Power MACS 4000 Quick Guide - Atlas Copco

Power MACS 4000 Quick Guide - Atlas Copco

Power MACS 4000 Quick Guide - Atlas Copco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Power</strong> <strong>MACS</strong> <strong>4000</strong><br />

<strong>Quick</strong> <strong>Guide</strong><br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 1

Contents<br />

TC Interface ...............................................................................3<br />

Software Installation ................................................................5<br />

Changing IP-address .................................................................6<br />

Download software to TC.........................................................9<br />

Connect PC to TC .................................................................... 10<br />

Basic Programming ................................................................ 11<br />

Help function ..................................................................... 11<br />

Create a new setup ........................................................... 11<br />

Add new program .............................................................13<br />

Delete program .................................................................13<br />

Add a step ..........................................................................13<br />

Cut, copy or delete a step ................................................. 14<br />

Set up problems ................................................................15<br />

Test bolt ..............................................................................16<br />

Checks, Restrictions and Monitoring ....................................17<br />

Checks ................................................................................18<br />

Restrictions ........................................................................ 19<br />

Monitoring ......................................................................... 19<br />

Advanced programming ........................................................20<br />

Create a new program by copying an existing ...............20<br />

<strong>Quick</strong> set .............................................................................21<br />

DynaTork ............................................................................23<br />

Reject Management ..........................................................24<br />

Reporters .................................................................................26<br />

Cycle data ..........................................................................26<br />

Event log ............................................................................27<br />

Traces .................................................................................28<br />

2 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

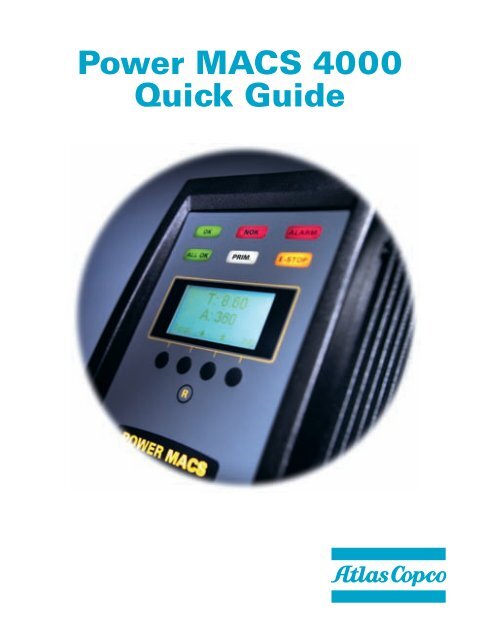

TC Interface<br />

Indicator lamps<br />

– OK<br />

– NOK<br />

– ALARM<br />

– ALL OK (TC-P only)<br />

– PRIM (TC-P only)<br />

– E-STOP (TC-P only)<br />

Text display<br />

– TC node address<br />

– IP-address<br />

– Error messages<br />

– Software version<br />

– Torque & Angle display<br />

Push buttons<br />

– Toggle between<br />

displayed information<br />

– Set IP-address<br />

– Reset E-stop button<br />

(TC-P only)<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 3

TC Interface<br />

Digital input<br />

(TC-P only)<br />

D-sub <strong>MACS</strong><br />

I/O (TC-P only)<br />

D-sub<br />

RS232/RS485<br />

(TC-P only)<br />

D-sub HD<br />

RS232/RS485<br />

(TC-P only)<br />

External Ethernet<br />

(TC-P only)<br />

Internal Ethernet<br />

Ethernet Switch<br />

<strong>Power</strong> supply<br />

4 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE<br />

E-stop in<br />

and <strong>MACS</strong> IO E-stop out and<br />

<strong>MACS</strong> IO<br />

Anybus slot,<br />

Fieldbus card<br />

Interface (TC-P<br />

only)<br />

<strong>Power</strong> connector<br />

Dip switch for<br />

<strong>MACS</strong> I/O<br />

and RS485<br />

termination<br />

(TC-P only)<br />

QST Spindle<br />

Connector<br />

Digital output<br />

(TC-P only)<br />

24V input

Software Installation<br />

<strong>Power</strong> <strong>MACS</strong><br />

To communicate with PM <strong>4000</strong> ToolsTalk PM has to be installed<br />

on your PC. To run ToolsTalk PM, Multiprog PLC editor is<br />

needed.<br />

Multiprog<br />

• Install MultiProg PLC Editor on your PC<br />

– Accept all default answers<br />

– Restart the computer when prompted<br />

ToolsTalk PM<br />

• Install ToolsTalk PM Software<br />

– Answer next to all questions<br />

– Launch the program when prompted<br />

Since the Multiprog PLC program is an integrated part of<br />

ToolsTalk <strong>Power</strong> <strong>MACS</strong>, both setup files are needed to run<br />

the system. That means that every setup consists of two<br />

files:<br />

Example:<br />

Demo_1sp.pm4<br />

Demo_1sp.zwt2<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 5

Changing IP-address<br />

The only way to connect your computer to <strong>Power</strong> <strong>MACS</strong><br />

<strong>4000</strong> is via Ethernet.<br />

The Primary Tightening Controller (TC-P) has two Ethernet<br />

ports, each with its own IP-address. The external port is for<br />

the factory network. The internal port is for internal<br />

communication and uses local addressing.<br />

Connect your Ethernet cable to the switch on the backplane<br />

of the TC-P.<br />

The TC ”ID number” shown on the TC and TC-P display and<br />

TC-P is the last part of the IP address. This number needs to<br />

be changed to a unique number if there is more than one<br />

TC in the system.<br />

The IP-address and TC ID number can be viewed on the<br />

display and set via using buttons on the front of the TC.<br />

The IP-address can also be set through the computer with<br />

ToolsTalk PM.<br />

1. Set the IP-address of the TC.<br />

Use the buttons on the front of<br />

the TC to toggle between the<br />

menus.<br />

a. Select Setup and enter the<br />

”Basic setup”<br />

b. Toggle to “IP Setup” and push<br />

”Select”<br />

c. Toggle to ”IF1 IP” and push<br />

”change”. Change the IP-adress<br />

by using the buttons on the TC<br />

d. Go back to the ”Basic setup”<br />

e. Toggle to ”TC number” in order to<br />

change the last part of the IP-adress. This number<br />

needs to be unique for every TC in a system<br />

6 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

2. Change IP-address and Subnet mask on your PC.<br />

a. Turn on your PC and open: Start/Control Panel/<br />

Network connections/Local area connection<br />

b. Click on “Properties”<br />

c. If you use a VPN client. De-select the check box<br />

“Checkpoint SecuRemote”<br />

d. Scroll down and double click<br />

“Internet Protocol (TCP/IP)<br />

e. Select “Use the following IP-address”<br />

f. Enter the IP address 192.168.0.250 and Subnet<br />

mask 255.255.255.0. Click “OK”<br />

3. Use “ipconfig” to verify that the computer has<br />

changed the IP-address<br />

a. Go to “Start” and select “Run…”<br />

b. Type cmd and click “OK”<br />

c. Type ipconfig and check that the IP-address is correct<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 7

4. Use Ping to verify communication between your<br />

computer and the TC-P in <strong>Power</strong> <strong>MACS</strong> <strong>4000</strong>.<br />

a. Go to “Start” and select “Run…”<br />

b. Type cmd and click “OK”<br />

c. Type ping + “IP-address of TC” and check that the<br />

TC is connected<br />

8 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Download software to TC<br />

The software version of the TC can be viewed on the TC<br />

display or in ToolsTalk PM.<br />

Check software version<br />

1. Go to the “Maintenance” menu and select<br />

“Configure target system”<br />

2. Click “Scan” to view all available TC<br />

3. Read the Software version in the column labelled “Version”<br />

Download new software<br />

To download new software to the TC, – follow the<br />

instructions below.<br />

1. Go to the “Maintenance” menu and select “Configure target<br />

system” – Highlight the TC to be upgraded<br />

2. Click “Download”<br />

3. Browse for the <strong>Power</strong> <strong>MACS</strong> <strong>4000</strong> Folder and select<br />

“TC System software”<br />

4. Select the .mx file and click “Open”<br />

5. Restart the TC once the new software has been downloaded<br />

successfully<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 9

Connect PC to TC<br />

Make sure you have a Set-up before you connect. To create a<br />

Set-up, see page 11.<br />

1. Start ToolsTalk <strong>Power</strong> <strong>MACS</strong> and select the desired<br />

system as described below.<br />

a. Open the “Maintenance” menu and select<br />

“Select Target System”<br />

b. Click “Scan” to scan for new TC<br />

c. Select the TC-P to connect to and click “OK”. The new<br />

TC is marked green in the list. See picture below<br />

2. Click “Connect” to connect ToolsTalk PM to the TC<br />

10 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Basic Programming<br />

Help function<br />

Help texts can be reached<br />

from the “Help” menu by<br />

pushing F1 or from the<br />

“Help” tab in the<br />

“Dynamic tool” window.<br />

Create a new setup<br />

A set up is needed for saving and running a program.<br />

The set up must be created before the program is built.<br />

Make sure the TC is disconnected.<br />

1. The Wizard for creating a new setup can be started either<br />

from the Start page when opening ToolsTalk PM (See<br />

picture below) or by selecting the “File” menu and the<br />

“New…” menu item<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 11

2. In the “New setup” wizard the settings for the system,<br />

station, spindles and bolts are entered. Follow the Wizard<br />

to finish the setup<br />

12 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Add new program<br />

After the Set up is created programming can start. To add a<br />

program the TC has to be disconnected.<br />

1. Under the “Tightening” menu. Select “New program…”<br />

Name the new program and click “OK”<br />

Delete program<br />

1. Open “System map” and Select “Program”<br />

2. Right click on the program that shall be deleted<br />

3. Choose “Remove program” and “OK”<br />

Add a step<br />

1. To add a step, drag the step from the ”Dynamic tool” window<br />

and drop it on the desired location in the program.<br />

It is also possible to right click between two steps and<br />

select ”Add step” from the pop up menu<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 13

2. Change the values in “Settings” under the menu<br />

“Control”. For more detailed programming, see page 17<br />

3. Click “Apply” to save the new settings in the setup<br />

If a warning is displayed when clicking “Apply” this<br />

indicates an error when programming. A description of<br />

this is displayed in “Set up problems”. See page 15<br />

Cut, copy or delte a step<br />

1. Right click on the step and select cut, copy or delete from<br />

the pop-up menu<br />

2. To insert a copied step, right click where you want the<br />

new step to be inserted and select “Paste”<br />

14 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Set up problems<br />

When applying new settings, during programming, a<br />

warning message will appear if settings are missing or<br />

incorrect.<br />

These errors or warnings are viewed in the “Set up<br />

problems” window and also at the step where the error<br />

occurs.<br />

To open this window – go to the “View” menu and select<br />

“Set up problems…”<br />

Unlike warnings, errors must be corrected before the system<br />

can continue to run.<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 15

Test bolt<br />

Test bolt is used for running the Spindle(s) from the PC.<br />

It is possible to run a Single run, Program or Mode.<br />

To run a Program, follow the instructions below.<br />

1. Click ”correct” to correct the PC to the TC<br />

2. Go to the “Maintenance” menu and select “Test bolt”<br />

3. Click “Program” to run the created Programs<br />

4. Under “Settings”, select the programs to run<br />

5. Adjust the “No. of cycles” tol be carried out<br />

6. Click ”Start” to run the programs<br />

16 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Checks, Restrictions and Monitoring<br />

By using checks, restrictions and monitoring, the tightening<br />

process can be monitored, controlled and evaluated.<br />

Programming of checks, restrictions and monitoring.<br />

1. Right click on the step or drag the selected item from the<br />

”Dynamic tool” window to the step.<br />

Note: Monitoring can only be added to Cycle End (CE)<br />

2. Set the parameters for each item in the setting window<br />

In the Program...<br />

…checks are marked with a yellow dot<br />

…restrictions are marked with a red dot<br />

…monitoring is marked with a blue dot<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 17

Checks<br />

Checks are used to define the variables that are to be<br />

measured and the limits to check in the tightening step. All<br />

checks can be set to Repairable or Fatal. If set to Fatal, the<br />

tightening can not be automatically repaired.<br />

If repairable, the Reject Management can try to re-tighten<br />

the bolt (see “Reject Management” page 24). Select the Fatal<br />

box if you want the incorrect tightening to be considered<br />

Fatal.<br />

18 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Restrictions<br />

A Restriction stops a running step immediately if the limits<br />

have been exceeded. A restriction can be set to Fatal if you<br />

do not want to retry.<br />

Monitoring<br />

Monitoring is set at the Cycle End. The Monitoring function<br />

is used to examine the result of an entire tightening cycle.<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 19

Advanced programming<br />

Create a new program by combining an existing<br />

program<br />

1. Select ”Tightening” menu<br />

2. Select ”New Program…” menu item<br />

3. Name the new program<br />

4. Click the check box “Build a new tightening program by<br />

combining existing programs”<br />

5. Select the program you want to reuse<br />

6. Click the “Add” button and then “OK”<br />

7. The new program is now added in the System Map under<br />

Programs<br />

20 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

<strong>Quick</strong> set<br />

<strong>Quick</strong> set is a function for creating a program where all<br />

parameters can be changed quickly and easily.<br />

1. Make sure the “Program settings” is highlighted<br />

2. In the “Settings” menu – select “User variables” and<br />

click “Add”<br />

3. Name the variable<br />

4. Enter a value and unit<br />

5. Click “Apply” and the variable is added to the Program<br />

settings<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 21

6. When programming a step – under “Settings” and<br />

“Control”, use the programmed Variable when entering<br />

the targets of the step<br />

7. When programming Checks<br />

and Restrictions set the max.<br />

and min. levels to a percent of<br />

the Variable<br />

Note: If the Value of the Variable<br />

is changed in the Program settings,<br />

the value will change in all places<br />

were the Variable is used.<br />

22 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

DynaTork<br />

DynaTork is a method patented by <strong>Atlas</strong> <strong>Copco</strong> designed to<br />

overcome relaxation in the joint. When the target torque is<br />

reached the DynaTork function holds the torque (current) in<br />

oreder to compensate for joint relaxation.<br />

1. IOn order to add a step, type ”DT – Run until DynaTork”<br />

2. Fill in the values for “Torque”, “Times” and “Current<br />

percentage” (If you are unsure about what values to fill in,<br />

use the Help function to get more information)<br />

3. Add “Checks” and “Restrictions” as described earlier<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 23

Reject management<br />

Reject Management is a function for automatically repairing<br />

tightenings in station and avoiding more time consuming repairs<br />

later in the process. When programming Reject Management,<br />

a step to loosen the bolt is added and the program<br />

is set to go back to an earlier step and retighten the bolt.<br />

For examples/illustrations – see next page.<br />

1. Add two steps at the end of the program.<br />

a. To loosen the bolt, add a “Run to Angle” step and set<br />

the direction to “Backwards”.<br />

b. After this step, add a “Return from repair” step.<br />

2. Click the step where the Reject Management functionality<br />

is to be added.<br />

a. Add the desired ”Checks” to evaluate if the tightening<br />

is OK or NOK<br />

b. In the “Settings” window under “Rejects” enter the<br />

following settings for the Reject Management:<br />

Retry<br />

Loosen with step: Enter the “Run to Angle” step for<br />

loosening the bolt<br />

Start from step: Enter the step that shall start the<br />

retightening of the bolt<br />

First failure<br />

Failing bolts – set to “Retry”<br />

Other bolts – set to “Wait”<br />

3. Click Apply to activate the new settings<br />

For a more detailed guide to Reject Management use the<br />

help function in ToolsTalk PM.<br />

24 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 25

Reporters<br />

When analysing a tightening, several tools are available in<br />

ToolsTalk PM. Cycle data for viewing the results, Event log<br />

for viewing errors that have occurred and Trace for a graphic<br />

picture of what is happening in the joint.<br />

Cycle data<br />

After a tightening cycle has been completed, variable data<br />

can be displayed in the ”Cycle data” window.<br />

“Cycle data” is opened by clicking the “Cycle data” icon on<br />

the Toolbar.<br />

To change the values viewed in “Cycle data”. Open the<br />

”Reporters” menu and select ”1 Screen...” or select the<br />

”reporters-Screen” from the ”System Map”.<br />

1. Click “Variables”<br />

2. Choose Station, Bolt and Step variables by dragging them<br />

from the “Dynamic Tool” window<br />

3. By highlighting the variables the parameters can be<br />

modified<br />

26 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

Use the Help function (F1) for more information.<br />

Event log<br />

After a tightening, is finalised reported events are displayed<br />

in “Event log”. Brief message about the error is displayed.<br />

To open this window – go to the “View” menu and select<br />

“Event log…”<br />

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 27

Traces<br />

Using the Trace function, the tightening can be viewed in a<br />

graph that can, in turn, be used for analysing the program<br />

and optimise the process. Traces can also be compared with<br />

a reference trace for finding deviations in the tightening<br />

process.<br />

View trace<br />

1. Click the “Trace” icon in the Toolbar to open the “Trace”<br />

window<br />

2. Open the “View” menu in the “Trace” window.<br />

3. Select “Latest” to view the latest tightening<br />

4. Set the preferred units for “Bottom axes”, “Right axes”<br />

and “Left axes” to adjust the layout of the trace<br />

Save trace<br />

1. Go to the “Trace” menu and select “Save to file”<br />

2. Save the trace<br />

3. Select the “View” menu and “Selected”<br />

4. Select trace and click “OK” to view the selected Trace<br />

28 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 29

30 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE

POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE | 31

32 | POWER <strong>MACS</strong> <strong>4000</strong> – QUICK GUIDE<br />

www.atlascopco.com<br />

9833 1761 01 Jetlag / Åtta.45 Tryckeri AB, 2011:1