06_ Weldability and defects in weldments.pdf

06_ Weldability and defects in weldments.pdf

06_ Weldability and defects in weldments.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

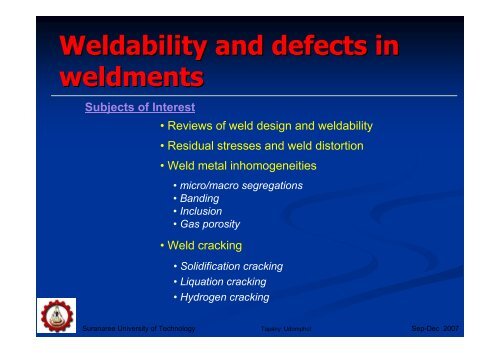

<strong>Weldability</strong> <strong>and</strong> <strong>defects</strong> <strong>in</strong><br />

<strong>weldments</strong><br />

Subjects of Interest<br />

• Reviews of weld design <strong>and</strong> weldability<br />

• Residual stresses <strong>and</strong> weld distortion<br />

• Weld metal <strong>in</strong>homogeneities<br />

• micro/macro segregations<br />

• B<strong>and</strong><strong>in</strong>g<br />

• Inclusion<br />

• Gas porosity<br />

• Weld crack<strong>in</strong>g<br />

• Solidification crack<strong>in</strong>g<br />

• Liquation crack<strong>in</strong>g<br />

• Hydrogen crack<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Objectives<br />

This chapter aims to:<br />

• Students are required to underst<strong>and</strong> the causes of<br />

residual stresses, distortion <strong>and</strong> their remedies.<br />

• Students are also required to differentiate weld <strong>defects</strong><br />

that might occur dur<strong>in</strong>g metal weld<strong>in</strong>g for example,<br />

solidification crack<strong>in</strong>g, liquation crack<strong>in</strong>g, distortion, weld<br />

embrittlement.<br />

• Students can suggest possible remedies associated<br />

with <strong>in</strong>dividual weld <strong>defects</strong>.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld design – jo<strong>in</strong>t type<br />

Five basic jo<strong>in</strong>t types<br />

Welds are made at the junction of all the pieces<br />

that make up the weldment (assembled part).<br />

A: Butt jo<strong>in</strong>t<br />

B: Corner jo<strong>in</strong>t<br />

C: T-jo<strong>in</strong>t<br />

D: Lap jo<strong>in</strong>t<br />

• A jo<strong>in</strong>t between two members aligned<br />

approximately <strong>in</strong> the same plane.<br />

• A jo<strong>in</strong>t between two members located<br />

approximately at right angles to each other<br />

<strong>in</strong> the form of an L.<br />

• A jo<strong>in</strong>t between two members located<br />

approximately at right angles to each other<br />

<strong>in</strong> a form of a T.<br />

• A jo<strong>in</strong>t between two overlapp<strong>in</strong>g<br />

members located <strong>in</strong> parallel.<br />

D: Edge jo<strong>in</strong>t •A jo<strong>in</strong>t between the edges of two or more<br />

parallel or nearly parallel members.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld design – weld type<br />

• There are eight weld types:<br />

Fillet weld - On the jo<strong>in</strong>t<br />

Groove weld<br />

Back weld<br />

Slot weld<br />

Spot weld<br />

Seam weld<br />

- In the jo<strong>in</strong>t<br />

- Made on the backside of the<br />

jo<strong>in</strong>t<br />

- Used with prepared holes<br />

- Weld at the <strong>in</strong>terface of the<br />

members<br />

- Without prepared holes<br />

Stud weld - Weld<strong>in</strong>g a metal stud<br />

Surface weld<br />

- Weld beads deposited on the<br />

base metal or broken surface<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld design – Fillet weld<br />

Fillet weld<br />

Def<strong>in</strong>itions of different parts <strong>in</strong> fillet weld<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld design – Groove weld<br />

• There are seven basic groove welds:<br />

square, V, bevel, U, J, flare V <strong>and</strong> flare<br />

bevel.<br />

Groove weld<br />

Types of groove welds<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld approval<br />

For quality control Weld<strong>in</strong>g<br />

procedure sheet is approved <strong>and</strong><br />

distributed to personnel concerned with<br />

its implementation.<br />

Details<br />

• approval of weld<strong>in</strong>g process<br />

• weld design<br />

• Electrode used<br />

• consumable used: filler, shield<strong>in</strong>g gas, flux<br />

• Inspection technique used<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Def<strong>in</strong>ition<br />

The capability of a material to be welded under the imposed<br />

fabrication conditions <strong>in</strong>to a specific, suitably designed structure<br />

<strong>and</strong> to perform satisfactorily <strong>in</strong> the <strong>in</strong>tended service.<br />

www.twi.co.uk<br />

• <strong>Weldability</strong> depends on various factors such as, nature<br />

of metals, weld designs, weld<strong>in</strong>g techniques, skills, etc.<br />

• It has been stated that all metals are weldable but<br />

some are more difficult than another.<br />

• Steel is readily weldable (<strong>in</strong> many ways) than<br />

alum<strong>in</strong>ium <strong>and</strong> copper.<br />

• Copper is not easily welded due to its high thermal<br />

conductivity which makes it difficult to raise the parent<br />

metal to its melt<strong>in</strong>g po<strong>in</strong>t. require preheat<strong>in</strong>g ~300-<br />

400 o C.<br />

• Some alum<strong>in</strong>ium based die cast<strong>in</strong>g alloys give weld<br />

pool too large to control, <strong>and</strong> alum<strong>in</strong>ium welds normally<br />

have oxide <strong>in</strong>clusions <strong>and</strong> porosity.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Steels<br />

• <strong>Weldability</strong> of steels is <strong>in</strong>versely proportional to its hardenability,<br />

due to martensite formation dur<strong>in</strong>g heat treatment<br />

Carbon content<br />

Hardenability<br />

<strong>Weldability</strong><br />

• There is a trade-off between materials strength <strong>and</strong> weldability.<br />

• Austenitic sta<strong>in</strong>less steels tend to be the most weldable but suffer<br />

from distortion due to high thermal expansion. Crack<strong>in</strong>g <strong>and</strong> reduced<br />

corrosion resistance.<br />

• Ferritic <strong>and</strong> martensitic sta<strong>in</strong>less steels are not easily welded, often<br />

to be preheated <strong>and</strong> use special electrodes.<br />

• Ferritic steels is susceptible to hot crack<strong>in</strong>g if the ferrite amount is not<br />

controlled.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Alum<strong>in</strong>ium <strong>and</strong> its alloys<br />

• <strong>Weldability</strong> of alum<strong>in</strong>ium depends on<br />

chemical composition of the alloy.<br />

• Alum<strong>in</strong>ium alloys are susceptible to hot crack<strong>in</strong>g, oxide <strong>in</strong>clusions,<br />

dross, porosity (hydrogen).<br />

• Most of wrought series, 1xxx, 3xxx, 5xxx, 6xxx, <strong>and</strong> medium strength<br />

7xxx can be fusion welded by TIG, MIG while 2xxx <strong>and</strong> high strength<br />

7xxx are not readily welded due to liquation <strong>and</strong> solidification crack<strong>in</strong>g.<br />

Cracks<br />

www.mig-weld<strong>in</strong>g.co.uk<br />

Cracks <strong>in</strong> alum<strong>in</strong>ium welds<br />

Porosity<br />

Porosity observed <strong>in</strong> alum<strong>in</strong>ium welded specimen<br />

after fractured.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Copper <strong>and</strong> copper alloys<br />

Copper<br />

Brasses<br />

Bronzes<br />

• <strong>Weldability</strong> of copper depends on<br />

chemical composition of the alloy.<br />

• High thermal conductivity required preheat<strong>in</strong>g to<br />

counteract heat s<strong>in</strong>k effect.<br />

• Can be TIG or MIG welded.<br />

• Volatilization (toxic) of z<strong>in</strong>c is the ma<strong>in</strong> problem, reduc<strong>in</strong>g<br />

weldability.<br />

• Low z<strong>in</strong>c content brass can be TIG or MIG welded.<br />

• Most are weldable, except gun metal or phosphor bronzes.<br />

• Require careful clean<strong>in</strong>g <strong>and</strong> deoxidization to avoid porosity.<br />

• Silicon improves weldability due to its deoxidiz<strong>in</strong>g <strong>and</strong> flux<strong>in</strong>g actions.<br />

• Oxygen causes porosity <strong>and</strong> reduce strength of welds.<br />

• T<strong>in</strong> <strong>in</strong>creases hot-cracked susceptibility dur<strong>in</strong>g weld<strong>in</strong>g.<br />

• Precipitation hardened alloys should be welded <strong>in</strong> the annealed<br />

condition, <strong>and</strong> then precipitation harden<strong>in</strong>g treatment.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Titanium alloys<br />

• <strong>Weldability</strong> of titanium depends on<br />

chemical composition of the alloy.<br />

• Titanium alloys with low amounts of alloy<strong>in</strong>g elements are more readily welded.<br />

For example: CP titanium alloys, α, α, α, α, α+β α+β α+β α+β titanium alloys.<br />

• Highly stabilised beta titanium alloys are difficult to weld due to segregation.<br />

• Weld<strong>in</strong>g at above 500-550 o C requires special precaution.<br />

• Fluxes are not normally used s<strong>in</strong>ce they comb<strong>in</strong>e with titanium to cause<br />

brittleness.<br />

• Weld<strong>in</strong>g processes: TIG, MIG, PAW, LBW, EBW, FW, RW.<br />

• Shield<strong>in</strong>g gases: Ar, He or the mixture of the two (avoid contact with oxygen).<br />

• Filler metal grades should match the alloys be<strong>in</strong>g welded, normally with lower<br />

yield strength to reta<strong>in</strong> ductility. (used unalloyed with lower ββββ content to avoid<br />

martensite transformation <strong>and</strong> with m<strong>in</strong>imised O, N, H contents).<br />

• Thoriated tungsten electrodes (EWTh-1 or EWTh-2) are used for TIG weld<strong>in</strong>g.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

<strong>Weldability</strong><br />

Magnesium alloys<br />

• <strong>Weldability</strong> of titanium depends on<br />

chemical composition of the alloy.<br />

• Weld<strong>in</strong>g processes: Arc weld<strong>in</strong>g, RW as well as oxyacetylene weld<strong>in</strong>g,<br />

braz<strong>in</strong>g. TIG <strong>and</strong> MIG are recommended.<br />

• Strength of the weld jo<strong>in</strong>t is lowered <strong>in</strong> the base metal, <strong>in</strong> the work<br />

hardened condition, due to recrystallisation <strong>and</strong> gra<strong>in</strong> growth <strong>in</strong> the HAZ.<br />

• Similar to weld<strong>in</strong>g of alum<strong>in</strong>ium, magnesium has low melt<strong>in</strong>g po<strong>in</strong>t, high<br />

thermal conductivity, thermal expansion, oxide surface coat<strong>in</strong>g.<br />

• In Mg-Al-Zn alloys (AZxx), Al >10% improves weldability by ref<strong>in</strong><strong>in</strong>g gra<strong>in</strong><br />

structure, while Zn > 1% <strong>in</strong>creases hot shortness.<br />

• Filler metals are selected by the composition of the base metals.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Defects <strong>in</strong> <strong>weldments</strong><br />

• It is unusual for the <strong>weldments</strong> to be completely sound.<br />

• They normally conta<strong>in</strong> small <strong>defects</strong> such as porosity, slag, oxide<br />

<strong>in</strong>clusions, lack of fusion, undercut, crack, distortion, etc.<br />

Cross sections of welds conta<strong>in</strong><strong>in</strong>g typical <strong>defects</strong><br />

Underst<strong>and</strong><br />

the cause<br />

Solve/prevent<br />

the problem<br />

• Furthermore, different<br />

metals have different<br />

weldability so we need to<br />

underst<strong>and</strong> the nature of the<br />

metal to be welded.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Defects <strong>in</strong> <strong>weldments</strong><br />

Incomplete fusion<br />

Groove welds <strong>and</strong><br />

various <strong>defects</strong><br />

Root <strong>and</strong> jo<strong>in</strong>t penetrations<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Residual stresses <strong>in</strong> weldment<br />

Residual stresses (<strong>in</strong>ternal stresses) are<br />

stresses that would exist <strong>in</strong> a body after<br />

remov<strong>in</strong>g all external loads (normally due<br />

to non uniform temperature change dur<strong>in</strong>g<br />

weld<strong>in</strong>g <strong>in</strong> this case).<br />

• Weld metal <strong>and</strong> adjacent base<br />

metal are restra<strong>in</strong>ed by the areas<br />

further away from the weld metal due<br />

to expansion <strong>and</strong> contraction.<br />

Weld metal <strong>and</strong><br />

adjacent base metal<br />

Areas further away<br />

from weld metal<br />

Residual tensile<br />

stresses<br />

Residual<br />

compressive<br />

stresses<br />

Thermally <strong>in</strong>duced residual stresses <strong>in</strong> weld.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Changes <strong>in</strong> temperature <strong>and</strong> stresses<br />

dur<strong>in</strong>g weld<strong>in</strong>g<br />

• Zero temperature <strong>and</strong> stress<br />

distribution at A-A.<br />

• Small compressive <strong>in</strong> the<br />

weld zone <strong>and</strong> small tensile <strong>in</strong><br />

the base metal at B-B dur<strong>in</strong>g<br />

melt<strong>in</strong>g of the weld metal.<br />

• Develop<strong>in</strong>g of tensile stress<br />

<strong>in</strong> the weld centre <strong>and</strong><br />

compressive <strong>in</strong> the area further<br />

away at C-C dur<strong>in</strong>g cool<strong>in</strong>g.<br />

• Further contraction of the<br />

weld metal produc<strong>in</strong>g higher<br />

tensile stress <strong>in</strong> the weld centre<br />

<strong>and</strong> compressive <strong>in</strong> the base<br />

metal at D-D.<br />

Changes <strong>in</strong> temperature <strong>and</strong> stresses dur<strong>in</strong>g weld<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Typical residual stress distribution <strong>in</strong><br />

weldment (longitud<strong>in</strong>al)<br />

• Residual stress distribution across the weld shows tensile <strong>in</strong> the weld<br />

metal <strong>and</strong> the adjacent base metal <strong>and</strong> then goes compressive <strong>in</strong> the area<br />

further away from the weld metal.<br />

• Residual tensile stresses are not<br />

desirable, which can cause problems<br />

such as hydrogen <strong>in</strong>duced crack<strong>in</strong>g<br />

<strong>and</strong> stress corrosion crack<strong>in</strong>g.<br />

Remedies<br />

• Post weld heat treatment is often<br />

used to reduce residual stresses.<br />

• Other techniques : preheat<strong>in</strong>g,<br />

peen<strong>in</strong>g, vibration have also been<br />

used for stress relief.<br />

Tension<br />

zone<br />

Typical residual stress (longitud<strong>in</strong>al)<br />

distribution <strong>in</strong> weldment<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Effect of temperature <strong>and</strong> time on<br />

stress relief of steel welds<br />

Stress relief temperature % Relief of <strong>in</strong>itial stress<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Typical thermal treatments for stress<br />

reliev<strong>in</strong>g <strong>weldments</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Distortion<br />

• Weld distortion is due to solidification shr<strong>in</strong>kage <strong>and</strong> thermal contraction<br />

of the weld metal dur<strong>in</strong>g weld<strong>in</strong>g.<br />

Distortion <strong>in</strong> welded structure<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Angular distortion<br />

S<strong>in</strong>gle-pass-s<strong>in</strong>gle-V groove butt jo<strong>in</strong>t<br />

Multiple-pass-s<strong>in</strong>gle-V groove butt jo<strong>in</strong>t<br />

• Upward angular distortion<br />

usually occurs when the weld is<br />

made from the top of the workpiece<br />

alone.<br />

• The weld tends to be wider at the<br />

top than the bottom, caus<strong>in</strong>g more<br />

solidification shr<strong>in</strong>kage <strong>and</strong><br />

thermal contraction.<br />

Th<strong>in</strong> plates<br />

Thick plates<br />

Inside fillet<br />

corner jo<strong>in</strong>t<br />

Fabricated beam<br />

Distortion <strong>in</strong> fillet weld<strong>in</strong>g of T jo<strong>in</strong>t<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for angular distortion<br />

There are several techniques used to reduce<br />

angular distortion.<br />

• Reduc<strong>in</strong>g volume of weld metal<br />

• Us<strong>in</strong>g double-V jo<strong>in</strong>t <strong>and</strong> alternate weld<strong>in</strong>g<br />

• Plac<strong>in</strong>g welds around neutral axis<br />

• Controll<strong>in</strong>g weld distortion<br />

Plac<strong>in</strong>g weld around neutral axis<br />

Reduc<strong>in</strong>g volume of weld metal <strong>and</strong><br />

by us<strong>in</strong>g s<strong>in</strong>gle-pass deep<br />

penetration weld<strong>in</strong>g.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for angular distortion<br />

• Balanc<strong>in</strong>g the angular weld distortion<br />

on either side of the double V jo<strong>in</strong>t.<br />

Us<strong>in</strong>g double-V jo<strong>in</strong>t <strong>and</strong> weld<br />

alternately on either side of jo<strong>in</strong>t.<br />

(a) Symmetrical<br />

double V (b) Asymmetrical<br />

double V<br />

(c) S<strong>in</strong>gle U<br />

• Double V-jo<strong>in</strong>ts balance the shr<strong>in</strong>kage almost<br />

same amount of contraction on each side (a).<br />

• Asymetrical double V : The first weld always<br />

produces more angular distortion the second side<br />

is larger too pull back the distortion when the first<br />

weld is made (b).<br />

• A s<strong>in</strong>gle U jo<strong>in</strong>t gives a uniform weld with through<br />

the section (c).<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for angular distortion<br />

Methods for controll<strong>in</strong>g weld distortion:<br />

• Presett<strong>in</strong>g: by compensat<strong>in</strong>g the amount of distortion to occur <strong>in</strong> weld<strong>in</strong>g.<br />

• Elastic prespr<strong>in</strong>g<strong>in</strong>g can reduce angular changes after restra<strong>in</strong>t is removed.<br />

• Preheat<strong>in</strong>g <strong>and</strong> post weld treatment<br />

(a) Preset<strong>in</strong>g<br />

(b) Spr<strong>in</strong>g<strong>in</strong>g (c) Perheat<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Longitud<strong>in</strong>al distortion<br />

• Heat<strong>in</strong>g <strong>and</strong> cool<strong>in</strong>g cycles along the jo<strong>in</strong>t dur<strong>in</strong>g weld<strong>in</strong>g build up a<br />

cumulative effect of longitud<strong>in</strong>al bow<strong>in</strong>g.<br />

Longitud<strong>in</strong>al bow<strong>in</strong>g of<br />

distortion <strong>in</strong> a butt jo<strong>in</strong>t<br />

Remedies<br />

• Weld<strong>in</strong>g short lengths on a planned or r<strong>and</strong>om<br />

distribution are used to controlled this problem.<br />

• Mechanical methods : straighten<strong>in</strong>g press,<br />

jacks, clamps<br />

• Thermal methods : local heat<strong>in</strong>g to relieve<br />

stresses (us<strong>in</strong>g torches) but cannot be used for<br />

highly conductive metal such as Al <strong>and</strong> Cu.<br />

Sequences for<br />

weld<strong>in</strong>g short<br />

lengths of a jo<strong>in</strong>t to<br />

reduce longitud<strong>in</strong>al<br />

bow<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Longitud<strong>in</strong>al distortion<br />

• Angular distortion <strong>and</strong> longitud<strong>in</strong>al bow<strong>in</strong>g can also be observed <strong>in</strong><br />

jo<strong>in</strong>ts made with fillet welds such as fillet-welded T jo<strong>in</strong>t.<br />

Longitud<strong>in</strong>al bow<strong>in</strong>g <strong>in</strong> a filletwelded<br />

T jo<strong>in</strong>t<br />

Remedies<br />

• Back-step technique is also used. Each<br />

small <strong>in</strong>crement will have its own shr<strong>in</strong>kage<br />

pattern which then becomes <strong>in</strong>significant to<br />

the whole pattern of weldment. (But time<br />

consum<strong>in</strong>g)<br />

• Us<strong>in</strong>g the smallest possible weld size.<br />

Back step technique<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld metal chemical<br />

<strong>in</strong>homogeneities<br />

• Micro segregation<br />

• Macro segregation<br />

• B<strong>and</strong><strong>in</strong>g<br />

• Inclusions <strong>and</strong> gas porosity.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Micro segregation<br />

• Lack of solid state diffusion might cause micro segregation <strong>in</strong> <strong>weldments</strong>.<br />

EX: Solid state diffusion <strong>in</strong> a more<br />

closely packed FCC structure<br />

(austenite) is more difficult than a<br />

more open BCC structure (ferrite).<br />

Microsegregation across columnar<br />

dendrite near quenched weld pool <strong>in</strong><br />

a martensitic sta<strong>in</strong>less steel.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

B<strong>and</strong><strong>in</strong>g<br />

• B<strong>and</strong><strong>in</strong>g occurs due to fluctuations <strong>in</strong> weld<strong>in</strong>g speed <strong>and</strong> power <strong>in</strong>put.<br />

B<strong>and</strong><strong>in</strong>g <strong>and</strong> rippl<strong>in</strong>g near centrel<strong>in</strong>e of as-welded top surface<br />

of a 304 sta<strong>in</strong>less steel YAG laser welded.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Inclusions <strong>and</strong> gas porosity<br />

• Gas-metal <strong>and</strong> slag-metal reactions produce slag <strong>in</strong>clusion <strong>and</strong> gas porosity.<br />

• Incomplete slag removal <strong>in</strong> multipass weld<strong>in</strong>g can cause slag <strong>in</strong>clusions<br />

trapped with<strong>in</strong> the weld.<br />

Slag<br />

<strong>in</strong>clusion<br />

Radiograph of a weld show<strong>in</strong>g<br />

a large slag <strong>in</strong>clusion.<br />

Gas porosity <strong>and</strong> <strong>in</strong>clusions <strong>in</strong> multipass weld<strong>in</strong>g.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Macro segregation<br />

• Weld pool macro segregation occur by lack of weld pool mix<strong>in</strong>g (by<br />

convection) especially <strong>in</strong> weld<strong>in</strong>g of dissimilar metals, or some special types of<br />

rapidly solidified power metallurgy alloys.<br />

• if the weld pool mix<strong>in</strong>g is <strong>in</strong>complete <strong>in</strong> s<strong>in</strong>gle pass weld<strong>in</strong>g (greater extent)<br />

<strong>and</strong> even <strong>in</strong> multipass weld<strong>in</strong>g.<br />

Ex: macro segregation <strong>in</strong> some<br />

powder metallurgy alloys<br />

• Switch<strong>in</strong>g from AC to DCEN mak<strong>in</strong>g<br />

the weld pool mixed better.<br />

Powder metallurgy Al-10Fe-5Ce GTA<br />

welded with Al-5Si filler metal (a) AC,<br />

(b) DCEN<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for macro segregation<br />

• Apply<strong>in</strong>g magnetic weld pool stirr<strong>in</strong>g to give a better mix<strong>in</strong>g <strong>in</strong> the<br />

weld pool.<br />

• For GTAW, us<strong>in</strong>g DCEN for a deeper weld penetration <strong>and</strong> mix<strong>in</strong>g.<br />

• Us<strong>in</strong>g proper filler metals.<br />

• Give enough time for the weld pool to be melt. Ex: EBW with a high<br />

weld<strong>in</strong>g speed might not give enough time for weld pool mix<strong>in</strong>g <strong>in</strong><br />

weld<strong>in</strong>g of dissimilar metals.<br />

Effect of weld pool stirr<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld crack<strong>in</strong>g<br />

There are various types of weld crack<strong>in</strong>g<br />

• Solidification crack<strong>in</strong>g (hot crack<strong>in</strong>g)<br />

• Hydrogen crack<strong>in</strong>g (cold crack<strong>in</strong>g)<br />

• Liquation crack<strong>in</strong>g<br />

• Lamellar Tear<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Solidification crack<strong>in</strong>g<br />

• Similar to cast<strong>in</strong>g, solidification crack<strong>in</strong>g can also occur <strong>in</strong> weld<strong>in</strong>g.<br />

• It happens at the term<strong>in</strong>al stage of solidification due to contraction of<br />

solidify<strong>in</strong>g metal <strong>and</strong> thermal contraction. (Intergranular crack)<br />

• Solidification crack<strong>in</strong>g is <strong>in</strong>tensified if the base metal is attached on to<br />

non mov<strong>in</strong>g parts (build<strong>in</strong>g up tensile stresses).<br />

• The less ductile the weld metal is, the more likely solidification crack<strong>in</strong>g<br />

to occur.<br />

Weld<br />

Base metal<br />

Solidification crack<br />

Solidification crack<strong>in</strong>g <strong>in</strong> a GMAW<br />

of 6<strong>06</strong>1 alum<strong>in</strong>ium<br />

Solidification crack<br />

(<strong>in</strong>tergranular)<br />

Solidification crack<strong>in</strong>g <strong>in</strong> an autogenous weld<br />

of 7075 alum<strong>in</strong>ium at high magnification.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Factors affect<strong>in</strong>g solidification crack<strong>in</strong>g<br />

Gra<strong>in</strong> structure<br />

• Coarse columnar gra<strong>in</strong>s are<br />

more susceptible to solidification<br />

crack<strong>in</strong>g than equiaxed gra<strong>in</strong>s.<br />

Centrel<strong>in</strong>e<br />

crack<strong>in</strong>g<br />

Centrel<strong>in</strong>e crack<strong>in</strong>g <strong>in</strong> a coarse-gra<strong>in</strong>ed<br />

sta<strong>in</strong>less steel weld<br />

Solidification<br />

crack<strong>in</strong>g <strong>in</strong> steel weld<br />

Contraction stresses<br />

• Contraction stresses can be due to thermal<br />

contraction, solidification shr<strong>in</strong>kage.<br />

Ex: Austenitic sta<strong>in</strong>less steels (high thermal<br />

expansion) susceptible to solidification<br />

crack<strong>in</strong>g.<br />

Restra<strong>in</strong><strong>in</strong>g<br />

• The weldment is restra<strong>in</strong>ed after the first<br />

weld, caus<strong>in</strong>g solidification crack<strong>in</strong>g <strong>in</strong> the<br />

second weld <strong>in</strong> T jo<strong>in</strong>ts.<br />

Solidification<br />

crack<strong>in</strong>g<br />

Second weld<br />

First weld<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for solidification crack<strong>in</strong>g<br />

• Controll<strong>in</strong>g composition of the metal to be welded.<br />

• Us<strong>in</strong>g filler metal with proper composition.<br />

• Controll<strong>in</strong>g Mn <strong>and</strong> S content <strong>in</strong> carbon <strong>and</strong> low alloy steels.<br />

• Controll<strong>in</strong>g solidification structure: gra<strong>in</strong> ref<strong>in</strong><strong>in</strong>g, arc oscillation,<br />

arc pulsation, etc.<br />

• Controll<strong>in</strong>g weld geometry: concave fillet weld suffers higher<br />

tensile stress on the face than the convex fillet weld, deep weld is<br />

more susceptible to solidification crack<strong>in</strong>g.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Hydrogen crack<strong>in</strong>g (Cold crack<strong>in</strong>g)<br />

Hydrogen crack<strong>in</strong>g occurs when<br />

• Hydrogen <strong>in</strong> the weld metal sources: moisture from metal surface, tools,<br />

atmosphere, flux,<br />

• High stresses<br />

• Susceptible microstructure : martensite (HAZ of carbon steels due to lower<br />

diffusion coefficient of hydrogen <strong>in</strong> austenite than <strong>in</strong> ferrite), comb<strong>in</strong>ation of<br />

hydrogen + martensite promotes hydrogen crack<strong>in</strong>g.<br />

• Relatively low temperature. (-100-200 o C) cold crack<strong>in</strong>g or delayed crack<strong>in</strong>g.<br />

Underbeaded crack <strong>in</strong> a low-alloy<br />

steel HAZ.<br />

Hydrogen<br />

crack<strong>in</strong>g <strong>in</strong> a fillet<br />

weld of 1040<br />

steel.<br />

Suranaree University of Technology Sep-Dec 2007<br />

Tapany Udomphol

Remedies for hydrogen crack<strong>in</strong>g<br />

• Controll<strong>in</strong>g weld<strong>in</strong>g parameters: proper preheat <strong>and</strong> <strong>in</strong>terpass<br />

temperature<br />

• Postweld treatment: stress relief.<br />

• Use proper weld<strong>in</strong>g processes <strong>and</strong> Materials (consumables),<br />

low strength filler metals.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Liquation crack<strong>in</strong>g<br />

Segregation <strong>in</strong> PMZ liquation crack<strong>in</strong>g<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Remedies for liquation crack<strong>in</strong>g<br />

• Use proper filler metal.<br />

• Reduc<strong>in</strong>g the heat <strong>in</strong>put to lower the size of PMZ.<br />

• Reduc<strong>in</strong>g the degree of restra<strong>in</strong>t, lower<strong>in</strong>g the level of tensile<br />

stresses.<br />

• Controll<strong>in</strong>g impurities, suppress<strong>in</strong>g micro segregation at gra<strong>in</strong><br />

boundaries.<br />

• Smaller gra<strong>in</strong> size is better (less concentration of impurities on<br />

gra<strong>in</strong> boundaries. Also control gra<strong>in</strong> orientation.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Lamellar Tear<strong>in</strong>g<br />

• Lamellar tear<strong>in</strong>g occurs when tensile stresses are act<strong>in</strong>g on fibred<br />

structure (str<strong>in</strong>gers of nonmetallic materials), caus<strong>in</strong>g decohesion of<br />

nonmetallic <strong>in</strong>clusions.<br />

Remedies<br />

Lamellar tear<strong>in</strong>g <strong>in</strong> steel Lamellar tear<strong>in</strong>g near a C-Mn steel weld<br />

• Avoid tensile stresses act<strong>in</strong>g on transverse direction of the sample.<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

Weld <strong>defects</strong><br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007

References<br />

• Kou, S., Weld<strong>in</strong>g metallurgy, 2 nd edition, 2003, John Willey <strong>and</strong><br />

Sons, Inc., USA, ISBN 0-471-43491-4.<br />

• Gourd, L.M., Pr<strong>in</strong>ciples of weld<strong>in</strong>g technology, 3 rd edition, 1995,<br />

Edward Arnold, ISBN 0 340 61399 8.<br />

• Cary, H.B., Modern weld<strong>in</strong>g technology, 4 th edition, 1998, Prentice<br />

Hall, ISBN 0-13-241803-7.<br />

• http://en.wikipedia.org/wiki/<strong>Weldability</strong><br />

• www.staff.ncl.ac.uk<br />

• http://www.key-to-metals.com<br />

Suranaree University of Technology Tapany Udomphol<br />

Sep-Dec 2007