ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

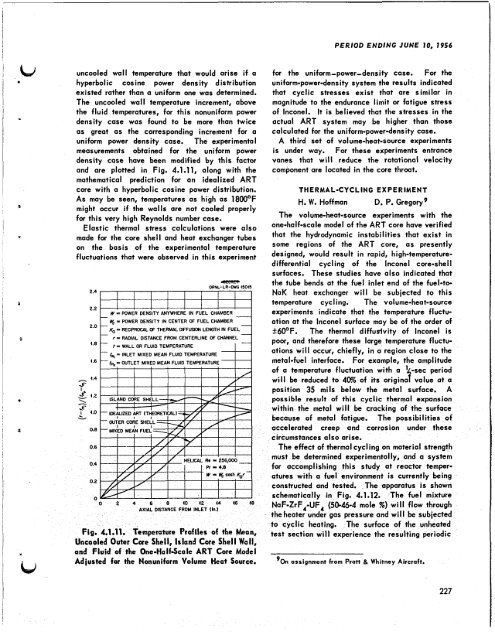

uncooled wall temperature that would arise if a<br />

hyperbolic cosine power density distribution<br />

existed ra<strong>the</strong>r than a uniform one was determined.<br />

The uncooled wal I temperature increment, above<br />

<strong>the</strong> fluid temperatures, for this nonuniform power<br />

density case was found to be more than twice<br />

as great as <strong>the</strong> corresponding increment for a<br />

uniform power density case. The experimental<br />

measurements obtained for <strong>the</strong> uniform power<br />

density case have been modified by this factor<br />

and are plotted in Fig. 4.1.11, along with <strong>the</strong><br />

ma<strong>the</strong>matical prediction for an idealized ART<br />

core with a hyperbolic cosine power distribution.<br />

As may be seen, temperatures as high as 1800OF<br />

might occur if <strong>the</strong> walls are not cooled properly<br />

for this very high Reynolds number case.<br />

Elastic <strong>the</strong>rmal stress calculations were also<br />

made for <strong>the</strong> core shell and heat exchanger tubes<br />

on <strong>the</strong> basis of <strong>the</strong> experimental temperature<br />

fluctuations that were observed in this experiment<br />

2.4<br />

2.2<br />

W = POWER DENSITY ANYWHERE IN FUEL CHAMBER<br />

- -<br />

W, = POWER DENSITY IN CENTER OF FUEL CHAMBER<br />

2.0 - -<br />

KO = RECIPROCAL OF THERMAL DIFFWON LENGTH IN FUEL<br />

- -<br />

r = RADIAL DISTANCE FROM CENTERLINE OF CHANNEL<br />

'" - -<br />

f = WALL OR FLUID TEMPERATURE<br />

- h, - INLET MIXED MEAN FLUID TEMPERATURE<br />

4.6 - h- = OUTLET MIXED MEAN FLUID TEMPERATURE<br />

0 2 4 6 8 q0 12 44 46 18<br />

AXIAL DISTANCE FROM INLET (In.)<br />

mperature Profiles of<br />

Uncooled Outer Core Shell, Island Core Shell Wall,<br />

and Fluid of <strong>the</strong> One-HaIf-Scale ART Core Model<br />

Adjusted for <strong>the</strong> Nonuniform Volume Heat Source.<br />

I<br />

I<br />

PERIOD ENDING JUNE 10, 1956<br />

for <strong>the</strong> uniform-power-density case. For <strong>the</strong><br />

uniform-power-density system <strong>the</strong> results indicated<br />

that cyclic stresses exist that are similar in<br />

magnitude to <strong>the</strong> endurance limit or fatigue stress<br />

of Inconel. It is believed that <strong>the</strong> stresses in <strong>the</strong><br />

actual ART system may be higher than those<br />

calculated for <strong>the</strong> uniform-power-density case.<br />

A third set of volume-heat-source experiments<br />

is under way. For <strong>the</strong>se experiments entrance<br />

vanes that will reduce <strong>the</strong> rotational velocity<br />

component are located in <strong>the</strong> core throat.<br />

THE RMAL-CYCL ING EXPERIMENT<br />

H. W. Hoffman D. P. Gregory9<br />

The volume-heat-source experiments with <strong>the</strong><br />

one-half-scale model of <strong>the</strong> ART core have verified<br />

that <strong>the</strong> hydrodynamic instabilities that exist in<br />

some regions of <strong>the</strong> ART core, as presently<br />

designed, would result in rapid, high-temperaturedifferential<br />

cycling of <strong>the</strong> lnconel core-shell<br />

surfaces. These studies have also indicated that<br />

<strong>the</strong> tube bends at <strong>the</strong> fuel inlet end of <strong>the</strong> fuel-to-<br />

NaK heat exchanger will be subjected to this<br />

temperature cycling. The volume-heat-source<br />

experiments indicate that <strong>the</strong> temperature fluctuation<br />

at <strong>the</strong> lnconel surface may be of <strong>the</strong> order of<br />

S6OoF. The <strong>the</strong>rmal diffusivity of lnconel is<br />

poor, and <strong>the</strong>refore <strong>the</strong>se large temperature fluctuations<br />

will occur, chiefly, in a region close to <strong>the</strong><br />

metal-fuel interface. For example, <strong>the</strong> amplitude<br />

of a temperature fluctuation with a -sec period<br />

will be reduced to 40% of its origina 4 value at a<br />

position 35 mils below <strong>the</strong> metal surface. A<br />

possible result of this cyclic <strong>the</strong>rmal expansion<br />

within <strong>the</strong> metal will be cracking of <strong>the</strong> surface<br />

because of metal fatigue. The possibilities of<br />

accelerated creep and corrosion under <strong>the</strong>se<br />

circumstances also arise.<br />

The effect of <strong>the</strong>rmal cycling on material strength<br />

must be determined experimentally, and a system<br />

for accomplishing this study at reactor temperatures<br />

with a fuel environment is currently being<br />

constructed and tested. The apparatus is shown<br />

schematically in Fig. 4.1.12. The fuel mixture<br />

NoF-ZrF,-UF, (5b46-4 mole %) will flow through<br />

<strong>the</strong>heater under gas pressure and will be subjected<br />

to cyclic heating. The surface of <strong>the</strong> unheated<br />

test section will experience <strong>the</strong> resulting periodic<br />

'On assignment from Pratt & Whitney Aircraft.<br />

227

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)