Provac 880 - Berkel Sales & Service

Provac 880 - Berkel Sales & Service

Provac 880 - Berkel Sales & Service

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

PROVAC <strong>880</strong> VACUUM CHAMBER<br />

PACKAGING MACHINE<br />

Owner’s<br />

Manual

KOCH EQUIPMENT LLC<br />

OWNER’S MANUAL<br />

905151<br />

H<br />

ProVac <strong>880</strong> Vacuum Chamber<br />

Packaging Machine

INTRODUCTION P A G E I<br />

TABLE OF CONTENTS<br />

INTRODUCTION ................................ III<br />

GENERAL ........................................... IV<br />

SECTION 1: SAFETY<br />

PERSONAL SAFETY .............................. 2<br />

FOOD SAFETY ..................................... 3<br />

GENERAL SAFETY GUIDELINES ........... 3<br />

SECTION 2: STARTUP<br />

UNPACKING ....................................... 6<br />

TRANSPORTATION INSTRUCTIONS ..... 6<br />

POWER REQUIREMENTS ...................... 6<br />

ENVIRONMENTAL REQUIREMENTS ..... 7<br />

STARTUP.............................................. 7<br />

VACUUM PUMP ROTATION ................. 7<br />

AIR CONNECTION .............................. 7<br />

GAS FLUSH OPTION ........................... 8<br />

PERFORATING KNIVES OPTION .......... 8<br />

SECTION 3: OPERATION<br />

PLACEMENT OF PRODUCT ................ 10<br />

STARTUP............................................ 10<br />

ENERGY SAVER .................................. 10<br />

DELAYED SHUT DOWN ......................11<br />

SEALING WITH AIR-ASSIST .................11<br />

GAS FLUSH OPTION ..........................11<br />

PERFORATING KNIFE .........................11<br />

CONTROL PANEL<br />

Operator’s Menu ............................... 12<br />

Panel Functions ................................. 12<br />

Edit Programs .................................... 13<br />

Error Messages ................................. 15<br />

SECTION 4: MAINTENANCE<br />

PRIOR TO CLEANING ........................ 18<br />

CLEANING RECOMMENDATIONS ..... 18<br />

VACUUM PUMP MAINTENANCE........ 19<br />

SEAL BAR MAINTENANCE ................. 19<br />

LID SPRING ADJUSTMENT ................. 20<br />

TROUBLESHOOTING<br />

Problems and Remedies ...................... 21<br />

SECTION 5: SCHEMATIC<br />

STANDARD UNIT.<br />

Designation and Function of Controls ... 23<br />

Electrical Diagram ............................. 24<br />

Electrical Diagram ............................. 25<br />

BIACTIVE SEALING UNIT<br />

Designation and Function of Controls ... 26<br />

Electrical Diagram ............................. 27<br />

Electrical Diagram ............................. 28<br />

PNEUMATIC DIAGRAM<br />

Designation and Function of Controls ... 29<br />

Diagram ........................................... 30<br />

SECTION 6: PARTS<br />

RECOMMENDED SPARE PARTS .......... 34<br />

CHAMBER LID<br />

Parts List ........................................... 35<br />

Diagram ........................................... 36<br />

SEAL BAR - 10MM<br />

Parts List ........................................... 37<br />

Diagram ........................................... 38<br />

SEAL BAR - CUT-OFF<br />

Parts List ........................................... 41<br />

Diagram ........................................... 42<br />

SEAL BAR - PERF KNIFE (OPTIONAL)<br />

Parts List ........................................... 43<br />

Diagram ........................................... 44<br />

WORKING BED, TOP<br />

Parts List ........................................... 45<br />

Diagram ........................................... 46<br />

CUSHION BAR - STANDARD<br />

Parts List and Diagram ........................ 47<br />

CUSHION BAR - GAS (OPTIONAL)<br />

Parts List and Diagram ........................ 48

INTRODUCTION P A G E II<br />

TABLE OF CONTENTS<br />

CUSHION BAR - BIACTIVE SEAL<br />

(OPTIONAL)<br />

Parts List ........................................... 48<br />

Diagram ........................................... 49<br />

CUSHION BAR - BIACTIVE SEAL W/GAS<br />

(OPTIONAL)<br />

Parts List ........................................... 50<br />

Diagram ........................................... 51<br />

CUSHION BAR - PERF KNIFE (OPTIONAL)<br />

Parts List ........................................... 52<br />

Diagram ........................................... 53<br />

CUSHION BAR - PERF KNIFE W/GAS<br />

(OPTIONAL)<br />

Parts List ........................................... 54<br />

Diagram ........................................... 55<br />

WORKING BED, BOTTOM<br />

Parts List ........................................... 56<br />

Diagram ........................................... 57<br />

BODY<br />

Parts List ........................................... 62<br />

Diagram ........................................... 63<br />

ELECTRICAL BOX - STANDARD<br />

Parts list ........................................... 64<br />

Diagram ........................................... 65<br />

ELECTRICAL BOX - AUTO LID SWING<br />

(OPTIONAL)<br />

Parts list ........................................... 66<br />

Diagram ........................................... 67<br />

ELECTRICAL BOX - BIACTIVE SEAL<br />

(OPTIONAL)<br />

Parts list ........................................... 68<br />

Diagram ........................................... 69<br />

ELECTRICAL BOX - BIACTIVE W/AUTO LID<br />

(OPTIONAL)<br />

Parts list ........................................... 70<br />

Diagram ........................................... 71<br />

SECTION 7: SERVICE HISTORY<br />

SERVICE HISTORY .............................. 74<br />

SECTION 8: VACUUM PUMP<br />

VACUUM PUMP MANUAL .................. 78

INTRODUCTION P A G E IV<br />

General<br />

This owner’s manual contains information pertinent to your ProVac<strong>880</strong>. Basic instructions<br />

and maintenance information is provided. Please read carefully. Failure to do so could result<br />

in bodily injury and/or damage to the equipment.<br />

Receiving Problems: As in all cases, before signing the bill of lading, be sure all items<br />

have been received as listed and there is no damage in shipment. If needed, a claim must<br />

be made immediately to the local truck line office and noted on the bill of lading.<br />

Please fill in the information from the bill of lading and the product identification tag.<br />

Model No.<br />

Serial No.<br />

Ship Date:<br />

Owner:<br />

Location:<br />

Electrical service size for you ProVac<strong>880</strong> (check one):<br />

208/240 Volt, 3 phase, 60 Hertz<br />

380/415 Volt, 3 phase, 50 Hertz<br />

460 Volt, 3 phase, 60 Hertz<br />

575 Volt, 3 phase, 50/60 Hertz<br />

Options installed on your ProVac<strong>880</strong> (check all that apply):<br />

Biactive Sealing<br />

Gas Flush<br />

Perforating Knife System<br />

Please fill in the serial number from the pump identification tag:<br />

Serial No.

INTRODUCTION P A G E V<br />

Specifications<br />

C<br />

F<br />

D<br />

G<br />

A B<br />

Length (A): 2040mm (80.3-in.)<br />

Width (B): 1300mm (51.2-in.)<br />

Minimum Height (C): 1220mm (48-in.)<br />

Working Height (D): 920mm (32.2-in.)<br />

Seal Bar Length (E): <strong>880</strong>mm (34.6-in.)<br />

Chamber Height (F): 254mm (10-in.)<br />

304mm (12-in.)<br />

Between Seal Bars (G): 860mm (34-in.)<br />

200m<br />

Vacuum Pumps:<br />

3 /h (117cfm) 5.6kW (7-1/2hp)<br />

306m3 /h (180cfm) 7.5kW (10hp)<br />

360m3 /h (212cfm) 9.0kW (12hp)<br />

Electrical Connection: See Power Requirements in Section 2<br />

Capacity: 15-35 seconds per cycle<br />

Net Weight: 780kg (1733-lbs)

INTRODUCTION P A G E VI<br />

This page left blank intentionally.

SAFETY P A G E 1<br />

SAFETY<br />

Personal Safety ................................................................................2<br />

Food Safety ......................................................................................3<br />

General Safety Guidelines ............................................................3<br />

SECTION<br />

1

SAFETY P A G E 2<br />

Personal Safety<br />

The procedures and guidelines herein must be followed precisely to avoid problems that can<br />

result in property damage, personal injury, or death. If you have any questions related to<br />

this information, please contact Koch Equipment <strong>Service</strong>s Inc. at (800) 777-5624.<br />

DANGER Hazardous voltage.<br />

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels<br />

unless power has been disconnected and locked out at risk of electric shock hazard.<br />

WARNING<br />

Read and understand owner’s manual before using this machine. Failure to follow operating<br />

instructions could result in personal injury or damage to equipment.<br />

WARNING Explosion hazard.<br />

Do not use a gas with an oxygen content greater than 22% with gas flush option.<br />

CAUTION Blade hazard.<br />

Do not remove, install, or replace blades without protective gloves. Perforating blade is<br />

sharp. Use care when handling.<br />

Cleaning agents.<br />

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,<br />

goggles, and protective clothing when contact is likely. Consult product manufacturer for<br />

specific details.<br />

Signal words used in classification of potential hazards are defined as follows:<br />

DANGER: Indicates an imminently hazardous situation, which, if not avoided, may result in death or<br />

serious injury.<br />

WARNING: Indicates a potentially hazardous situation, which, if not avoided, could result in death or<br />

serious injury.<br />

CAUTION: Indicates a potentially hazardous situation, which, if not avoided, may result in minor or<br />

moderate injury. Caution also indicates actions that may cause property damage.

SAFETY P A G E 3<br />

Food Safety<br />

Food Packaging<br />

While this machine is often used for food packaging and vacuum cooking, there are<br />

inherent risks associated with this packaging technique that could cause serious illness<br />

or death to the consumer of the food product. If you are using this machine for a food<br />

application, you must consult with a reputable food technologist or specialist in vacuum/<br />

modified atmosphere packaging (M.A.P.) to review the safety of your application.<br />

Gas Flush<br />

In order to ensure proper shelf life of the food product packaged in this machine, you<br />

must contact a reputable food technologist or specialist in vacuum/modified atmosphere<br />

packaging (M.A.P.) to review and develop the appropriate gas mixture for your package,<br />

and you must perform quality control and gas analysis on your finished M.A.P. packages.<br />

General Safety Guidelines<br />

Obvious safety guidelines should be observed.<br />

Use a certified electrician to install permanent electrical connection for your packaging<br />

machine. Failure to do so may result in death or serious injury and/or permanent<br />

damage to the machine.<br />

Disconnect and lockout power to your packaging machine before any maintenance work<br />

is performed.<br />

Place machine on a flat, stable surface.<br />

Do not place tools, parts, or other objects on or inside machine while operating.

SAFETY P A G E 4<br />

This page left blank intentionally.

STARTUP P A G E 5<br />

STARTUP<br />

Unpacking ........................................................................................6<br />

Transportation Instructions ............................................................6<br />

Power Requirements .......................................................................6<br />

Environmental Requirements ........................................................7<br />

Startup ..............................................................................................7<br />

Vacuum Pump Rotation ..................................................................7<br />

Air Connection ................................................................................7<br />

Gas Flush Option ............................................................................8<br />

Perforating Knives Option .............................................................8<br />

SECTION<br />

2

STARTUP P A G E 6<br />

Unpacking<br />

1. Carefully remove crate from the skid.<br />

2. Remove machine from skid.<br />

3. Wipe down outside of the machine.<br />

Transportation Instructions<br />

Precautions to take:<br />

Lift the machine by its center of gravity; this is not necessarily the same as the center of<br />

the machine.<br />

On lifting the machine with the forklift, do so from the front part (that opposite the<br />

electrical box). Check for components hanging under the machine.<br />

Always lift the machine by placing the forks of the truck between the two free casters of<br />

the machine; never lift it by the ends or extensions.<br />

Always take the utmost care when carrying out lifting and moving operations.<br />

Approximate weight of the machine: 780-kg or 1733-lbs.<br />

Power Requirements<br />

The owner must supply the correct 3 phase power source in accordance with the National<br />

Electric Code. The table below is based on the National Electric Code and is to be used as a<br />

guide in wire size selection and short circuit protection. The requirements noted in the table<br />

may change. Use a certified electrician to install permanent electrical connection for your<br />

packaging machine. Failure to do so may result in death or serious injury and/or permanent<br />

damage to the machine.

STARTUP P A G E 7<br />

Environmental Requirements<br />

Certain environmental factors affect the operation and lifespan of your vacuum packaging<br />

machine. The following requirements need to be adhered to when placing the machine:<br />

Room temperature from 5˚ to 40˚C.<br />

Machine must be at least 8-in. from walls or any other obstruction that would prevent air<br />

flow to the vacuum pump.<br />

Startup<br />

It is essential to check the oil level daily and to change the oil after every 500 hours of<br />

operation. Read the oil level with the machine turned off. Oil should be added until the<br />

level reaches the MAX level. Monitor the oil change indicator light on the control panel<br />

which signals an oil change is due. Refer to the pump manual, supplied (see Section 8), for<br />

details on changing the oil.<br />

OIL SIGHT<br />

MAX<br />

GLASS<br />

ON PUMP<br />

MIN<br />

Vacuum Pump<br />

NOTE: ALL CHAMBER MACHINES ARE SHIPPED WITH OIL IN THE PUMP. ALTHOUGH THE<br />

FACTORY RECOMMENDS CHECKING THE OIL LEVEL PRIOR TO FIRST USE!<br />

Vacuum Pump Rotation<br />

Cation: Check oil level of pump before starting pump. To check the direction of the pump<br />

rotation, briefly engage the “POWER ON” switch and observe the motor fan at the end<br />

of the pump. The fan should rotate as indicated by the arrow on the fan cover. To correct<br />

the rotation, switch any two phases in the plug. Ground wire must remain in the ground<br />

location.<br />

Air Connection<br />

The machine is equipped with a 1/4-in. hose barb for regulated air. The recommended air<br />

supply is 90 p.s.i. (6.2 bar) at 6 c.f.m. (10m 3 /h). There are three air regulators inside and in<br />

the rear of the machine. The maximum setting is 30 p.s.i. (2 bar) for the air-assist regulator.<br />

The Up Lid and Down Lid regulators are preset at the factory and should not be adjusted<br />

without consulting the Koch Equipment <strong>Service</strong>s Inc.

STARTUP P A G E 8<br />

Gas Flush Option<br />

The owner must supply a suitable regulator with a range of 0 to 60 p.s.i. A food-grade<br />

flexible hose with a 1/4-in. I.D. and a maximum length of 15-ft. Maximum regulator<br />

pressure is 55 p.s.i. is recommended.<br />

Perforating Knives Option<br />

CAUTION Blade hazard.<br />

Do not remove, install, or replace blades without protective gloves. Perforating blade is<br />

sharp. Use care when handling.<br />

Remove standard seal bars. Install perforating bars with the cutting blade facing toward<br />

the outside of the lid. The use of air-assist is required for proper operation. The air-assist<br />

regulator should be set at 20 to 30 p.s.i. As the backup strip wears, it can be removed and<br />

turned upside down for a better surface.

OPERATION P A G E 9<br />

OPERATION<br />

Placement of Product ................................................................... 10<br />

Startup ............................................................................................ 10<br />

Energy Saver .................................................................................. 10<br />

Delayed Shut Down ...................................................................... 11<br />

Sealing with Air-Assist .................................................................. 11<br />

Gas Flush Option .......................................................................... 11<br />

Perforating Knife ........................................................................... 11<br />

Control Panel<br />

Operator’s Menu .......................................................................... 12<br />

Panel Functions ............................................................................ 12<br />

Edit Programs ............................................................................... 13<br />

Error Messages ............................................................................ 15<br />

SECTION<br />

3

OPERATION P A G E 10<br />

Placement of Product<br />

For best sealing results, it is important to:<br />

Check the pump oil level daily and change oil as needed.<br />

Select a pouch that fits the product.<br />

Carefully load the product into the pouch.<br />

Keep the product and the product residue away from the seal area of the pouch.<br />

Place the product as far into the pouch as possible.<br />

Maintain an equal amount of the product above and below the seal bar by removing or<br />

installing filler plates.<br />

Lay the pouch flat on the seal area, keeping the pouch free of wrinkles.<br />

Place the pouch so that the open end is inside the chamber when the lid is closed.<br />

Startup<br />

In order to start machine the following steps must be taken:<br />

1. Power cord must be connected to the dedicated disconnect.<br />

2. Disconnect must be turned on.<br />

3. Green power button must be pressed.<br />

“STBY” Led on the control panel will be lit.<br />

4. “ON” button on the control panel must be pressed.<br />

Control Panel will begin startup.<br />

Vacuum Pumps will start running.<br />

5. Place bag on machine. (Note: the filler plates on the working table are used for product<br />

height positioning as well as for decreasing the volume of the chamber and speeding up<br />

evacuation. It will take longer to pull a vacuum time if the plates are removed.)<br />

6. Close lid to start vacuum packaging cycle.<br />

7. After vacuum cycle is completed, raise lid and remove sealed product from vacuum<br />

chamber.<br />

8. The machine is again ready for operation.<br />

9. After work is finished, please allow vacuum pump to continue running for about 15<br />

minutes and then turn off the main switch to shut off the machine.<br />

Energy Saver<br />

Energy saver mode keeps the vacuum pumps from running while the machine is not being<br />

used. The machine is set to begin the energy saver mode 15 minutes after the last cycle.<br />

Only the “STBY” led will be lit on the control panel. To continue normal operation, close lid.

OPERATION P A G E 11<br />

Delayed Shut Down<br />

Delayed shut down mode allows the vacuum pump to run for 15 minutes before shutting<br />

down. Running the vacuum pump at the end of a shift allows the moisture that the pump<br />

has pulled into it’s system to be expelled through the exhaust. Using the delayed shut down<br />

mode is suggested for companies that are vacuum packaging liquids or products with a high<br />

moisture content, such as fish.<br />

Sealing with Air-Assist<br />

All machines are equipped with regulators for air-assisted sealing. Set the air pressure<br />

regulator to 20 p.s.i. increasing to a maximum of 30 p.s.i. While a good seal can be<br />

obtained without air-assist, use air-assist when:<br />

Gas back-flushing above average pressure.<br />

Using food-grade or pre-made pouches.<br />

Packaging a product that easily contaminates the seal area of the pouch.<br />

Trying to overlap pouches.<br />

Wrinkles cannot be avoided in the seal area.<br />

Using the Bi-active Seal option.<br />

Always use air-assist when using the Perforating Knife Option<br />

Gas Flush Option<br />

The gas flush options allow the operator to introduce an inert gas into the chamber after<br />

the vacuum stage. This option can be used as a filler to prevent crushing of product after<br />

sealing, as a means to prolong shelf life, or as a means to maintain desirable product<br />

appearance. Commonly used gasses include Nitrogen, Carbon Dioxide, or a mixture of<br />

both. Consult your local gas supplier to select the proper gas for your product.<br />

WARNING Explosion hazard.<br />

Do not use a gas with an oxygen content greater than 22% with gas flush option.<br />

Perforating Knife<br />

Perforating knives are used to facilitate the removal of excess pouch material. Perforating<br />

knives are not intended to cut pouches off completely, only to perforate so that excess<br />

material can be easily removed by hand.<br />

CAUTION Blade hazard.<br />

Do not remove, install, or replace blades without protective gloves. Perforating blade is<br />

sharp. Use care when handling.

OPERATION P A G E 12<br />

CONTROL PANEL<br />

Basic Operating Instructions:<br />

1. Standby Mode: After turning on the machine power, the operation panel will be in<br />

standby mode, STB lamps will illuminated, all other lamps will be off and the digital<br />

indicator will be off.<br />

2. Start Operation Panel: After pressing POWER ON, the digital indicator will show the<br />

software revision, then approximately 3 seconds later will enter into the general operation<br />

mode, during this time the digital indicator shows the numeric values of the program and<br />

VAC steps used last time, STB and VAC lamps will be illuminated.<br />

3. Start Vacuum Packaging: During this time, put the package in the chamber, close the<br />

vacuum lid, then start the vacuum packaging mode. The machine will follow the VAC, GAS,<br />

SEAL 1, SEAL2, COOL, SOFT settings step by step. When finished, the chamber will vent,<br />

and the vacuum lid will open.<br />

4. Setting Parameters: Under general operation mode, press either one of the Left or Right<br />

arrow keys for more than 3 seconds, the VAC lamps will flash, and the control panel will<br />

enter “setting mode”. From there, you may press the left or right arrow buttons to toggle<br />

through the various settings, and use the + or - key to change values. When done, press<br />

either one of the Up or Down Program buttons to save and escape.<br />

5. Close Operation Panel: Under general operation mode, press POWER OFF, this will turn<br />

the panel off and illuminate the STB lamp.

OPERATION P A G E 13<br />

CLOSE<br />

VACUUM<br />

LID<br />

(CLOSE)<br />

STEPS<br />

GENERAL<br />

FUNCTIONS<br />

ADVANCED<br />

FUNCTIONS<br />

VACUUM<br />

(VAC<br />

STEPS)<br />

WITH VACUUM<br />

PERCENT & VACUUM<br />

EXTENSION<br />

SECONDS, USE ONLY<br />

TIME COUNTED<br />

SECONDS TO<br />

CONTROL VACUUM<br />

WITH VACUUM<br />

PERCENT TO<br />

CONTROL VACUUM.<br />

WHEN VACUUM<br />

IS AT 100% USE<br />

EXTENSION<br />

SECONDS TO<br />

GRADUALLY<br />

INCREASE VACUUM.<br />

USE ONLY TIME TO<br />

CONTROL VACUUM<br />

COUNTED BY<br />

SECONDS.<br />

PURGE FUNCTION:<br />

GAS<br />

FLUSHING<br />

(GAS STEPS)<br />

FLUSHING GAS WITH<br />

SECONDS TO CONTROL<br />

PRESS GAS BUTTON,<br />

STARTS GAS FLUSHING<br />

FUNCTION.<br />

THEN PRESS PULSE<br />

BUTTON, STARTS<br />

PULSE GAS FLUSHING<br />

FUNCTION.<br />

CAN SET TOTAL PULSE<br />

ACTION TIME AND GAS<br />

FLUSH INTERVAL TIME.<br />

SEAL 1 /<br />

SEAL 2<br />

STEPS<br />

ACCORDING TO<br />

THE SET SECONDS<br />

FOR SEAL BAR 1 & 2,<br />

HEATING SEALBARS<br />

INDIVIDUALLY AT<br />

THE SAME TIME,<br />

AND STOP HEATING<br />

SEPERATELY AFTER<br />

ALL STOP, ENTERS<br />

NEXT STEP.<br />

CAN SET HEATING<br />

TIME FOR SEAL BARS<br />

1 & 2 INDIVIDUALLY.<br />

SEALING<br />

BAR COOL<br />

STEPS<br />

THE COOLING TIME<br />

FOR SEALING BARS<br />

1 & 2, PREVENTS<br />

OVERHEAT OF<br />

THE SEALING<br />

BARS CAUSING<br />

PACKAGING ERROR.<br />

SLOW<br />

SPEED<br />

PRESSURE<br />

BACK<br />

PULSE RECOVER<br />

GENERAL AIR<br />

PRESSURE, TO<br />

IMPROVE THE<br />

APPEARANCE AND<br />

QUALITY OF PACKED<br />

PRODUCT.<br />

CAN SET TOTAL<br />

TIME OF STEPS AND<br />

INTERVAL TIME.<br />

COMBINE VACUUM & GAS FLUSHING TWO STEPS, ACT SYNCHONOUSLY, WHEN PRESS PURGE BUTTON STARTS THIS<br />

FUNCTION.<br />

FUNCTION 1: VACUUM & GAS FLUSHING EXCHANGE 5 TIMES, THE FINAL ENDING ACTION IS GAS FLUSHING.<br />

FUNCTION 2: PRE-VACUUM 2 SECONDS TO CLOSE VACUUM LID, THEN GAS FLUSHING & VACUUM EXCHANGE 5 TIMES,<br />

THE FINAL ENDING ACTION IS VACUUM.<br />

VAC STEP PULSE: TO LET THIS STEP NOT CONTINOUSLY, BUT PULSE.<br />

RESTRICTION SETTINGS WHENVACUUM PERCENT CANT REACH UP TO 99%.<br />

MAYBE HAVE THE FACTORS OF AIR LEAKAGE, OR LOCAL AIR PRESSUE IS HIGHT, OR HIGH ALTITUDE APPLICATIONS, AND<br />

SO ON, CAN CAUSE AN INABILITY TO REACH 99% VACUUM.<br />

OPEN<br />

VACUUM<br />

LID<br />

(OPEN)

OPERATION P A G E 14<br />

GENERAL MODE<br />

Program Selections:<br />

By pressing the Program UP and DOWN buttons, you can toggle through the stored<br />

programs (Program 1-24). From this menu you can change the currently selected program,<br />

although the program settings cannot be altered without entering Edit Mode by holding<br />

either of the left or right buttons for 3 seconds or more.<br />

STEP Selections:<br />

You can review the settings of each program, by pressing the Left or Right buttons. Again,<br />

to edit these values you must hold the Left or Right button for 3 seconds or more.<br />

VAC: You can set the vacuum percent, the vacuum percent and seconds of continous<br />

vacuum, or vacuum time in seconds only.<br />

GAS: Set the total open time of GAS under the GAS ON status.<br />

SEAL 1 - SEAL 2: You can set the seal bar time for Seal Bar 1, and Seal Bar 2 in<br />

seconds.<br />

COOL: The cooling time for each seal bar. This function is available to allow the seal<br />

bar to cool, preventing overheating in rapid use environment.<br />

SOFT: This is the slow speed air vent time in seconds.<br />

Increase - Decrease:<br />

Under noraml conditions the + and - keys are inactive, only in edit mode will these<br />

keys be active, and will allow you to toggle values of each program value.<br />

SKIP:<br />

By pressing SKIP you will skip the current stage in the program.<br />

STOP:<br />

This will stop the program and open the vacuum lid.

OPERATION P A G E 15<br />

GENERAL MODE (CONTINUED).<br />

Gas Flushing:<br />

When the GAS ON/OFF button is pressed, the gas flush feature will be activated/<br />

deactivated. This button must be pressed prior to the lid closing to take effect.<br />

Pulse Flushing:<br />

When the PULSE ON/OFF button is pressed the pulse gas flush feature will be activated/<br />

deactivated. This button must be pressed prior to the lid closing to take effect.<br />

Power On / Power Off:<br />

When the power on button is pressed the machine will enter General Mode, when the<br />

Power Off button is pressed the machine will enter Standby Mode.<br />

Advanced User Level:<br />

Under General Mode, press STOP for 5 seconds or more, and enter password 111 to enter<br />

advanced mode.<br />

Treatment when VAC % cant reach 99%:<br />

-1: Cancel the vaccum settings and proceed with seconds only.<br />

0: Remain at original status, until VAC % is reached<br />

0 Up: After VAC isn’t reached, continue until the set seconds are reached.<br />

For Example, set vacuum percent is 70 %, after 70% the system will act<br />

continously according to the set seconds.<br />

PIN NO FUNCTION PIN NO FUNCTION<br />

1 AC24V INPUT (INTERNAL) 13 EXTERNAL DC24V GROUND<br />

2 AC24V INPUT (INTERNAL) 14 EXTERNAL DC24V OUTPUT<br />

3 AC24V INPUT (EXTERNAL) 15 SEAL BAR 2 HEAT CONTACT<br />

4 AC24V INPUT (EXTERNAL) 16 PULSE SOFT AIR CONTACT<br />

5 AIR INLET VALVE 17<br />

6 SEALING PRESS BAR GAS FLUSH 18<br />

7 SEAL BAR 1 HEAT 19<br />

8 EXTERNAL SPECIAL GAS VALVE 20<br />

9 VACUUM VALVE 21 OVER RELAY INPUT (25)<br />

10 COM 22 INTERNAL GROUND<br />

11 INTERNAL GROUND 23 COM POINT<br />

12 VACUUM LID SIGNAL INPUT 24 VACUUM MOTOR CONTACT<br />

25 OVER RELAY INPUT (25)

OPERATION P A G E 16<br />

This page left blank intentionally.

MAINTENANCE P A G E 17<br />

MAINTENANCE<br />

Prior to Cleaning ........................................................................... 18<br />

Cleaning Recommendations ....................................................... 18<br />

Vacuum Pump Maintenance ....................................................... 19<br />

Seal Bar Maintenance .................................................................. 19<br />

Troubleshooting<br />

Problems and Remedies................................................................20<br />

SECTION<br />

4

MAINTENANCE P A G E 18<br />

Prior to Cleaning<br />

Every environment and application is different; therefore, Koch Equipment LLC cannot<br />

provide cleaning instructions to guarantee microbiological sanitation. Koch Equipment<br />

requests that the owner of this machine consult with sanitation experts to review the<br />

unit working in their particular environment to develop a robust cleaning schedule and<br />

methodology, followed by bacterial testing to ensure satisfactory cleaning procedures are<br />

followed.<br />

Cleaning Recommendations<br />

Before cleaning the machine, turn power off; disconnect the main power, and lockout the<br />

connection.<br />

DANGER Hazardous voltage.<br />

Disconnect and lockout power before servicing machine or cleaning. Do not remove panels<br />

unless power has been disconnected and locked out at risk of electric shock hazard.<br />

Check with the detergent and sanitizer manufacturers that their products are compatible<br />

with the listed materials.<br />

Cleaning agents.<br />

Do not get the cleaning agents in eyes, on skin, or on clothing. Always wear rubber gloves,<br />

goggles, and protective clothing when contact is likely. Consult product manufacturer for<br />

specific details.<br />

Never hose down the machine. Damage caused by hosing or high pressure<br />

washing is not covered under warranty.<br />

1. Filler Plates: Remove filler plates. The filler plates are made from polyethylene. Clean,<br />

sanitize, and dry. High pressure water spray can be used on the filler plates.<br />

2. Backup Bars: Remove the backup bars. Clean and sanitize the backup bars. Do not<br />

use high pressure water spray.<br />

3. Seal Bars: Remove the seal bars. Seal bars can be dropped down by removing the<br />

center screw for better cleaning. The seal bars are made of aluminum. Clean, sanitize,<br />

and dry.<br />

4. Lid and Base: These components are made of stainless steel. Clean the lid, base, and<br />

silicone seal backup strip with a non-ionic cleaning solution such as Crystal Simple<br />

Green®.<br />

5. Clean under the machine.<br />

6. Use bacteriological testing to insure cleaning process.

MAINTENANCE P A G E 19<br />

Vacuum Pump Maintenance<br />

Check vacuum pump oil daily. Koch Equipment LLC recommends the oil, oil filter, and<br />

exhaust filters be changed after 500 hours of service. Refer to section 6 for part numbers of<br />

oil, oil filter, and exhaust filter. Consult the pump manufacturer’s manual provided with the<br />

machine for detailed information on oil change and maintenance procedures.<br />

Seal Bar Maintenance<br />

Remove seal bar units from vacuum<br />

lid.<br />

Remove the steel strips that hold the<br />

Teflon tape (Fig.A).<br />

Pull off Teflon tape and discard.<br />

Using a 3mm Allen wrench, loosen<br />

the clamping screw on the seal<br />

element holder at each end of the<br />

seal bar (Fig.A).<br />

Remove the seal element and discard.<br />

Clean the Teflon tape adhesive from<br />

the bars using an acetone cleaner or<br />

equivalent.<br />

Insert a spring into each spring retainer<br />

(Fig.B). Otherwise the seal element will<br />

easily break during the heating cycle.<br />

Feed the new element through one seal<br />

element holder and secure, leaving about<br />

3/4-in. (20mm) of excess, thread the<br />

element through the opposite end and leave the clamping screw loose.<br />

Using needle-nose pliers (Fig.C), stretch the<br />

element tight. Secure the clamping screw and<br />

check tension.<br />

To check tension, pull the element up at the<br />

middle of the seal bar. The maximum pull<br />

should not exceed 3/16-in. (5mm). If there is<br />

not enough tension, retighten.<br />

NOTE: Elements will break in the middle of the<br />

bar if not enough tension is set.<br />

Install new Teflon tape onto the bar and<br />

replace steel strips to hold tape. Change the Teflon tape on regular intervals to ensure<br />

proper sealing surface.

MAINTENANCE P A G E 20<br />

Lid Spring Adjustment / Replacement<br />

Lid Springs should be adjusted according to the chart below, based on your machine.<br />

Failure to adjust the springs accordingly could result in premature failure, and/or<br />

inneffective operation.

MAINTENANCE P A G E 21<br />

Troubleshooting<br />

Problems and Remedies<br />

Problem Indications Remedy<br />

Control panel is under<br />

normal function, but vacuum<br />

pump will not start<br />

The KM1, QM1, MCB1, MCB2<br />

protectors are disconnected<br />

Vacuum pump does not run Power source does not match<br />

nameplate<br />

Insufficient vacuum in<br />

chamber<br />

Insufficient vacuum in bag<br />

Note: Insufficiency is caused<br />

by bag leakage not faulty<br />

machinery.<br />

Vacuum pouch is easily<br />

pulled apart by hand<br />

Sealed area has burn marks<br />

or bubbles in it<br />

Check each part and turn<br />

the switch on<br />

Change power source<br />

Low oil level in vacuum pump Add oil if necessary<br />

Vacuum pump is rotating in<br />

wrong direction<br />

Repolarize motor<br />

Lid silicone rubber damage Replace lid silicone<br />

Vacuum valve does not open Clean membrane rubber<br />

Bag is leaking Change bag<br />

Sharp corners penetrate bag Use thicker bag<br />

Bag is too large Change bag size<br />

Sealing time (temperature) is<br />

too short (low)<br />

Sealed area is contaminated<br />

with oil or meat juice<br />

Sealing time (temperature) is<br />

too long (high)<br />

Adjust sealing time<br />

Clean sealing area prior to<br />

sealing<br />

Adjust sealing time<br />

Lid does not open Vacuum valve broken Replace valve<br />

Lid does not close Vacuum valve broken Replace valve<br />

Limit switch disconnected Adjust limit switch<br />

No sealing or bad sealing<br />

Note: Do not adjust sealing<br />

time longer than regular<br />

time, it will reduce the life of<br />

the teflon tape and silicone<br />

rubber.<br />

Sealing wire is broken Replace sealing wire<br />

Sealing wire is loose Tighten sealing wire<br />

Insufficient pressure Replace defective pressure<br />

bar<br />

Defective sealing transformer Replace transformer<br />

Damaged Teflon tape or<br />

silicon rubber<br />

Replace tape and/or rubber<br />

Sealing and cooling times are<br />

too short<br />

Adjust to proper sealing<br />

time<br />

Sealing pressure is too low Replace bladder

SCHEMATIC P A G E 22<br />

SCHEMATIC<br />

Standard Unit.<br />

Designation and Function of Controls ...........................................22<br />

Electrical Diagram ........................................................................ 23<br />

Biactive Sealing Unit<br />

Designation and Function of Controls ...........................................25<br />

Electrical Diagram ........................................................................ 26<br />

Pneumatic Diagram<br />

Designation and Function of Controls ...........................................28<br />

Diagram ......................................................................................29<br />

SECTION<br />

5

SCHEMATIC P A G E 23<br />

Standard Unit.<br />

Designation and Function of Controls<br />

The following designations are found on the Standard Unit Electrical Diagram:<br />

Switches:<br />

SW1, SW2 Lid Switch<br />

SW3 Gas Switch (Right/Left Chamber)<br />

QM1 Main Power Switch<br />

PB1 Power Switch<br />

Contactors and Relays:<br />

KM1 Motor Contactor<br />

KM2 Heater Contactor<br />

OL Over Relay<br />

R1 Pump Contactor Coil Relay<br />

Overloads and Fusing:<br />

F1, F2 Control Panel Fuse - 4A<br />

F3, F4 Sealing Transformer Fuse - 20A<br />

Timers:<br />

TMR1 Sealing Limit Timer<br />

Transformers:<br />

T1 Control Panel Transformer<br />

T2, T3 Sealing Transformer<br />

Valves:<br />

Y1 Ventilation Valve<br />

Y2 Sealing Valve<br />

Y3 Left Gas Valve<br />

Y4 Vacuum Valve<br />

Y5 Soft Air Valve (Option)<br />

Y6 Right Gas Valve

L1<br />

L2<br />

L3<br />

PE<br />

GROUND<br />

QM1<br />

A1<br />

A2<br />

OL<br />

W1 V1 U1<br />

VAC MOTOR<br />

220V/6KW/R5-202<br />

220V/9KW/R5-302<br />

KM1<br />

A1 KM2<br />

A2<br />

R2<br />

F4<br />

0<br />

S2<br />

50V<br />

H3 H4<br />

REAR SEALING<br />

T3<br />

F3<br />

0<br />

50V<br />

H1 H2<br />

FRONT SEALING<br />

6<br />

7<br />

35 17<br />

0 24V<br />

F1<br />

PB1<br />

F2<br />

35 17<br />

0 24V<br />

R1<br />

S1<br />

T1<br />

Standard Unit<br />

Electrical Diagram<br />

SCHEMATIC P A G E 24

SCHEMATIC P A G E 25<br />

Standard Unit<br />

Electrical Diagram<br />

Y1<br />

Y2<br />

Y3<br />

Y6<br />

Y4<br />

Y5<br />

17<br />

RY<br />

30<br />

29L<br />

29R<br />

28<br />

32<br />

60<br />

OL<br />

KM2<br />

59<br />

31<br />

34<br />

TMR1<br />

NC<br />

SW3<br />

NO<br />

COM<br />

OL<br />

35<br />

58<br />

0<br />

24V<br />

35<br />

17<br />

TMR1<br />

RY<br />

2<br />

SW1<br />

SW2<br />

35<br />

PROPOSED PLUG<br />

AND SOCKET<br />

25P D-SUB<br />

22<br />

23<br />

1 BLACK<br />

2 BROWN<br />

3<br />

4<br />

5 YELLOW<br />

6 GREEN<br />

7 BLUE<br />

8 PURPLE<br />

9 GREY<br />

10 WHITE<br />

11 PINK<br />

12 LIGHT GREEN<br />

13<br />

14<br />

15<br />

16 ORANGE/WHITE<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22 YELLOW/BLACK<br />

23<br />

24 GREY/BLACK<br />

25 PINK/BLACK

SCHEMATIC P A G E 26<br />

Biactive Sealing Unit<br />

Designation and Function of Controls<br />

The following designations are found on the Biactive Sealing Unit Electrical Diagram:<br />

Switches:<br />

SW1, SW2 Lid Switch<br />

SW3 Sealing Switch (Right/Left Chamber)<br />

SW4 Gas Switch (Right/Left Chamber)<br />

QM1 Main Power Switch<br />

PB1 Power Switch<br />

Contactors and Relays:<br />

KM1 Motor Contactor<br />

KM2 Top Sealing Contactor<br />

KM3 Bottom Left Sealing Contactor<br />

KM4 Bottom Right Sealing Contactor<br />

OL Over Relay<br />

R1 Pump Contactor Coil Relay<br />

Overloads and Fusing:<br />

F1, F2 Control Panel Fuse - 4A<br />

F3, F4, F5 Sealing Transformer Fuse<br />

Timers:<br />

TMR1 Sealing Limit Timer<br />

Transformers:<br />

T1 Control Panel Transformer<br />

T2, T3, T4 Sealing Transformer<br />

Valves:<br />

Y1 Ventilation Valve<br />

Y2 Sealing Valve<br />

Y3 Left Gas Valve<br />

Y4 Vacuum Valve<br />

Y5 Soft Air Valve (Option)<br />

Y6 Right Gas Valve

L1<br />

L2<br />

L3<br />

PE<br />

GROUND<br />

QM1<br />

A1<br />

A2<br />

OL<br />

W1 V1 U1<br />

VAC MOTOR<br />

220V/6KW/R5-200<br />

KM1<br />

A1 KM4<br />

A2<br />

R5 S5<br />

F5<br />

0<br />

60V<br />

H1 H2<br />

TOP SEALING<br />

T4<br />

A1 KM3<br />

A2<br />

R4 S4<br />

F4<br />

0<br />

60V<br />

H3 H4<br />

BOTTOM LEFT<br />

SEALING<br />

T3<br />

A1 KM2<br />

A2<br />

R3 S3<br />

F3<br />

0<br />

60V<br />

H5 H6<br />

BOTTOM RIGHT<br />

SEALING<br />

T2<br />

6<br />

7<br />

35 17<br />

0 24V<br />

F1<br />

PB1<br />

F2<br />

35 17<br />

0 24V<br />

R1<br />

S1<br />

T1<br />

T1<br />

Biactive Sealing Unit<br />

Electrical Diagram<br />

SCHEMATIC P A G E 27

SCHEMATIC P A G E 28<br />

Biactive Sealing Unit<br />

Electrical Diagram<br />

Y1<br />

Y2<br />

Y3<br />

Y6<br />

Y4<br />

Y5<br />

17<br />

KM2<br />

KM3<br />

30<br />

34R<br />

34L<br />

29L<br />

29R<br />

28<br />

32<br />

OL<br />

TMR1<br />

60<br />

OL<br />

KM4<br />

59<br />

31<br />

34<br />

NC<br />

SW3<br />

SW4<br />

NO<br />

NC<br />

NO<br />

A1<br />

KM1<br />

COM<br />

COM<br />

A2<br />

35<br />

0<br />

24V<br />

35<br />

17<br />

TMR1<br />

58<br />

2<br />

SW1<br />

SW2<br />

PROPOSED PLUG<br />

AND SOCKET<br />

25P D-SUB<br />

22<br />

23<br />

1 BLACK<br />

2 BROWN<br />

3<br />

4<br />

5 YELLOW<br />

6 GREEN<br />

7 BLUE<br />

8 PURPLE<br />

9 GREY<br />

10 WHITE<br />

11 PINK<br />

12 LIGHT GREEN<br />

13<br />

14<br />

15<br />

16 ORANGE/WHITE<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22 YELLOW/BLACK<br />

23<br />

24 GREY/BLACK<br />

25 PINK/BLACK

SCHEMATIC P A G E 29<br />

Pneumatic Diagram<br />

Designation and Function of Controls<br />

The following designations are found on the Pneumatic Diagram:<br />

1 Vacuum Valve Set<br />

2 Vacuum Gauge<br />

3 Y1 Ventilation Valve<br />

4 Y2 Sealing Valve<br />

5 Y3 Gas Valve<br />

6 Y6 Gas Valve<br />

7 Y4 Vacuum Valve<br />

8 Y5 Soft Air Valve<br />

9 Gas Tank<br />

P Vacuum Pump

SCHEMATIC P A G E 30<br />

Pneumatic Diagram<br />

Diagram<br />

4 Y2<br />

9<br />

Gas<br />

Tank<br />

max. 3bar<br />

6 Y6<br />

5 Y3<br />

P<br />

1<br />

2<br />

3 Y1<br />

8 Y5<br />

7 Y4

SCHEMATIC P A G E 31<br />

This page left blank intentionally.

PARTS P A G E 32<br />

PARTS<br />

Recommended Spare Parts ................................................ 33<br />

Chamber Lid<br />

Parts List ......................................................................................34<br />

Diagram ......................................................................................35<br />

Seal Bar - 10mm<br />

Parts List ......................................................................................38<br />

Diagram ......................................................................................39<br />

Seal Bar - Cut-off<br />

Parts List ......................................................................................40<br />

Diagram ...................................................................................... 41<br />

Seal Bar - Perf Knife (Optional)<br />

Parts List ......................................................................................42<br />

Diagram ......................................................................................43<br />

Working Bed, Top<br />

Parts List ......................................................................................44<br />

Diagram ......................................................................................45<br />

Cushion Bar - Standard<br />

Parts List and Diagram .................................................................46<br />

Cushion Bar - Gas (Optional)<br />

Parts List and Diagram ................................................................. 47<br />

Cushion Bar - Biactive Seal (Optional)<br />

Parts List ......................................................................................48<br />

Diagram ......................................................................................49<br />

Cushion Bar - Biactive Seal w/Gas (Optional)<br />

Parts List ......................................................................................50<br />

Diagram ...................................................................................... 51<br />

Cushion Bar - Perf Knife (Optional)<br />

Parts List ......................................................................................52<br />

Diagram ......................................................................................53<br />

SECTION<br />

6

PARTS P A G E 33<br />

Cushion Bar - Perf Knife w/Gas (Optional)<br />

Parts List ......................................................................................54<br />

Diagram ......................................................................................55<br />

Working Bed, Bottom<br />

Parts List ......................................................................................56<br />

Diagram ...................................................................................... 57<br />

Body<br />

Parts List ......................................................................................62<br />

Diagram ......................................................................................63<br />

Electrical Box - Standard<br />

Parts list .......................................................................................64<br />

Diagram ......................................................................................65<br />

Electrical Box - Auto Lid Swing (Optional)<br />

Parts list .......................................................................................66<br />

Diagram ...................................................................................... 67<br />

Electrical Box - Biactive Seal (Optional)<br />

Parts list .......................................................................................68<br />

Diagram ......................................................................................69<br />

Electrical Box - Biactive w/Auto Lid (Optional)<br />

Parts list ....................................................................................... 70<br />

Diagram ...................................................................................... 71

PARTS P A G E 34<br />

Recommended Spare Parts<br />

Qty.<br />

Koch<br />

Part No.<br />

Description<br />

1 ea 905 214 Sensor, Magnetic Switch<br />

1 ea 601 188 Magnet, 17x22x16<br />

1 ea 905 204 Fuse, 5A<br />

1 ea 905 203 Fuse, 3A<br />

3 ea 905 077 Microswitch<br />

1 ea 905 087 Limit Timer<br />

33 ft 905 060 Teflon Tape<br />

33 ft 905 058 Teflon Tape<br />

14 ft 905 336 Seal Element<br />

14 ft 905 051 Lid Gasket<br />

14 ft 905 202 Sealing Silicone<br />

1 ea 905 403 Relay<br />

1 ea 905 457 Seal Bar Complete<br />

1 ea 840 904 Oil Filter<br />

8 qt 884 755 Oil, 30W ND

PARTS P A G E 35<br />

Chamber Lid<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 SA100973010D Vacuum Lid<br />

2 EB1716152000 Cable Gland<br />

3 EB1503000000 Cable Clamp<br />

4 NA0704000001 905 123 Washer<br />

5 NA0804000001 905 033 Spring Washer<br />

6 NA0004001201 905 115 Round Head Screw<br />

7 CA100005170D Handle Bar<br />

8 NA0004001201 905 115 Round Head Screw<br />

9 NA0704000001 905 123 Washer<br />

10 SA100282270D Arm Electric Wire Trough<br />

11 NA0210008001 905 286 Hex Head Screw<br />

12 AA100085160D Handle Bar Socket<br />

13 QA0202201801 905 110 Retaining Ring<br />

14 BA0602302020 Self-lube Bearing<br />

15 AA100290160D 905 111 Arm Assembly<br />

15-1 AA100096160D Machine Arm Fitting<br />

15-2 AA100314160D Arm Assembly<br />

16 NA0208003501 Hex Head Screw<br />

17 RA100082240D Lid Shaft<br />

18 PA0420040200 905 051 Lid Gasket<br />

19 NA0806000001 905 122 Spring Washer<br />

20 NA1016000001 Screw Nut<br />

21 NA0406001001 Hex Head Screw<br />

22 NA0806000001 905 122 Spring Washer<br />

23 HA0008204100 905 052 Pressure Bag<br />

24 SA100921020D 905 004 Pressure Bag Holder<br />

25 SA100922010D 905 006 Sealing Assistance Part<br />

26 AA100305060D Sealing Bar Holder<br />

27 NA0106001001 Flat Head Screw<br />

28 NA0004001001 Round Head Screw<br />

29 HA1000000000 905 112 End Block Complete Assembly<br />

30 GA100005290E 905 017 Sealing Wire Holder

Chamber Lid<br />

Diagram<br />

PARTS P A G E 36

PARTS P A G E 37<br />

Chamber Lid<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

31 NA0306001001 905 053 Hex Head Screw<br />

32 NA0004002001 Round Head Screw<br />

33 QA1410060105 905 097 Spring<br />

34 GA100017060D End Block<br />

35 NA0408008001 Bolt, M8x80 Hex Head<br />

36 NA0708000001 Washer, M8 Flat<br />

37 CA100004050D Spacer, Chamber Lid<br />

38 QA1410060105 905 027 Spring, Bladder Return<br />

39 NA0710000001 Washer, M10<br />

40 AA100315160D 905 056 Bag Retainer Bar (Gas Option)<br />

41 NA0808000001 905 129 Spring Washer (Gas Option)<br />

42 NA1008000001 Screw Nut (Gas Option)<br />

43 PA0420504200 905 057 Bag Retainer Silicone (Gas Option)<br />

44 A A100861160D Sealing Bar<br />

45 SA200907090D 905 020 Teflon Tape Clamp<br />

46 NA0004001001 Round Head Screw<br />

47 PA0803116011 905 058 Teflon Tape<br />

48 QA0506003001 905 322 Sealing Wire<br />

49 PA0802540011 905 060 Teflon Tape<br />

A HA01<strong>880</strong>10003 905 308 Sealing Bar Set (28-34, 44-49)

Chamber Lid<br />

Diagram<br />

PARTS P A G E 38

PARTS P A G E 39<br />

Seal Bar - 10mm<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA01<strong>880</strong>10003 905 308 Seal Bar - 10mm<br />

1 A A100861160D Sealing Bar<br />

2 GA100017060D Sealing Bar End Block<br />

3 SA200907090D 905 020 Teflon Tamp Clamp<br />

4 GA100005290E 905 017 Sealing Wire Holder<br />

5 NA0004000601 Round Head Screw<br />

6 QA1410060105 905 097 Spring<br />

7 PA0803116011 905 058 Teflon Tape<br />

8 QA0510002501 905 336 Sealing Wire<br />

9 PA0802540011 905 060 Teflon Tape<br />

10 NA0306001001 905 053 Hex Head Screw<br />

11 NA0004002001 Round Head Screw<br />

12 HA1000000000 905 112 Wire Connector Set<br />

A HA5100000000 905 018 End Block Complete Assembly

Seal Bar - 10mm<br />

Diagram<br />

PARTS P A G E 40

PARTS P A G E 41<br />

Seal Bar - Cut-off<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA01<strong>880</strong>12001 Seal Bar - Cut-off<br />

1 A A100861160D Sealing Bar<br />

2 GA100015060D Sealing Bar End Block<br />

3 SA200907090D 905 020 Teflon Tamp Clamp<br />

4 GA100016010D Sealing Wire Holder<br />

5 NA0004000601 Round Head Screw<br />

6 PA0803116011 905 058 Teflon Tape<br />

7 QA0503000005 905 104 Sealing Wire<br />

8 PA0802540011 905 060 Teflon Tape<br />

9 NA0304001101 Hex Head Screw<br />

10 NA0004002001 Round Head Screw<br />

11 QA0501200004 905 105 Cut Wire<br />

12 HA1000000000 905 112 Wire Connector Set

Seal Bar - Cut-off<br />

Diagram<br />

PARTS P A G E 42

PARTS P A G E 43<br />

Seal Bar - Perf Knife (Optional)<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA01<strong>880</strong>10005 Seal Bar - Perf Knife<br />

1 SA101020260D Pressure Bag Cover<br />

2 HA1000000000 905 112 Wire Connector Set<br />

3 NA0004002001 Screw<br />

4 PA0803116011 905 058 Teflon Tape<br />

5 AA100330360D Sealing Bar<br />

6 AA100329360D Top<br />

7 AA100328360D Knife Mold Stand<br />

8 AA100332360D Teflon Tape Bar<br />

9 AA100331360D Teflon Tape Clamp<br />

10 SA101033030D 905 247 Straight Perf Knife<br />

11 PA0802540011 905 060 Teflon Tape<br />

12 QA0510002501 905 336 Sealing Wire<br />

13 GA100008360E End Block<br />

14 PA0420504200 905 057 Lid Gasket<br />

15 NA0405004001 Hex Head Screw<br />

16 NA0705000001 905 160 Washer<br />

17 NA0805000001 Spring Washer<br />

18 QA1410060105 905 097 Spring Board<br />

19 RA100087050D Sealing Bar Bushing<br />

20 NA0304000601 Hex Head Screw<br />

21 SA101027120D Top Spring<br />

22 NA0005003501 Round Head Screw<br />

23 NA0003002001 Round Head Screw<br />

24 NA0004001501 905 168 Round Head Screw<br />

25 SG10011350D Top Spring<br />

26 NA0005002001 Round Head Screw<br />

27 PA100367430E Sealing Bushing<br />

28 PA100368430D Sealing Bushing<br />

29 GA100005290E 905 017 Sealing Wire Holder<br />

30 SA101026010D Teflon Tape Clamp<br />

31 NA0004002001 Round Head Screw

PARTS P A G E 44<br />

Seal Bar - Perf Knife (Optional)<br />

Diagram

PARTS P A G E 45<br />

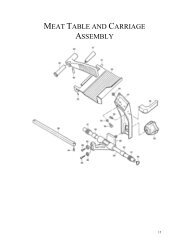

Working Bed, Top<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 SA200906020D Working Bed<br />

2 PA200521000E 905 248 Insert Plate<br />

3 PA200531240D 905 026 Spacer<br />

4 AA200348060D Cushion Bar<br />

5 PA200546062D 905 162 Silicon Bar End Insert (Left)<br />

5-1 PA200546061D 905 163 Silicon Bar End Insert (Right)<br />

6 RA200108050D Gas Nozzle Nut<br />

7 CA20010050D Gas Nozzle Tube<br />

8 DA2501000000 905 061 Teflon Tape Clamp<br />

9 PA0317084200 905 202 Sealing Silicon<br />

10 AA200284160D 905 114 Insert Plate Hold<br />

11 NA0004001201 905 115 Round Head Screw<br />

12 AA200006220D Hexagon Bushing<br />

13 PA1000300000 O-Ring<br />

14 AA200904240D Hexagon Bushing Block Holder<br />

15 CA1801002000 Gas Hose Connector<br />

16 NA0004001201 905 115 Round Head Screw<br />

17 NA0704000001 905 123 Washer<br />

18 NA0804000001 905 033 Spring Washer<br />

19 HA3310050403 905 064 Vacuum Suction Cover<br />

A HA0230021600 905 311 Cushion Bar Set (4-11)

Working Bed, Top<br />

Diagram<br />

PARTS P A G E 46

PARTS P A G E 47<br />

Cushion Bar - Standard<br />

Parts List and Diagram<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0230021600 905 311 Cushion Bar - Standard<br />

1 AA200348060D Cushion Bar<br />

2 PA0317084200 905 202 Sealing Silicon<br />

3 AA200284160D 905 114 Insert Plate Holder<br />

4 PA200546062D 905 162 Silicon Bar End Insert (Left)<br />

5 PA200546061D 905 163 Silicon Bar End Insert (Right)<br />

6 NA0004001501 905 168 Round Head Screw<br />

7 NA2101000000 905 222 Plug

PARTS P A G E 48<br />

Cushion Bar - Gas (Optional)<br />

Parts List and Diagram<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0210021600 905 312 Cushion Bar - Gas<br />

1 AA200348060D Cushion Bar<br />

2 PA0317084200 905 202 Sealing Silicon<br />

3 AA200284160D 905 114 Insert Plate Holder<br />

4 PA200546062D 905 162 Silicon Bar End Insert (Left)<br />

5 PA200546061D 905 163 Silicon Bar End Insert (Right)<br />

6 NA0004001501 905 168 Round Head Screw<br />

7 CA200010050D Gas Nozzle Tube<br />

8 RA200108050D Gas Nozzle Nut<br />

9 DA2501000000 905 061 Gas Nozzle

PARTS P A G E 49<br />

Cushion Bar - Biactive Seal (Optional)<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0230011600 905 315 Cushion Bar - Biactive Seal<br />

1 PC200008000D 905 159 Isolated Plug<br />

2 PA0316084100 905 202 Sealing Silicon<br />

3 NA0705000001 905 160 Washer<br />

4 AA200284160D 905 114 Insert Plate Holder<br />

5 PA200543061D 905 162 Silicon Bar End Insert (Left)<br />

6 PA200543062D 905 163 Silicon Bar End Insert (Right)<br />

7 PA100103320D Insulation Fiber<br />

8 GC200002020D 905 164 Copper Insert<br />

9 GC200001320D 905 165 Roller Wiring<br />

10 SB200818090D 905 166 Teflon Tape Clamp<br />

11 NA0004000601 Round Head Screw<br />

12 NA0004001501 905 168 Round Head Screw<br />

13 PA0803116011 905 058 Teflon Tape<br />

14 QA0510002501 905 336 Sealing Wire<br />

15 PA0802540011 905 060 Teflon Tape<br />

16 NA0404001501 905 169 Hex Head Screw<br />

17 NA0405005001 905 009 Hex Head Screw<br />

18 AA200358060D 905 156 Cushion Bar<br />

19 NA2101000000 905 222 Plug

PARTS P A G E 50<br />

Cushion Bar - Biactive Seal (Optional)<br />

Diagram

PARTS P A G E 51<br />

Cushion Bar - Biactive Seal w/Gas (Optional)<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0210011600 905 316 Cushion Bar - Biactive Seal with Gas<br />

1 DA2501000000 905 061 Gas Nozzle<br />

2 PC200008000D 905 159 Isolated Plug<br />

3 NA0705000001 905 160 Washer<br />

4 AA200284160D 905 114 Insert Plate Holder<br />

5 NA0004000601 Round Head Screw<br />

6 NA0004001501 905 168 Round Head Screw<br />

7 PA0803116011 905 058 Teflon Tape<br />

8 QA0510002501 905 336 Sealing Wire<br />

9 PA0202540011 905 060 Teflong Tape<br />

10 NA0404001501 905 168 Hex Head Screw<br />

11 NA0405005001 905 009 Hex Head Screw<br />

12 CA200010050D Gas Nozzle Tube<br />

13 RA200108050D Gas Nozzle Nut<br />

14 PA0316084100 905 202 Sealing Silicon<br />

15 PA200543061D 905 162 Silicon Bar End Insert (Left)<br />

16 PA200543062D 905 163 Silicon Bar End Insert (Right)<br />

17 PA100103320D End Block<br />

18 GC200002020D 905 164 Copper Insert<br />

19 GC20001320D Roller Wiring<br />

20 SB200818090D 905 166 Teflon Tape Clamp<br />

21 AA200372060D Cushion Bar

PARTS P A G E 52<br />

Cushion Bar - Biactive Seal w/Gas (Optional)<br />

Diagram

PARTS P A G E 53<br />

Cushion Bar - Perf Knife (Optional)<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0210601602 Cushion Bar - Perf Knife<br />

1 NA0104003001 Flat Head Screw<br />

2 AA200341050D Teflon Tape Bar Place (Bottom)<br />

3 AA200334050D Hexagon Bushing<br />

4 AA200374360D Cushion Bar<br />

5 AA200373360E Teflon Tape Bar (Bottom)<br />

6 PA200560110D 905 411 Sealing Silicon<br />

7 AA200359060D Insert Plate Hold<br />

8 PA0305075300 905 410 Sealing Silicon<br />

9 NA0004001201 905 115 Round Head Screw<br />

10 PA200086250D Silicon Bar End Insert

PARTS P A G E 54<br />

Cushion Bar - Perf Knife (Optional)<br />

Diagram

PARTS P A G E 55<br />

Cushion Bar - Perf Knife w/Gas (Optional)<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

HA0210601603 Cushion Bar - Perf Knife with Gas<br />

1 NA0104003001 Flat Head Screw<br />

2 AA200341050D Teflon Tape Bar Place (Bottom)<br />

3 AA200334050D Hexagon Bushing<br />

4 AA200374360D Cushion Bar<br />

5 AA200373360E Teflon Tape Bar (Bottom)<br />

6 PA200560110D 905 411 Sealing Silicon<br />

7 AA200359060D Insert Plate Hold<br />

8 PA0305075300 905 410 Sealing Silicon<br />

9 NA0004001201 905 115 Round Head Screw<br />

10 PA200086250D Silicon Bar End Insert<br />

11 NA1008000001 Screw Nut<br />

12 CA200015120D Gas Nozzle Tube<br />

13 NA0306001001 905 053 Hex Head Screw<br />

14 NA0004002001 Round Head Screw

PARTS P A G E 56<br />

Cushion Bar - Perf Knife w/Gas (Optional)<br />

Diagram

PARTS P A G E 57<br />

Working Bed, Bottom<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 SA200906020D Working Bed<br />

2 CA0014021003 Elbow<br />

3 CA0214018012 Nipple<br />

4 CA0214004012 Nipple<br />

4-1 CA0116014020 Bushing<br />

5 CA0214018012 Nipple<br />

6 HA1502420000 Vacuum Valve Set<br />

6-1 QA1140632000 Hose Clamp<br />

6-2 PA0605080635 835 162 Vacuum Hose<br />

7 NA0510030001 905 069 Set Screw<br />

8 NA0710000001 Washer<br />

9 MA200001280D 905 025 Hexagon Nut Lid Spring Threaded Rod<br />

10 NA0810000001 Spring Washer<br />

11 NA0410003501 Hex Head Screw<br />

12 NA1010000001 Screw Nut<br />

13 MA200015090D Spring Tension Block<br />

14 RA20092080D Tension Spring<br />

15 QA2259540210 905 074 Retaining Ring<br />

16 BA0403500000 Bearing<br />

17 AA200903010D Beaing Holder<br />

18 NA0406003501 Hex Head Screw<br />

19 RA200103320D Main Shaft<br />

20 NA1006000001 905 120 Screw Nut<br />

21 NA0806000001 905 122 Spring Washer<br />

22 NA0706000001 Washer<br />

23 SA201069010E Switch Holder Plate<br />

24 NA0804000001 905 033 Spring Washer<br />

25 NA0004004501 905 125 Round Head Screw<br />

26 EA24152500474 Micro Switch<br />

27 NA0806000001 905 122 Spring Washer<br />

28 NA0406001501 905 119 Hex Head Screw<br />

29 MA200003160D 905 078 Top Cam

Working Bed, Bottom<br />

Diagram<br />

PARTS P A G E 58

PARTS P A G E 59<br />

Working Bed, Bottom<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

30 MA200004160D 905 079 Bottom Cam<br />

31 NA0808000001 905 129 Spring Washer<br />

31-1 NA0708000001 Washer<br />

32 NA0408004001 905 126 Hex Head Screw<br />

33 MA200011010D 905 127 Top Spring Bracket<br />

34 MA200010010D 905 128 Bottome Spring Bracket<br />

35 NA0808000001 905 129 Spring Washer<br />

36 NA0408005001 905 081 Hex Head Screw<br />

37 NA0808000001 905 129 Spring Washer<br />

38 NA0408003501 Hex Head Screw<br />

39 NA046001501 905 119 Hex Head Screw (Gas Option)<br />

40 DA2401040080 905 130 Gas Distributor Block (Gas Option)<br />

41 CA0204003010 905 131 Nipple (Gas Option)<br />

42 EA0370201241 Gas Solenoid Valve (Gas Option)<br />

43 NA0706000001 Washer (Gas Option)<br />

44 NA0806000001 905 122 Spring Washer (Gas Option)<br />

45 NA0406001501 905 119 Hex Head Screw (Gas Option)<br />

46 NA1006000001 905 120 Screw Nut (Gas Option)<br />

47 CA0804010050 905 136 Threaded Flared Nipple (Gas Option)<br />

48 CA0404004010 T-Connector (Gas Option)<br />

49 WA300021010D Valve Holder Plate (Gas Option)<br />

50 CA0302008100 Straight Connector<br />

51 CA0303008200 905 132 Straight Connector<br />

52 DA0302030000 905 241 Air Regulator with Gauge<br />

53 EA0310201030 905 082 Sealing Solenoid Valve<br />

54 CA1901002000 905 138 L-Shaped Connector<br />

55 EB1720151001 Cable Gland<br />

56 EB1732151100 905 143 Cable Gland<br />

57 NA1006000001 905 120 Screw Nut (Gas Option)<br />

58 NA0806000001 905 122 Spring Washer (Gas Option)<br />

59 NA0706000001 Washer (Gas Option)<br />

60 SA201069010E Switch Holder Plate (Gas Option)

Working Bed, Bottom<br />

Diagram<br />

PARTS P A G E 60

PARTS P A G E 61<br />

Working Bed, Bottom<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

61 NA0804000001 905 033 Spring Washer (Gas Option)<br />

62 NA0004004501 905 125 Round Head Screw (Gas Option)<br />

63 EA2415250044 905 077 Micro Switch (Gas Option)<br />

64 NA0806000001 905 122 Spring Washer (Gas Option)<br />

65 NA0406001501 905 119 Hex Head Screw (Gas Option)<br />

66 NA0706000001 Washer<br />

67 NA0806000001 905 122 Spring Washer<br />

68 NA0406001501 905 119 Hex Head Screw<br />

69 SA200978270D 905 135 Valve Holder Plate<br />

70 MA200003160D 905 078 Top Cam (Gas Option)<br />

71 MA200004160D 905 079 Bottom Cam (Gas Option)<br />

72 NA0808000001 905 129 Spring Washer (Gas Option)<br />

72-1 NA0708000001 Washer (Gas Option)<br />

73 NA0408004001 905 126 Hex Head Screw (Gas Option)<br />

A HA3501000000 Valve for Gas Flushing Set (39-49)<br />

E HA1112000000 Tension Spring Set (7, 13, 14)

Working Bed, Bottom<br />

Diagram<br />

PARTS P A G E 62

PARTS P A G E 63<br />

Body<br />

Parts List<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 SA300967270D 905 144 Machine Body<br />

2 NA1008000001 Screw Nut<br />

3 NA0808000001 905 129 Spring Washer<br />

4 NA0708000001 Washer<br />

5 NA0408002001 Hex Head Screw<br />

6 CA0901008000 VAcuum Gauge Coupling<br />

7 QA0413500000 Vacuum Gauge<br />

8 NA0004001001 Round Head Screw<br />

9 HA1303020204 Control Panel<br />

10 EA2012224000 Main Switch<br />

11 NA1008000001 Screw Nut<br />

12 NA0808000001 905 129 Spring Washer<br />

13 QA0315222100 905 264 Casters<br />

14 NA0408001501 Round Head Screw<br />

15 SA300985270D Right Back Door<br />

16 QA3100401010 905 280 Door Lock<br />

17 SA300984270D Left Back Door<br />

18 TA0001432160 Vacuum Pump<br />

19 SA300983270D Side Door<br />

20 NA0810000001 Spring Washer<br />

21 NA0410001501 Hex Head Screw

Body<br />

Diagram<br />

PARTS P A G E 64

PARTS P A G E 65<br />

Electrical Box - Standard<br />

Parts list<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 EA4548592210 Control Box<br />

2 Plate<br />

3 XA2002000000 Ground Block Holder<br />

4 EA5101000000 Limit Timer Place<br />

5 EA5001024310 Limit Timer<br />

6 EA7803204500 Electric Wire Trough<br />

7 HA2502510000 Main Power Switch (for pump 100m3/h)<br />

HA2506310000 Main Power Switch (for pump 200m3/h and<br />

300m3/h)<br />

8 EA1601120100 905 090 Contactor for Heater<br />

9 EA1504741011 Transformer for Heater<br />

10 EA7803204500 Electric Wire Trough<br />

11 EA1504751011 Transformer for panel<br />

12 EA1603118400 Contactor for vacuum pump (for pump 100m3/h)<br />

EA1603132400 Contactor for vacuum pump (for pump 200m3/h)<br />

EA1604150700 Contactor for vacuum pump (for pump 300m3/h)<br />

13 EB1720151100 Cable Gland<br />

14 EB1718903100 Cable Gland<br />

15 EA1703050000 Overload for vacuum pump (for pump 100m3/h)<br />

EA1703075000 Overload for vacuum pump (for pump 200m3/h)<br />

EA1703125000 905 092 Overload for vacuum pump (for pump 300m3/h)<br />

16 EA4810024030 Relay<br />

17 EA4902000000 Relay Place

Electrical Box - Standard<br />

Diagram<br />

PARTS P A G E 66

PARTS P A G E 67<br />

Electrical Box - Auto Lid Swing (Optional)<br />

Parts list<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 EA4548592210 Control Box<br />

2 Plate<br />

3 XA2002000000 Ground Block Holder<br />

4 EA5101000000 Limit Timer Place<br />

5 EA5001024310 Limit Timer<br />

6 EA7803204500 Electric Wire Trough<br />

7 HA2502510000 Main Power Switch (for pump 100m3/h)<br />

HA2506310000 Main Power Switch (for pump 200m3/h and<br />

300m3/h)<br />

8 EA1601120100 905 090 Contactor for Heater<br />

9 EA1504741011 Transformer for Heater<br />

10 EA7803204500 Electric Wire Trough<br />

11 EA1504751011 Transformer for panel<br />

12 EA1603118400 Contactor for vacuum pump (for pump 100m3/h)<br />

EA1603132400 Contactor for vacuum pump (for pump 200m3/h)<br />

EA1604150700 Contactor for vacuum pump (for pump 300m3/h)<br />

13 EA4902000000 Relay Place<br />

14 EA4810024031 905 245 Relay<br />

15 EB1729151000 Cable Gland<br />

16 EB1720151100 Cable Gland<br />

17 EB1718903100 Cable Gland<br />

18 EA1703050000 Overload for vacuum pump (for pump 100m3/h)<br />

EA1703075000 Overload for vacuum pump (for pump 200m3/h)<br />

EA1703125000 905 092 Overload for vacuum pump (for pump 300m3/h)

Electrical Box - Auto Lid Swing (Optional)<br />

Diagram<br />

PARTS P A G E 68

PARTS P A G E 69<br />

Electrical Box - Biactive Seal (Optional)<br />

Parts list<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 EA4548592210 Control Box<br />

2 Plate<br />

3 XA2002000000 Ground Block Holder<br />

4 EA5101000000 Limit Timer Place<br />

5 EA5001024310 Limit Timer<br />

6 EA7803204500 Electric Wire Trough<br />

7 HA2502510000 Main Power Switch (for pump 100m3/h)<br />

HA2506310000 Main Power Switch (for pump 200m3/h and<br />

300m3/h)<br />

8 EA1601120100 905 090 Contactor for Heater<br />

9 EA1504741011 Transformer for Heater<br />

10 EA7803204500 Electric Wire Trough<br />

11 EA1504751011 Transformer for panel<br />

12 EA1603118400 Contactor for vacuum pump (for pump 100m3/h)<br />

EA1603132400 Contactor for vacuum pump (for pump 200m3/h)<br />

EA1604150700 Contactor for vacuum pump (for pump 300m3/h)<br />

13 EB1720151100 Cable Gland<br />

14 EB1718903100 Cable Gland<br />

15 EA1703050000 Overload for vacuum pump (for pump 100m3/h)<br />

EA1703075000 Overload for vacuum pump (for pump 200m3/h)<br />

EA1703125000 905 092 Overload for vacuum pump (for pump 300m3/h)<br />

16 EA4810024030 Relay<br />

17 EA4902000000 Relay Place

Electrical Box - Biactive Seal (Optional)<br />

Diagram<br />

PARTS P A G E 70

PARTS P A G E 71<br />

Electrical Box - Biactive w/Auto Lid (Optional)<br />

Parts list<br />

Item<br />

No.<br />

Mfg.<br />

Part No.<br />

Koch<br />

Part No. Description<br />

1 EA4548592210 Control Box<br />

2 Plate<br />

3 XA2002000000 Ground Block Holder<br />

4 EA5101000000 Limit Timer Place<br />

5 EA5001024310 Limit Timer<br />

6 EA7803204500 Electric Wire Trough<br />

7 HA2502510000 Main Power Switch (for pump 100m3/h)<br />

HA2506310000 Main Power Switch (for pump 200m3/h and<br />

300m3/h)<br />

8 EA1601120100 905 090 Contactor for Heater<br />

9 EA1504741011 Transformer for Heater<br />

10 EA7803204500 Electric Wire Trough<br />

11 EA1504751011 Transformer for panel<br />

12 EA1603118400 Contactor for vacuum pump (for pump 100m3/h)<br />