Download pdf Brochure - James G. Murphy Co.

Download pdf Brochure - James G. Murphy Co.

Download pdf Brochure - James G. Murphy Co.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

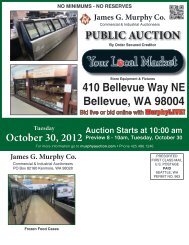

PUBLIC <strong>James</strong> G. AUCTION<br />

<strong>Murphy</strong> <strong>Co</strong>.<br />

<strong>Co</strong>mmercial & Industrial Auctioneers<br />

9AM - SATURDAY <strong>James</strong> - MAY G. 5<br />

PUBLIC AUCTION<br />

<strong>Murphy</strong> Inc.<br />

Preview 8-5, Friday, May 4<br />

<strong>Co</strong>mmercial & Industrial Auctioneers<br />

18226 68th Ave NE, Kenmore, By Order Secured WACreditor<br />

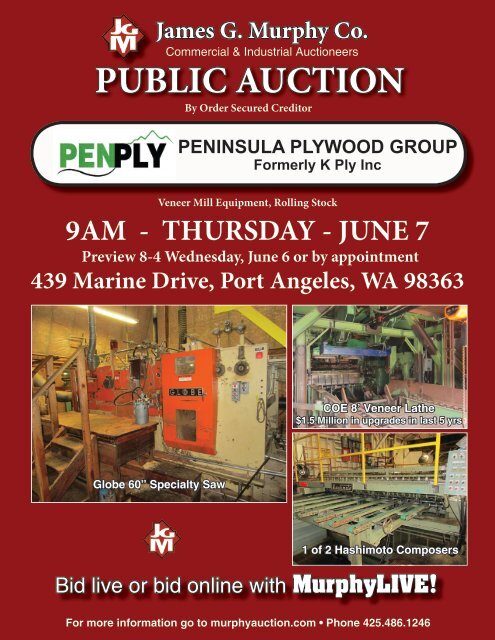

Veneer Mill Equipment, Rolling Stock<br />

9AM - THURSDAY - JUNE 7<br />

Preview 8-4 Wednesday, June 6 or by appointment<br />

439 Marine Drive, Port Angeles, WA 98363<br />

Globe 60” Specialty Saw<br />

PENINSULA PLYWOOD GROUP<br />

Formerly K Ply Inc<br />

COE 8’ Veneer Lathe<br />

$1.5 Million in upgrades in last 5 yrs<br />

1 of 2 Hashimoto <strong>Co</strong>mposers<br />

Bid live or bid online with <strong>Murphy</strong>LIVE!<br />

For more information go to www.murphyauction.com • Phone 425.486.1246<br />

For more information go to murphyauction.com • Phone 425.486.1246

VENEER EQUIPMENT<br />

NO MINIMUMS - NO RESERVES<br />

COE 244 8’ veneer lathe w/4” high speed retractable chucks<br />

(changeable to 3”), 300 hp RELIANCE DC shunt wood lathe<br />

drive motors, 65 & 75 hp hydraulic units, upgraded JACOBSEN<br />

ENGINEERING controls & electrics in 1997, 1995 PREMIER 87”<br />

powered back up roller bar w/120 hp hydraulic unit, s/n: CSR-89-B,<br />

upgraded JACOBSEN ENGINEERING controls & electrics in 1997,<br />

PREMIER 8’ carriage type charger w/1985 DURAND RAUTE<br />

Temposonic positioning, upgraded 2006, X-Y axis pre-charger w/30<br />

& 90 hp hydraulic units, JACOBSEN ENGINEERING controls &<br />

electrics<br />

COE 10’ veneer lathe, 60”x7 1/2” core, hydraulic nose bar, 5 & 10<br />

ton overhead cranes for chargers, controls, electrics, new 100 hp<br />

hydraulic unit in 2010<br />

MERRITT 4’ veneer lathe, 52”x7” carriage rail type charger w/350 V8<br />

gas engine, feed thru belts, 60’ 3-section single tray outfeed belts<br />

w/27” barrel chipper, (2) 24”x20’ outfeed waste belts<br />

1981 DURAND RAUTE 8’ rotary clipper w/25 hp hydraulic unit, infeed<br />

& outfeed belt transfers, 25 hp DC drive, updated JACOBSEN<br />

ENGINEERING controls & electrics in 1997, 1991 VENTEK New<br />

Vision II scanner defect system<br />

1991 VENTEK clipper control system w/PLC & electrics, 8’, 9’ or 10’<br />

capabilities<br />

150’ 3-deck veneer tray system w/(3) RELIANCE 100 hp/650-850<br />

rpm DC tray drive motors, return tray, JACOBSEN ENGINEERING<br />

controls & electrics<br />

Approximately 150’ 4-tray veneer system w/DC drives, controls &<br />

electrics<br />

DURAND RAUTE 4-bin auto veneer stacker w/(2) 24” & (2) 54” bins,<br />

rollout rollcases, hydraulic unit, 8’ vacuum type veneer diverter w/30”<br />

blower, blowpipe & cyclone<br />

1990 HASHIMOTO NVW-110D-00 10’ veneer composer, top, bottom<br />

& trailing edge knives, 10-strand feed thru chains, (8) applicators,<br />

accumulating stacker w/scissor lift elevator, controls & electrics,<br />

s/n: 70015<br />

1990 HASHIMOTO NVW-50D-1, 4’ veneer composer, top, bottom<br />

& trailing edge knives, 10-strand feed thru chains, (8) applicators,<br />

accumulating stacker w/scissor lift elevator, controls & electrics,<br />

s/n: 8236<br />

P.E.S. 8’ veneer composer, top, bottom & trailing edge knives, 8-strand<br />

feed thru transfer, 10’ 5-strand infeed w/drive to 8’ 2-strand hydraulic<br />

tilt hoist, 8’ 6-strand belt infeed, accumulating stacker, ALLEN<br />

BRADLEY PanelView 1200 touch screen controls, trash transfer<br />

60’ overhead tray feed system w/60’ hand pull green veneer belt transfer<br />

(2) GLOBE 5000 lb hydraulic pre-presses w/54”x128” platens, in &<br />

outfeed gravity rollcases, feed thru slat chains<br />

WILLIAMS & WHITE 24-opening hot press, steam heated, hydraulic<br />

operated, manual load & unload, CLOUSTON compression control<br />

systems, scissor lifts in & out, powered out rolls, hydraulics, controls<br />

& electrics<br />

LAMB 24-opening hot press, steam heated, hydraulic operated, manual<br />

load & unload, CLOUSTON compression control systems, scissor<br />

lifts in & out, powered out rolls, hydraulics, controls & electrics<br />

OSGOOD 18-opening hot press, steam heated, hydraulic operated,<br />

manual load & unload, hydraulics, controls & electrics<br />

MOORE 5-tray steam only dryer w/(21) doors, SWEED feeder w/3strand<br />

scissor lift, 240° 3-strand infeed transfer, tipple outfeed<br />

to 2-strand outfeed transfer, scissor lift w/gravity rolls, controls,<br />

electrics, piping, carts & moisture scanner

NO MINIMUMS - NO RESERVES<br />

MOORE 5-tray steam only dryer w/(21) doors, SWEED feeder<br />

w/3-strand scissor lift, 3-strand infeed transfer, tipple outfeed to<br />

4-strand transfer w/drive, carts, controls, electrics, piping, moisture<br />

scanner<br />

MOORE 5-tray steam only dryer w/(24) doors, 3-strand infeed transfer,<br />

tipple outfeed to 5-belt outfeed transfer w/drive, carts, controls,<br />

electrics, piping & moisture scanner<br />

GLOBE texture line w/18’ 3-strand slat chain infeed to vacuum<br />

unstacker to powered infeed rolls to Globe 60” gang type multi rip<br />

saw w/pre-sander roll, brush roll, scarring chain, saw arbor, press<br />

& feed rolls, (2) side heads, stamp wheel, outfeed belt transfer to<br />

infeed re-entry transfer to vacuum stacker to outfeed transfer to<br />

3-bin grading station w/gravity rolls, spare arbors & saws<br />

GLOBE 10’ skinner saw line w/16’ 3-strand infeed & transfer,<br />

BURELBACH vacuum unstacker, powered outfeed rolls, (2) saw<br />

edge & end trim saws w/powered rolls & transfers, outfeed belt<br />

transfer to accumulating scissor lift to gravity rolls<br />

GLOBE bevel scarifier line w/GLOBE bevel saw, outfeed gravity rolls,<br />

scissor lift, flying cut off saw, gravity roll transfers, WILLAMETTE<br />

glue pump system, GLOBE hydraulic hot press, in & out gravity<br />

rolls, scissor lift<br />

8’ precision end trim recovery saw w/scissor lift infeed, 6’ 9-belt feed<br />

thru transfer, 40’ 10-belt outfeed transfer, carts<br />

SWEED 10’ stationary vertical circular saw, 10’ 4-strand feed thru<br />

transfer<br />

YATES AMERICAN S28 panel scoring saw w/scissor lift infeed<br />

SALEM 64” traveling vertical band saw, powered rolls<br />

GLOBE 18” gang rip saw<br />

TOPS radial arm saw w/in & outfeed<br />

10” compound miter saw<br />

1966 KIMWOOD SMITHWAY 4-head sander, auto tracking & tension<br />

controls, 150 hp on heads, ALLEN BRADLEY 1336 plus adjustable<br />

frequency drives, scissor lift infeed, powered in & out rollcases,<br />

hydraulic unit, accumulating stacker, gravity rolls, blowpipe,<br />

electrics, controls<br />

Filler line w/10’ 3-strand slat chain infeed transfer, vacuum unstacker,<br />

90’ 4-section feed thru heated belt, filler & router equipment,<br />

WILLAMETTE pumps, accumulating scissor lift stacker, outfeed<br />

gravity rolls<br />

(2) BLACK BROS 64” glue spreaders w/scissor lift in & outfeeds<br />

(6) SKOOG patching machines, (5) w/scissor lift infeed &<br />

approximately 80’ 2-section 4-belt feed thru transfer to 20’ diameter<br />

turntable, carts<br />

Oil & paint coating area equipment w/spreader, scissor lift infeed,<br />

lowering stacker, gravity rolls, coating & spray equipment<br />

Grading station w/powered infeed rollcase, scissor lift feeder, 70’<br />

4-section 2-strand inspection belt transfer, (2) scissor lifts, outfeed<br />

rollcase to BURELBACH stacker<br />

78’ 3-section 4 & 5 belt grading station w/drives & carts<br />

JEDDELOH BROS six 286 hydraulic panel turner<br />

JENKINS tenoner frame w/multi-rip attachment, (2) side heads,<br />

outfeed panel stacker<br />

KIMWOOD panel stacker<br />

SIGNODE packaging station, top & bottom squeeze, auto bunk placer,<br />

12’ 2-strand slat chain infeed & outfeed transfers w/drives, gravity<br />

rolls, scissor lift, banding 1970 & tools 2010<br />

Custom built table saw

CHIP EQUIPMENT<br />

PENINSULA PLYWOOD • PORT ANGELES, WA<br />

BC-SUMNER 84” 6-knife chipper w/GE 250 hp/1180 rpm motor, chip<br />

breaker, controls & electrics<br />

ELLIOTT BAY guillotine type chipper w/40’ 6-belt feed thru transfer &<br />

drive<br />

Approximately 72” 8-knife chipper w/WESTINGHOUSE 200 hp drive,<br />

horizontal infeed, bottom discharge<br />

Approximately 84” 6-knife chipper w/TOSHIBA 100 hp drive & chip<br />

breaker, horizontal infeed, bottom discharge<br />

ARASMITH V-drum chipper w/drive<br />

LAMB wood waste hog w/drive<br />

Approximately 30” veneer hog w/GE 75 hp/885 rpm motor, chip<br />

breaker, controls & electrics<br />

24”x24” chip feeder w/drive, controls & electrics<br />

BC-SUMNER 612 6’x15’ 2-deck chip screen, s/n: 3183<br />

SODERHAMN CS28 8’x8’ 2-deck chip screen w/drive & supports<br />

16”x24” high pressure blower w/drive, controls & electrics<br />

Approximately 72” blower w/I.E.S. starter & MGM 34 KVA transformer<br />

PEERLESS 14 unit hydraulic chip bin w/hydraulic unit<br />

Approximately 12’x8’x20’ surge bin w/auger bottom<br />

Approximately 100 unit surge bin w/double box chain bottom<br />

CARTER DAY baghouse w/high pressure blower, feed & fan<br />

TRANSFERS, CONVEYORS<br />

(2) 24’ 6-strand infeed log decks w/drives<br />

60’ 1-strand infeed deck w/drive<br />

(2) 24’ 2-strand infeed block transfer w/drives<br />

20’ 2-strand infeed block transfer w/drive & log sweep<br />

24’ box chain waste conveyor w/drive & log sweep<br />

24”x60’ waste belt conveyor w/drive & log sweep<br />

24”x46’ waste belt conveyor w/drive & log sweep w/RENS L240 metal<br />

detector<br />

200’ drag chain clean out conveyor w/drive<br />

100’ drag chain clean out conveyor w/drive<br />

16”x100’ troughing belt conveyor w/drive<br />

30”x100’ troughing belt conveyor w/drive<br />

30”x150’ troughing belt conveyor w/drive<br />

18”x24’ troughing belt conveyor w/drive<br />

18”x42’ troughing belt conveyor w/drive<br />

250’ 8-belt trash return belt system w/drive<br />

20’, 40’ 6-belt hand pull transfer w/drives & carts<br />

30”x240’ belt transfer w/drive (in floor)<br />

30”x30’ belt transfer w/drive & MDI (to hog)<br />

24”x120’ belt transfer w/drive (in floor)<br />

24”x30’ belt transfer w/drive & RENS (to chipper)<br />

100’ box chain to bin w/drive & support<br />

60’ twin strand box chain conveyor w/drive<br />

16”x40’ belt transfer conveyor w/drive<br />

270’ long link clean out conveyor w/drive<br />

24”x60’ bucket type conveyor belt w/drive<br />

45’ long link clean out conveyor<br />

Jack ladder transfer w/drive<br />

Additional photos & information on our website:<br />

murphyauction.com

JUNE 7, 2012 • AUCTION STARTS 9AM<br />

BOILER EQUIPMENT<br />

(2) 1938 RILEY hog fuel fired steam boilers, 250 lb max, 60,000<br />

lb/hr, boiler water make up & chemical systems, fuel auger<br />

conveyors, associated piping & valves, controls & electrics, multilevel<br />

all steel boiler house building, 2000 FILTER TECHNOLOGY<br />

dry type baghouse, 32000 cfm, 18” static pressure, 450 bag system,<br />

multi-cone w/(64) cones, pre-heater, heat exchanger, 150 hp I.D. fan,<br />

breaching section w/diverter valve, replacement bags, 2010 QNW<br />

G-751-F rotary screw compressor, s/n: 1006515915<br />

MILL ELECTRICS<br />

CUTLER HAMMER/WESTINGHOUSE Pow-R-Line-C 4000 amp<br />

switchboard, (2) sections, AB-PLC w/cabinet, assorted electrics<br />

(2) CUTLER HAMMER Freedom 2100 motor control centers w/(12) &<br />

(10) switches (chipper starters) & assorted electrics<br />

FEDERAL PACIFIC 550 KVA transformers, (2) CUTLER HAMMER<br />

Freedom 2100 motor control centers w/(28) & (8) switches, (5)<br />

assorted transformers & electrics w/lathe parts<br />

FILING & GRINDING EQUIPMENT, MACHINE SHOP EQUIPMENT<br />

Newman G280 rotary tub grinder, s/n: 28050<br />

(2) COE 431-135” travel bed knife grinders<br />

(2) NIELSEN chain sharpeners<br />

HOE 102 grinder<br />

FOLEY 357 grinder<br />

ARMSTRONG #16 sharpener, s/n: 540<br />

ACME circle saw sharpener<br />

MONARCH 18”x120” engine lathe<br />

LEBLOND 17”x72” engine lathe<br />

SIDNEY 17”x60” engine lathe<br />

CLAUSING 12”x36” engine lathe<br />

POND 48”x144” engine lathe<br />

HERCULES 3’x8” radial arm drill<br />

ROYERS FORD 21” swing drill press<br />

BROWN & SHARPE No. 3A universal mill<br />

POWERMATIC 20” drill press<br />

DOALL C916 horizontal metal cutting band saw<br />

WELDAN POWER 225G7, Wasp 200 amp welder<br />

1997 QUINCY NORTHWEST 751-C rotary screw compressor w/graphic<br />

operator access terminal, 150 hp, s/n: 970448C<br />

1982 QUINCY NORTHWEST 740B/S rotary screw compressor, 150 hp,<br />

10529 hrs, new controls in 2010, s/n: 820533<br />

QUINCY NORTHWEST 650G rotary screw compressor, s/n: 73493, w/<br />

VanAir, electrical room w/GE 2, 5 & 6-section motor controls centers<br />

& assorted electrics<br />

ZEKS 800 HSCA air dryer<br />

(200) motors, reducers & gearheads<br />

Approximately 30’x60’ bolt together all steel hog fuel building

NO MINIMUMS - NO RESERVES<br />

Shop equipment & tools including: RIDGID 300 threader, GREENLEE<br />

555 bender, IMPERIAL EASTMAN crimper & dies, welders, acorn<br />

table, pattern burner, grinders, steel stock, shop press, vises, tooling,<br />

steel tables, chain hoists & jibs, precision measuring tools, hand<br />

tools, porta power & broaching tools, come-a-longs, clamps, assorted<br />

electrics, SWEED scrap chopper, chain hoist, welder, oxy/acetylene<br />

set, tires, transmissions, starters, drill press, CAT parts, forklift<br />

baskets, diesel tank, floor jack, shop heater, chain hoist, grinder, oil<br />

tanks, chargers, forklift parts & supplies, 20’ cargo container, scissor<br />

lift, HYSTER parts, golf cart, large quantity of steel stock, 2-ton<br />

A-frame hoist w/rail, transfers, motors, chain, (2) panel stackers, glue<br />

rolls, hydraulic unit transfer, (3) scissor lifts, approximately 12’x20’<br />

wooden lunch room, much more<br />

ROLLING STOCK<br />

2005 HYSTER H90XMS, 9000 lb capacity forklift, s/n: L005V4309C<br />

1990 HYSTER H90XLS, 9000 lb capacity forklift, s/n: G005D06387S<br />

1990 HYSTER H80XL, 8000 lb capacity forklift, s/n: F005D02937L<br />

CLARK approx 8000 lb capacity rough terrain forklift<br />

HYSTER Challenger 80, 8000 lb capacity forklift<br />

2001 HYSTER S60XM, 6000 lb capacity forklift, s/n: D187V24145Y<br />

HYSTER 6000 lb capacity forklift<br />

2003 HYSTER S50XM, 5000 lb capacity forklift, s/n: D187V29748A<br />

2000 HYSTER S50XM, 5000 lb capacity forklift, s/n: D187V18398X<br />

HYSTER approx 4000 lb capacity forklift<br />

CLARK CH100, 10,000 lb capacity forklift, s/n: CH100-31941<br />

HYSTER S60XM, 6000 lb capacity forklift, s/n: D187V24383Z<br />

MITSUBISHI FGC30K, 5500 lb capacity forklift, s/n: AP83C00271<br />

BOBCAT skid steer w/bucket<br />

1980 FORD 1 ton flatbed pickup, gas, manual<br />

1998 CHEV 1500 4x4 extended cab pickup<br />

1989 CHEV 1/2 ton 4x4 pickup<br />

1980 FORD dump truck<br />

Additional photos & information on our website:<br />

murphyauction.com<br />

Bid live or bid online with <strong>Murphy</strong>LIVE!

NO MINIMUMS - NO RESERVES<br />

<strong>James</strong> G. <strong>Murphy</strong> <strong>Co</strong>.<br />

<strong>Co</strong>mmercial & Industrial Auctioneers<br />

murphyauction.com<br />

425.486.1246 or 800.426.3008<br />

TERMS & CONDITIONS<br />

An On-Site Buyers Premium of 10% will be charged on all successful bids.<br />

An Online Buyers Premium of 13% will be charged on all successful bids.<br />

PAYMENT: Full payment must be made by no later than 4pm, Friday, June 8..<br />

A 25% deposit is required by the close of business, auction day.<br />

Cash, cashiers check, Master & Visa Cards, wire transfers only. Personal or company<br />

checks accepted ONLY with bank letter of guarantee.<br />

Absentee bids accepted with 25% deposit<br />

REMOVAL: No purchase may be removed during the auction unless otherwise<br />

announced by the auctioneer. Removal schedule announced on auction day.<br />

Announcements made by the auctioneer at the time of sale take precedence over<br />

printed matter.<br />

Auctioneer reserves the right to sell accessories, parts or attachments on a separate<br />

and/or aggregate basis.<br />

Due to safety & insurance reasons, persons under 12 not admitted.<br />

DRIVER DIRECTIONS<br />

From downtown Port Angeles, drive west on Hwy 101/Front St to Marine Drive. <strong>Co</strong>ntinue<br />

west on Marine Drive approximately 2/10 mile to the auction site, located on the right.<br />

WATCH FOR AUCTION SIGNS<br />

1970 2010<br />

FOOD SERVICE AVAILABLE AT THE AUCTION SITE

Public Auction Thursday, June 7, 2012<br />

<strong>James</strong> G. <strong>Murphy</strong> <strong>Co</strong>.<br />

<strong>Co</strong>mmercial & Industrial Auctioneers<br />

P.O. Box 82160, Kenmore, WA 98028<br />

COE 10’ Veneer Lathe<br />

<strong>James</strong> G. <strong>Murphy</strong> <strong>Co</strong>.<br />

<strong>Co</strong>mmercial & Industrial Auctioneers<br />

PUBLIC AUCTION<br />

Veneer Mill Equipment, Rolling Stock<br />

439 Marine Drive, Port Angeles, WA 98363<br />

Bid live or bid online with <strong>Murphy</strong>LIVE!<br />

PRESORTED<br />

FIRST CLASS MAIL<br />

U.S. POSTAGE<br />

PAID<br />

SEATTLE, WA<br />

PERMIT NO. 963<br />

PENINSULA PLYWOOD GROUP<br />

Formerly K Ply Inc<br />

Thursday, June 7, 2012 • 9am