SurTec® 650

SurTec® 650

SurTec® 650

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

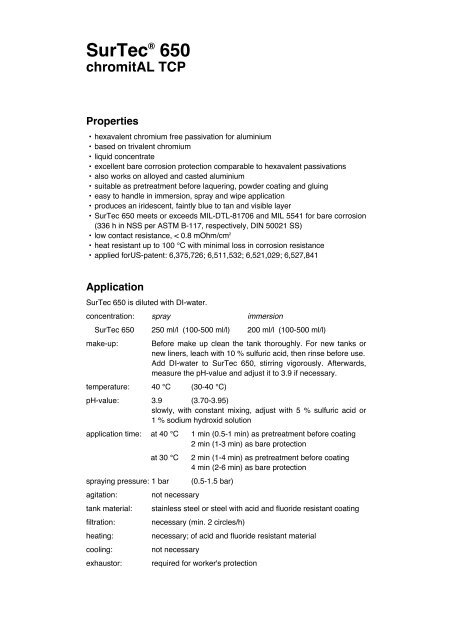

SurTec ® <strong>650</strong><br />

chromitAL TCP<br />

Properties<br />

• hexavalent chromium free passivation for aluminium<br />

• based on trivalent chromium<br />

• liquid concentrate<br />

• excellent bare corrosion protection comparable to hexavalent passivations<br />

• also works on alloyed and casted aluminium<br />

• suitable as pretreatment before laquering, powder coating and gluing<br />

• easy to handle in immersion, spray and wipe application<br />

• produces an iridescent, faintly blue to tan and visible layer<br />

• SurTec <strong>650</strong> meets or exceeds MIL-DTL-81706 and MIL 5541 for bare corrosion<br />

(336 h in NSS per ASTM B-117, respectively, DIN 50021 SS)<br />

• low contact resistance, < 0.8 mOhm/cm 2<br />

• heat resistant up to 100 °C with minimal loss in corrosion resistance<br />

• applied forUS-patent: 6,375,726; 6,511,532; 6,521,029; 6,527,841<br />

Application<br />

SurTec <strong>650</strong> is diluted with DI-water.<br />

concentration: spray immersion<br />

SurTec <strong>650</strong> 250 ml/l (100-500 ml/l) 200 ml/l (100-500 ml/l)<br />

make-up: Before make up clean the tank thoroughly. For new tanks or<br />

new liners, leach with 10 % sulfuric acid, then rinse before use.<br />

Add DI-water to SurTec <strong>650</strong>, stirring vigorously. Afterwards,<br />

measure the pH-value and adjust it to 3.9 if necessary.<br />

temperature: 40 °C (30-40 °C)<br />

pH-value: 3.9 (3.70-3.95)<br />

slowly, with constant mixing, adjust with 5 % sulfuric acid or<br />

1 % sodium hydroxid solution<br />

application time: at 40 °C 1 min (0.5-1 min) as pretreatment before coating<br />

2 min (1-3 min) as bare protection<br />

at 30 °C 2 min (1-4 min) as pretreatment before coating<br />

4 min (2-6 min) as bare protection<br />

spraying pressure: 1 bar (0.5-1.5 bar)<br />

agitation: not necessary<br />

tank material: stainless steel or steel with acid and fluoride resistant coating<br />

filtration: necessary (min. 2 circles/h)<br />

heating: necessary; of acid and fluoride resistant material<br />

cooling: not necessary<br />

exhaustor: required for worker's protection

hints: During storage a slight precipitation may occur which does not<br />

impair the quality and the function of the product.<br />

Prior to the passivation with SurTec <strong>650</strong> the aluminium surface<br />

must be cleaned and deoxidized thoroughly. The surface must<br />

be water-break free.<br />

Standard procedures for immersion are:<br />

For aluminum alloys with < 1 % Silicon:<br />

1. mild alkaline degreasing, SurTec 133<br />

2. alkaline etching, SurTec 181<br />

3. deoxidizing, SurTec 495<br />

For aluminum alloys with > 1 % silicon:<br />

1. mild alkaline degreasing, SurTec 136<br />

2. deoxidizing, SurTec 495<br />

Standard procedure for spray is:<br />

1. acid degreasing, SurTec 472 / SurTec 086<br />

Treated surfaces with SurTec <strong>650</strong> can be coated immediately<br />

after drying or stored as long as they are protected from contamination<br />

and temperature extremes. For optimum results, parts<br />

should stand for 24 h before subsequent coatings are applied.<br />

maintenance: Analyse and adjust pH-value by using a frequently calibrated<br />

pH-meter. Analyse and adjust the concentration regularly.<br />

consumption: The consumption strongly depends on the drag-out (for the<br />

exact determination of the drag-out see SurTec Technical<br />

Letter 11). As a general orientation can be taken:<br />

Analysis<br />

Sample Preparation<br />

15-25 ml SurTec <strong>650</strong> concentrate are sufficient for treating 1 m 2<br />

surface (drag-out included).<br />

Take the sample at a homogeneously mixed position and let it cool down to room<br />

temperature. If dull, allow to settle and decant or filter.<br />

Concentration via chromium content<br />

page 2<br />

reagents: 10 % sodium hydroxide, 30 % H 2O 2, 17 % hydrochloric acid,<br />

potassium iodide, 0.1 N sodium thiosulfate, 1 % starch solution<br />

process: Pipette 100 ml passivation bath into a 250 ml Erlenmeyer flask,<br />

and add 20 ml sodium hydroxide solution. Then add appr. 5 ml<br />

H 2O 2, stirr for 5 min, add another 5 ml H 2O 2, stirr for 5 min at<br />

room temperature and boil the solution for 30-40 min. It is very<br />

important to evaporate excessive H 2O 2. The volume must not<br />

evaporate below 50 ml.<br />

Chill the solution, add demineralised water up to about 100 ml<br />

and filter it using a fine grained filter paper (blue band). Rinse<br />

the filter with 5 ml DI-water. The filtrate must be clear and free<br />

of precipitates.

Add 40 ml hydrochloric acid to the filtrate (colour change from<br />

yellow to orange). Add about 1 g potassium iodide, titrate with<br />

0.1 N sodium thiosulfate until the solution is only slightly<br />

yellowish, then add some starch solution and continue to titrate<br />

until the blue colour disappears.<br />

calculation: consumption in ml · 1.613 = Vol% SurTec <strong>650</strong><br />

Technical Specification<br />

at 20 °C appearance density pH-value<br />

(g/ml) concentrate<br />

SurTec <strong>650</strong> green liquid 1.005 (1.000-1.010) 3.8 (3.6-4.0)<br />

Ingredients<br />

• trivalent chromium salts<br />

Stock Keeping<br />

To prevent interruptions due to logistic problems, a certain stock is indispensable.<br />

We recommend to keep the following amounts per 1000 l bath:<br />

Passivation SurTec <strong>650</strong> 500 kg<br />

Ecology<br />

Used solutions of SurTec <strong>650</strong> and its rinsing waters have to be worked up and disposed<br />

corresponding to national and local regulations. SurTec <strong>650</strong> itself is slightly<br />

hazardous for water, Water Hazard Class 1 (self-assessment).<br />

Product Safety<br />

SurTec <strong>650</strong> is not subject to classification according to General EC Classification<br />

Guidelines for Preparations.<br />

Please consult also the EC safety data sheet.<br />

Guarantee<br />

page 3<br />

Our guarantee extends to the continuous quality of our products as they leave our<br />

factory and not to their usage in the field. Our technical service will be pleased to<br />

answer any question you may have concerning operation and use of our products:<br />

Fax: 0(049)-6251/171-844, Tel.: 0(049)-6251/171-744, e-Mail: TZ@SurTec.com.<br />

20.06.2005/SV, PV