ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PROJECT PROGRESS REPORT<br />

system was 1000°F, <strong>the</strong> temperature of <strong>the</strong> lubri-<br />

cant was 16OoF (max), <strong>the</strong> pump speed was 2400<br />

rpm, and <strong>the</strong> gas pressure in <strong>the</strong> system was 5 psig.<br />

There was no liquid in <strong>the</strong> main pump loop. The<br />

seal leakage data were obtained by bleeding 550<br />

liters of helium through <strong>the</strong> pump into <strong>the</strong> loop<br />

system each day and at <strong>the</strong> same time bleeding<br />

500 liters of argon into <strong>the</strong> loop system directly.<br />

Fifty liters of gas was bled from <strong>the</strong> pump catch-<br />

basin drain each day and lo00 liters of gas was<br />

bled from <strong>the</strong> pump loop system. Gas samples<br />

were taken by evacuating a glass container and<br />

<strong>the</strong>n filling it through a line connected to a sample<br />

joint. The sample joints were at <strong>the</strong> catch-basin<br />

drain, <strong>the</strong> off-gas line from <strong>the</strong> loop system, and<br />

<strong>the</strong> gas space over <strong>the</strong> lube-oil reservoir. The<br />

samples were analyzed spectrographically for<br />

argon, helium, oxygen, and nitrogen. The appear-<br />

ance of argon in a sample taken at <strong>the</strong> catch-basin<br />

drain was an indication that <strong>the</strong> argon had back-<br />

diffused up <strong>the</strong> annulus between <strong>the</strong> pump shaft<br />

and shield-barrier plug. The appearance of argon<br />

in <strong>the</strong> sample taken at <strong>the</strong> lube-oil reservoir gas<br />

space was an indication that <strong>the</strong> argon was leaking<br />

across <strong>the</strong> lower pump seal. The data obtained<br />

from this test are presented in Table 1.4.1.<br />

48<br />

During <strong>the</strong> tests it became apparent that <strong>the</strong><br />

control of <strong>the</strong> small gas flow rates and low pres-<br />

sures was more difficult that had &en anticipated<br />

and that <strong>the</strong> adequacy of <strong>the</strong> method of gas sampling<br />

was questionable. Therefore <strong>the</strong> data presented<br />

in Table 1.4.1 give only qualitative indications of<br />

<strong>the</strong> leakage. Future seal leakage tests will be<br />

made by bleeding argon down <strong>the</strong> pump shaft and<br />

using helium as <strong>the</strong> trace gas. This should improve<br />

<strong>the</strong> accuracy of <strong>the</strong> data obtained spectrographically.<br />

The masking effect of air will also be less. The<br />

sampling technique will be improved by continuously<br />

bleeding gas through <strong>the</strong> sample bottles to elimi-<br />

nate <strong>the</strong> possibility of drawing gas from regions<br />

o<strong>the</strong>r than <strong>the</strong> sampling points.<br />

Fuel Pump Endumnce Tests<br />

S. M. Decamp<br />

An endurance test of an ART fuel pump (model<br />

MF) was started on April 10, 1956 with <strong>the</strong> fuel<br />

mixture (No. 30) NaF-ZrF4-UF, (50.46-4 mole %)<br />

as <strong>the</strong> pump fluid. The first 1488 hr of operation<br />

of <strong>the</strong> system is described here. The operating<br />

conditions are indicated on Fig. 1.4.1, which gives<br />

<strong>the</strong> system temperatures, oil flow rates, and seal<br />

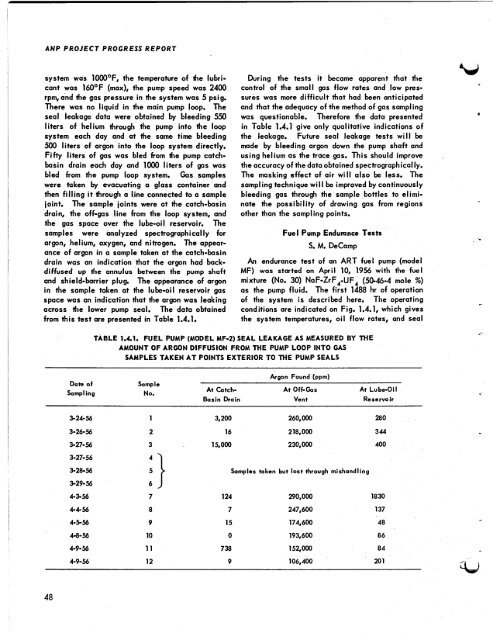

TABLE 1.41. FUEL PUMP (MODEL MF-2) SEAL LEAKAGE AS MEASURED BY THE<br />

AMOUNT OF ARGON DIFFUSION FROM THE PUMP LOOP INTO GAS<br />

SAMPLES TAKEN AT POINTS EXTERIOR TO THE PUMP SEALS<br />

Date of Sample<br />

Sampling No.<br />

3-24-56<br />

~ ~~ ~~ _________~~~<br />

Argon Found (ppm)<br />

At Catch- At Off-Gas At Lu be-Oi I<br />

Basin Drain Vent Reservoir<br />

1 3,200 260, OOO 280<br />

3-26-56<br />

2 16 218,000 344<br />

3-27-56<br />

3-27-56<br />

3 15,000 230,000 400<br />

3-28-56<br />

3-29-56 :> 6<br />

Samples taken but lost through mishandling<br />

4-3-56<br />

7 124 290,000 1830<br />

4-4-56<br />

8<br />

7 247,600 137<br />

4-5-56 9 15 174,600 4%<br />

4-8-56 10 0 193,600 86<br />

4-9-56 11 738 152,000 84<br />

4-9-56 12 9 1 06,400 20 1<br />

,<br />

a

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)