Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DESIGN AND BUILD AN RC BIRD MODEL<br />

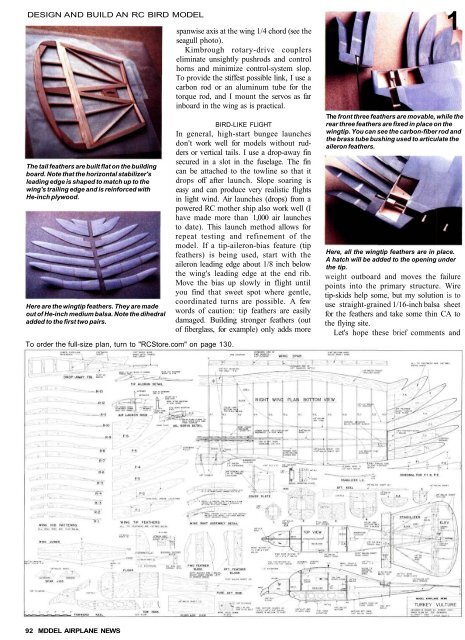

The tail feathers are built flat on the building<br />

board. Note that the horizontal stabilizer's<br />

leading edge is shaped to match up to the<br />

wing's trailing edge and is reinforced with<br />

He-inch plywood.<br />

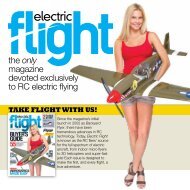

Here are the wingtip feathers. They are made<br />

out of He-inch medium balsa. Note the dihedral<br />

added to the first two pairs.<br />

To order the full-size plan, turn to "RCStore.com" on page 130.<br />

92 MDDEL AIRPLANE NEWS<br />

spanwise axis at the wing 1/4 chord (see the<br />

seagull photo).<br />

Kimbrough rotary-drive couplers<br />

eliminate unsightly pushrods and control<br />

horns and minimize control-system slop.<br />

To provide the stiffest possible link, I use a<br />

carbon rod or an aluminum tube for the<br />

torque rod, and I mount the servos as far<br />

inboard in the wing as is practical.<br />

BIRD-LIKE FLIGHT<br />

In general, high-start bungee launches<br />

don't work well for models without rudders<br />

or vertical tails. I use a drop-away fin<br />

secured in a slot in the fuselage. The fin<br />

can be attached to the towline so that it<br />

drops off after launch. Slope soaring is<br />

easy and can produce very realistic flights<br />

in light wind. Air launches (drops) from a<br />

powered RC mother ship also work well (I<br />

have made more than 1,000 air launches<br />

to date). This launch method allows for<br />

repeat testing and refinement of the<br />

model. If a tip-aileron-bias feature (tip<br />

feathers) is being used, start with the<br />

aileron leading edge about 1/8 inch below<br />

the wing's leading edge at the end rib.<br />

Move the bias up slowly in flight until<br />

you find that sweet spot where gentle,<br />

coordinated turns are possible. A few<br />

words of caution: tip feathers are easily<br />

damaged. Building stronger feathers (out<br />

of fiberglass, for example) only adds more<br />

1<br />

The front three feathers are movable, while the<br />

rear three feathers are fixed in place on the<br />

wingtip. You can see the carbon-fiber rod and<br />

the brass tube bushing used to articulate the<br />

aileron feathers.<br />

Here, all the wingtip feathers are in place.<br />

A hatch will be added to the opening under<br />

the tip.<br />

weight outboard and moves the failure<br />

points into the primary structure. Wire<br />

tip-skids help some, but my solution is to<br />

use straight-grained 1/16-inch balsa sheet<br />

for the feathers and take some thin CA to<br />

the flying site.<br />

Let's hope these brief comments and