ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1. CIRCULATING-FUEL AIRCRAFT REACTOR EXPERIMENT<br />

OPERATION OF THE AIRCRAFT REACTOR<br />

EXPERIMENT<br />

The Aircraft Reactor Exper iment was success-<br />

fully operated during <strong>the</strong> quarter. Uranium in <strong>the</strong><br />

form of molten Na,UF, was added to <strong>the</strong> barren<br />

carrier, NaZrF,, with which <strong>the</strong> fuel system was<br />

initially filled, to make <strong>the</strong> reactor critical. The<br />

fuel composition at initial criticality was 52.8-<br />

41.5-5.7 mole 5% (RaF-ZrF,-UF,), which has a<br />

melting point of 990°F, whereas <strong>the</strong> final fuel<br />

mixture (which included excess uranium) had a<br />

composition of 53.2-40.5-6.3 mole % (NaF-ZrF,-<br />

UF,) and a melting point of 1000°F.<br />

It was initially intended to remotely add <strong>the</strong><br />

concentrate to <strong>the</strong> fuel system from a large tank<br />

which contained all <strong>the</strong> concentrate, after first<br />

passing. it through an intermediate transfer tank.<br />

This system was discarded when temperature-<br />

control and continuous-weight-measuring instru-<br />

mentation on <strong>the</strong> transfer tank proved to be un-<br />

satisfactory. Instead, a less elaborate, but more<br />

direct, method of concentrate addition was em-<br />

ployed. This enrichment operation involved <strong>the</strong><br />

successive connection of numerous smal I concen-<br />

trate containers to an intermediate transfer pot,<br />

which was, in turn, connected to <strong>the</strong> fuel system<br />

by a line which injected <strong>the</strong> concentrate in <strong>the</strong><br />

pump above <strong>the</strong> liquid level. Each of <strong>the</strong> concen-<br />

trate containers was weighed before and after a<br />

transfer in order to determine <strong>the</strong> amount of<br />

uranium injected into <strong>the</strong> system. The concentrate<br />

was supplied in batches in cans containing from<br />

about 0.25 Ib of Na,UF, (for rod calibration) up<br />

to about 33 Ib (as was used during <strong>the</strong> first<br />

subcritical loading). In <strong>the</strong> enrichment operation<br />

<strong>the</strong> pump bowl served as a mixing chamber and<br />

uniformly distributed <strong>the</strong> concentrate into <strong>the</strong><br />

circulating stream. (For details of <strong>the</strong> loading<br />

operation see -foliowing subsection on “Loading<br />

of <strong>the</strong> ARE.”)<br />

The first concentrate addition was made on<br />

October 30, but <strong>the</strong> reactor did not become critical<br />

until three days later (3:45 PM, November 3).<br />

Most of <strong>the</strong> intervening time was spent in clearing<br />

<strong>the</strong> end of <strong>the</strong> transfer line at <strong>the</strong> pump, which,<br />

because of limitations inherent to only this par-<br />

E. S. Bettis J. L. Meem<br />

Aircraft Reactor Engineering Division<br />

ticular design, was difficult to heat and even more<br />

difficult to service.<br />

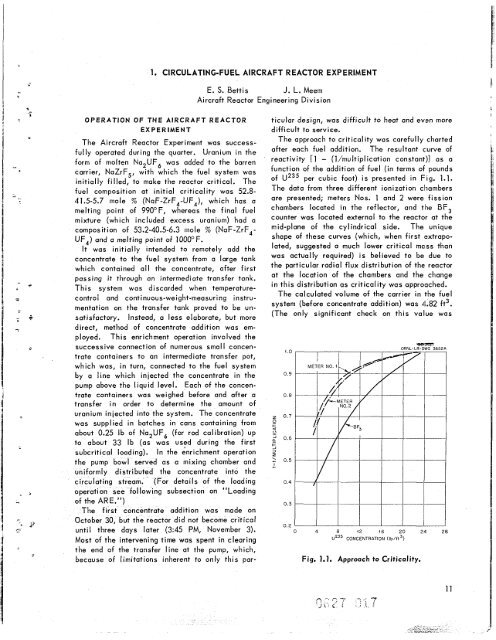

The approach to criticality was carefully charted<br />

after each fuel addition. The resultant curve of<br />

reactivity [I - (l/multiplication constant)] as a<br />

function of <strong>the</strong> addition of fuel (in terms of pounds<br />

of U235 per cubic foot) is presented in Fig. 1.1.<br />

The data from three different ionization chambers<br />

are presented; meters Nos. 1 and 2 were fission<br />

chambers located in <strong>the</strong> reflector, and <strong>the</strong> BF,<br />

counter was located external to <strong>the</strong> reactor at <strong>the</strong><br />

mid-plane of <strong>the</strong> cylindrical side. The unique<br />

shape of <strong>the</strong>se curves (which, when first (extrapo-<br />

lated, suggested a much lower critical mass than<br />

was actually required) is believed to be due to<br />

<strong>the</strong> particular radial flux distribution of <strong>the</strong> reactor<br />

at <strong>the</strong> location of <strong>the</strong> chambers and <strong>the</strong> change<br />

in this distribution as criticality was approached.<br />

The calculated volume of <strong>the</strong> carrier in <strong>the</strong> fuel<br />

system (before concentrate addition) was 4.82 ft3.<br />

(The only significant check on this value was<br />

1.0<br />

0.9<br />

0.8<br />

z 0.7<br />

0<br />

+<br />

0<br />

2 0.6<br />

-<br />

+<br />

-I 3<br />

I<br />

1 0.5<br />

-.<br />

0.4<br />

0.3<br />

02<br />

0 4 8 i2 16 20 24 28<br />

U235 CONCENTRATION (lb/ft3)<br />

Fig. 1.1. Approach to Criticality.

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)