ORNL-1771 - Oak Ridge National Laboratory

ORNL-1771 - Oak Ridge National Laboratory

ORNL-1771 - Oak Ridge National Laboratory

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

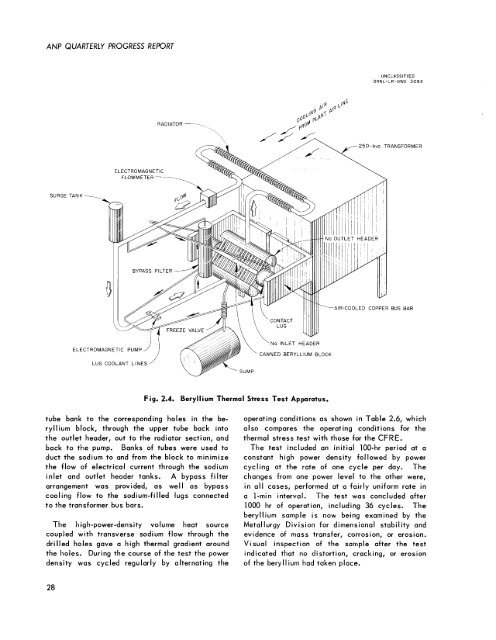

SURGE TANK-<br />

tube bank to the corresponding holes in the be-<br />

ryllium block, through the upper tube back into<br />

the outlet header, out to the radiator section, and<br />

back to the pump. Banks of tubes were used to<br />

duct the sodium to and from the block to minimize<br />

the flow of electrical current through the sodium<br />

inlet and outlet header tanks. A bypass filter<br />

arrangement was provided, as well as bypass<br />

cooling flow to the sodium-filled lugs connected<br />

to the transformer bus bars.<br />

The high-power-density volume heat source<br />

coupled with transverse sodium flow through the<br />

drilled holes gave a high thermal gradient around<br />

the holes. During the course of the test the power<br />

density was cycled regularly by alternating the<br />

28<br />

ELECl<br />

Fig. 2.4. Beryllium Thermal Stress Test Apparatus.<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-LR-DWG 3093<br />

-kvo TRANSFORMER<br />

\<br />

111 ' ~ ~ ~ / ~ A I R - C O OCOPPER L E D BUS BAR<br />

operating conditions as shown in Table 2.6, which<br />

also compares the operating conditions for the<br />

thermal stress test with those for the CFRE.<br />

The test included an initial 100-hr period at a<br />

constant high power density followed by power<br />

cycling at the rate of one cycle per day. The<br />

changes from one power level to the other were,<br />

in all cases, performed at a fairly uniform rate in<br />

a 1-min interval. The test was concluded after<br />

1000 hr of operation, including 36 cycles. The<br />

beryllium sample is now being examined by the<br />

Metallurgy Division for dimensional stability and<br />

evidence of mass transfer, corrosion, or erosion.<br />

Visual inspection of the sample after the test<br />

indicated that no distortion, cracking, or erosion<br />

of the beryllium had taken place.

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)