ORNL-1771 - Oak Ridge National Laboratory

ORNL-1771 - Oak Ridge National Laboratory

ORNL-1771 - Oak Ridge National Laboratory

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

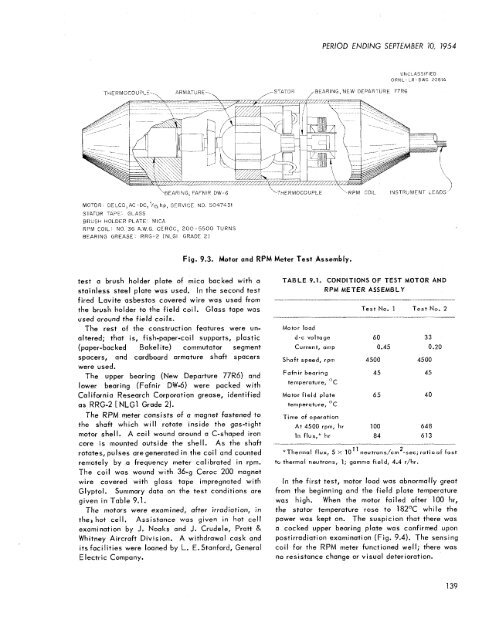

MOTOR<br />

SlATOR TAPE GLASS<br />

BRUSH HOLDER PLATE MICA<br />

PERIOD ENDING SEPTEMBER IO, 7954<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-1.R-DWG 20814<br />

'HFARING, FAFNIR DVJ-6 \THERMOCOUPLE RPM COIL 'NSTRUMFNT LEADS '<br />

DELCO,AC-DC, '115 hp, SFRVICE NO 5047431<br />

RPM COIL NO 36 A W G CCROC, 200-5500 TURNS<br />

BFARING GREASE RRG-2 (NL.GI GRADE 2)<br />

test a brush holder plate of mica backed with a<br />

stainless steel plate was used, In the second test<br />

fired Lavite asbestos covered wire was used from<br />

the brush holder to the field coil. Glass tape was<br />

used around the field coils.<br />

The rest of the construction features were un-<br />

altered; that is, fish-paper-coil supports, plastic<br />

(paper-backed Bake1 ite) commutator segment<br />

spacers, and cardboard armature shaft spacers<br />

were used.<br />

The upper bearing (New Departure 77R6) and<br />

lower bearing (Fafnir DW-6) were packed with<br />

California Research Corporation grease, identified<br />

as RRG-2 [NLGl Grade 21.<br />

The RPM meter consists of a magnet fastened to<br />

the shaft which will rotate inside the gas-tight<br />

motor shell. A coil wound around a C-shaped iron<br />

core is mounted outside the shell. As the shaft<br />

rotates, pulses aregenerated in the coil and counted<br />

remotely by a frequency meter calibrated in rprn.<br />

The coil was wound with 36-9 Ceroc 200 magnet<br />

wire covered with glass tape impregnated with<br />

Glyptol. Summary data on the test conditions are<br />

given in Table 9.1.<br />

The motors were examined, after irradiation, in<br />

the* hot cell. Assistance was given in hot cell<br />

examination by J. Noaks and J. Crudele, Pratt &<br />

Whitney Aircraft Division. A withdrawal cask and<br />

its facilities were loaned by L. E.Stanford, General<br />

Electric Company.<br />

Fig. 9.3. Motor and RPM Meter Test Assembly.<br />

TABLE 9.1. CONDITIONS OF TEST MOTOR AND<br />

RPM METER ASSEMBLY<br />

Motor load<br />

Test No. 1 Test No. 2<br />

d-c voltage 60 33<br />

Current, amp 0.45 0.20<br />

Shaft speed, rprn 4500 4500<br />

Fufnir bearing<br />

temperature, 'C<br />

45 45<br />

Motor field plate<br />

temperature, OC<br />

65 40<br />

Time of operation<br />

At 4500 rprn, hr 100 648<br />

In flux,* hr 84 613<br />

*Thermal flux, 5 x 10" neu+rons/cm2-sec; ratio of fast<br />

to thermal neutrons, 1; gumma field, 4.4 r/hr.<br />

In the first test, motor load was abnormally great<br />

from the beginning and the field plate temperature<br />

was high. When the motor failed after 100 hr,<br />

the stator temperature rose to 182OC while the<br />

power was kept on. The suspicion that there was<br />

a cocked upper bearing plate was confirmed upon<br />

postirradiation examination (Fig. 9.4). The sensing<br />

coil for the RPM meter functioned well; there was<br />

no resistance change or visual deterioration.<br />

139

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)