ORNL-2106 - the Molten Salt Energy Technologies Web Site

ORNL-2106 - the Molten Salt Energy Technologies Web Site ORNL-2106 - the Molten Salt Energy Technologies Web Site

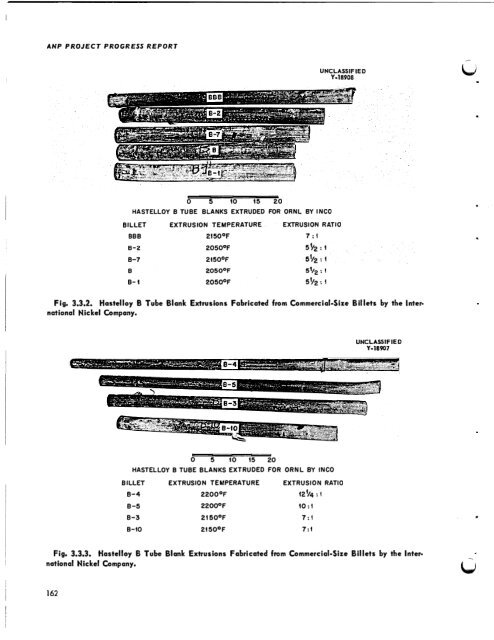

1 ANP PROJECT PROGRESS REPORT 0-0 HASTELLOY B TUBE BLANKS EXTRUDED FOR ORNL BY INCO BILLET EXTRUSION TEMPERATURE EXTRUSION RATIO BBB 215OoF 7:1 8-2 8-7 205OoF 215OoF 0 2050°F 5'4 : t 8- t 205OOF 592: f UNCLASSIFIED Y. 18908 Fig. 3.3.2. Hastelloy B Tube Blank Extrusions Fabricated from Commercial-Sire Billets by the Inter- national Nickel Company. 0 5 10 15 20 HASTELLOY B TUBE BLANKS EXTRUDED FOR ORNL BY INCO BILLET EXTRUSION TEMPERATURE EXTRUSION RATIO 8-4 220OoF 1294 : 1 B -5 220OoF 10:1 8-3 21 5OoF 7:1 B-10 2150OF 7:1 UNCLASSIFIED Y.18907 Fig. 3.3.3. Hastelloy B Tube Blank Extrusions Fabricated from Commercial-Sire Billets by the Inter- national Nickel Company. 162 W * . . w I

2. Canning of the billets with '/,-in.-thick type 316 stainless steel appears to be advantageous from the standpoint of reducing the extrusion pressure. Because of the number of variables involved, however, this point needs to be con- firmed. 3. The larger mass of the commercially produced billets made possible the use of lower soaking temperatures at the smaller extrusion ratios (i.e., 5.5:l) than were found to be optimum for the extrusion of small laboratory billets. 4. For successful extrusion of these alloys it is necessary that the billets be upset with suf- ficient pressure to start the material through the die and then extruded ut a relatively slow rate to prevent h ot-sh ort cracking. These were the first successful attempts to extrude these materials on a large scale, and it now appears to be feasible to produce seamless tubing of these alloys, Three Hastelloy B tube blanks and one Hastelloy W tube blank are scheduled to be reduced to 1-in. pipe and small- diameter tubing for use at ORNL. Extrusion of Special Alloys The study of single-phase alloys in the nickel- molybdenum alloy system that contain 15 to 20% molybdenum was continued. It is hoped in this study to find a solution to the problem of em- brittlement of the Hasteltoy-type alloys as a result of aging. At present the only readily apparent solution is to change the composition of the a 1 I oy s. It was reported previously that the corrosion resistance to fused sdlts of the binary alloys of 'T. K. Roche ond H. Inouye, ANP Quar. Prog. Rep. March 10, 1956, ORNL-2061, p 155. PERIOD ENDING JUNE 10, 1956 TABLE 3.3.3. COMPOSITIONS OF SPECIAL ALLOYS PREPARED BY INTERNATIONAL NICKEL COMPANY Alloy No. Composition (wt %) Mo Cr W Nb AI Ti C Ni T-23011 15 5 3 3 0.5 73.5 To23012 17 0.5 82.5 T-23013 15 3 3 0.5 78.5 T-23014 15 1 1.5 82.5 T-23015 15 3 3 0.5 0.25 78.25 Four extrusion billets, 3 in. in diameter and 3 in. long, were machined from each ingot, three for tube blanks and one for rod fabrication. The rod extrusions were for rolling to 0.065-in. strip for the preparation of test specimens for strength evaluation. The initial tube blank extrusion ex- periments involving one billet of each composition met with little success. When a fast extrusion rate was used, the alloys demonstrated the hot- short tendencies of Hastelloy B, with the ex- ception of alloy T-23013, 15% Moa% Nb-3% W-0.5% Al-78.5% Ni. The results of this initial experiment are presented in Table 3.3.4. Before the remaining billets of these alloys were extruded, the results obtained in the fabrication of Hastelloy W at a slow extrusion rate were sufficiently favorable io prompt an alteration in TABLE 3.3.4. RESULTS OF PRELIMINARY ATTEMPTS TO EXTRUDE THE SPECIAL ALLOYS PREPARED BY THE INTER- NATIONAL NICKEL COMPANY Extrusion mtio: 5.4:l Mandrel size: 3/4 in. dia Alloy No. Extrusion Temperature Results (OF) T-23011 2060 2100 Good tube blank obtained Press stalled T-23015 2080 Tube blank crocked on the inside 163

- Page 97 and 98: , . 2.3. PHYSICAL PROPERTIES OF MOL

- Page 99 and 100: -0 a rn u) u) DO2 oot c ;o rn OS g

- Page 101 and 102: IL, - PERIOD ENDING JUNE 70, 7956 O

- Page 103 and 104: 8 00 700 600 - 0 0, w 500 a 3 I- U

- Page 105 and 106: supporting plaque is loaded into th

- Page 107 and 108: u 2.4. PRODUCTION OF FUELS c G. J.

- Page 109 and 110: half of fiscal year 1957. This esti

- Page 111 and 112: 2.5. COMPATIBILITY OF MATERIALS AT

- Page 113 and 114: volume of 1 M tartaric acid solutio

- Page 115 and 116: After the trap has been opened, bot

- Page 117 and 118: \ Part 3 METALLURGY W. D. Manly

- Page 119 and 120: FLUORIDE FUEL MIXTURES IN INCONEL F

- Page 121 and 122: PERIOD ENDING JUNE 10, 1956 TABLE 3

- Page 123 and 124: Fig.3.1.3. Region of Maximum Attack

- Page 125 and 126: (d . terminated after 1217 and 1339

- Page 127 and 128: - . LJ BRAZING ALLOYS IN LIQUID MET

- Page 129 and 130: PERIOD ENDING JUNE 10, 1956 NaK wer

- Page 131 and 132: I PERIOD ENDING JUNE 10, 1956 I Fig

- Page 133 and 134: 0. PERIOD ENDING JUNE 10, 1956 Fig.

- Page 135 and 136: Fig. 3.2.10. Apparatus for Studying

- Page 137 and 138: STATIC TESTS OF INCONEL CASTINGS R.

- Page 139 and 140: t (JnOOSll 3n918-3NOt IOH (JoOOSI)

- Page 141 and 142: after the l00hr test. The extent of

- Page 143 and 144: tests of the Lindsay Mix specimens,

- Page 145 and 146: LJ DEVELOPMENT OF NICKEL-MOLYBDENUM

- Page 147: LJ PERIOD ENDING JUNE 10, 1956 Fig.

- Page 151 and 152: 165 . c, e . c3 a PERIOD ENDING JUN

- Page 153 and 154: u allow the billet to start through

- Page 155 and 156: NEUTRON SHIELD MATERIAL FOR HIGH-TE

- Page 157 and 158: PERIOD ENDfNG JUNE 10, 7956 Fig. 3.

- Page 159 and 160: wrought plate used as base material

- Page 161 and 162: J point. A mixture of 50-50 vol % L

- Page 163 and 164: WELDING PROCEDURE: VERTICAL FIXED,

- Page 165 and 166: 4 2 t 4 2 in. t 2 WCLASSFKO ORNL-LR

- Page 167 and 168: FABRICATION OF JOINTS BETWEEN PUMP

- Page 169 and 170: * h WELDING PROCEDURE PERlOD ENDING

- Page 171 and 172: 1 1 6 in. PUMP BARREL t SECTION AA

- Page 173 and 174: '4 x 6 x 20-in. INCONEL PLATES (/*-

- Page 175 and 176: UNCLASSIFIED PHOTO 17248 Fig. 3.4.1

- Page 177 and 178: through the radiator by passing col

- Page 179 and 180: L, . 1 Q t V ERIOD ENDING JUNE 10,

- Page 181 and 182: to permit the examination of indivi

- Page 183 and 184: LJ . t L t * I LJ Fig. 3.4.33. Tube

- Page 185 and 186: Fig. 3.4.37. Inner Surface of Tube

- Page 187 and 188: EFFECTOF ENVIRONMENTONCREEP- RUPTUR

- Page 189 and 190: PERIOD ENDING JUNE 10, 1956 UNCLASS

- Page 191 and 192: Fig. 35.7. Surface Effect on the St

- Page 193 and 194: 44,000 42,000 40,000 - ._ (D 8000 v

- Page 195 and 196: \:r 1 U UNCL 1158 W ioo,ooo 80,000

- Page 197 and 198: fuel mixture (No. 30) NaF-ZrF -UF,

1<br />

ANP PROJECT PROGRESS REPORT<br />

0-0<br />

HASTELLOY B TUBE BLANKS EXTRUDED FOR <strong>ORNL</strong> BY INCO<br />

BILLET EXTRUSION TEMPERATURE EXTRUSION RATIO<br />

BBB 215OoF 7:1<br />

8-2<br />

8-7<br />

205OoF<br />

215OoF<br />

0 2050°F 5'4 : t<br />

8- t 205OOF 592: f<br />

UNCLASSIFIED<br />

Y. 18908<br />

Fig. 3.3.2. Hastelloy B Tube Blank Extrusions Fabricated from Commercial-Sire Billets by <strong>the</strong> Inter-<br />

national Nickel Company.<br />

0 5 10 15 20<br />

HASTELLOY B TUBE BLANKS EXTRUDED FOR <strong>ORNL</strong> BY INCO<br />

BILLET EXTRUSION TEMPERATURE EXTRUSION RATIO<br />

8-4 220OoF 1294 : 1<br />

B -5 220OoF 10:1<br />

8-3 21 5OoF 7:1<br />

B-10 2150OF 7:1<br />

UNCLASSIFIED<br />

Y.18907<br />

Fig. 3.3.3. Hastelloy B Tube Blank Extrusions Fabricated from Commercial-Sire Billets by <strong>the</strong> Inter-<br />

national Nickel Company.<br />

162<br />

W *<br />

.<br />

.<br />

w<br />

I