Langboard OSB, Quitman City - Georgia Air Protection Branch

Langboard OSB, Quitman City - Georgia Air Protection Branch

Langboard OSB, Quitman City - Georgia Air Protection Branch

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

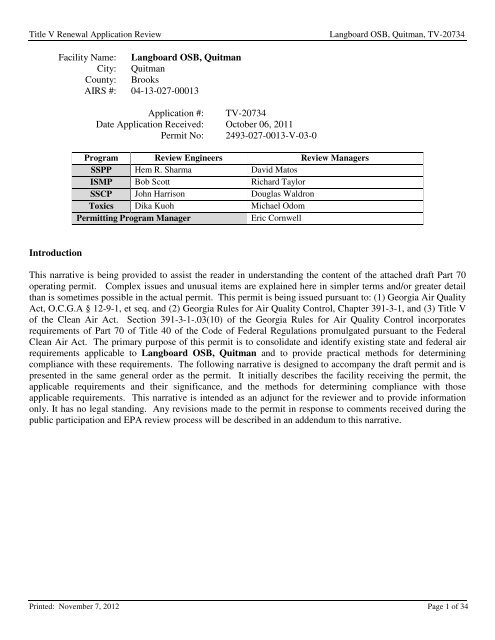

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Introduction<br />

Facility Name: <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong><br />

<strong>City</strong>: <strong>Quitman</strong><br />

County: Brooks<br />

AIRS #: 04-13-027-00013<br />

Application #: TV-20734<br />

Date Application Received: October 06, 2011<br />

Permit No: 2493-027-0013-V-03-0<br />

Program Review Engineers Review Managers<br />

SSPP Hem R. Sharma David Matos<br />

ISMP Bob Scott Richard Taylor<br />

SSCP John Harrison Douglas Waldron<br />

Toxics Dika Kuoh Michael Odom<br />

Permitting Program Manager Eric Cornwell<br />

This narrative is being provided to assist the reader in understanding the content of the attached draft Part 70<br />

operating permit. Complex issues and unusual items are explained here in simpler terms and/or greater detail<br />

than is sometimes possible in the actual permit. This permit is being issued pursuant to: (1) <strong>Georgia</strong> <strong>Air</strong> Quality<br />

Act, O.C.G.A § 12-9-1, et seq. and (2) <strong>Georgia</strong> Rules for <strong>Air</strong> Quality Control, Chapter 391-3-1, and (3) Title V<br />

of the Clean <strong>Air</strong> Act. Section 391-3-1-.03(10) of the <strong>Georgia</strong> Rules for <strong>Air</strong> Quality Control incorporates<br />

requirements of Part 70 of Title 40 of the Code of Federal Regulations promulgated pursuant to the Federal<br />

Clean <strong>Air</strong> Act. The primary purpose of this permit is to consolidate and identify existing state and federal air<br />

requirements applicable to <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong> and to provide practical methods for determining<br />

compliance with these requirements. The following narrative is designed to accompany the draft permit and is<br />

presented in the same general order as the permit. It initially describes the facility receiving the permit, the<br />

applicable requirements and their significance, and the methods for determining compliance with those<br />

applicable requirements. This narrative is intended as an adjunct for the reviewer and to provide information<br />

only. It has no legal standing. Any revisions made to the permit in response to comments received during the<br />

public participation and EPA review process will be described in an addendum to this narrative.<br />

Printed: November 7, 2012 Page 1 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

I. Facility Description<br />

A. Facility Identification<br />

1. Facility Name: <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong><br />

2. Parent/Holding Company Name<br />

Langdale Industries<br />

3. Previous and/or Other Name(s); <strong>Langboard</strong>, Inc.<br />

4. Facility Location<br />

U.S. Highway 84 East, <strong>Quitman</strong>, Brooks County, <strong>Georgia</strong> 31643<br />

5. Attainment, Non-attainment Area Location, or Contributing Area<br />

B. Site Determination<br />

The facility is located in an attainment area.<br />

This permit covers the <strong>OSB</strong> plant constructed in 2005, the details of which are included in Title<br />

V permit application No. 15084. Note that the original old <strong>OSB</strong> plant, which was adjacent and<br />

under common control, ceased to operate after the startup of the exiting new plant.<br />

C. Existing Permits<br />

Table 1 below lists all current Title V permits, all amendments, 502(b)(10) changes, and offpermit<br />

changes, issued to the facility, based on a comparative review of form A.6, Current<br />

Permits, of the Title V application and the "Permit" file(s) on the facility found in the <strong>Air</strong> <strong>Branch</strong><br />

office.<br />

Table 1: List of Current Permits, Amendments, and Off-Permit Changes<br />

Permit Number and/or Off- Date of Issuance/ Purpose of Issuance<br />

Permit Change<br />

Effectiveness<br />

2493-027-0013-V-02-0<br />

April 05, 2007<br />

First Title V permit renewal<br />

Printed: November 7, 2012 Page 2 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

D. Process Description<br />

1. SIC Codes(s)<br />

2493<br />

The SIC Code(s) identified above were assigned by EPD's <strong>Air</strong> <strong>Protection</strong> <strong>Branch</strong> for<br />

purposes pursuant to the <strong>Georgia</strong> <strong>Air</strong> Quality Act and related administrative purposes<br />

only and are not intended to be used for any other purpose. Assignment of SIC Codes by<br />

EPD's <strong>Air</strong> <strong>Protection</strong> <strong>Branch</strong> for these purposes does not prohibit the facility from using<br />

these or different SIC Codes for other regulatory and non-regulatory purposes.<br />

Should the reference(s) to SIC Code(s) in any narratives or narrative addendum<br />

previously issued for the Title V permit for this facility conflict with the revised language<br />

herein, the language herein shall control; provided, however, language in previously<br />

issued narratives that does not expressly reference SIC Code(s) shall not be affected.<br />

2. Description of Product(s)<br />

This plant produces oriented strand board (<strong>OSB</strong>).<br />

3. Overall Facility Process Description<br />

Mixed pine and limited amount of southern hardwoods are received by truck, debarked,<br />

cut to length, flaked, conveyed to wet flake metering bins, and dried. The wood flakes<br />

are dried in two single pass rotary flake dryers, each with a maximum input rate of<br />

75,000 pounds per hour (lb/hr). The drying heat is provided by one of two wood fired<br />

furnaces (aka Energy Systems). The heat input capacity of each energy system is 160<br />

million British thermal units per hour (MMBtu/hr), burning wood bark and other wood<br />

waste fuel recovered from the process, and controlled by an electrostatic precipitator<br />

(ESP) and nitrogen oxide (NOx) Abatement System. The Energy Systems receive<br />

exhaust gases from the dryers, board press, and blenders for reduction of VOC emissions.<br />

The dried flakes are screened for fines removal and then mixed with wax and phenolformaldehyde<br />

resin in the blenders. Flakes are then aligned in a continuous mat. The mat<br />

is cut into sections, pressed at high temperature and pressure in a board press, which is<br />

heated by thermal oil. The boards are then sanded, trimmed to size, graded, edge coated,<br />

and packaged for shipment. The plant can manufacture up to 500 million square feet per<br />

year (MMsf/yr) of <strong>OSB</strong>.<br />

4. Overall Process Flow Diagram<br />

The facility provided a process flow diagram in their previous Title V permit application.<br />

No physical or operational changes have occurred since the current permit.<br />

Printed: November 7, 2012 Page 3 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

E. Regulatory Status<br />

1. PSD/NSR<br />

<strong>Langboard</strong>’s potential to emit (with permit limits) each PSD regulated pollutant does not<br />

exceed the 250-ton per year PSD major source threshold for any pollutant. The facility is,<br />

therefore, not a major source for PSD/NSR regulations. This facility is not one of the 28<br />

named source categories under PSD for which the PTE threshold is 100 tons per year.<br />

Also the facility is not located in a non-attainment area. Note that the facility is presently<br />

a synthetic minor source for the purposes of PSD permitting requirements as emissions of<br />

CO and NOx are limited below the major source threshold of 250 tpy.<br />

2. Title V Major Source Status by Pollutant<br />

Table 2: Title V Major Source Status<br />

Pollutant<br />

Is the<br />

Pollutant<br />

Emitted? Major Source Status<br />

PM <br />

PM 10 <br />

If emitted, what is the facility’s Title V status for the pollutant?<br />

Major Source<br />

Requesting SM Status<br />

Non-Major Source<br />

Status<br />

SO 2 <br />

VOC <br />

NO x <br />

CO <br />

TRS <br />

H2S <br />

<br />

Greenhouse<br />

Gases<br />

Individual<br />

HAP <br />

Total HAPs <br />

3. MACT Standards<br />

No MACT standards apply to this plant.<br />

40 CFR 63, Subpart DDDDD, NESHAP for Industrial/Commercial/Institutional Boilers<br />

and Process heaters (The Boiler MACT), was promulgated on March 21, 2011with an<br />

affected date of May 20, 2011. However, this MACT is not applicable to the facility<br />

because potential HAP emissions are estimated to be less than 10/25 tpy, and this is only<br />

applicable to the major sources of HAPs emissions.<br />

The promulgated MACT, 40 CFR 63, Subpart DDDD, NESHAP for Plywood and<br />

Composite Wood Products (PCWP) (Federal Register, Vol. 69, No. 146/Friday, July 30,<br />

Printed: November 7, 2012 Page 4 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

2004/Rules and Regulations), regulates HAP emissions from major HAP sources. As this<br />

facility is not a major source for HAPs, the facility is not subject to the PCWP MACT.<br />

A facility is subject to the Area Source Boilers NESHAP (40 CFR 63 Subpart JJJJJJ –<br />

National Emission Standards for hazardous <strong>Air</strong> Pollutants for Industrial, Commercial,<br />

and institutional boilers Area Sources, if the facility owns or operate an industrial,<br />

commercial, or institutional boiler as defined in §63.11237 that is located at, or is part of,<br />

an area source of hazardous air pollutants (HAP). A list of the regulated hazardous air<br />

pollutants can be found at http://www.epa.gov/ttnatw01/orig189.html.<br />

In accordance with §63.11237 of this NESHAP, a boiler means an enclosed device using<br />

controlled flame combustion in which water is heated to recover thermal energy in the<br />

form of steam or hot water. Controlled flame combustion refers to a steady-state, or near<br />

steady-state, process wherein fuel and/or oxidizer feed rates are controlled.<br />

However, this NESHAP is not applicable to the facility because the Energy System A<br />

and Energy System B (Emission Unit ID Nos. P001 and P002) are fuel-burning<br />

equipment and are not defined as boilers per this NESHAP.<br />

4. Program Applicability (AIRS Program Codes)<br />

Program Code<br />

Applicable<br />

(y/n)<br />

Program Code 6 - PSD No<br />

Program Code 8 – Part 61 NESHAP No<br />

Program Code 9 - NSPS Yes<br />

Program Code M – Part 63 NESHAP No<br />

Program Code V – Title V Yes<br />

Printed: November 7, 2012 Page 5 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Regulatory Analysis<br />

II. Facility Wide Requirements<br />

A. Emission and Operating Caps:<br />

VOC emissions from the <strong>Langboard</strong>'s existing (new) <strong>OSB</strong> plant are controlled by Energy System<br />

incineration, and emissions are estimated to be less than 250 tpy. Therefore, no condition<br />

limiting the pine usage was included in the existing permit (No. 2493-027-0013-V-02-0).<br />

However, since the existing (new) plant’s PTE individual and total HAPs emission were 8.5 and<br />

24.3 tpy respectively, which are very close to the 10/25 tpy HAP major source thresholds,<br />

emissions of HAPs were capped. Since all major emission sources are to be routed through the<br />

Energy System, limiting HAP emissions from the Energy System will effectively limit HAP<br />

emissions facility wide. The following Condition 2.1.1, included in the Title V Permit No. 2493-<br />

027-0013-V-02-0, is carried over in this permit renewal:<br />

2.1.1 The Permittee shall not cause, let, suffer, permit or allow the rate of emissions from the<br />

entire facility any gases, which contain individual and total hazardous air pollutants<br />

(HAP), including but not limited to acetaldehyde, acrolein, formaldehyde, methanol,<br />

phenol, and propionaldehyde in amounts in excess of 10 tpy and 25 tpy respectively<br />

during any twelve (12) consecutive months.<br />

[MACT and 112(g) Avoidance Limit, 391-3-1-.02(2)(a)3]<br />

B. Applicable Rules and Regulations<br />

40 CFR Parts 51, 52, 70, et al.: Prevention of Significant Deterioration and Title V Greenhouse<br />

Gas Tailoring Rule; Final Rule (Thursday, June 3, 2010). Per PSD Permitting rule of this part,<br />

Step 2 began on July 1, 2011. Under Step 2, anyway PSD sources—that is, sources already<br />

subject to PSD based on non-GHGs and covered under Step 1 previously—will remain subject to<br />

PSD. In addition, sources with the potential to emit 100,000 tpy CO2e or more of GHG will be<br />

considered major sources for PSD permitting purposes (provided that they also emit GHGs or<br />

some other regulated NSR pollutant above the 100/ 250 tpy (mass based) statutory thresholds.<br />

On July 20, 2011, EPA issued a deferral for CO2 emissions from biogenic and other biogenic<br />

sources under the PSD and Title V permitting programs. The action defers for a period of three<br />

years the application of PSD permitting requirements for biogenic CO2 emissions only. The<br />

application indicates that the facility has excluded CO2 emissions only (not CH4 or N2O<br />

emissions) from the biomass fueled energy systems, for estimating the total facility-wide CO2e<br />

emissions from the <strong>OSB</strong> plant.<br />

The application indicates that the facility-wide GHG potential to emit CO2e is 6,267 tpy which is<br />

less than 100,000 tons per year. Therefore, the facility is not a major of GHG with respect to<br />

Title V and PSD.<br />

C. Compliance Status<br />

The plant is currently operating in compliance per record.<br />

Printed: November 7, 2012 Page 6 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

D. Operational Flexibility<br />

The facility did not request any operational flexibility.<br />

E. Permit Conditions<br />

Since this permit renewal is only for the operation of the existing (new) <strong>OSB</strong> plant, which was<br />

commissioned in the year 2005, only conditions pertaining to the existing <strong>OSB</strong> plant, from the<br />

Title V Permit No. 2493-027-0013-V-02-0, are included in this renewal permit.<br />

Note: The original plant, before this existing <strong>OSB</strong> plant, which was authorized to operate by<br />

Permits No. 2493-027-0013-V-01-0 (Initial TV Permit issued on August 31, 1999, No. 2493-<br />

027-0013-V-01-1 [a 502(b)(10) Permit Amendment issued on July 16, 2002], and an off permit<br />

change letter dated October 1, 2002, had ceased to operate. The facility, in a letter dated June 30,<br />

2005, indicated that the original plant equipment, including the Geka Thermal Oil Heater and<br />

wood fired dryers, had been permanently shut down in June 2005.<br />

Condition No. 2.1.1:<br />

Condition No. 2.1.1, which requires the Permittee to limit individual and total HAP emissions to<br />

less than 10/25 tons per year to avoid being a major source of HAPs, is the same as existing<br />

permit Condition No. 2.1.1.<br />

Printed: November 7, 2012 Page 7 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

III. Regulated Equipment Requirements<br />

A. Brief Process Description<br />

<strong>Langboard</strong>, Inc. currently operates a plant with a capacity to manufacture 500 million square feet<br />

per year (MMsf/yr) of Oriented Strand Board (<strong>OSB</strong>). For the manufacturing of <strong>OSB</strong>, mixed<br />

southern hardwoods and pine are received by truck, debarked, cut to length, flaked, and<br />

conveyed to dryer metering bins and dried. Single pass rotary dryers are indirectly heated by the<br />

hot air supplied by the energy systems. The dried flakes are screened for fines removal, and<br />

conveyed to blender metering bins. The flakes are mixed with wax and phenol-formaldehyde<br />

resin in the blenders. Flakes are then aligned in a continuous mat. The mat is cut into sections<br />

and pressed at high temperature and pressure. Finally, the boards are sanded, trimmed to size,<br />

graded, edge coated, and packaged for shipment. Note that, all emissions from the <strong>OSB</strong> dryers,<br />

blending, and board press are routed to the energy system for incineration<br />

B. Equipment List for the Process<br />

Emission Units Specific Limitations/Requirements <strong>Air</strong> Pollution Control Devices<br />

ID No. Description<br />

P001<br />

P002<br />

P003<br />

P004<br />

P005<br />

Energy System A<br />

(160 MMBtu/hr<br />

heat input capacity,<br />

wood-fired combustion<br />

system)<br />

Energy System B<br />

(160 MMBtu/hr<br />

heat input capacity,<br />

wood-fired combustion<br />

system)<br />

Dryer System A<br />

(Single pass rotary flake<br />

dryer)<br />

Dryer System B<br />

(Single pass rotary flake<br />

dryer)<br />

Fines/Flake Screening<br />

Applicable<br />

Requirements/Standards<br />

40 CFR 60, Subpart A<br />

40 CFR 60, Subpart Db<br />

GA Rule 391-3-1-.02(2)(d)<br />

GA Rule 391-3-1-.02(2)(g)<br />

40 CFR 60, Subpart A<br />

40 CFR 60, Subpart Db<br />

GA Rule 391-3-1-.02(2)(d)<br />

GA Rule 391-3-1-.02(2)(g)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

Corresponding Permit<br />

Conditions<br />

3.2.1, 3.2.3, 3.3.1, 3.3.2,<br />

3.3.3, 3.4.1, 3.4.2, 3.5.1,<br />

3.5.2, 3.5.4, 4.2.1, 4.2.2,<br />

4.2.3, 4.2.4, 4.2.5, 4.2.7,<br />

4.2.8, 5.2.1, 5.2.2, 5.2.8,<br />

5.2.9, 5.2.10, 5.2.11,<br />

5.2.12, 5.2.13, 6.1.7, 6.2.1,<br />

6.2.3, 6.2.7, 6.2.8<br />

3.2.1, 3.2.3, 3.3.1, 3.3.2,<br />

3.3.3, 3.4.1, 3.4.2, 3.5.1,<br />

3.5.2, 3.5.4, 4.2.1, 4.2.2,<br />

4.2.3, 4.2.4, 4.2.5, 4.2.7,<br />

4.2.8, 5.2.1, 5.2.2, 5.2.8,<br />

5.2.9, 5.2.10, 5.2.11,<br />

5.2.12, 5.2.13, 6.1.7, 6.2.1,<br />

6.2.3, 6.2.7, 6.2.8<br />

3.4.3, 3.4.4, 3.4.5, 3.4.6,<br />

3.5.1, 3.5.2, 3.5.4, 4.2.5,<br />

5.2.8, 5.2.11, 5.2.12,<br />

5.2.13, 6.1.7, 6.2.1, 6.2.4<br />

3.4.3, 3.4.4, 3.4.5, 3.4.6,<br />

3.5.1, 3.5.2, 3.5.4, 4.2.5,<br />

5.2.8, 5.2.11, 5.2.12,<br />

5.2.13, 6.1.7, 6.2.1, 6.2.4<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.2, 3.5.3, 3.5.4,<br />

5.2.3, 5.2.4, 5.2.5, 5.2.6,<br />

6.1.7, 6.2.3, 6.2.9<br />

Printed: November 7, 2012 Page 8 of 34<br />

ID<br />

No.<br />

C001<br />

C007<br />

C001<br />

C007<br />

P001<br />

and<br />

P002<br />

P001<br />

and<br />

P002<br />

C002<br />

Description<br />

Electrostatic<br />

Precipitator (ESP)<br />

NOx Abatement<br />

System<br />

(Stack ID. S001)<br />

Electrostatic<br />

Precipitator (ESP)<br />

NOx Abatement<br />

System<br />

(Stack ID. S001)<br />

Energy System A<br />

and<br />

Energy System B<br />

(Stack ID. S001)<br />

Energy System A<br />

and<br />

Energy System B<br />

(Stack ID. S001)<br />

Fuel Storage Bin Vent<br />

(OG03)<br />

(Stack ID. S002)

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Emission Units Specific Limitations/Requirements <strong>Air</strong> Pollution Control Devices<br />

ID No. Description<br />

P006<br />

P007<br />

P008<br />

P009<br />

P010<br />

P011<br />

Flake<br />

Handling/Blending<br />

Forming Line<br />

Board Press<br />

Sander Line<br />

Saw & Trim Line<br />

Fuel Relay and<br />

Storage Silo<br />

Applicable<br />

Requirements/Standards<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

GA Rule 391-3-1-.02(2)(e)<br />

GA Rule 391-3-1-.02(2)(b)<br />

Corresponding Permit<br />

Conditions<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.1, 3.5.2, 3.5.3,<br />

3.5.4, 4.2.5, 5.2.3, 5.2.4,<br />

5.2.5, 5.2.6, 5.2.7, 5.2.11,<br />

5.2.13, 5.2.14, 6.1.7, 6.2.1,<br />

6.2.3, 6.2.4, 6.2.9<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.2, 3.5.3, 3.5.4,<br />

5.2.3, 5.2.4, 5.2.5, 5.2.6,<br />

5.2.7, 6.1.7, 6.2.3, 6.2.5,<br />

6.2.9<br />

3.4.3, 3.4.4, 3.4.5, 3.4.6,<br />

3.5.1, 3.5.2, 3.5.4, 3.5.5,<br />

4.2.5, 4.2.6, 5.2.11, 5.2.13,<br />

5.2.15, 6.1.7, 6.2.2, 6.2.4,<br />

6.2.5, 6.2.6<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.2, 3.5.3, 3.5.4,<br />

5.2.3, 5.2.4, 5.2.5, 5.2.6,<br />

6.1.7, 6.2.3, 6.2.9<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.2, 3.5.3, 3.5.4,<br />

5.2.3, 5.2.4, 5.2.5, 5.2.6,<br />

6.1.7, 6.2.3, 6.2.9<br />

3.2.2, 3.4.3, 3.4.4, 3.4.5,<br />

3.4.6, 3.5.2, 3.5.3, 3.5.4,<br />

5.2.3, 5.2.4, 5.2.5, 5.2.6,<br />

6.1.7, 6.2.3, 6.2.9<br />

Printed: November 7, 2012 Page 9 of 34<br />

ID<br />

No.<br />

C004<br />

P001<br />

and<br />

P002<br />

C003<br />

P001<br />

and<br />

P002<br />

C006<br />

C003<br />

C002<br />

Description<br />

Flaker Handling (dry<br />

bins) Baghouse for PM<br />

control<br />

(Stack ID. S004)<br />

Energy System A<br />

and<br />

Energy System B<br />

used to incinerate VOC<br />

and HAP emissions<br />

(Stack ID. S001)<br />

Forming Line and<br />

Saw & Trim Baghouse<br />

(OG02)<br />

(Stack ID. S003)<br />

Energy System A<br />

and<br />

Energy System B<br />

used to incinerate VOC<br />

and HAP emissions<br />

(Stack ID. S001)<br />

Sander Line Baghouse<br />

(Stack ID. S006)<br />

Forming Line and<br />

Saw & Trim Baghouse<br />

(OG02)<br />

(Stack ID. S003)<br />

Fuel Storage Bin Vent<br />

(OG03)<br />

(Stack ID. S002)<br />

* Generally applicable requirements contained in this permit may also apply to emission units listed above. This table includes all the<br />

emission sources and control equipment as per revised configuration provided in the updated Title V renewal applications dated<br />

November 17, 2005, and December 15, 2006. This renewal application No. 20734 confirms this configuration/emission sources.<br />

___________________________________________________________________________________<br />

Note: 1. Energy System A was originally manufactured in 2004. During construction, the primary air heater was severely damaged.<br />

It was rebuilt and installed in 2005.<br />

2. NOx abatement system uses a urea injection system, which is automated and controlled by a feedback connection to the<br />

CERMS installed on the NOx abatement system.

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

C. Equipment & Rule Applicability<br />

Emission and Operating Caps:<br />

The emission and operating Caps, as indicated in the existing Title V Permit No. 2493-027-0013-<br />

V-02-0 (no amendment issued), which was based on Title V Permit Amendment No. 2491-027-<br />

0013-V-01-2 ,2491-027-0013-V-01-3 and 2491-027-0013-V-01-4, are as below:<br />

The Energy System emits NOx and CO. The PTE indicated by the facility in their applications,<br />

for each of these pollutants, were not much less than the 250 tpy PSD major source threshold for<br />

each. To help assure that the facility stays a minor source for PSD, the following facility wide<br />

limits for NOx and CO emissions are imposed in their Title V Permit No. 2493-027-0013-V-02-<br />

0.<br />

3.2.1 The Permittee shall not cause, let, suffer, permit or allow the rate of emissions from<br />

Energy System A and Energy System B (Emission Unit ID Nos. P001 and P002),<br />

combined, nitrogen oxides (NOx) or carbon monoxide (CO) equal to or in excess of<br />

57.05 lb/hr (30 day rolling average).<br />

[PSD Avoidance Limits]<br />

AP-42, Fifth Edition (9/2003), Section 1.6 (Wood Residue Combustion in Boilers) indicates a<br />

NOx emission factor of 0.22 lb/MMbtu for bark/bark and wet wood/wet wood-fired boilers, and<br />

0.44 lb/MMbtu for dry wood-fired boilers. Using the emission factor of 0.22, NOx emissions are<br />

estimated to be 70.4 lb/hr from both Energy Systems A and B, compared against the emission<br />

cap of 57.05 lb/hr (Condition 3.2.1). Therefore, it is expected that the facility might not be able<br />

to comply with the emission standards for CO and NOx without controls. Note that NOx<br />

emissions from wet bark in wood boilers are typically lower (approximately one-half), in<br />

comparison to NOx emissions from dry wood-fired boilers.<br />

The narrative for the existing Title V Permit No. 2493-027-0013-V-02-0 indicates the following:<br />

“The updated Title V renewal application indicates that the energy systems had not performed up<br />

to the manufacturer’s specifications. The Permittee has worked with the energy system<br />

manufacturer on strategies to reduce emissions of CO and NOx in order to meet the guaranteed<br />

levels and comply with the permit limits.<br />

To reduce CO emissions, <strong>Langboard</strong> has determined that it must maintain a higher temperature<br />

in the combustion chamber. However, while reducing CO emissions, the higher chamber<br />

temperature is likely to result in more NOx formation and thus higher NOx emissions. That can<br />

only be countered with add-on control equipment.<br />

AP-42 literature indicates that, in those areas of the U. S. where NOx emissions must be reduced<br />

to their lowest levels, the application of selective noncatalytic reduction (SNCR) equipment to<br />

residue wood fired boilers has achieved reductions; also, that the application of selective<br />

catalytic reduction (SCR) is being contemplated where better control is required. Both systems<br />

are post-combustion NOx reduction techniques, in which ammonia (or urea) is injected into the<br />

flue gas to selectively reduce NOx to nitrogen and water. In one application of SNCR to an<br />

Printed: November 7, 2012 Page 10 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

industrial wood-fired boiler, NOx reduction efficiencies varied between 35 and 75 percent, as the<br />

ammonia-to-NOx ratio increased from 0.4 to 3.2.<br />

The updated renewal application indicated that a previously considered NOx abatement system<br />

would need to be added to the energy system, as recommended by the manufacturer, to lower<br />

annual NOx emissions to less than the major source threshold. The Permittee has requested that<br />

EPD authorize the installation and operation of an ammonia injection NOx abatement system.<br />

The Permittee initially stated that it would only operate the NOx abatement system on an as<br />

needed basis, using the NOx Continuous Emission Rate Monitoring System (CERMS) to<br />

demonstrate compliance with the permit limits. However, it now appears that the overall level of<br />

control needed, in order to be a minor source for NOx, will require them to use the NOx<br />

abatement system most of the time.<br />

Therefore, the permit requires that the NOx abatement system be operated at all times when the<br />

furnaces are operating, except during startup, shutdown and malfunction. For compliance<br />

purposes, the current NOx CERMS will be used to demonstrate that NOx and CO emissions<br />

from the plant each remain below the permitted limits of 57.05 lb/hr (30 day rolling average).<br />

Also, in order to minimize the use of urea and ammonia slip, the urea injection system is to be<br />

controlled by feedback connection to the CERMS.”<br />

To ensure that facility wide PM emissions cannot exceed the 250 tpy PSD major source<br />

threshold, the Permittee accepted a PM emissions limit of 0.060 lb/MMBtu, from Energy System<br />

Units A and B (Emission Unit ID Nos. P001 and P002). Therefore, the Energy System PTE is<br />

lower than it would be, if only considering the NSPS limit. It is 84.10 tpy. The PM emissions are<br />

controlled by a dedicated ESP. Given the reliability of ESPs, it was therefore expected that the<br />

energy system will be in compliance with the NSPS and this limit. The PM limit is included in<br />

Condition 3.2.3, which is same as existing permit condition and as indicated below.<br />

3.2.3 The Permittee shall not cause, let, suffer, permit or allow the rate of emissions from the<br />

Energy System (Emission Unit ID Nos. P001 and P002) stack (Stack ID. S001),<br />

downstream of the electrostatic precipitator (APCD ID No. C001), any emissions which<br />

contain PM in excess of 0.060 lb/MMBtu.<br />

[PSD Avoidance Limits and 40 CFR 60 Subpart Db-subsumed]<br />

Manufacturing Processes<br />

The previous Title V application indicates that the facility wide PTE PM is revised to 249.5 from<br />

222.5 tpy, and 69.2 tpy from 106.2 tpy for VOC. The Permittee has accepted the following<br />

revised limits for the following manufacturing processes, each of whose PM emissions are<br />

controlled by a dedicated baghouse, to ensure that PM emissions stay under the PSD major<br />

source threshold of 250 tpy, facility wide; the limits are revised, as requested, because the<br />

configuration of the control equipment was modified:<br />

a. Forming (Emission Unit ID No. P07) and<br />

Saw Line (Emission Unit ID No. P10)-<br />

Controlled by BGH1 (APCD ID No. C03): 12.9 lb/hr.<br />

Printed: November 7, 2012 Page 11 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

b. Sander Line (Emission Unit ID No. P09)-<br />

Controlled by BGH2 (APCD ID No. C04): 9.6 lb/hr.<br />

c. Flaker Handling/Blending (Emission Unit ID No. P06)-<br />

Controlled by BGH3 (APCD ID No. C05): 8.6 lb/hr.<br />

d. Fines/Flake Screening (Emission Unit ID No. P05) and<br />

Fuel Relay and Storage (Emission Unit ID No. P11)-<br />

Controlled by BGH4 (APCD ID No. C02): 3.2 lb/hr.<br />

e. Flakers (Emission Unit ID Nos. P12 and P13)-<br />

Controlled by BGH5 (APCD ID No. C06): 3.2 lb/hr.<br />

Further, the above indicated emissions and operating caps were revised, as indicated in the<br />

existing Title V Permit No. 2493-027-0013-V-02-0 (no amendment issued), as below:<br />

“The Title V renewal application No. 15084 indicates that, for the existing <strong>OSB</strong> plant, the<br />

facility wide PTE for PM is 222.0 tpy. It also states that the Energy System PM PTE is 84.5 tpy<br />

and a total of about 1.02 tpy PM is emitted from a group of sources which includes the debarker,<br />

the bark hog, the bark bin, the bark file, truck unloading. I therefore deduce [222.0-(84.5+1.02)]<br />

that the remaining PM PTE of about 136.48 tpy is emitted by the Fines/Flake Screening<br />

(Emission Unit ID No. P005), Flake Handling/Blending (Emission Unit ID No. P006), Forming<br />

(Emission Unit ID No. P007), Sander Line (Emission Unit ID No. P009), and Saw & Trim Line<br />

(Emission Unit ID No. P010). The Permittee, by their updated renewal application dated Nov 17,<br />

2005, has excluded Flaker A and Flaker B (earlier assigned Emission Unit ID Nos. P012 and<br />

P013) from the list of significant sources (Table 3.1). It has been indicated that these flakers have<br />

insignificant emissions of PM and the facility does not intend to install the flaker baghouse,<br />

which was earlier proposed to minimize wood dust that could accumulate in the area, for<br />

housekeeping. The potential PM emission from the flakers was restricted to 3.2 lb/hr or 14.02<br />

tpy. Therefore, I presume that the remaining PM PTE of 122.46 tpy (136.48-14.02) of PM is<br />

emitted from the four baghouses that control all the above processes. The Permittee has accepted<br />

the following limits, as per their renewal application, for the above manufacturing processes,<br />

each of whose PM emissions are controlled by a dedicated baghouse, to ensure that PM<br />

emissions stay under the PSD major source threshold of 250 tpy, facility wide. The operating<br />

emission caps are found in Condition 3.2.2; this is similar to old Condition No. 3.2.6:<br />

3.2.2 The Permittee shall not discharge or cause the discharge into the atmosphere from the<br />

following process equipment, any gases that contain Particulate Matter (PM) in excess<br />

of the indicated rates:<br />

[PSD Avoidance Limits]<br />

a. Forming (Emission Unit ID No. P007) and<br />

Saw & Trim Line (Emission Unit ID No. P010),<br />

Controlled by Baghouse OG02 (APCD ID No. C003): 12.90<br />

lb/hr.<br />

b. Sander Line (Emission Unit ID No. P009),<br />

Printed: November 7, 2012 Page 12 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Controlled by Sander Line Baghouse (APCD ID No. C006): 10.70<br />

lb/hr.<br />

c. Flake Handling/Blending (Emission Unit ID No. P006),<br />

Controlled by Flaker Handling Baghouse (APCD ID No. C004): 4.29 lb/hr.<br />

d. Fines/Flake Screening (Emission Unit ID No. P005) and<br />

Fuel Relay and Storage Silo (Emission Unit ID No. P011),<br />

Controlled by Fuel Storage Bin Vent Baghouse OG03<br />

(APCD ID No. C002): 0.54 lb/hr.<br />

Note that emission rate stated in d. is rounded off to 1.0 lb/hr in the existing permit condition, as<br />

the PTE will be still less than 250 tpy.<br />

Applicable Rules and Regulations -<br />

Rules and Regulations Assessment:<br />

Rules and Regulations Assessment, as indicated in the existing Title V Permit No. 2493-027-<br />

0013-V-02-0 (no amendment issued) for Energy System Units A and B (Emission Unit ID Nos.<br />

P001 and P002) (with language updated), are as below:<br />

Energy System A and B (Emission Unit ID No. P01 and P02)<br />

The energy system is a Wellons wood-fired “Detox” combustion system which includes two 160<br />

MMBtu/hr heat input capacity combustion units (for a combined output of 320 MMBtu/hr). The<br />

combustion gases supply hot process air to (1) the dryers for flake drying, (2) the thermal oil<br />

heater to provide thermal oil for the board press and (3) a steam turbine to produce steam for<br />

electrical power generation. Energy system flue gases are discharged from a single stack (ID #<br />

S001) after passing through a common dry ESP (APCD ID No. C001), for particulate matter<br />

removal.<br />

Since Energy System Units A and B employ indirect heat transfer, they are thus considered to be<br />

“fuel-burning equipment” according to the <strong>Georgia</strong> Rules for <strong>Air</strong> Quality Control. Therefore,<br />

emissions from these units are subject to Rule (d).<br />

Being constructed after January 1, 1972, Energy System Units A and B (Emission Unit ID Nos.<br />

P001 and P002) is subject to the particulate matter limit outlined in <strong>Georgia</strong> Rule 391-3-1-<br />

.02(2)(d) for "Fuel Burning Equipment" which contains the following equation:<br />

Where:<br />

P = 0.5 (10/R) 0.5 pounds per million BTU heat input;<br />

P = allowable weight of emissions of fly ash and/or other particulate matter in<br />

pounds per million BTU heat input<br />

Printed: November 7, 2012 Page 13 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

R = heat input of fuel-burning equipment in million BTU per hour.<br />

Per Rule (d) the allowable PM emission rate for Energy System Unit A or Energy System Unit B<br />

can be calculated, for maximum heat input, as follows:<br />

P = 0.5 (10/160) 0.5 = 0.125 lb/MMBtu<br />

On an hourly basis: (0.125 lb/MMBtu) (160 MMBtu/hr) = 20.0 lb/hr of PM<br />

Because the fuel burning equipment is constructed after January 1, 1972, the Energy Systems are<br />

also subject to <strong>Georgia</strong> Rule for <strong>Air</strong> Quality Control 391-3-1-.02(2)(d)3, which limits the opacity<br />

to 20 percent except for one six-minute period per hour of not more than 27 percent opacity.<br />

<strong>Georgia</strong> Rule 391-3-1-.02(2)(g) requires that all fuel burning sources having heat input of 100<br />

million BTU’s per hour or greater shall not burn a fuel containing more than 3 percent sulfur, by<br />

weight. The Energy System (Emission Unit ID Nos. P001 and P002) is subject to Rule (g) for<br />

sulfur dioxide. It burn only wood waste, so the sulfur content will always be much less than 3<br />

percent; hence no monitoring is needed for sulfur dioxide.<br />

This Energy System will continue to employ indirect heat transfer and are considered to be “fuelburning<br />

equipment” according to the <strong>Georgia</strong> Rules for <strong>Air</strong> Quality Control. Therefore, PM<br />

emissions from these units will continue to be subject to state Rule (d). Likewise, the units will<br />

be subject to NSPS Subpart Db.<br />

As per 40 CFR Part 60, Subpart Db, these fuel-burning units are defined as steam generating<br />

units. Each being above 100 MMBtu/hr heat input capacity and constructed after June 19, 1984,<br />

they are subject to the New Source Performance Standards (NSPS) found in 40 CFR 60, Subpart<br />

Db-“Standards of Performance for industrial-Commercial Institutional Steam Generating Units”.<br />

As per the NSPS, the units shall not cause to be discharged any gases that contain PM in excess<br />

of the following emission limits:<br />

a. Contain PM in excess of 0.10 lb/MMBtu<br />

[40 CFR 60.43b(c)][Subsumed by PSD avoidance limit in 3.2.3]<br />

b. Exhibit equal to or greater than 20 percent opacity (6-minute average), except for one 6minute<br />

period per hour of not more than 27 percent opacity. The opacity standard shall<br />

apply at all times except periods of startup, shutdown, and malfunction of the boiler.<br />

[40 CFR 60.43b(f)]<br />

The NSPS requires start-up notification, an initial performance test for PM, fuel-usage record<br />

keeping, and calculation of the annual capacity factor for wood. Because neither Energy System<br />

Unit A nor B use any fossil fuel, they are not subject to any Subpart Db sulfur dioxide or<br />

nitrogen oxides limits but are required to calculate capacity factors to prove this status. The<br />

condition to keep records of wood burned in the combustion units and to calculate the annual<br />

factor is included in the existing permit as Condition 6.2.9 (renumbered Condition No. 6.2.8).<br />

Printed: November 7, 2012 Page 14 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

The NSPS particulate matter emission standard of 0.10 lb/MMBtu is more stringent than the<br />

limit of 0.125 lb/MMBtu calculated as per <strong>Georgia</strong> Rule (d). However, the facility has taken a<br />

limit of 0.060 lb/MMBtu, which is even more stringent. Therefore, the Energy System is likely<br />

to be in compliance with Rule (d) while complying with the provisions of the NSPS.<br />

Rules and Regulations Assessment, as indicated in the existing Title V Permit No. 2493-027-<br />

0013-V-02-0 (no amendment issued) for applicability of CAM, are as below:<br />

Emission Units P001, P002, P003, P004, P006, and P008 are subject to the provisions of 40 CFR<br />

Part 64, “Compliance Assurance Monitoring” (CAM) The purpose of CAM is to provide a<br />

reasonable assurance of compliance with emission limitations and standards for the anticipated<br />

range of operations at a pollutant-specific emission unit (PSEU) [§64.3(a)]. Applicability of<br />

CAM for the above indicated emission sources are explained below:<br />

• They are located at a major source that is required to obtain a Title V Permit. [§64.2(a)]<br />

• They are subject to emission limitation or standard. [§64.2(a)(1)]<br />

• They use control device to achieve compliance. [§64.2(a)(2)]<br />

• Potential pre-controlled emissions of applicable pollutant are at least 100 percent of their<br />

major source threshold. [§64.2(a)(3)]<br />

• They are not otherwise exempt. [§64.2(b)]<br />

The Energy Systems (P001 and P002) are subject to Rule (d), Subpart Db and PSD-avoidance<br />

limits for PM. An ESP is used to control emissions. The precontrolled allowable PM emission<br />

rate is 160.2 tpy, which exceeds 100 tons per year threshold. Therefore, CAM is applicable.<br />

The Dryers (P003 and P004) are subject to emission limits for VOCs and HAPs to avoid being<br />

subject to PSD. The precontrolled allowable emission rate is above 100 tons per year for VOC<br />

and 25 tons per year for HAPs. The exhaust is ducted to the energy systems for incineration.<br />

Therefore, CAM is applicable.<br />

The Dryer Systems A and B (Emission Units ID Nos. P003 and P004), Fines/Flake Screening<br />

(Emission Unit ID No. P005), Forming Line (Emission Unit ID No. P007), Board Press<br />

(Emission Unit ID No. P008), Sander Line (Emission Unit ID No. P009), and Saw & Trim Line<br />

(Emission Unit ID No. P010) are subject to Rule (e), which contains an emission limit for PM.<br />

However, their exhaust is uncontrolled. Therefore, CAM is not applicable.<br />

The applicability of rules and regulations, as indicated in the Title V Permit Amendment No.<br />

2491-027-0013-V-01-3, are as below:<br />

“The only change in the applicability of rules and regulation to Energy Systems A and B, with<br />

this modification, is due to the use of on-site generated waste oil and other waste. Since the<br />

Energy System is subject to Rule 391-3-1-.02(2)(g), the concentration of sulfur in the oil and<br />

other material must not exceed 3.0%. It is expected that they will easily comply with this limit,<br />

since oils used for lubrication (as well as other materials burned) will have very low sulfur<br />

contents. Note that Rule(g) also applies to wood fuel to be burned in the Energy Systems; that<br />

was never an issue, since there is very little sulfur present in wood.”<br />

Printed: November 7, 2012 Page 15 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

“The Permittee has requested in their application that they be allowed to obtain up to 2% of total<br />

heat input by using waste materials as fuel. This is the same as currently allowed by the Division<br />

at their MDF plant. The application indicates that the waste materials to be combusted will<br />

consist of the following: used oil which is almost exclusively press hydraulic fluid, and plant<br />

waste, which will almost exclusively consist of resin tank washout water with a minute VOC<br />

content. The used oil and plant waste will be sprayed on the wood fuel on the conveyor belt,<br />

prior to boiler entry. The Permittee has indicated that the amount of used oil to be burned is<br />

expected no more than 1000 gallons over any given 12 month period. The heat content of used<br />

oil is close to that of fuel oil (140,000 Btu/gallon) but with almost zero sulfur content. The fuel to<br />

be combusted is expected to contain some heavy metal, but the contents will be well below the<br />

parameters specified in 40 CFR 279.11 for burning of used oil.”<br />

“Under this permit modification, 2491-027-0013-V-01-3, the Permittee is authorized to burn<br />

various plant and office wastes (non-hazardous) including office paper, used oil, hydraulic fluids<br />

etc., in the Energy System A and Energy System B) in addition to wood waste. For the purpose<br />

of this permit, hazardous waste is defined as in 40 CFR Part 261.3.”<br />

“A consultant for the company clarified the company’s actual intention with regard to this<br />

request, in conversations with EPD. This was summarized in four points that were e-mailed to<br />

EPD on December 1, 2003:<br />

(1) Only on-site generated hydraulic oil from the press will be incinerated. No used oil received<br />

from off-site, of any kind, will be disposed of in the boilers.<br />

(2) No more than 1,000 gallons of waste oil will be disposed of per year.<br />

(3) The amount of other plant waste to be disposed of is not easily predicted, but it will comprise<br />

almost exclusively resin tank washout water. This water will be sprayed onto the wood chips<br />

pile, prior to combustion. As best can estimated, the percentage will be less than 0.1%, on an<br />

annual basis.<br />

(4) The used press hydraulic oil from the existing plant operations is currently shipped off-site<br />

for disposal. The contractor that picks up the oil will not dispose of hazardous waste and<br />

therefore does its own testing to confirm that the press oil is on-spec. If it was off-spec, they<br />

would have to bring the oil back and then would refuse to make future pickups. The used oil<br />

from the new press will meet the same non-hazardous waste requirements and <strong>Langboard</strong> will<br />

complete quarterly testing prior to incineration to verify this.<br />

Note that the permit requires an analysis of this used oil (in accordance to specified EPA test<br />

methods) at least four times per year, to assure that the oil is on-spec.”<br />

Rules and Regulations Assessment for the Boiler MACT Title V Permit No. 2493-027-0013-V-<br />

02-0 (no amendment issued) for Energy System Units A and B (Emission Unit ID Nos. P001 and<br />

P002), are as below:<br />

“A facility is subject to the Area Source Boilers NESHAP (40 CFR 63 Subpart JJJJJJ –National<br />

Emission Standards for hazardous <strong>Air</strong> Pollutants for Industrial, Commercial, and institutional<br />

Printed: November 7, 2012 Page 16 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

boilers Area Sources, if the facility owns or operate an industrial, commercial, or institutional<br />

boiler as defined in §63.11237 that is located at, or is part of, an area source of hazardous air<br />

pollutants (HAP). A list of the regulated hazardous air pollutants can be found at<br />

http://www.epa.gov/ttnatw01/orig189.html.<br />

In accordance with §63.11237 of this NESHAP, a boiler means an enclosed device using<br />

controlled flame combustion in which water is heated to recover thermal energy in the form of<br />

steam or hot water. Controlled flame combustion refers to a steady-state, or near steady-state,<br />

process wherein fuel and/or oxidizer feed rates are controlled.”<br />

Rules and Regulations Assessment, as indicated in the existing Title V Permit No. 2493-027-<br />

0013-V-02-0 (no amendment issued) for “Manufacturing Processes,” are as below:<br />

Manufacturing Processes<br />

“<strong>Georgia</strong> Rule (e) “Particulate Emissions from Manufacturing Processes.” limits particulate<br />

emissions from all manufacturing processes. From new sources (those constructed after July 2,<br />

1968) with process rates up to 30 tons per hour, it limits emissions according to the rate<br />

calculated using the formula: E = 4.1P 0.67 ; and with process rates above 30 tons per hour, it<br />

limits emissions according to the rate calculated using the formula: E = 55P 0.11 - 40; where E<br />

equals the allowable emission rate in pounds per hour and P equals the process input weight rate<br />

in tons per hour. The following emission units are subject to these limits: Dryer Systems A and<br />

B (Emission Units ID Nos. P003 and P004), Fines/Flake Screening (Emission Unit ID No.<br />

P005), Flake Handling/Blending (Emission Unit ID No. P006), Forming Line (Emission Unit ID<br />

No. P007), Board Press (Emission Unit ID No. P008), Sander Line (Emission Unit ID No.<br />

P009), Saw & Trim Line (P010), and Fuel Relay and Storage Silo (P011). [Flakers A and B<br />

(earlier assigned Emission Unit ID Nos. P012 and P013 in permit amendment) have been moved<br />

to the insignificant activities list; therefore flaking has been excluded from the new conditions.]<br />

Condition 3.4.3 subjects these units to Rule (e) which is similar to old Condition 3.4.9.”<br />

“<strong>Georgia</strong> Rule (b) “Visible Emissions” limits opacity to 40% and applies to most sources that<br />

are not subject to another more stringent opacity limit. Processes that are subject to this rule at<br />

<strong>Langboard</strong> include Dryer Systems A and B (Emission Units ID Nos. P003 and P004),<br />

Fines/Flake Screening (Emission Unit ID No. P005), Flake Handling/Blending (Emission Unit<br />

ID No. P006), Forming Line (Emission Unit ID No. P007), Board Press (Emission Unit ID No.<br />

P008), Sander Line (P009), Saw & Trim Line (P010), and Fuel Relay and Storage Silo (P011),<br />

which are also all subject to Rule (e) as indicated above. Condition 3.4.4 subjects these units to<br />

Rule (b).”<br />

Rules and Regulations Assessment for the emergency generators, as included by this renewal<br />

application, are discussed below:<br />

The renewal application indicates that the facility operates two (2) diesel fired emergency<br />

generators. One generator is a Cummins DGFA, Model 6CTA8.3 – G2 with a maximum engine<br />

rating of 201 hp (150 kW), and other unit is a Onan DFM Genset, Model 275 with a maximum<br />

engine rating of 369 hp (275 kW). Applicability of NSPS and NESHAP rules to these generators<br />

is as below.<br />

Printed: November 7, 2012 Page 17 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

40 CFR 60, Subpart IIII – “Standards of Performance for Stationary Compression Ignition<br />

Internal Combustion Engines,” is applicable to stationary compression ignition (CI) internal<br />

combustion engines that commenced construction after July 11, 2005 and were manufacture after<br />

April 1, 2006. The renewal application indicates that both engines were installed prior to the July<br />

11, 2005 applicability date and therefore, both these engines are not subject to this NSPS.<br />

40 CFR 63, Subpart ZZZZ – “National Emission Standard for Hazardous <strong>Air</strong> Pollutants for<br />

Stationary Reciprocating Internal Combustion Engines,” regulates various size stationary internal<br />

combustion engines, including small engines locates at major and area sources of HAP<br />

emissions. Under this NESHAP, both engines are considered existing stationary engines and are<br />

subject to this NESHAP, and therefore, the facility is required to comply with all applicable<br />

provisions of this NESHAP. The facility is required to operate and maintain the engines<br />

according to manufacturer’s emission related written instructions, including to change the oil and<br />

filter every 500 hours of operation or annually and inspect air cleaner every 1,000 hours of<br />

operation or annually, and inspect hoses and belts every 500 hours of operation or annually.<br />

Note that the Division has determined that these engines are not significant sources of emissions<br />

and thus not included in Table 3.0. There are general conditions, which are included in Section<br />

8.0 (Conditions No. 8.27.1 and 8.27.3) of the latest Title V permit template, to address such<br />

engines.<br />

D. Compliance Status<br />

No noncompliance issue exists per permit application.<br />

E. Operational Flexibility<br />

None applicable.<br />

F. Permit Conditions<br />

Permit conditions included in this permit renewal, based on the existing Title V Permit No.<br />

2493-027-0013-V-02-0, are discussed below:<br />

Condition No. 3.2.1:<br />

This condition limits the NOx and CO emissions from the Energy Systems (Emission Unit ID<br />

Nos. P001 and P002) to 57.05 lb/hr (30 day rolling average) each to ensure that facility wide<br />

emissions are less than 250 tpy each, for PSD avoidance. This is similar to existing permit<br />

Condition 3.2.1. [Originally Condition No. 3.2.5 of Title V permit amendment No. 2493-027-<br />

0013-V-01-2.]<br />

Condition No. 3.2.2:<br />

This condition limits the total emissions of PM from various processes of Fines/Flake Screening<br />

(Emission Unit ID No. P005), Flake Handling/Blending (Emission Unit ID No. P006), Forming<br />

Printed: November 7, 2012 Page 18 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

line (Emission Unit ID No. P007), Sander Line (P009), Saw & Trim Line (P010), and Fuel Relay<br />

and Storage Silo (Emission Unit ID No. P011), and other sources, equal to or less than 138.52<br />

tpy, which ensures that facility wide PM emissions are no more than 222.62 tpy, which is less<br />

than 250 tpy, including the PM PTE of 84.1 tpy from the Energy System. This is similar to<br />

existing permit Condition 3.2.2. [Originally old Condition No. 3.2.6 of Title V Permit<br />

Amendment No. 2493-027-0013-V-01-3.]<br />

Condition No. 3.2.3:<br />

This condition limits the emissions of PM from the Energy System (Emission unit ID Nos. P001<br />

and P002) to 0.060 lb/MMBtu to ensure that emissions are not more than 84.1 tpy. This is similar<br />

to existing permit Condition 3.2.3. [Originally old Condition No. 3.2.7 of Title V Permit<br />

Amendment No. 2493-027-0013-V-01-3.]<br />

Condition No. 3.3.1:<br />

This condition limits visible emissions from the Energy System (Emission unit ID Nos. P001 and<br />

P002), based on Subpart Db and <strong>Georgia</strong> Rule (d), to 20% except for one six-minute period per<br />

hour of not more than 27 %. This is similar to existing permit Condition 3.3.1. [Originally old<br />

Condition No. 3.3.1 of Title V Permit Amendment No. 2493-027-0013-V-01-2.]<br />

Condition No. 3.3.2:<br />

This condition allows the Permittee to burn plant and office waste (but not hazardous waste) in<br />

Energy System Units A and B (Emissions Unit ID Nos. P001 and P002), up to 2 percent of total<br />

fuel heat input. For purposes of this Permit, hazardous waste is defined as in 40 CFR Part 261.3.<br />

This is similar to existing permit Condition 3.3.2.<br />

Condition 3.3.2 also limits the total amount of used oil that can be consumed in the Energy<br />

System to 1000 gallons per twelve consecutive month period. This is similar to old Condition<br />

No. 3.3.2 of Title V Permit Amendment No. 2493-027-0013-V-01-3.<br />

Condition No. 3.3.3:<br />

This condition provides the specifications to be met for the combustion of used oil (nonhazardous<br />

only), along with the wood fuel, in the Energy System (Emissions Unit ID Nos. P001<br />

and P002). This is a requirement of 40 CFR 279.11. This is similar to existing permit Condition<br />

3.3.3. [Originally old Condition No. 3.3.3 of Title V Permit Amendment No. 2493-027-0013-V-<br />

01-3.], and updated per vault conditions. Also, it is indicated that used oil cannot be burned<br />

during periods of startup and shutdown<br />

Condition No. 3.4.1:<br />

This condition limits the emissions of PM from the Energy System (Emission unit ID Nos. P001<br />

and P002), based on <strong>Georgia</strong> Rule (d). This is similar to existing permit Condition 3.4.1.<br />

[Originally Condition No. 3.4.7 of the initial Title V Permit No. 2493-027-0013-V-01-0.]<br />

Printed: November 7, 2012 Page 19 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Condition No. 3.4.2:<br />

This condition limits the sulfur content of fuel fired in the Energy System (Emission unit ID No.<br />

P001 and P002) based on <strong>Georgia</strong> Rule (g). This is similar to existing permit Condition 3.4.2.<br />

[Originally Condition No. 3.4.8 of the initial Title V Permit No. 2493-027-0013-V-01-0.].<br />

Conditions No. 3.4.3 and 3.4.4:<br />

These conditions limit the emissions of PM from Dryer Systems A and B (Emission Units ID<br />

Nos. P003 and P004), Fines/Flake Screening (Emission Unit ID No. P005), Blending (Emission<br />

Unit ID No. P006), Forming Line (Emission Unit ID No. P007), Board Press (Emission Unit ID<br />

No. P008), Sander Line (Emission Unit ID No. P009), Saw & Trim Line (Emission Unit ID No.<br />

P010), and Fuel Relay and Storage Silo (Emission Unit ID No. P011), based on <strong>Georgia</strong> Rule (e)<br />

and visible emissions opacity to 40%, based on <strong>Georgia</strong> Rule (b).<br />

This is similar to existing permit Conditions 3.4.3 and 3.4.4. [Originally Conditions No. 3.4.9<br />

and 3.4.10 of the initial Title V Permit Amendment No. 2493-027-0013-V-01-3.]<br />

Conditions No. 3.4.5 and 3.4.6:<br />

These conditions requires that fugitive dust generation be minimized from any process or process<br />

equipment and other miscellaneous PM emission sources, such as material handling, storage, and<br />

roads, by adopting reasonable precautions such as the application of water on dirt roads,<br />

materials and stockpiles. The percent opacity from any fugitive dust source shall not equal or<br />

exceed 20%. This operational limitation is based on <strong>Georgia</strong> Rule (n). These are similar to<br />

existing permit Condition 3.4.5. [Originally Condition No. 3.2.11 of Title V Permit Amendment<br />

No. 2493-027-0013-V-01-2.]. These are per vault conditions for Rule (n).<br />

Condition No. 3.5.1:<br />

The process emissions from rotary dryers, blending, and board press are routed to the energy<br />

system for VOC and HAP control by incineration. The significant point source of air emissions<br />

associated with these is the Energy System stack. Energy system flue gas is discharged from a<br />

single stack after passing through a common dry ESP for particulate matter removal. Condition<br />

No. 3.5.1 requires the Permittee to ensure that the process emissions are routed through the<br />

Energy System; the emissions from the Energy System are vented to the ESP for PM control.<br />

This is similar to existing permit Condition 3.5.1. [Originally Condition No. 3.5.3 of Title V<br />

Permit Amendment No. 2493-027-0013-V-01-2.]<br />

Condition No. 3.5.2:<br />

This condition requires that routine maintenance be done on all air pollution control equipment<br />

and that records be maintained and available for inspection. This condition is based on <strong>Georgia</strong><br />

Rule 391-3-1-.02(2)(a)10. This is similar to existing permit Condition 3.5.2. [Originally<br />

Condition No. 3.5.4 of Title V Permit Amendment No. 2493-027-0013-V-01-2.]<br />

Printed: November 7, 2012 Page 20 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Condition No. 3.5.3:<br />

There are several baghouses installed by the facility for the control of PM emissions from<br />

various manufacturing processes. Having an adequate supply of bags on hand for replacements<br />

of defective bags is required to help assure the control equipment is operating properly.<br />

Condition No. 3.5.3 requires the Permittee to maintain an inventory of filter bags so that<br />

defective bags in a baghouse may be replaced when needed. This is similar to existing permit<br />

Condition 3.5.3. [Old Condition No. 3.5.5 of Title V Permit Amendment No. 2493-027-0013-V-<br />

01-2.]<br />

Condition No. 3.5.4:<br />

This condition requires the Permittee to operate all control devices (baghouse, ESP, and NOx<br />

abatement system) when their associated processes are in operation. This is similar to existing<br />

permit Condition 3.5.4. [Originally Condition No. 3.5.6 of Title V Permit Amendment No. 2493-<br />

027-0013-V-01-3.]<br />

Condition No. 3.5.5:<br />

This condition requires the Permittee to install capture devices on the board press and the board<br />

cooling area, which either meet the criteria of Method 204 for permanent enclosure or achieve<br />

95% capture efficiency. This is same as existing permit condition.<br />

Printed: November 7, 2012 Page 21 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

IV. Testing Requirements (with Associated Record Keeping and Reporting)<br />

A. General Testing Requirements<br />

The permit includes a requirement that the Permittee conduct performance testing on any<br />

specified emission unit when directed by the Division. Additionally, a written notification of any<br />

performance test(s) is required 30 days (or sixty (60) days for tests required by 40 CFR Part 63)<br />

prior to the date of the test(s) and a test plan is required to be submitted with the test notification.<br />

Test methods and procedures for determining compliance with applicable emission limitations<br />

are listed and test results are required to be submitted to the Division within 60 days of<br />

completion of the testing.<br />

B. Specific Testing Requirements<br />

Testing Requirements included in this renewal permit based on the current Title V Permit No.<br />

2491-027-0013-V-02-0, which was based on Title V Permit Amendment No. 2491-027-0013-V-<br />

01-2, No. 2491-027-0013-V-01-3 and No. 2491-027-0013-V-01-3 are described below:<br />

NOTE: As indicated through various submittals of reports to the SSCP, the facility has already<br />

conducted all the initial performance tests required by Conditions No. 4.2.1, 4.2.2, 4.2.6, 4.2.8,<br />

and 4.2.10. Clearly, the Permittee used the initial performance tests to satisfy these conditions,<br />

subject to Division approval of the test reports. Therefore, the initial testing conditions are<br />

removed from this renewal permit.<br />

Energy System (Emission Unit ID Nos. P001 and P002)<br />

The major pollutant of concern from wood fired combustion systems is particulate matter (PM).<br />

PM emissions depend primarily on the composition of the wood fuel burned and the particulate<br />

control device. Oxides of nitrogen (NOx) may also be emitted in significant quantities when<br />

certain types of wood residue are combusted or under certain operating conditions. Carbon<br />

monoxide (CO) can be emitted in large amounts under conditions of partial combustion. The<br />

Energy Systems A and B mainly consume bark (33,230 lbs/hr) as per data provided in Title V<br />

applications. However, wood residue generated from the various <strong>OSB</strong> manufacturing processes<br />

can also be fired in the system.<br />

The previous Title V applications indicated that PTE PM, NOx and CO is all close to the 250-tpy<br />

PSD major source threshold. The two Energy System units are each subject to the provisions of<br />

the NSPS Subpart A general requirements and NSPS Subpart Db boiler rules for PM standards<br />

and opacity limit, so the Permittee was required to conduct performance tests to demonstrate<br />

compliance with the NSPS limits.<br />

Existing Condition 4.2.1 required the Permittee to conduct tests on the Energy System controlled<br />

by the electrostatic precipitator (ESP) (APCD ID No. C01) after the initial start-up of the system.<br />

The performance tests were to be used to determine compliance with the particulate matter<br />

emission limit and to establish a power level for the ESP at which compliance with the PM<br />

emissions limit is assured. The report of the test results for PM and opacity was also required to<br />

be submitted. Since the required testing has already been done, this condition is deleted. Note<br />

Printed: November 7, 2012 Page 22 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

that the average total power in the ESP determined by the facility during April 2006 compliance<br />

test was 33,152 kilowatts (kW). Therefore, any 3-hour period during which the average total<br />

power in the ESP is less than 24,864 kW (75% of 33,152) is reported as an excursion per<br />

Condition 6.1.7. The facility has already conducted the initial performance tests required by<br />

existing Condition No. 4.2.2 for NOx. Therefore, this condition is also deleted.<br />

Condition No. 4.2.1:<br />

Existing Condition 4.2.3, which requires the Permittee to determine compliance for NOx<br />

emissions following the tests done per Condition 4.2.2, is revised. This is similar to existing<br />

Condition 4.2.3, and renumbered as Condition No. 4.2.1.<br />

Condition No. 4.2.2:<br />

Existing Condition No. 4.2.4 requires routine tests for PM on a regular basis at 12 or 24 months<br />

interval depending upon the results. The Permittee has requested, through this renewal<br />

application No. 20734, to modify this condition as below, because the PM test results for the<br />

energy systems demonstrated that the emissions from the units have consistently been below<br />

50% of the applicable PM emission limits.<br />

4.2.4 Following the initial performance tests, the Permittee shall conduct PM tests on the<br />

Energy System, at 12-month 24 month intervals. Should the PM emissions for the<br />

Energy System be fifty (50) percent or less of the emissions limit contained in Condition<br />

3.2.3, the testing may be conducted at 24 month intervals once per permit term until<br />

such time that an emissions test indicates an emission rate greater than 50 percent of that<br />

limit, at which time testing shall revert to 12 month intervals.<br />

[391-3-1-.02(6)(b)1(i)]<br />

The latest testing results for PM conducted on April 10, 2012, indicates that the PM emissions<br />

are 96.7% of the allowable. Thus testing is required to be done at 12-month interval, and it shall<br />

be 24-months only if emissions are below 50%.<br />

In view of this, the condition cannot be modified as requested. However, this condition is carried<br />

over in this renewal with some general language changes as Condition No. 4.2.2.<br />

Condition No. 4.2.3:<br />

Existing Condition 4.2.5, which requires conducting additional tests if fuel material is changed,<br />

is carried over in this renewal as Condition No. 4.2.3.<br />

Condition No. 4.2.4:<br />

The facility has already conducted the initial performance tests for emissions of CO, as required<br />

by Condition No. 4.2.6. Therefore, this condition is deleted. Existing Condition 4.2.7, which<br />

requires the Permittee to determine compliance for CO emissions following the tests done per<br />

existing Condition 4.2.6, is revised and renumbered as Condition No. 4.2.4.<br />

Printed: November 7, 2012 Page 23 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

Manufacturing Processes (Emission Unit ID Nos. P003, P004, P006, and P008) for VOC and<br />

HAPs Control<br />

The narrative for the existing permit indicates that the process emissions from Rotary Flake<br />

Dryers A and B (Emission Units ID No. P03 and P04), Blending (Emission Unit ID No. P06),<br />

and Board Press (Emission Unit ID No. P08) which include VOC and HAPs, in addition to PM<br />

emissions, are routed through the Energy System for control via incineration. Since the dry ESP<br />

controls the emissions from the Energy System, PM emissions from the above-indicated<br />

processes are controlled via the ESP. Therefore the Permittee was required to conduct initial<br />

performance tests for the HAPs (acetaldehyde, acrolein, formaldehyde, methanol, phenol, and<br />

propionaldehyde) emissions at the outlet of the Energy System, per Condition 4.2.8, in addition<br />

to tests for PM emissions as required by Condition 4.2.1. The performance tests were required to<br />

be conducted after startup of the plant. Condition 4.2.9 required the Permittee to thereafter<br />

conduct performance tests at approximately 24- month interval to establish total HAPs emission<br />

factors.<br />

Since the initial performance tests for emissions of individual and total HAPs, per existing<br />

Condition 4.2.8, is already done, therefore, this condition is deleted.<br />

Condition No. 4.2.5:<br />

Existing Condition No. 4.2.9 requires the Permittee to conduct HAPs emission tests at least once<br />

in 24-month to demonstrate compliance. The Permittee has requested, through this renewal<br />

application No. 20734, to modify this condition as below, because the HAPs emissions are well<br />

below the major source threshold of 10/25 tpy. Note that this condition assures to regulate HAPs<br />

emissions. The facility is currently demonstrating compliance by using the emission factors from<br />

the April 2010 tests.<br />

4.2.9 The Permittee shall conduct performance tests at least once per 24 months permit term<br />

in order to assure that the HAPs, including acetaldehyde, acrolein, formaldehyde,<br />

methanol, phenol, and propionaldehyde, emission factors established, per Condition<br />

4.2.8, remain accurate.<br />

[391-3-1-.02(2)(a)3 and 391-3-1-.02(6)(b)]<br />

As indicated in this renewal application, since the HAPs emission tests conducted during 2005 to<br />

2010 indicates that the emissions are much below the prescribed threshold, the requests can be<br />

considered. Note that the review conducted by the Division, of the test results done on dated<br />

April 7, 2010, indicates that the individual and total HAPs are much lower than the threshold<br />

limits. Therefore, EPD has determined that the testing requirement be changed from once in 24months<br />

to more flexible testing of once in 48 months. This condition is revised as below, and<br />

renumbered as Condition No. 4.2.5.<br />

4.2.5 The Permittee shall conduct performance tests at the outlet of the Energy System<br />

(Emission Unit ID Nos. P001 and P002) to determine individual and total HAP,<br />

including acetaldehyde, acrolein, formaldehyde, methanol, phenol, and propionaldehyde<br />

emissions, while the process emissions from Dryer Systems A and B (Emission Unit ID<br />

Nos. P003 and P004), Blending (Emission Unit ID No. P006) and Board Press<br />

Printed: November 7, 2012 Page 24 of 34

Title V Renewal Application Review <strong>Langboard</strong> <strong>OSB</strong>, <strong>Quitman</strong>, TV-20734<br />

(Emission Unit ID No. P008), are vented to the Energy System (Emission Unit ID Nos.<br />

P001 and P002). at least once per 48 months in order to assure that the HAPs, including<br />

acetaldehyde, acrolein, formaldehyde, methanol, phenol, and propionaldehyde,<br />

emission factors established during each performance tests remain accurate.<br />

[391-3-1-.02(2)(a)3 and 391-3-1-.02(6)(b)]<br />

The facility has already conducted the performance tests as required by Conditions 4.2.10 and<br />

4.2.11 for PM emissions from various baghouses. Therefore, these conditions are no longer<br />

needed and hence deleted.<br />

Condition No. 4.2.6:<br />

Existing Condition 4.2.12, which requires the Permittee to conduct testing once in 24-moths to<br />

re-determine the enclosure capture efficiency determined and approved by the Division, is<br />

carried over from the existing permit as Condition No. 4.2.6. Note that this testing is not required<br />

if the capture device meets the criteria of Method 204 for permanent enclosure.<br />

Manufacturing Processes (Emission Unit ID Nos. P005 through P0011) for PM Control<br />

The narrative for the existing permit indicates that the process emissions, which mainly contain<br />

PM from emission units of Fines/Flake Screening (Emission Unit ID No. P005), Forming Line<br />

(Emission Unit ID No. P007), Sander Line (Emission Unit ID No. P009), Saw & Trim Line<br />

(Emission Unit ID No. P010), and the Fuel Relay and Storage Silo (Emission Unit ID No. P011),<br />

are controlled by dedicated baghouses, APCD ID Nos. C002, C003, C004, C006. Each of these<br />

processes is subject to a PM limit specified in Condition 3.2.2. To ensure that PM emissions<br />

from these processes, vented through a baghouse, are not more than their PM limits, performance<br />

tests were required to be conducted within 180 days after the initial startup of the plant, per<br />

Condition 4.2.10. During these tests, the Permittee was required to acquire data of the pressure<br />

drop across each baghouse to establish ranges for the proper functioning of each baghouse which<br />

will assure continuous compliance with the PM emissions limits for each process (Condition<br />

4.2.11).<br />

Condition No. 4.2.7:<br />

Existing Condition 4.2.13, which defines an operating day as a 24-hour period between 12:00<br />

midnight and the following midnight, is carried over as Condition No. 4.2.7.<br />

Existing Condition 4.2.14 required the Permittee to submit a report containing the results of the<br />

performance testing required by existing Condition 4.2.1, as well as the secondary voltages and<br />