ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SHIELD MOCKUP REACTOR STUDY<br />

L. C. Palmer<br />

A general study of <strong>the</strong> heat transfer and fluid<br />

flow characteristics of <strong>the</strong> proposed Shield Mockup<br />

Reactor (see Chap. 5.5, "Shield Mockup Reactor<br />

Design and Construction") has been initiated. An<br />

analysis of <strong>the</strong> temperature structure within <strong>the</strong><br />

fuel elements and <strong>the</strong> coolant and a study of <strong>the</strong><br />

pressure distribution within <strong>the</strong> core were com-<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-LR-W 14744<br />

- o io 20 30 40 50 60 m 80 90 (00<br />

HEATER POWER (XI<br />

.T'<br />

' FU f<br />

' Y<br />

Fig. 4.1.13. Temperatwe Amplitudes Observed<br />

in Preliminory Thermal-Cycling Tests of lnconel<br />

Tubing.<br />

PERIOD ENDING JUNE 10, 1956<br />

pleted. ,The studies are being extended to o<strong>the</strong>r<br />

regions of <strong>the</strong> reactor.<br />

TEMPERATURE STRUCTURE IN THE REGION<br />

BEYONDTHEARTREFLECTOR<br />

H. W. Hoffman<br />

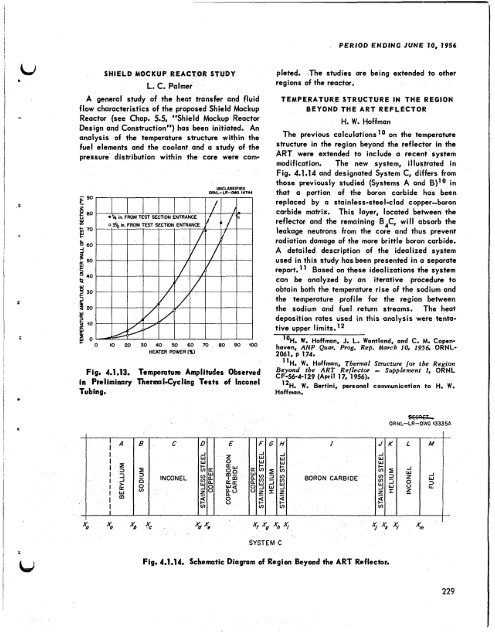

The previous calculations10 on <strong>the</strong> temperature<br />

structure in <strong>the</strong> region beyond <strong>the</strong> reflector in <strong>the</strong><br />

ART were extended to include a recent system<br />

modification. The new system, illustrated in<br />

Fig. 4.1.14 and designated System C, differs from<br />

those previously studied (Systems A and 8)'O in<br />

that a portion of <strong>the</strong> boron carbide has been<br />

replaced by a stain les s-stee I-c lad copper-boron<br />

carbide matrix. This layer, located between <strong>the</strong><br />

reflector and <strong>the</strong> remaining B4C, will absorb <strong>the</strong><br />

leakage neutrons from <strong>the</strong> core and thus prevent<br />

radiation damage of <strong>the</strong> more brittle boron carbide.<br />

A detailed description of <strong>the</strong> idealized system<br />

used in this study has been presented in a separate<br />

report. Based on <strong>the</strong>se idealizations <strong>the</strong> system<br />

can be analyzed by an iterative procedure to<br />

obtain both <strong>the</strong> temperature rise of <strong>the</strong> sodium and<br />

<strong>the</strong> temperature profile for <strong>the</strong> region between<br />

<strong>the</strong> sodium and fuel return streams. The heat<br />

deposition rates used in this analysis were tenta-<br />

tive upper Iirnits.12<br />

'OH. W. Hoffman. J. L. Wantland. and C. M. CoDenhoven,<br />

ANP Quar.-Prog. Rep. March 10, 1956, <strong>ORNL</strong>-<br />

2061, P 174.<br />

"H. W. Hoffman, Thermal Structure /or <strong>the</strong> Region<br />

Beyond <strong>the</strong> ART Reflector - Supplement I, <strong>ORNL</strong><br />

CF-56-4-129 (April 17, 1956).<br />

12H. W. Bertini, personal communication to H. W.<br />

Hoffman.<br />

sEGRE;L.<br />

<strong>ORNL</strong>-LA-DWG 43U5A<br />

x, x, 3 % %% xf xg xh 4 $34 x*<br />

SYSTEM C<br />

Fig. 4.1.14. Schematic Diagram of Region Beyond <strong>the</strong> ART Reflector.<br />

I<br />

229

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)