Processing kodak motion picture films, module 3 analytical procedures

Processing kodak motion picture films, module 3 analytical procedures

Processing kodak motion picture films, module 3 analytical procedures

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

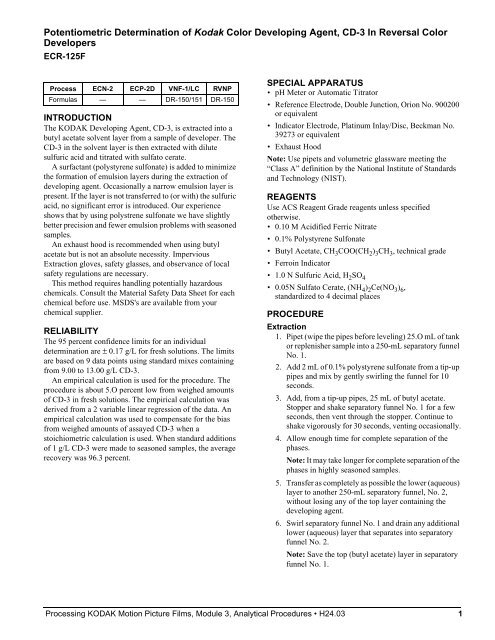

Potentiometric Determination of Kodak Color Developing Agent, CD-3 In Reversal Color<br />

Developers<br />

ECR-125F<br />

Process ECN-2 ECP-2D VNF-1/LC RVNP<br />

Formulas — — DR-150/151 DR-150<br />

INTRODUCTION<br />

The KODAK Developing Agent, CD-3, is extracted into a<br />

butyl acetate solvent layer from a sample of developer. The<br />

CD-3 in the solvent layer is then extracted with dilute<br />

sulfuric acid and titrated with sulfato cerate.<br />

A surfactant (polystyrene sulfonate) is added to minimize<br />

the formation of emulsion layers during the extraction of<br />

developing agent. Occasionally a narrow emulsion layer is<br />

present. If the layer is not transferred to (or with) the sulfuric<br />

acid, no significant error is introduced. Our experience<br />

shows that by using polystrene sulfonate we have slightly<br />

better precision and fewer emulsion problems with seasoned<br />

samples.<br />

An exhaust hood is recommended when using butyl<br />

acetate but is not an absolute necessity. Impervious<br />

Extraction gloves, safety glasses, and observance of local<br />

safety regulations are necessary.<br />

This method requires handling potentially hazardous<br />

chemicals. Consult the Material Safety Data Sheet for each<br />

chemical before use. MSDS's are available from your<br />

chemical supplier.<br />

RELIABILITY<br />

The 95 percent confidence limits for an individual<br />

determination are ± 0.17 g/L for fresh solutions. The limits<br />

are based on 9 data points using standard mixes containing<br />

from 9.00 to 13.00 g/L CD-3.<br />

An empirical calculation is used for the procedure. The<br />

procedure is about 5.O percent low from weighed amounts<br />

of CD-3 in fresh solutions. The empirical calculation was<br />

derived from a 2 variable linear regression of the data. An<br />

empirical calculation was used to compensate for the bias<br />

from weighed amounts of assayed CD-3 when a<br />

stoichiometric calculation is used. When standard additions<br />

of 1 g/L CD-3 were made to seasoned samples, the average<br />

recovery was 96.3 percent.<br />

SPECIAL APPARATUS<br />

pH Meter or Automatic Titrator<br />

Reference Electrode, Double Junction, Orion No. 900200<br />

or equivalent<br />

Indicator Electrode, Platinum Inlay/Disc, Beckman No.<br />

39273 or equivalent<br />

Exhaust Hood<br />

Note: Use pipets and volumetric glassware meeting the<br />

“Class A” definition by the National Institute of Standards<br />

and Technology (NIST).<br />

REAGENTS<br />

Use ACS Reagent Grade reagents unless specified<br />

otherwise.<br />

0.10 M Acidified Ferric Nitrate<br />

0.1% Polystyrene Sulfonate<br />

Butyl Acetate, CH 3 COO(CH 2 ) 3 CH 3 , technical grade<br />

Ferroin Indicator<br />

1.0 N Sulfuric Acid, H 2 SO 4<br />

0.05N Sulfato Cerate, (NH 4 ) 2 Ce(NO 3 ) 6 ,<br />

standardized to 4 decimal places<br />

PROCEDURE<br />

Extraction<br />

1. Pipet (wipe the pipes before leveling) 25.O mL of tank<br />

or replenisher sample into a 250-mL separatory funnel<br />

No. 1.<br />

2. Add 2 mL of 0.1% polystyrene sulfonate from a tip-up<br />

pipes and mix by gently swirling the funnel for 10<br />

seconds.<br />

3. Add, from a tip-up pipes, 25 mL of butyl acetate.<br />

Stopper and shake separatory funnel No. 1 for a few<br />

seconds, then vent through the stopper. Continue to<br />

shake vigorously for 30 seconds, venting occasionally.<br />

4. Allow enough time for complete separation of the<br />

phases.<br />

Note: It may take longer for complete separation of the<br />

phases in highly seasoned samples.<br />

5. Transfer as completely as possible the lower (aqueous)<br />

layer to another 250-mL separatory funnel, No. 2,<br />

without losing any of the top layer containing the<br />

developing agent.<br />

6. Swirl separatory funnel No. 1 and drain any additional<br />

lower (aqueous) layer that separates into separatory<br />

funnel No. 2.<br />

Note: Save the top (butyl acetate) layer in separatory<br />

funnel No. 1.<br />

<strong>Processing</strong> KODAK Motion Picture Films, Module 3, Analytical Procedures H24.03 1