ORNL-4191 - the Molten Salt Energy Technologies Web Site

ORNL-4191 - the Molten Salt Energy Technologies Web Site

ORNL-4191 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THERMOCOUPI-F<br />

FURNACE<br />

I<br />

TO VACUUM<br />

<strong>ORNL</strong>-DWG 67-1f827<br />

e TO TAYLOR PRESSURE<br />

TRANSMITTER<br />

*GAS SAMPLING<br />

STPT IO ‘\i<br />

PRESSURE<br />

GAUGE k&<br />

Fig. 13.5. Appnratus for Measuring Decomposition<br />

Pressure of Fluoroborate Melts.<br />

is shown schematically in Fig. 13.5. The mclt,<br />

contained in nickel, exerts its vapor pressure on<br />

a mercury manometer and on diaphragm gages. To<br />

remove adsorbed gases, <strong>the</strong> vessel, containing a<br />

weighed salt sample, is initially evacuated at 100<br />

to 125°C for at least 15 hr. Then to release gases<br />

encapsulated within <strong>the</strong> salt crystals <strong>the</strong> sample is<br />

heated about 25OC above its liquidus temperature.<br />

The sample is subsequently cooled down to room<br />

temperature. If <strong>the</strong> apparent pressure is greater<br />

than 0.5 mm at room temperature, <strong>the</strong> system is<br />

reevacuated and <strong>the</strong>n reheated and cooled until<br />

<strong>the</strong> vapor pressure at room temperature is essentially<br />

nil.<br />

After this desorbing procedure, <strong>the</strong> observed<br />

vapor pressures should be caused only by <strong>the</strong><br />

dissociation<br />

NaRF,(2) = BF,(g) + NaF(2) .<br />

Gas samples collected during <strong>the</strong> vapor pressure<br />

measurements and analyzed mass spectrometrically<br />

confirmed that <strong>the</strong> vapor was virtually pure BF,.<br />

Usually about 1% SiF, is observed in <strong>the</strong> vapor,<br />

this probably originates from <strong>the</strong> reaction of<br />

desorbed KF with <strong>the</strong> glass parts of <strong>the</strong> apparatus.<br />

After completing vapor pressure measurements,<br />

<strong>the</strong> containment vessel is cut open and <strong>the</strong> contents<br />

160<br />

‘OrOOO r<br />

-e-<br />

FAEASURED<br />

7 - 1-<br />

<strong>ORNL</strong> DWG 67-41828<br />

65 70 75 80 85 30 95 100<br />

mole % Na BF4<br />

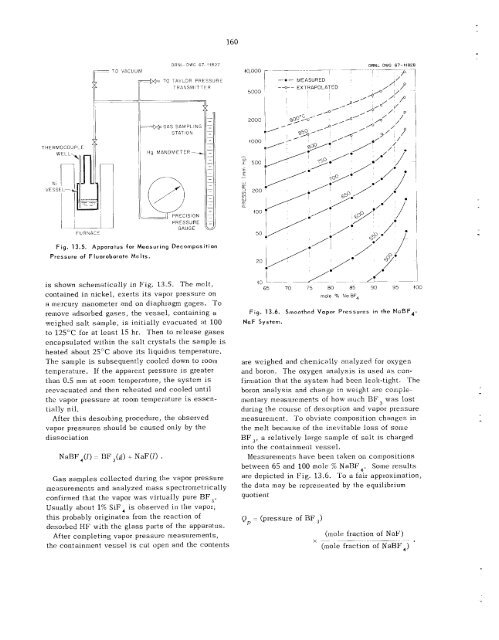

Fig. 13.6. Smoo<strong>the</strong>d Vapor Pressures in <strong>the</strong> No5F4-<br />

NaF System.<br />

are weighed and chemically analyzed for oxygen<br />

and boron. The oxygen analysis is used as con-<br />

firmation that <strong>the</strong> system had been leak-tight. ‘The<br />

boron analysis and change in weight are comple-<br />

mentary measurements of how much BE’, was lost<br />

during <strong>the</strong> course of desorption and vapor pressure<br />

measurement. To obviate coinposition changes in<br />

<strong>the</strong> melt because of <strong>the</strong> inevitable loss of some<br />

BF,, a relatively large sample of salt is charged<br />

into <strong>the</strong> containment vessel.<br />

Measurements have been taken on compositions<br />

between 65 and 100 mole % NaRF4. Some results<br />

are depicted in Fig. 13.6. To a fair approximation,<br />

<strong>the</strong> data may be represented by <strong>the</strong> equilibrium<br />

quotient<br />

Q = (pressure of BF,)<br />

P<br />

(molc fraction of NaF)<br />

x - - ~<br />

(mole fraction of NaBF,)

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)