive two-phased national<br />

program under the auspices of the<br />

National Pollutant Discharge Elimination<br />

System. This permitting mechanism<br />

requires contractors to prevent<br />

harmful pollutants from washing into<br />

local watersheds.<br />

Basically, before obtaining a<br />

construction permit, each contractor<br />

must show proof of a stormwater<br />

pollution prevention plan – commonly<br />

known as SWPPPs – that meet best<br />

practices guidelines and effectively<br />

reduce or prevent the discharge of<br />

pollutants into any nearby waterways.<br />

<strong>The</strong> permits, like the one pictured,<br />

are usually displayed on a light-refl<br />

ecting green sign on the construction<br />

site.<br />

Fall 2010 <strong>The</strong> <strong>Alaska</strong> conTrAcTor 37

<strong>Contractor</strong>s, Native Corporation and cinema chain<br />

create maximum entertainment<br />

In 2007, CIRI and Oakland, Calif.-based Browman<br />

Development Co. broke ground on Tikahtnu Commons<br />

in northeast Anchorage. Three years later, the 95-acre<br />

shopping and entertainment center features such major<br />

national retailers as Target, Kohl’s, <strong>The</strong> Sports Authority, Best<br />

Buy and Lowe’s.<br />

On June 11, 2010, the latest and largest addition to the<br />

950,000 square-foot, $100 million project opened – the<br />

Regal Tikahtnu Stadium 16 with the state’s first IMAX<br />

theater. Nearly three weeks later, a second IMAX theater<br />