ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

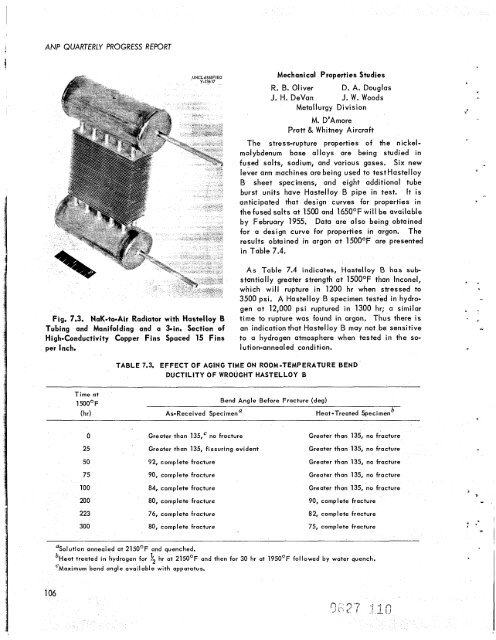

Fig. 7.3. NaK-to-Air Radiator with Hastelloy 6<br />

Tubing and Manifolding and a Sin. Section of<br />

High-Conductivity Copper Fins Spaced 15 Fins<br />

per Inch.<br />

106<br />

Mechanical Properties Studies<br />

R. B. Oliver D. A. Douglas<br />

J. H. DeVan J. W. Woods<br />

Metallurgy Division<br />

M. D'Amore<br />

Pratt & Whitney Aircraft<br />

The stress-rupture properties of <strong>the</strong> nickel-<br />

molybdenum base alloys are being studied in<br />

fused salts, sodium, and various gases. Six new<br />

lever arm machines are being used to testHastelloy<br />

B sheet specimens, and eight additional tube<br />

burst units have Hastelloy B pipe in test. It is<br />

anticipated that design curves for properties in<br />

<strong>the</strong> fused salts at 1500 and 165OOF will be available<br />

by February 1955. Data are also being obtained<br />

for a design curve for properties in argon. The<br />

results obtained in argon at 15OOOF are presented<br />

in Table 7.4.<br />

As Table 7.4 indicates, Hastelloy B has sub-<br />

stantially greater strength at 15OOOF than Inconel,<br />

which will rupture in 1200 hr when stressed to<br />

3500 psi. A Hastelloy B specimen tested in hydro-<br />

gen at 12,000 psi ruptured in 1300 hr; a similar<br />

time to rupture was found in argon. Thus <strong>the</strong>re is<br />

an indication that Hastelloy B may not be sensitive<br />

to a hydrogen atmosphere when tested in <strong>the</strong> so-<br />

l ution-annealed condition.<br />

TABLE 7.3. EFFECT OF AGING TIME ON ROOM-TEMPERATURE BEND<br />

DUCTILITY OF WROUGHT HASTELLOY B<br />

Time at<br />

Bend Angle Before Fracture (deg)<br />

150OoF<br />

b<br />

(hr) As-Received Specimen ' Heat-Treated Specimen<br />

0<br />

25<br />

50<br />

75<br />

100<br />

200<br />

223<br />

300<br />

Greater than 135,c no fracture<br />

Greater than 135, fissuring evideni<br />

92, complete fracture<br />

90, complete fracture<br />

84, complete fracture<br />

80, complete fracture<br />

76, complete fracture<br />

80, complete fracture<br />

'Solution annealed at 215OOF and quenched.<br />

1<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

90, complete fracture<br />

82, complete fracture<br />

75, complete fracture<br />

bHeat treated in hydrogen for /2 hr at 215OoF and <strong>the</strong>n for 30 hr at 195OOF followed by water quench.<br />

CMaximum bend angle available with apparatus.<br />

i -<br />

*<br />

a<br />

.<br />

-

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)