ORNL-4191 - the Molten Salt Energy Technologies Web Site

ORNL-4191 - the Molten Salt Energy Technologies Web Site

ORNL-4191 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

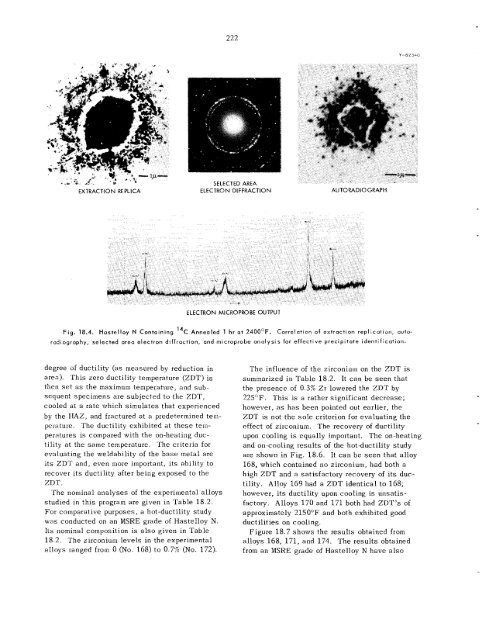

EX TRAC TI0 N RE PLICA<br />

222<br />

SELECTED AREA<br />

ELECTRON DIFFRACTION AUTO MDlO GRAPH<br />

ELECTRON MICROPROBE OUTPUT<br />

Fig. 18.4. Hastelloy N Containing 14C Annealed 1 hr at 24OOOF. Correlation of extraction replication, auto-<br />

radiography, selected area electron diffraction, and microprobe analysis for effective precipitate identification.<br />

degree of ductility (as measured by reduction in<br />

area). 'This zero ductility temperature (ZDT) is<br />

<strong>the</strong>n set as <strong>the</strong> maximum temperature, and sub-<br />

sequent specimens are subjected to <strong>the</strong> ZDT,<br />

cooled at a rate which simulates that experienced<br />

by <strong>the</strong> IIAZ, and fractured at a predetermined tem-<br />

perature. The ductility exhibited at <strong>the</strong>se tem-<br />

peratures is compared with <strong>the</strong> on-heating duc-<br />

tility at <strong>the</strong> same temperature. 'The criteria for<br />

evaluating <strong>the</strong> weldability of <strong>the</strong> base metal are<br />

its ZDT and, even more important, its ability to<br />

recover its ductility after being exposed to <strong>the</strong><br />

m'r.<br />

'The nominal analyses of <strong>the</strong> experimental alloys<br />

studied in this program are given in 'Table 18.2.<br />

For comparative purposes, a hot-ductility study<br />

was conducted on an MSRE grade of Hastelloy N.<br />

Its nominal composition is also given in Table<br />

18.2. The zirconium levels in <strong>the</strong> experimental<br />

alloys ranged from 0 (No. 168) to 0.7% (No. 172).<br />

Y--8254C<br />

The influence of <strong>the</strong> zirconium on <strong>the</strong> ZDT is<br />

summarized in Table 18.2. Kt can be seen that<br />

<strong>the</strong> presence of 0.3% Zr lowered <strong>the</strong> ZDT by<br />

225°F. This is a ra<strong>the</strong>r significant decrease;<br />

however, as has been pointed out earlier, <strong>the</strong><br />

ZDT is not <strong>the</strong> sole criterion for evaluating <strong>the</strong><br />

effect of zirconium. The recovery of ductility<br />

upon cooling is equally important. The on-heating<br />

and on-cooling results of <strong>the</strong> hotductility study<br />

are shown in Fig. 18.6. It can be seen that alloy<br />

168, which contained no zirconium, had both a<br />

high ZDT and a satisfactory recovery of its duc-<br />

tility. Alloy 169 had a ZDT identical to 158;<br />

however, its ductility upon cooling is unsatis-<br />

factory. Alloys 170 and 171 both had ZDT's of<br />

appioxirnately 2150OF and both exhibited good<br />

ductilities on cooling.<br />

Figure 18.7 shows <strong>the</strong> results obtained from<br />

alloys 168, 171, and 174. The results obtained<br />

from an MSRE grade of Hastelloy N have also

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)