Processing kodak motion picture films, module 3 analytical procedures

Processing kodak motion picture films, module 3 analytical procedures Processing kodak motion picture films, module 3 analytical procedures

PROCEDURE Treatment of the Sample 1. Pipet 50 mL of sample into a 250-mL beaker containing 75 mL of distilled water and a Teflon stirring bar. 2. Immerse the pH electrodes into the solution and turn on the stirrer. 3. Adjust the pH of the solution to 4.5 ± 0.1, dropwise, with Glacial Acetic Acid. 4. Rinse the electrode assembly with distilled water. Collect all rinses in the beaker containing the sample. Titration 1. Place the beaker containing the sample on a magnetic stirrer. Turn on the stirrer and immerse the Platinum indicator and double-junction reference electrodes into the solution. 2. Add 10 drops of 0.001 N Ferrous Ammonium Sulfate to the solution. 3. Wait 2 minutes for the electrodes to equilibrate. 4. If using a METROHM 536 titrator, adjust the parameters to the following settings: 5. Titrate the sample with standardized 0.1 N Ferric Ammonium Sulfate using a 20 mL buret. 6. Determine the equivalence point on the titration curve using a concentric arcs template. (Refer to Universal Method ULM-0003-01, Potentiometric Titrations for Photoprocessing Solutions, or subsequent revisions.) Calculations where: Automatic Titration Stop (stop % U) off Vertical Chart Span (min/100% vol) 400 Automatic Titration Speed (auto control) off Maximum Titration Speed (min/100% vol) 15 Titration Mode mV/pH Horizontal Chart Span (mV) 250 Uncomplexed 1,3-PDTA g/L = 306 = equivalent weight of 1,3-PDTA (mL titrant) (N titrant) (306) mL sample Figure 1 Typical Titration Curve of Free 1,3-PDTA in ECN-2 ML Bleach 0 2 4 6 8 mL of 0.1000 N FERRIC AMMONIUM SULFATE 405 mv F002_0942AC Note: A seasoned solution may exhibit a slightly more shallow curve shape due to extraneous components. 2 Processing KODAK Motion Picture Films, Module 3, Analytical Procedures H24.03 380 mv 355 mv 330 mv 305 mv 280 mv 255 mv 230 mv 205 mv 180 mv

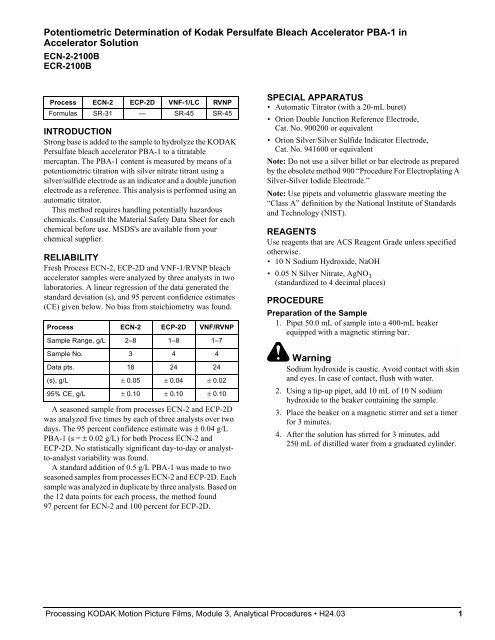

Potentiometric Determination of Kodak Persulfate Bleach Accelerator PBA-1 in Accelerator Solution ECN-2-2100B ECR-2100B Process ECN-2 ECP-2D VNF-1/LC RVNP Formulas SR-31 — SR-45 SR-45 INTRODUCTION Strong base is added to the sample to hydrolyze the KODAK Persulfate bleach accelerator PBA-1 to a titratable mercaptan. The PBA-1 content is measured by means of a potentiometric titration with silver nitrate titrant using a silver/sulfide electrode as an indicator and a double junction electrode as a reference. This analysis is performed using an automatic titrator. This method requires handling potentially hazardous chemicals. Consult the Material Safety Data Sheet for each chemical before use. MSDS's are available from your chemical supplier. RELIABILITY Fresh Process ECN-2, ECP-2D and VNF-1/RVNP bleach accelerator samples were analyzed by three analysts in two laboratories. A linear regression of the data generated the standard deviation (s), and 95 percent confidence estimates (CE) given below. No bias from stoichiometry was found. Process ECN-2 ECP-2D VNF/RVNP Sample Range, g/L 2–8 1–8 1–7 Sample No. 3 4 4 Data pts. 18 24 24 (s), g/L ± 0.05 ± 0.04 ± 0.02 95% CE, g/L ± 0.10 ± 0.10 ± 0.10 A seasoned sample from processes ECN-2 and ECP-2D was analyzed five times by each of three analysts over two days. The 95 percent confidence estimate was ± 0.04 g/L PBA-1 (s = ± 0.02 g/L) for both Process ECN-2 and ECP-2D. No statistically significant day-to-day or analystto-analyst variability was found. A standard addition of 0.5 g/L PBA-1 was made to two seasoned samples from processes ECN-2 and ECP-2D. Each sample was analyzed in duplicate by three analysts. Based on the 12 data points for each process, the method found 97 percent for ECN-2 and 100 percent for ECP-2D. SPECIAL APPARATUS Automatic Titrator (with a 20-mL buret) Orion Double Junction Reference Electrode, Cat. No. 900200 or equivalent Orion Silver/Silver Sulfide Indicator Electrode, Cat. No. 941600 or equivalent Note: Do not use a silver billet or bar electrode as prepared by the obsolete method 900 “Procedure For Electroplating A Silver-Silver Iodide Electrode.” Note: Use pipets and volumetric glassware meeting the “Class A” definition by the National Institute of Standards and Technology (NIST). REAGENTS Use reagents that are ACS Reagent Grade unless specified otherwise. 10 N Sodium Hydroxide, NaOH 0.05 N Silver Nitrate, AgNO 3 (standardized to 4 decimal places) PROCEDURE Preparation of the Sample 1. Pipet 50.0 mL of sample into a 400-mL beaker equipped with a magnetic stirring bar. Warning Sodium hydroxide is caustic. Avoid contact with skin and eyes. In case of contact, flush with water. 2. Using a tip-up pipet, add 10 mL of 10 N sodium hydroxide to the beaker containing the sample. 3. Place the beaker on a magnetic stirrer and set a timer for 3 minutes. 4. After the solution has stirred for 3 minutes, add 250 mL of distilled water from a graduated cylinder. Processing KODAK Motion Picture Films, Module 3, Analytical Procedures H24.03 1

- Page 51 and 52: B. Analysis of Standards 1. Run eac

- Page 53 and 54: Determination of Ferrous Iron in EA

- Page 55 and 56: PROCEDURE Blank 1. Set a double-bea

- Page 57 and 58: APPENDIX B This appendix contains t

- Page 59 and 60: Titrimetric Determination of Hypo I

- Page 61 and 62: Recovery Recovery is used instead o

- Page 63 and 64: Recovery Recovery is used instead o

- Page 65 and 66: B. Thiosulfate Determination 1. Sam

- Page 67 and 68: Example Potentiometric Calculations

- Page 69 and 70: Spectrophotometric Determination of

- Page 71 and 72: APPARATUS Double Beam Spectrophotom

- Page 73 and 74: APPENDIX II This appendix contains

- Page 75 and 76: Spectrophotometric Determination of

- Page 77 and 78: Calculations a. Range: 0.5-2.5 g/L

- Page 79 and 80: APPENDIX 2 Typical Absorptivity mL

- Page 81 and 82: Spectrophotometric Determination of

- Page 83 and 84: APPARATUS All volumetric glassware

- Page 85 and 86: Procedure Preparation of 10 g/L Iro

- Page 87 and 88: Determination of Total Iron in East

- Page 89 and 90: Determination of Total Iron in East

- Page 91 and 92: Determination of Total Iron in EAST

- Page 93 and 94: 12. Press ‘ZERO’. The instrumen

- Page 95 and 96: Spectrophotometric Determination of

- Page 97 and 98: PROCEDURE A. Spectrophotometer Zero

- Page 99 and 100: Absorptivity of Iron-Thiocyanate Co

- Page 101: Potentiometric Determination of Unc

- Page 105 and 106: Titrimetric Determination of Persul

- Page 107 and 108: APPARATUS Conical Flask with stoppe

- Page 109 and 110: Potentiometric Determination of Sil

- Page 111 and 112: APPARATUS METROHM 536 Titrator or e

- Page 113 and 114: Potentiometric Determination of Sod

- Page 115 and 116: PROCEDURE Treatment of the Sample 1

- Page 117 and 118: Iodometric Determination of Sodium

- Page 119 and 120: Determination of Sodium Sulfite in

- Page 121 and 122: Procedure Treatment and Titration o

- Page 123 and 124: Iodometric Determination of Sulfite

- Page 125 and 126: Potentiometric Determination of Tot

- Page 127 and 128: Automated Titration An example of a

- Page 129 and 130: Buffering Capacity Determination of

- Page 131 and 132: Buffering Capacity Determination of

- Page 133 and 134: Titrimetric Determination of EASTMA

- Page 135 and 136: VISUAL TITRATION STATISTICS Repeata

- Page 137 and 138: Titration of the Developing Agent w

- Page 139 and 140: Cerimetric Determination of CD-2 Co

- Page 141 and 142: Cerimetric Determination of KODAK C

- Page 143 and 144: Back-Extraction of CD-2 1. Add 50 m

- Page 145 and 146: Potentiometric Determination of Fer

- Page 147 and 148: Recovery Recovery is used instead o

- Page 149 and 150: CALCULATIONS For Na3Fe(CN) 6 g/L Na

- Page 151 and 152: Potentiometric Determination of Fer

Potentiometric Determination of Kodak Persulfate Bleach Accelerator PBA-1 in<br />

Accelerator Solution<br />

ECN-2-2100B<br />

ECR-2100B<br />

Process ECN-2 ECP-2D VNF-1/LC RVNP<br />

Formulas SR-31 — SR-45 SR-45<br />

INTRODUCTION<br />

Strong base is added to the sample to hydrolyze the KODAK<br />

Persulfate bleach accelerator PBA-1 to a titratable<br />

mercaptan. The PBA-1 content is measured by means of a<br />

potentiometric titration with silver nitrate titrant using a<br />

silver/sulfide electrode as an indicator and a double junction<br />

electrode as a reference. This analysis is performed using an<br />

automatic titrator.<br />

This method requires handling potentially hazardous<br />

chemicals. Consult the Material Safety Data Sheet for each<br />

chemical before use. MSDS's are available from your<br />

chemical supplier.<br />

RELIABILITY<br />

Fresh Process ECN-2, ECP-2D and VNF-1/RVNP bleach<br />

accelerator samples were analyzed by three analysts in two<br />

laboratories. A linear regression of the data generated the<br />

standard deviation (s), and 95 percent confidence estimates<br />

(CE) given below. No bias from stoichiometry was found.<br />

Process ECN-2 ECP-2D VNF/RVNP<br />

Sample Range, g/L 2–8 1–8 1–7<br />

Sample No. 3 4 4<br />

Data pts. 18 24 24<br />

(s), g/L ± 0.05 ± 0.04 ± 0.02<br />

95% CE, g/L ± 0.10 ± 0.10 ± 0.10<br />

A seasoned sample from processes ECN-2 and ECP-2D<br />

was analyzed five times by each of three analysts over two<br />

days. The 95 percent confidence estimate was ± 0.04 g/L<br />

PBA-1 (s = ± 0.02 g/L) for both Process ECN-2 and<br />

ECP-2D. No statistically significant day-to-day or analystto-analyst<br />

variability was found.<br />

A standard addition of 0.5 g/L PBA-1 was made to two<br />

seasoned samples from processes ECN-2 and ECP-2D. Each<br />

sample was analyzed in duplicate by three analysts. Based on<br />

the 12 data points for each process, the method found<br />

97 percent for ECN-2 and 100 percent for ECP-2D.<br />

SPECIAL APPARATUS<br />

Automatic Titrator (with a 20-mL buret)<br />

Orion Double Junction Reference Electrode,<br />

Cat. No. 900200 or equivalent<br />

Orion Silver/Silver Sulfide Indicator Electrode,<br />

Cat. No. 941600 or equivalent<br />

Note: Do not use a silver billet or bar electrode as prepared<br />

by the obsolete method 900 “Procedure For Electroplating A<br />

Silver-Silver Iodide Electrode.”<br />

Note: Use pipets and volumetric glassware meeting the<br />

“Class A” definition by the National Institute of Standards<br />

and Technology (NIST).<br />

REAGENTS<br />

Use reagents that are ACS Reagent Grade unless specified<br />

otherwise.<br />

10 N Sodium Hydroxide, NaOH<br />

0.05 N Silver Nitrate, AgNO 3<br />

(standardized to 4 decimal places)<br />

PROCEDURE<br />

Preparation of the Sample<br />

1. Pipet 50.0 mL of sample into a 400-mL beaker<br />

equipped with a magnetic stirring bar.<br />

Warning<br />

Sodium hydroxide is caustic. Avoid contact with skin<br />

and eyes. In case of contact, flush with water.<br />

2. Using a tip-up pipet, add 10 mL of 10 N sodium<br />

hydroxide to the beaker containing the sample.<br />

3. Place the beaker on a magnetic stirrer and set a timer<br />

for 3 minutes.<br />

4. After the solution has stirred for 3 minutes, add<br />

250 mL of distilled water from a graduated cylinder.<br />

<strong>Processing</strong> KODAK Motion Picture Films, Module 3, Analytical Procedures H24.03 1