IMPORTANT NOTICE - Berkel Sales & Service

IMPORTANT NOTICE - Berkel Sales & Service IMPORTANT NOTICE - Berkel Sales & Service

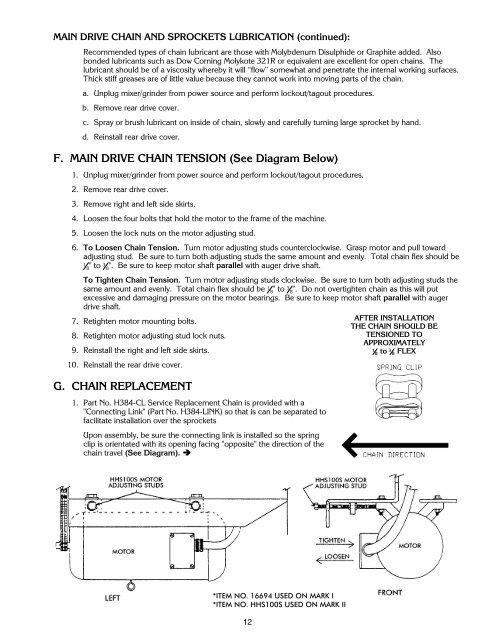

MAIN DRIVE CHAIN AND SPROCKETS LUBRICATION (continued): Recommended types of chain lubricant are those with Molybdenum Disulphide or Graphite added. Also bonded lubricants such as Dow Corning Molykote 321R or equivalent are excellent for open chains. The lubricant should be of a viscosity whereby it will “flow” somewhat and penetrate the internal working surfaces. Thick stiff greases are of little value because they cannot work into moving parts of the chain. a. Unplug mixer/grinder from power source and perform lockout/tagout procedures. b. Remove rear drive cover. c. Spray or brush lubricant on inside of chain, slowly and carefully turning large sprocket by hand. d. Reinstall rear drive cover. F. MAIN DRIVE CHAIN TENSION (See Diagram Below) 1. Unplug mixer/grinder from power source and perform lockout/tagout procedures. 2. Remove rear drive cover. 3. Remove right and left side skirts. 4. Loosen the four bolts that hold the motor to the frame of the machine. 5. Loosen the lock nuts on the motor adjusting stud. 6. To Loosen Chain Tension. Turn motor adjusting studs counterclockwise. Grasp motor and pull toward adjusting stud. Be sure to turn both adjusting studs the same amount and evenly. Total chain flex should be 1 8"to3 8". Be sure to keep motor shaft parallel with auger drive shaft. To Tighten Chain Tension. Turn motor adjusting studs clockwise. Be sure to turn both adjusting studs the same amount and evenly. Total chain flex should be 1 8"to3 8". Do not overtighten chain as this will put excessive and damaging pressure on the motor bearings. Be sure to keep motor shaft parallel with auger drive shaft. 7. Retighten motor mounting bolts. AFTER INSTALLATION THE CHAIN SHOULD BE 8. Retighten motor adjusting stud lock nuts. TENSIONED TO APPROXIMATELY 9. Reinstall the right and left side skirts. 1 8 to 10. Reinstall the rear drive cover. 3 8 FLEX G. CHAIN REPLACEMENT 1. Part No. H384-CL Service Replacement Chain is provided with a "Connecting Link" (Part No. H384-LINK) so that is can be separated to facilitate installation over the sprockets Upon assembly, be sure the connecting link is installed so the spring clip is orientated with its opening facing "opposite" the direction of the chain travel (See Diagram). 12 11

- Page 1 and 2: ✰ IMPORTANT NOTICE ✰ This Manua

- Page 3 and 4: TABLE OF CONTENTS NOTICETOOWNERSAND

- Page 5 and 6: SAFETY TIPS ROTATING GRINDING AUGER

- Page 8 and 9: 10. Two sets of green and red pushb

- Page 10 and 11: CLEANING THE BOWL - RING AND WORM C

- Page 17 and 18: — NOTES — 13 14

- Page 19 and 20: BIRO MODEL AFMG-48-II MIXER GRINDER

- Page 21 and 22: F 18 17

- Page 23 and 24: NO. 53886 JOURNAL BOX ASSEMBLY 20 1

- Page 25 and 26: TANDEM OPERATION ILLUSTRATION FOR 9

- Page 27 and 28: CONNECTION INSTRUCTIONS TANDEM OPER

- Page 30 and 31: OPERATOR’S SIGNATURE PAGE MY SIGN

- Page 32: LIMITED WARRANTY WARRANTY: The Biro

MAIN DRIVE CHAIN AND SPROCKETS LUBRICATION (continued):<br />

Recommended types of chain lubricant are those with Molybdenum Disulphide or Graphite added. Also<br />

bonded lubricants such as Dow Corning Molykote 321R or equivalent are excellent for open chains. The<br />

lubricant should be of a viscosity whereby it will “flow” somewhat and penetrate the internal working surfaces.<br />

Thick stiff greases are of little value because they cannot work into moving parts of the chain.<br />

a. Unplug mixer/grinder from power source and perform lockout/tagout procedures.<br />

b. Remove rear drive cover.<br />

c. Spray or brush lubricant on inside of chain, slowly and carefully turning large sprocket by hand.<br />

d. Reinstall rear drive cover.<br />

F. MAIN DRIVE CHAIN TENSION (See Diagram Below)<br />

1. Unplug mixer/grinder from power source and perform lockout/tagout procedures.<br />

2. Remove rear drive cover.<br />

3. Remove right and left side skirts.<br />

4. Loosen the four bolts that hold the motor to the frame of the machine.<br />

5. Loosen the lock nuts on the motor adjusting stud.<br />

6. To Loosen Chain Tension. Turn motor adjusting studs counterclockwise. Grasp motor and pull toward<br />

adjusting stud. Be sure to turn both adjusting studs the same amount and evenly. Total chain flex should be<br />

1<br />

8"to3 8". Be sure to keep motor shaft parallel with auger drive shaft.<br />

To Tighten Chain Tension. Turn motor adjusting studs clockwise. Be sure to turn both adjusting studs the<br />

same amount and evenly. Total chain flex should be 1 8"to3 8". Do not overtighten chain as this will put<br />

excessive and damaging pressure on the motor bearings. Be sure to keep motor shaft parallel with auger<br />

drive shaft.<br />

7. Retighten motor mounting bolts.<br />

AFTER INSTALLATION<br />

THE CHAIN SHOULD BE<br />

8. Retighten motor adjusting stud lock nuts.<br />

TENSIONED TO<br />

APPROXIMATELY<br />

9. Reinstall the right and left side skirts.<br />

1<br />

8 to<br />

10. Reinstall the rear drive cover.<br />

3 8 FLEX<br />

G. CHAIN REPLACEMENT<br />

1. Part No. H384-CL <strong>Service</strong> Replacement Chain is provided with a<br />

"Connecting Link" (Part No. H384-LINK) so that is can be separated to<br />

facilitate installation over the sprockets<br />

Upon assembly, be sure the connecting link is installed so the spring<br />

clip is orientated with its opening facing "opposite" the direction of the<br />

chain travel (See Diagram). <br />

12<br />

11