ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site ORNL-1816 - the Molten Salt Energy Technologies Web Site

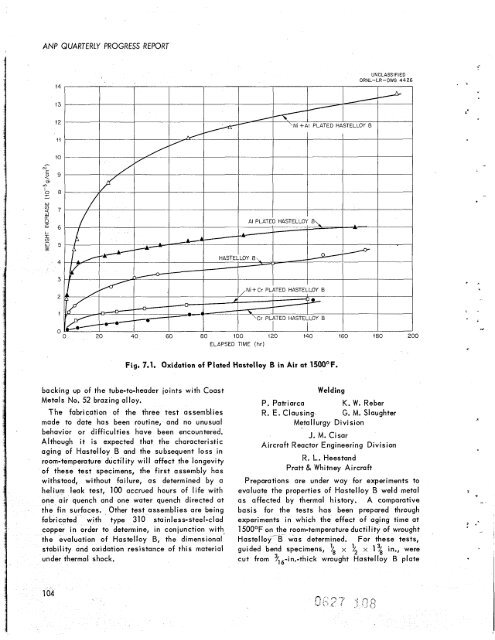

ANP QUARTERLY PROGRESS REPORT - N -. 14 13 12 11 IO $ 9 0 10 ‘ 0 8 - W m 4 7 W (L 0 z 6 I- I (.!I f 5 s 4 3 2 1 UNCLASSIFIED ORNL-LR-DWG 4426 0 0 20 40 60 80 100 I20 140 160 180 200 ELAPSED TIME (hr) Fig. 7.1. Oxidation of Plated Hastelloy B in Air at 1500OF. backing up of the tube-to-header joints with Coast Welding Metals No. 52 brazing alloy. The fabrication of the three test assemblies P. Patriarca R. E. Clausing K. W. Reber G. M. Slaughter made to date has been routine, and no unusual Metallurgy Division behavior or difficulties have been encountered. Although it is expected that the characteristic aging of Hastelloy B and the subsequent loss in room-temperature ductility will affect the longevity of these test specimens, the first assembly has J. M. Cisar Aircraft R eactor Engineering Division R. L. Heestand Pratt & Whitney Aircraft withstood, without failure, as determined by a Preparations are under way for experiments to helium leak test, 100 accrued hours of life with evaluate the properties of Hastelloy B weld metal one air quench and one water quench directed at as affected by thermal history. A comparative the fin surfaces. Other test assemblies are being basis for the tests has been prepared through fabricated with type 310 stainless-steel-clad experiments in which the effect of aging time at copper in order to determine, in conjunction with 15OOOF on the room-temperature ductility of wrought the evaluation of Hastelloy B, the dimensional stability and oxidation resistance of this material Hastelloy- B was determined. For these tests, guided bend specimens, x y2 x 1% in., were under thermal shock. cut from 3/,6-in.-thick wrought Hastelloy B plate . . . - 4

- N E \ cn s 14 12 io z a e F $6 w 3 4 2 0 0 20 ELAPSED TIME (hr) PERIOD ENDING DECEMBER 70, 7954 Fig. 7.2. Oxidation of Nickel-Molybdenum Base Alloys in Air at 15OOOF. UNCLASSIFIED ORNL-LR-DWG 4427 which had been solution annealed at 215OOF and a period of exposure of less than 50 hr. If the quenched. One set of specimens was then aged material is given a stabilizing heat trtzatment, ctility is prolonged and 200 hr. The estigation indicate zing heat tteatment r treatments at 195OOF mperature and 15OOOF bend tests, and the will be compared with those for wrought 105

- Page 65 and 66: Fig. 4.1. Second Reflector-Moderate

- Page 67: - . c ' t P - 9 Part I MATERIALS RE

- Page 70 and 71: ANP QUARTERLY PROGRESS REPORT 58 4e

- Page 72 and 73: ANP QUARTERLY PROGRESS REPORT UF, S

- Page 74 and 75: ANP QUARTERLY PROGRESS REPORT wheth

- Page 76 and 77: ANP QUARTERLY PROGRESS REPORT In th

- Page 78 and 79: 1Y PROGRESS REPORT y equilibration

- Page 80 and 81: ANP QUARTERLY PROGRESS REPORT were

- Page 82 and 83: ANP QUARTERLY PROGRESS REPORT Conse

- Page 84 and 85: AN P QUARTERLY PROGRESS R €PO RT

- Page 86 and 87: ANP QUARTERLY PROGRESS REPORT TABLE

- Page 88 and 89: ANP QUARTERLY PROGRESS REPORT Studi

- Page 90 and 91: ANP QUARTERLY PROGRESS REPORT TABLE

- Page 92 and 93: 1 ANP QUARTERLY PROGRESS REPORT 19.

- Page 94 and 95: ANP QUARTERLY PROGRESS REPORT TABLE

- Page 96 and 97: ANP QUARTERLY PROGRESS REPORT appea

- Page 98 and 99: 1 I I I . . ANP QUARTERLY PROGRESS

- Page 100 and 101: ANP QUARTERLY PROGRESS REPORT Fig.

- Page 102 and 103: 06 dWnd lV'91NVH33W 01 A XI13 X3tlA

- Page 104 and 105: ANP QUARTERLY PROGRESS REPORT 0.001

- Page 106 and 107: I ANP QUARTERLY PROGRESS REPORT ] 1

- Page 108 and 109: ANP QUARTERLY PROGRESS REPORT If a

- Page 110 and 111: ANP QUARTERLY PROGRESS REPORT phase

- Page 112 and 113: ANP QUARTERLY PROGRESS REPORT 7. ME

- Page 114 and 115: ANP QUARTERLY PROGRESS REPORT fabri

- Page 118 and 119: ANP QUARTERLY PROGRESS REPORT Fig.

- Page 120 and 121: 1 I ANP QUARTERLY PROGRESS REPORT h

- Page 122 and 123: ANP QUARTERLY PROGRESS REPORT rruga

- Page 124 and 125: ANP QUARTERLY PROGRESS REPORT eat t

- Page 126 and 127: ANP QUARTERLY PROGRESS REPORT Plast

- Page 128 and 129: ANP QUARTERLY PROGRESS REPORT 0.2 0

- Page 130 and 131: ANP QUARTERLY PROGRESS REPORT STAIN

- Page 132 and 133: i ANP QUARTERLY PROGRESS REPORT The

- Page 134 and 135: ANP QUARTERLY PROGRESS REPORT Three

- Page 136 and 137: ANP QUARTERLY PROGRESS REPORT - ORN

- Page 138 and 139: ANP QUARTERLY PROGRESS REPORT kw at

- Page 140 and 141: ANP QUARTERLY PROGRESS REPORT felt

- Page 142 and 143: ANP QUARTERLY PROGRESS REPORT chlor

- Page 144 and 145: ANP QUARTERLY PROGRESS REPORT prese

- Page 146 and 147: ! ANP QUARTERLY PROGRESS REPORT 11.

- Page 148 and 149: ANP QUARTERLY PROGRESS REPORT 136 A

- Page 150 and 151: ANP QUARTERLY PROGRESS REPORT stand

- Page 152 and 153: fused salt bath to permit dissoluti

- Page 154 and 155: Fr . F

- Page 156 and 157: ANP QUARlERlY PROGRESS REPORT chara

- Page 158 and 159: ANP QUARTERLY PROGRESS REPORT injur

- Page 160 and 161: ANP QUARTERLY PROGRESS REPORT 148 X

- Page 162 and 163: ANP QUARTERLY PROGRESS REPORT In co

- Page 164 and 165: ANP QUARTERLY PROGRESS REPORT - 103

ANP QUARTERLY PROGRESS REPORT<br />

-<br />

N<br />

-.<br />

14<br />

13<br />

12<br />

11<br />

IO<br />

$ 9<br />

0<br />

10<br />

‘ 0 8 -<br />

W<br />

m<br />

4 7<br />

W<br />

(L<br />

0<br />

z 6<br />

I-<br />

I<br />

(.!I<br />

f 5<br />

s<br />

4<br />

3<br />

2<br />

1<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-LR-DWG 4426<br />

0 0 20 40 60 80 100 I20 140 160 180 200<br />

ELAPSED TIME (hr)<br />

Fig. 7.1. Oxidation of Plated Hastelloy B in Air at 1500OF.<br />

backing up of <strong>the</strong> tube-to-header joints with Coast<br />

Welding<br />

Metals No. 52 brazing alloy.<br />

The fabrication of <strong>the</strong> three test assemblies<br />

P. Patriarca<br />

R. E. Clausing<br />

K. W. Reber<br />

G. M. Slaughter<br />

made to date has been routine, and no unusual Metallurgy Division<br />

behavior or difficulties have been encountered.<br />

Although it is expected that <strong>the</strong> characteristic<br />

aging of Hastelloy B and <strong>the</strong> subsequent loss in<br />

room-temperature ductility will affect <strong>the</strong> longevity<br />

of <strong>the</strong>se test specimens, <strong>the</strong> first assembly has<br />

J. M. Cisar<br />

Aircraft R eactor Engineering Division<br />

R. L. Heestand<br />

Pratt & Whitney Aircraft<br />

withstood, without failure, as determined by a Preparations are under way for experiments to<br />

helium leak test, 100 accrued hours of life with evaluate <strong>the</strong> properties of Hastelloy B weld metal<br />

one air quench and one water quench directed at as affected by <strong>the</strong>rmal history. A comparative<br />

<strong>the</strong> fin surfaces. O<strong>the</strong>r test assemblies are being basis for <strong>the</strong> tests has been prepared through<br />

fabricated with type 310 stainless-steel-clad experiments in which <strong>the</strong> effect of aging time at<br />

copper in order to determine, in conjunction with 15OOOF on <strong>the</strong> room-temperature ductility of wrought<br />

<strong>the</strong> evaluation of Hastelloy B, <strong>the</strong> dimensional<br />

stability and oxidation resistance of this material<br />

Hastelloy- B was determined. For <strong>the</strong>se tests,<br />

guided bend specimens, x y2 x 1% in., were<br />

under <strong>the</strong>rmal shock. cut from 3/,6-in.-thick wrought Hastelloy B plate<br />

. .<br />

. -<br />

4