ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

obtained from subsequent analyses of fuel samples,<br />

toge<strong>the</strong>r with <strong>the</strong> known amounts of concentrate<br />

added.) While <strong>the</strong> total amount of uranium (U235)<br />

added to <strong>the</strong> system in order to make <strong>the</strong> reactor<br />

critical was approximately 135 Ib, because of <strong>the</strong><br />

amounts withdrawn from <strong>the</strong> system for samples<br />

and in trimming <strong>the</strong> pump level, <strong>the</strong> uranium<br />

concentration at criticality was 23;7 Ib/ft3; or,<br />

since <strong>the</strong> calculated volume of <strong>the</strong> 1300°F core<br />

was 1.37 ft3, <strong>the</strong> “cold,” clean critical mass of<br />

<strong>the</strong> reactor was 32.5 Ib of UZ3’.<br />

Low-Power Experiments<br />

Several “experiments” were performed on <strong>the</strong><br />

critical reactor at low power, including reactor<br />

power and rod calibrations. In addition, <strong>the</strong><br />

effects of <strong>the</strong> process system parameters on re-<br />

activity were noted, and a preliminary measure-<br />

ment of <strong>the</strong> temperature coefficient was under-<br />

taken. The tests were started on <strong>the</strong> morning of<br />

November 4 and were completed by noon on<br />

November 8.<br />

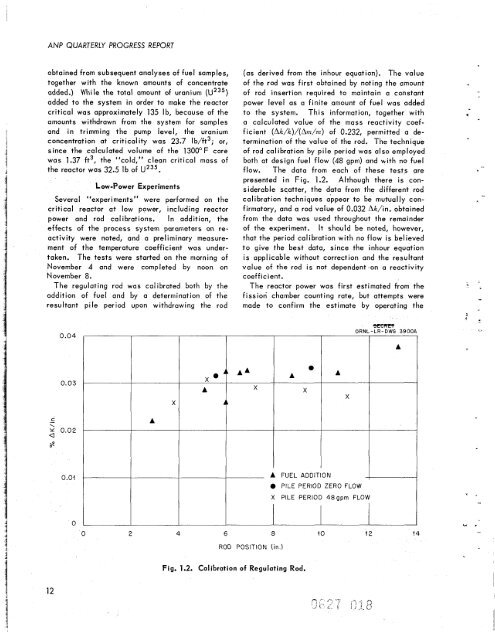

The regulating rod was calibrated both by <strong>the</strong><br />

addition of fuel and by a determination of <strong>the</strong><br />

resultant pile period upon withdrawing <strong>the</strong> rod<br />

.- c<br />

0*04 1<br />

c<br />

\<br />

y 0.02<br />

a<br />

12<br />

0.01 t<br />

0 L<br />

A<br />

X<br />

(as derived from <strong>the</strong> inhour equation). The value<br />

of <strong>the</strong> rod was first obtained by noting <strong>the</strong> amount<br />

of rod insertion required to maintain a constant<br />

power level as a finite amount of fuel was added<br />

to <strong>the</strong> system. This information, toge<strong>the</strong>r with<br />

a calculated value of <strong>the</strong> mass reactivity coef-<br />

ficient (Ak/k)/(Am/m) of 0.232, permitted a de-<br />

termination of <strong>the</strong> value of <strong>the</strong> rod. The technique<br />

of rod calibration by pile period was also employed<br />

both at design fuel flow (48 gpm) and with no fuel<br />

flow. The data from each of <strong>the</strong>se tests are<br />

presented in Fig. 1.2. Although <strong>the</strong>re is con-<br />

siderable scatter, <strong>the</strong> data from <strong>the</strong> different rod<br />

calibration techniques appear to be mutually con-<br />

firmatory, and a rod value of 0.032 Ak/in. obtained<br />

from <strong>the</strong> data was used throughout <strong>the</strong> remainder<br />

of <strong>the</strong> experiment. It should be noted, however,<br />

that <strong>the</strong> period calibration with no flow is believed<br />

to give <strong>the</strong> best data, since <strong>the</strong> inhour equation<br />

is applicable without correction and <strong>the</strong> resultant<br />

value of <strong>the</strong> rod is not dependent’on a reactivity<br />

coefficient .<br />

The reactor power was first estimated from <strong>the</strong><br />

fission chamber counting rate, but attempts were<br />

made to confirm <strong>the</strong> estimate by operating <strong>the</strong><br />

A FUEL ADDITION<br />

0 PILE PERIOD ZERO FLOW<br />

3i?cnm<br />

OR NL - LR - D WG 39 008<br />

X PILE PERIOD 48gpm FLOW<br />

0 2 4 6 8 io 12 14<br />

ROD POSITION (in.)<br />

Fig. 1.2. Calibration of Regulating Rod,

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)