ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site ORNL-1816 - the Molten Salt Energy Technologies Web Site

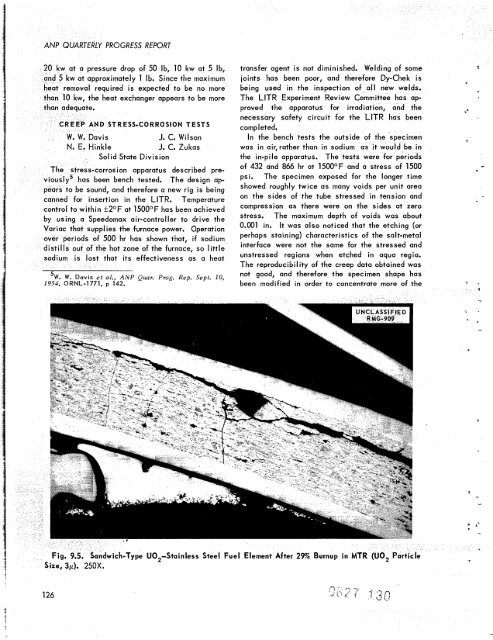

ANP QUARTERLY PROGRESS REPORT kw at a pressure drop of 50 Ib, 10 kw at 5 Ib, d 5 kw at approximately 1 Ib. Since the maximum at removal required is expected to be no more an 10 kw, the heat exchanger appears to be more CREEP AND STRESS-CORROSION TESTS avis J. C. Wilson N. E. Hinkle J. C. Zukas Solid State Division stress-corrosion apparatus described pre- s has been bench tested. The design ap- o be sound, and therefore a new rig is being canned for insertion in the LITR. Temperature control to within 52°F at 150OOF has been achieved by using a Speedomax air-controller to drive the that supplies the furnace power. Operation riods of 500 hr has shown that, if sodium distills out of the hot zone of the furnace, so little sodium is lost that its effectiveness as a heat 'W. W. Davis et al., ANP Qwr. Prog. Rep. Sept. 10, 1954, ORNL-1771, p 142. .t transfer agent is not diminished. Welding of some t joints has been poor, and therefore Dy-Chek is being used in the inspection of all new welds. The LITR Experiment Review Committee has ape proved the apparatus for irradiat necessary safety circuit for the LITR has been completed. In the bench tests the outside of t was in air,rather than in sodium as it would be in the in-pile apparatus. The tests were for periods of 432 and 866 hr at 15OOOF and a stress of 1500 psi. The specimen exposed for the longer time showed roughly twice as many voids per unit area on the sides of the tube stressed in tension and compression as there were on the sides at zero stress. The maximum depth of voids was about 0.001 in. It was also noticed that the etching (or perhaps staining) characteristics of the salt-metal interface were not the same for the stressed and unstressed regions when etched in aqua regia. The reproducibility of the creep data obtained was not good, and therefore the specimen shape has been modified in order to concentrate more of the * . Fig. 9.5. Sandwich-Type U0,-Stainless Steel Fuel Element After 29% Burnup in MTR S Nize, 3p). 250X. 126 . 1 1

creep deformation in the gage length. A specimen tube with thicker walls will be used, and the wall thickness will be reduced only at that part of the tube which is in contact with the fused salt. This modification should greatly increase the accuracy of creep measurements. The MTR creep test equipment is being bench tested prior to shipment to NRTS. REMOTE METALLOGRAPHY M. J. Feldman R. N. Ramsey W. B. Parsley A. E. Richt Solid State Division Two additional Pratt & Whitney Aircraft capsules, each containing sandwich-type U0,-stainless steel fuel elements, were opened, and the elements were examined metallographically. The stainless steel- UO, particle size was less than 3p for one capsule, and it was between 15 and 44p for the other. The capsules were irradiated at a temperature of about 5OO0F, and the total burnup for each capsule was 2%. Comparison of the results from the element PERIOD ENDING DECEMBER 10, 7954 with 3-p particle size and the element with 15- to 44-p particle size showed that irradiation induced greater final hardness in the elements with the smaller-particle-size material (Figs. 9.5 and 9.6). Four samples from the smaller-particle-size elements showed cracking of the core without bending. Since cracking did not occur in elements with lower total burnups, it appears that the increased burnup (29%), together with the small partic:le size, can cause cracking of the core, as illustrated in Fig. 9.5. MASS SPECTROGRAPHIC ANALYSElS R. Baldock Stable Isotope Research and Production Division The isotope dilution method has been used during the last one and one-half years for analyzing ARE- type (NaF-ZrF,-UF,) fuels for their uranium con- tent.' As a result of this experience, a need was 'L. 0. Gilpatrick and J. R. Sites, Stable Isotope Re- search and Production Semiann. Prog. Rep. May 20, 19.54, ORNL-1732, p 24. Fig. 9.6. Sandwich-Type UOp-Stainless Steel Fuel Element After 29% Burnup in MTR and a Bend Test (UO, Particle Size, 15 to 441.1). 250X. 127

- Page 88 and 89: ANP QUARTERLY PROGRESS REPORT Studi

- Page 90 and 91: ANP QUARTERLY PROGRESS REPORT TABLE

- Page 92 and 93: 1 ANP QUARTERLY PROGRESS REPORT 19.

- Page 94 and 95: ANP QUARTERLY PROGRESS REPORT TABLE

- Page 96 and 97: ANP QUARTERLY PROGRESS REPORT appea

- Page 98 and 99: 1 I I I . . ANP QUARTERLY PROGRESS

- Page 100 and 101: ANP QUARTERLY PROGRESS REPORT Fig.

- Page 102 and 103: 06 dWnd lV'91NVH33W 01 A XI13 X3tlA

- Page 104 and 105: ANP QUARTERLY PROGRESS REPORT 0.001

- Page 106 and 107: I ANP QUARTERLY PROGRESS REPORT ] 1

- Page 108 and 109: ANP QUARTERLY PROGRESS REPORT If a

- Page 110 and 111: ANP QUARTERLY PROGRESS REPORT phase

- Page 112 and 113: ANP QUARTERLY PROGRESS REPORT 7. ME

- Page 114 and 115: ANP QUARTERLY PROGRESS REPORT fabri

- Page 116 and 117: ANP QUARTERLY PROGRESS REPORT - N -

- Page 118 and 119: ANP QUARTERLY PROGRESS REPORT Fig.

- Page 120 and 121: 1 I ANP QUARTERLY PROGRESS REPORT h

- Page 122 and 123: ANP QUARTERLY PROGRESS REPORT rruga

- Page 124 and 125: ANP QUARTERLY PROGRESS REPORT eat t

- Page 126 and 127: ANP QUARTERLY PROGRESS REPORT Plast

- Page 128 and 129: ANP QUARTERLY PROGRESS REPORT 0.2 0

- Page 130 and 131: ANP QUARTERLY PROGRESS REPORT STAIN

- Page 132 and 133: i ANP QUARTERLY PROGRESS REPORT The

- Page 134 and 135: ANP QUARTERLY PROGRESS REPORT Three

- Page 136 and 137: ANP QUARTERLY PROGRESS REPORT - ORN

- Page 140 and 141: ANP QUARTERLY PROGRESS REPORT felt

- Page 142 and 143: ANP QUARTERLY PROGRESS REPORT chlor

- Page 144 and 145: ANP QUARTERLY PROGRESS REPORT prese

- Page 146 and 147: ! ANP QUARTERLY PROGRESS REPORT 11.

- Page 148 and 149: ANP QUARTERLY PROGRESS REPORT 136 A

- Page 150 and 151: ANP QUARTERLY PROGRESS REPORT stand

- Page 152 and 153: fused salt bath to permit dissoluti

- Page 154 and 155: Fr . F

- Page 156 and 157: ANP QUARlERlY PROGRESS REPORT chara

- Page 158 and 159: ANP QUARTERLY PROGRESS REPORT injur

- Page 160 and 161: ANP QUARTERLY PROGRESS REPORT 148 X

- Page 162 and 163: ANP QUARTERLY PROGRESS REPORT In co

- Page 164 and 165: ANP QUARTERLY PROGRESS REPORT - 103

- Page 166 and 167: ANP QUARTERLY PROGRESS REPORT condu

- Page 168 and 169: ANP QUARTERLY PROGRESS REPORT For m

- Page 170 and 171: 15. TOWER SHIELDING FACILITY C. E.

- Page 172 and 173: ANP QUARTERLY PROGRESS REPORT - .-

- Page 174 and 175: ANP QUARTERLY PROGRESS REPORT 162 -

- Page 176 and 177: h .e 0 c 0 L ’c v c t 0 W v) 0 a

- Page 178 and 179: f r e

ANP QUARTERLY PROGRESS REPORT<br />

kw at a pressure drop of 50 Ib, 10 kw at 5 Ib,<br />

d 5 kw at approximately 1 Ib. Since <strong>the</strong> maximum<br />

at removal required is expected to be no more<br />

an 10 kw, <strong>the</strong> heat exchanger appears to be more<br />

CREEP AND STRESS-CORROSION TESTS<br />

avis J. C. Wilson<br />

N. E. Hinkle<br />

J. C. Zukas<br />

Solid State Division<br />

stress-corrosion apparatus described pre-<br />

s has been bench tested. The design ap-<br />

o be sound, and <strong>the</strong>refore a new rig is being<br />

canned for insertion in <strong>the</strong> LITR. Temperature<br />

control to within 52°F at 150OOF has been achieved<br />

by using a Speedomax air-controller to drive <strong>the</strong><br />

that supplies <strong>the</strong> furnace power. Operation<br />

riods of 500 hr has shown that, if sodium<br />

distills out of <strong>the</strong> hot zone of <strong>the</strong> furnace, so little<br />

sodium is lost that its effectiveness as a heat<br />

'W. W. Davis et al., ANP Qwr. Prog. Rep. Sept. 10,<br />

1954, <strong>ORNL</strong>-1771, p 142.<br />

.t<br />

transfer agent is not diminished. Welding of some t<br />

joints has been poor, and <strong>the</strong>refore Dy-Chek is<br />

being used in <strong>the</strong> inspection of all new welds.<br />

The LITR Experiment Review Committee has ape<br />

proved <strong>the</strong> apparatus for irradiat<br />

necessary safety circuit for <strong>the</strong> LITR has been<br />

completed.<br />

In <strong>the</strong> bench tests <strong>the</strong> outside of t<br />

was in air,ra<strong>the</strong>r than in sodium as it would be in<br />

<strong>the</strong> in-pile apparatus. The tests were for periods<br />

of 432 and 866 hr at 15OOOF and a stress of 1500<br />

psi. The specimen exposed for <strong>the</strong> longer time<br />

showed roughly twice as many voids per unit area<br />

on <strong>the</strong> sides of <strong>the</strong> tube stressed in tension and<br />

compression as <strong>the</strong>re were on <strong>the</strong> sides at zero<br />

stress. The maximum depth of voids was about<br />

0.001 in. It was also noticed that <strong>the</strong> etching (or<br />

perhaps staining) characteristics of <strong>the</strong> salt-metal<br />

interface were not <strong>the</strong> same for <strong>the</strong> stressed and<br />

unstressed regions when etched in aqua regia.<br />

The reproducibility of <strong>the</strong> creep data obtained was<br />

not good, and <strong>the</strong>refore <strong>the</strong> specimen shape has<br />

been modified in order to concentrate more of <strong>the</strong> * .<br />

Fig. 9.5. Sandwich-Type U0,-Stainless Steel Fuel Element After 29% Burnup in MTR<br />

S Nize, 3p). 250X.<br />

126<br />

.<br />

1<br />

1