UDC 621.3 REAL-TIME REGULATION SYSTEMS BASED ON ...

UDC 621.3 REAL-TIME REGULATION SYSTEMS BASED ON ...

UDC 621.3 REAL-TIME REGULATION SYSTEMS BASED ON ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>UDC</strong> <strong>621.3</strong><br />

ІНФОРМАЦІЙНІ СИСТЕМИ І МОДЕЛЮВАННЯ<br />

<strong>REAL</strong>-<strong>TIME</strong> <strong>REGULATI<strong>ON</strong></strong> <strong>SYSTEMS</strong> <strong>BASED</strong> <strong>ON</strong> INTERNET – OPTIMIZATI<strong>ON</strong><br />

ALGORITHM<br />

Vince T., research, Ing., assist. Prof., Molnár J., research, Ing., assist. Prof., Bučko R., research, Ing., assist. Prof.<br />

Technical University of Košice<br />

Park Komenského 3, 04200 Košice, Slovak Republic<br />

E-mail: tibor.vince@tuke.sk , jan.molnar@tuke.sk , radoslav.bucko@tuke.sk<br />

The article presents one of the ways for implementing Internet as a communication bus between real-time system<br />

elements. It handles the advantages and disadvantages of Internet as a control and communication bus in different level<br />

of the information hierarchy. The paper describes algorithm, which helps to build network for a real-time system. This<br />

algorithm is suitable for creating new network, or own domain of system elements. For implementing system in existing<br />

network, there would be few modifications in algorithm.<br />

Key words: Internet, real-time system, algorithm.<br />

Introduction. The Internet begins to playing a very<br />

important role in industrial processes manipulation, not<br />

only in information retrieving. New concept of<br />

controlling, which has been paid much attention in these<br />

years is distance remote via Internet, or other words,<br />

Internet-based control. Such a type of control bus allows<br />

remote monitoring or regulation of plants or single<br />

devices over the Internet. With the progress of the<br />

Internet it is possible to control and regulate from<br />

anywhere around the world at any time. The design<br />

process for the Internet-based control systems includes<br />

requirement specification, architecture design, control<br />

algorithm, interface design and possibly safety analysis.<br />

Due to the low price and robustness resulting from its<br />

wide acceptance and deployment, Ethernet has become<br />

an attractive candidate for real-time control networks.<br />

Requirements to put Internet depend on the system.<br />

Since each system has its own requirements, there is no<br />

prototype of such Internet bus. Therefore there should<br />

exist an algorithm for building suitable network.<br />

Specific algorithm depends on the number of system<br />

elements (if system is complex or not), if system should<br />

be implemented in existing network, or it is necessary<br />

build a new one etc. This contribution solves the cases,<br />

when system needs to build a new network, or all<br />

system elements could be included in system own<br />

network domain.<br />

Network Performance. Network performance is<br />

referred in more parameters in mutual relationship. One<br />

of performance parameters is Latency. Latency means a<br />

time required to transfer an empty message between<br />

relevant computers. Another parameter is Data transfer<br />

rate. Data transfer rate is the speed at which data can be<br />

transferred between sender and receiver in a network.<br />

The unit of this parameter is Bits/sec. For message<br />

transfer time calculating is equation 1. A third parameter<br />

of network performance is Bandwidth. Bandwidth is a<br />

total volume of traffic that can be transferred across the<br />

network. Maximal data rate formula is shown in<br />

equation 2. This maximum is only theoretical, not<br />

reachable in practice [5].<br />

LM<br />

MTT = LT + (1)<br />

DTR<br />

where MTT is Message transfer time, LT is latency, LM<br />

is Length of message and DTR is Data transfer time.<br />

sg<br />

MDR = CB . log 2 (1 + )<br />

ns<br />

(2)<br />

where MDR is maximal data rate (bps) and CB is carrier<br />

Bandwidth, sg is signal magnitude and ns is noise<br />

magnitude.<br />

The all parameters are pointing on the main<br />

disadvantage of controlling via the Internet – packets<br />

delivery delay. When packets are concurrently<br />

transported over an ordinary Ethernet, packets may<br />

experience a large delay due to contention with other<br />

packets in the local node where they originate and<br />

collision with other packets from the other nodes. By<br />

data transmission, four sources of delay spring up at<br />

each hop: nodal processing, queuing, transmission delay<br />

and propagation delay. The most significant part of total<br />

delay belongs to queuing. By queuing is considered the<br />

following equation 3:<br />

A<br />

TI = L . (3)<br />

W<br />

where TI is traffic intensity, L is packet length (bits), A<br />

is average packet arrival rate, and W is link bandwidth<br />

(bps).<br />

If ratio L*A/W will be very small almost 0, average<br />

queuing delay is small. If ratio L*A/W rise up to 1,<br />

delays become large (exponentially) and if ratio L*A/W<br />

is bigger than 1 average delay is infinite, more “work”<br />

arriving than can be serviced. Today, there is a term<br />

Quality of Service (QoS). Quality of Service is the<br />

ability to provide different priority to different<br />

applications, users, or data flows, or to guarantee a<br />

certain level of performance to a data flow.<br />

Information Architecture. It is becoming<br />

increasingly necessary to think in terms of integration of<br />

information and control, across the entire plant site. The<br />

term of integration, especially integration of information<br />

and control across the entire plant site, becomes more<br />

and more significant. In the manufacturing industries<br />

this is often referred to as "Computer Integrated<br />

Manufacturing" (CIM). On the surface, it would seem<br />

that the increasing use of microprocessor-based plant<br />

level devices such as programmable controllers,<br />

distributed digital control systems, smart analyzers,<br />

personal computers, etc., would make this easy. After<br />

all, most of these devices have "RS232" connectors,<br />

which enable connection to computers. Unfortunately,<br />

the real world situation is somewhat more challenging.<br />

Вісник КДУ імені Михайла Остроградського. Випуск 4/2010 (63). Частина 3<br />

150

If we began to hook all these RS232 ports together,<br />

there would soon be an unmanageable mess of wiring,<br />

custom software and little or no communication. This<br />

problem solution results in integration these devices into<br />

a meaningful "Information Architecture". This<br />

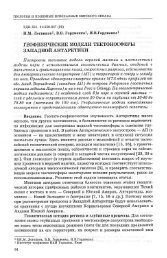

Information Architecture can be separated into 4 levels<br />

with the sensor/actuator level as shown in Fig. 1, which<br />

are distinguished from each other by“4Rs” principle<br />

criteria.<br />

Local<br />

Computer<br />

fast<br />

more<br />

slow<br />

less<br />

Response time Resolution Reliability Reparability<br />

ІНФОРМАЦІЙНІ СИСТЕМИ І МОДЕЛЮВАННЯ<br />

Scheduling,<br />

Management<br />

easy<br />

low<br />

Optimisation,<br />

Maintenance<br />

Supervisory<br />

Control<br />

high<br />

Interlocking<br />

& Regulatory<br />

hard<br />

Figure 1- Information Architecture<br />

Sensor,<br />

Actuator<br />

The 4Rs criteria are: Response time, Resolution,<br />

Reliability and Reparability.<br />

Response time: as one moves higher in the<br />

information architecture, the time delay, which can be<br />

tolerated in receiving the data, increases. Conversely,<br />

information used at the management & scheduling level<br />

can be several days old without impacting its usefulness.<br />

Resolution: an Abstraction level for data varies<br />

among all the levels in the architecture. The higher the<br />

level is, the more abstract the data is.<br />

Reliability: Just as communication response time<br />

must decrease as one descends through the levels of the<br />

information architecture, the required level of reliability<br />

increases. For instance, host computers at the<br />

management & scheduling level can safely be shut<br />

down for hours or even days, with relatively minor<br />

consequences. If the network, which connects<br />

controllers at the supervisory control level and/or the<br />

regulatory control level, fails for a few minutes, a plant<br />

shutdown may be necessary.<br />

Reparability: The reparability considers the ease<br />

with which control and computing devices can be<br />

maintained.<br />

Local computer on supervisory control level is able<br />

communicate with higher levels of information<br />

architecture via Internet, but there is also possibility to<br />

use the Internet also in lower levels of the Information<br />

architecture. The Internet can be linked with the local<br />

computer system at any level in the information<br />

architecture, or even at the sensor/actuator level. These<br />

links result in a range of 4Rs (response time, resolution,<br />

reliability, and reparability). For example, if a fast<br />

response time is required a link to the control loop level<br />

should be made. If only abstracted information is needed<br />

the Internet should be linked with a higher level in the<br />

information architecture such as the management level<br />

or the optimization level.<br />

Industry’s Buses. There are various types of buses<br />

using in Industry to connect of different devices, which<br />

are supported on the type of interface/bus [6]:<br />

AS-Interface – the Actuator Sensor Interface offers<br />

many of the benefits of more powerful and expensive<br />

fieldbuses, but at much lower cost and as a much<br />

simpler installation. Transmission of analog signals via<br />

time multiplex procedure. Data and power via the same<br />

line. No termination necessary. Address setting<br />

automatically from the master or via service tool. ASI<br />

conforment power supply required. It supports 62 nodes,<br />

max 300m with 3 repeaters. Date rate is 167kbit/s.<br />

Addressing is Master/Slave.<br />

CANopen – is a CAN-based higher layer protocol. It<br />

was developed as a standardized embedded network<br />

with highly flexible configuration capabilities. Node<br />

removal without severing the network is possible.<br />

Provisions for the typical request/response orientated<br />

network communications. Provisions for the effiecient<br />

movement of data framentation for moving larger bodies<br />

of information It supports 127 nodes, 25-5000m<br />

(depending on boudrate). Data rate is from 10kbit/s to<br />

1Mbit/s, addressing is Master/Slave, Peer-to-Peer,<br />

Multi-cast and Multi-master.<br />

ProfiBus – is a Multi-Master System and makes<br />

possible the mutual operation of several automation,<br />

engineering or visualizing systems at a Bus. The<br />

Masters, also designated as active devices, define the<br />

data traffic on the Bus. When in possession of the access<br />

permission (Token), they can send data without external<br />

requests. The Slaves, designated as passive devices,<br />

have no Bus access permission. They can only confirm<br />

received messages or send messages when requested by<br />

a Master. Baud rates from 9.6 kBaud up to 12 MBaud<br />

are supported. A maximum of 126 devices can be<br />

operated at the Bus. Profibus also supports Broadcast<br />

and Multicast communication. Network length is<br />

possible 100-1200m, addressing is DP: Master/Slave,<br />

Cyclic, Polling, DPV1: Cyclic, Polling + acyclic data<br />

transfer.<br />

EthernNet/IP – The Industrial Ethernet Protocol<br />

(Ethernet/IP) has been developed by ODVA with strong<br />

support from Rockwell Automation. It uses the Control<br />

& Information Protocol (CIP) which is already well<br />

known from ControlNet and DeviceNet. Network size<br />

(number of nodes) is scalable and nearly unlimited.<br />

Network size can be 100m (10/100 Base-T) or 35-<br />

2000m (fiber optic). Standard layers 1-4 providing<br />

Ethernet data transmisson, bus access, internet protocol<br />

(IP) and TCP & UDP protocols. CIP "implicit" and<br />

"explicit" messaging with encapsuslation technology.<br />

Message routing between EtherNet/IP, DeviceNet &<br />

ControlNet.<br />

Network Improve Methods. If the network doesn’t<br />

meet system requirements, it should be improved.<br />

Among the ordinary methods of improvement we can<br />

include: improvement of network architecture,<br />

improvement of network bandwidth and special<br />

protocols implementation. The sequence of these<br />

methods in algorithm can vary depending for example<br />

on the cost of implementing these methods.<br />

Improvement of network architecture can lead to the<br />

increase of the number of nodes, branches and changing<br />

architecture. The goal is to decrease network traffic jam<br />

and that way decrease packets time delay in.<br />

Вісник КДУ імені Михайла Остроградського. Випуск 4/2010 (63). Частина 3<br />

151

Classic Ethernet has 10MBps bandwidth and has<br />

reserve in 100MBps and also 1GBps bandwidth.<br />

Widening Ethernet bandwidth is another way to<br />

decrease packet delivery time. It is possible to decrease<br />

time delay by using special protocols, for example<br />

RSVP- Resource Reservation Protocol, IPv6-support<br />

packet priority.<br />

Applied special protocols must be supported by all<br />

network elements. Special protocols are meaningful<br />

only in complex systems.<br />

Time deterministic Ethernet is a special way for<br />

decreasing time delay. For example: Industrial Ethernet,<br />

Ethernet Powerlink etc. Deterministic timing is achieved<br />

by applying a cyclic timing schedule for all connected<br />

nodes to access the physical layer. To apply<br />

deterministic type of Ethernet, all system elements in a<br />

real-time domain must support such type of Ethernet.<br />

The last chance to use Internet is to modify system<br />

requirements. Sometimes, with small system changes,<br />

can modified system requirements meets the network<br />

parameters.<br />

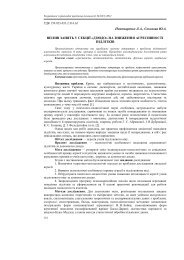

Algorithm.<br />

The whole diagram is shown in figure Fig. 2<br />

The first step is dataflow analysis. The most<br />

important question that needs to be answered is the<br />

following: What amount of data will be transported over<br />

the net and what is the greatest acceptable time delay?<br />

The next step is an architecture proposal. The<br />

architecture should follow dataflow analysis. The first<br />

architecture proposal should be as simple as possible.<br />

Next there is network type proposal. Network type<br />

determines network bandwidth, type of wiring etc. The<br />

first proposal of network should be with low bandwidth.<br />

After first proposals, there is a testing, if the network (as<br />

simple as possible) meets the system requirements. This<br />

is the most difficult part of the algorithm – to answer<br />

this question.<br />

The answer should include the most inopportune<br />

system state with the biggest possible network traffic<br />

jam. To answer the question for simple systems it is<br />

possible to use calculation, but it is better to use some<br />

simulation tools (OMNeT++, ns2, OPNET …) for more<br />

complex systems.<br />

In case of special (not standard) situations the time<br />

delay exceeds the system requirements, the system<br />

needs to be maintained to handle such situations.<br />

Algorithm is shown in figure Fig. 3. It is possible to<br />

ignore such situations when they appear rarely and time<br />

delay exceeding does not cause system to malfunction.<br />

Conclusion. It is become to be a standard, that<br />

many control elements have been embedded with<br />

Internet-enabled functions, for example, PLC with<br />

TCP/IP stack, smart control valves with a built-in<br />

wireless communication based on TCP/IP protocol, and<br />

process control computer (DCS) with an Internet<br />

gateway. There possibility that some mechatronic<br />

system could be connected directly to the Internet<br />

(without a necessity of a server computer).<br />

These days, there is effort to utilize Internet also in<br />

real-time systems. However there is no guide for<br />

building such a network yet. This algorithm describes<br />

ІНФОРМАЦІЙНІ СИСТЕМИ І МОДЕЛЮВАННЯ<br />

one of the possible ways. The whole algorithm aims to<br />

build a network that is as simple as possible and<br />

gradually improve it until the network parameters meet<br />

the system requirements.<br />

Requirements of feedback less than tens of<br />

miliseconds can be achieved only with deterministic<br />

type of Ethernet, but all devices in real-time domain<br />

must support such type of Ethernet. Time delay<br />

exceeding can be ignored, when it does not cause<br />

system malfunction.<br />

Is is possible to apply<br />

special protocols to<br />

speed up the<br />

communication ?<br />

are the<br />

system<br />

requirements<br />

satisfied ?<br />

Вісник КДУ імені Михайла Остроградського. Випуск 4/2010 (63). Частина 3<br />

152<br />

yes<br />

apply suggest<br />

network<br />

no<br />

no<br />

no<br />

Is it possible to<br />

apply time<br />

deterministic type<br />

of Ethernet ?<br />

no<br />

Is it possible to<br />

change system<br />

requirements ?<br />

no<br />

new network<br />

creation<br />

algorithm<br />

data flow<br />

analysis<br />

architecture<br />

proposal<br />

network type<br />

proposal<br />

Is is possible to<br />

apply higher<br />

bandwidth net ?<br />

no<br />

Is it possible to<br />

change the net<br />

architecture to<br />

decrease network<br />

delay ?<br />

yes<br />

apply the special<br />

protocols<br />

change the system<br />

requirements<br />

yes<br />

apply the higher<br />

bandwidth net<br />

apply time deterministic<br />

type of Ethernet<br />

yes<br />

change the<br />

architecture<br />

yes<br />

maintain<br />

are the<br />

requirements<br />

satisfied in<br />

standard state of<br />

system and net ?<br />

no<br />

in these circumstances is<br />

not possible to build system<br />

bus based on the Ethernet<br />

yes<br />

yes<br />

Figure - 2 The algorithm<br />

Acknowledgement. The paper has been prepared by<br />

the support of Slovak grant projects VEGA 1/0660/08,<br />

KEGA 3/6386/08, KEGA 3/6388/08, KEGA 003-<br />

003TUKE-4/2010

yes<br />

maintain the system for<br />

time-delay exceeding<br />

apply suggest<br />

network<br />

no<br />

maintain<br />

Is it possible to<br />

maintain the system in<br />

handling with<br />

situations, when time<br />

delay exceeds the<br />

system requirements ?<br />

Exceeding a<br />

time delay<br />

limit would<br />

cause system<br />

malfunction ?<br />

Figure - 3 The system maintain algorithm<br />

ІНФОРМАЦІЙНІ СИСТЕМИ І МОДЕЛЮВАННЯ<br />

no<br />

yes<br />

in these circumstances is<br />

not possible to build<br />

system bus based on<br />

the Ethernet<br />

REFERENCES<br />

1. Yang, S.H., Tan, L.S., Chen X: Requirements<br />

Specification and Architecture Design for Internet-based<br />

Control Systems, proceedings of the 26th Annual<br />

International Computer Software and Applications<br />

Conference (COMPSAC’02), 2002.<br />

2. Kweon, S. K, Cho M., Shin K. G.: Soft Real-<br />

Time Communication over Ethernet with Adaptive<br />

Traffic Smoothing, IEEE Transactions on parallel and<br />

distributed systems, VOL. 15, NO. 10, October 2004.<br />

3. Hall E.: Internet Core Protocols: The Definitive<br />

Guide, O'Reilly & Associates (February, 2000) USA,<br />

ISBN: 1-56592-572-6.<br />

4. Yang, X., Chen Q.: Virtual Reality Tools for<br />

Internet-Based Robotic Teleoperation, proceedings of<br />

the 8th IEEE International Symposium on Distributed<br />

Simulation and Real-Time Applications (DS-RT’04).<br />

5. Fonda C., Postogna F.: Computer networking<br />

basics, ICTP workshop on telecommunications: science,<br />

technology and applications. Trieste, 15th September -<br />

3rd October 1997<br />

6. http://www.anybus.com/technologies/technolog<br />

ies.shtml, 10.2.2008<br />

7. Molnár, J., Kováčová, I.: Distance remote<br />

measurement of magnetic field. In: Acta Electrotechnica<br />

et Informatica, 2007, Vol.7, No.4, pp. 52-55, ISSN<br />

1335-8243.<br />

8. Molnár, J.: Telemetric system based on<br />

internet. In: OWD 2009 : 11 International PhD<br />

Workshop : Wisa, 17-20 October 2009, p. 38-41. ISBN<br />

83-922242-5-6.<br />

9. Kováčová, I., Kováč, D.: Non-harmonic power<br />

measuring. In: Acta Electrotechnica et Informatica. Vol.<br />

8, No. 3 (2008), pp. 3-6. ISSN 1335-8243.<br />

10. Tomčík, J., Tomčíková, I.: Safety politics in the<br />

enviroment of the automatized and SCADA systems ( In<br />

Slovak). In: EE Journal. Vol. 14, No. 1 (2008), pp. 46-<br />

47. ISSN 1335-2547<br />

11. Vince, T., Molnár, J., Tomčíková, I.: Remote<br />

DC motor speed regulation via Internet. In: OWD 2008:<br />

10th international PhD workshop : Wisla, 18-21 October<br />

2008. p. 293-296. ISBN 83-922242-4-8.<br />

Вісник КДУ імені Михайла Остроградського. Випуск 4/2010 (63). Частина 3<br />

153<br />

Стаття надійшла 20.04.10 р.<br />

Рекомендовано до друку к.т.н., доц.<br />

Гладирем А.І.<br />

СИСТЕМЫ РЕАЛЬНОГО ВРЕМЕНИ НА ОСНОВЕ АЛГОРИТМА ИНТЕРНЕТ-<br />

ОПТИМИЗАЦИИ<br />

Винс Т., научный сотрудник, инж., ассист., Мольнар Дж., научный сотрудник, инж., ассист., Бучко Р.,<br />

научный сотрудник, инж., ассист.<br />

Технический университет в Кошице<br />

Park Komenského 3, 04200, Košice, Slovak Republic<br />

E-mail: tibor.vince @ tuke.sk, jan.molnar @ tuke.sk, radoslav.bucko @ tuke.sk<br />

Данная статья представляет один из способов применения Интернета в качестве коммуникационной шины<br />

между элементами системы реального времени. Рассмотрены преимущества и недостатки Интернета как шины<br />

управления и коммуникационной шины на различных уровнях информационной иерархии. В статье<br />

описывается алгоритм, который облегчает создание сети для систем реального времени и пригоден для<br />

создания, как новой сети, так и собственного домена элементов системы. При внедрении системы в<br />

существующую сеть потребуются некоторые изменения в алгоритме.<br />

Ключевые слова: Интернет, система реального времени, алгоритм<br />

СИСТЕМИ РЕАЛЬНОГО ЧАСУ НА ОСНОВІ АЛГОРИТМУ ІНТЕРНЕТ-<br />

ОПТИМІЗАЦІЇ<br />

Вінс Т., науковий співробітник, інж., асист., Мольнар Дж., науковий співробітник, інж., асист., Бучко Р.,<br />

науковий співробітник, інж., асист.<br />

Технічний університет в Кошице<br />

Park Komenského 3, 04200, Košice, Slovak Republic<br />

E-mail: tibor.vince @ tuke.sk, jan.molnar @ tuke.sk, radoslav.bucko @ tuke.sk<br />

Дана стаття представляє один зі способів застосування Інтернету в якості комунікаційної шини між<br />

елементами системи реального часу. Розглянуто переваги і недоліки Інтернету як шини управління та<br />

комунікаційної шини на різних рівнях інформаційної ієрархії. У статті описується алгоритм, який полегшує<br />

створення мережі для систем реального часу і придатний для створення, як нової мережі, так і власного домену<br />

елементів системи. При впровадженні системи в існуючу мережу будуть потрібні деякі зміни в алгоритмі.<br />

Ключові слова: Інтернет, система реального часу, алгоритм.