SHIPPING UNIT LOADING / UNLOANDING POINT - Ludwigshafen

SHIPPING UNIT LOADING / UNLOANDING POINT - Ludwigshafen

SHIPPING UNIT LOADING / UNLOANDING POINT - Ludwigshafen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

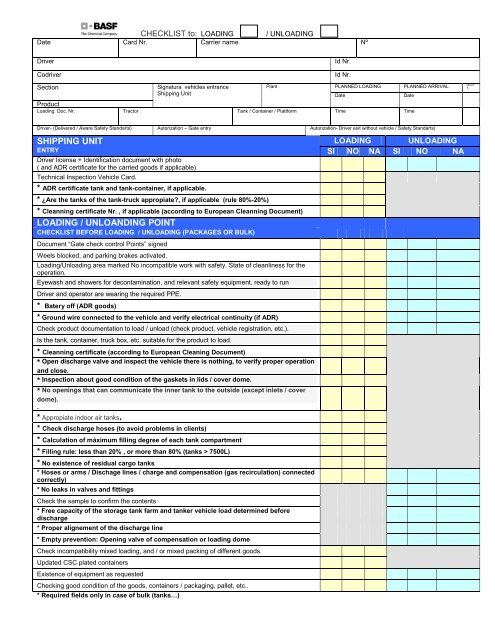

Date<br />

CHECKLIST to: <strong>LOADING</strong> / UN<strong>LOADING</strong><br />

Card Nr. Carrier name<br />

Driver Id Nr.<br />

Codriver Id Nr.<br />

Section<br />

Product<br />

Loading Doc. Nr.<br />

Tractor<br />

Driver- (Delivered / Aware Safety Standarts)<br />

Signatura vehicles entrance<br />

Shipping Unit<br />

Plant PLANNED <strong>LOADING</strong> PLANNED ARRIVAL<br />

Tank / Container / Plattform<br />

Nº<br />

Date Date<br />

Time Time<br />

Autorization – Gate entry Autorizatión- Driver exit without vehicle / Safety Standarts)<br />

<strong>SHIPPING</strong> <strong>UNIT</strong> <strong>LOADING</strong> UN<strong>LOADING</strong><br />

ENTRY SI NO NA SI NO NA<br />

Driver license + Identification document with photo<br />

( and ADR certificate for the carried goods if applicable)<br />

Technical Inspection Vehicle Card.<br />

* ADR certificate tank and tank-container, if applicable.<br />

* ¿Are the tanks of the tank-truck appropiate?, if applicable (rule 80%-20%)<br />

* Cleanning certificate Nr. , if applicable (according to European Cleanning Document)<br />

<strong>LOADING</strong> / <strong>UNLOANDING</strong> <strong>POINT</strong><br />

CHECKLIST BEFORE <strong>LOADING</strong> / UN<strong>LOADING</strong> (PACKAGES OR BULK)<br />

Document “Gate check control Points” signed<br />

Weels blocked, and parking brakes activated.<br />

Loading/Unloading area marked No incompatible work with safety. State of cleanliness for the<br />

operation.<br />

Eyewash and showers for decontamination, and relevant safety equipment, ready to run<br />

Driver and operator are wearing the required PPE.<br />

* Batery off (ADR goods)<br />

* Ground wire connected to the vehicle and verify electrical continuity (if ADR)<br />

Check product documentation to load / unload (check product, vehicle registration, etc.).<br />

Is the tank, container, truck box, etc. suitable for the product to load.<br />

* Cleanning certificate (according to European Cleaning Document)<br />

* Open discharge valve and inspect the vehicle there is nothing, to verify proper operation<br />

and close.<br />

* Inspection about good condition of the gaskets in lids / cover dome.<br />

* No openings that can communicate the inner tank to the outside (except inlets / cover<br />

dome).<br />

.<br />

* Appropiate indoor air tanks.<br />

* Check discharge hoses (to avoid problems in clients)<br />

* Calculation of máximum filling degree of each tank compartment<br />

* Filling rule: less than 20% , or more than 80% (tanks > 7500L)<br />

* No existence of residual cargo tanks<br />

* Hoses or arms / Dischage lines / charge and compensation (gas recirculation) connected<br />

correctly)<br />

* No leaks in valves and fittings<br />

Check the sample to confirm the contents<br />

* Free capacity of the storage tank farm and tanker vehicle load determined before<br />

discharge<br />

* Proper alignement of the discharge line<br />

* Empty prevention: Opening valve of compensation or loading dome<br />

Check incompatibility mixed loading, and / or mixed packing of different goods.<br />

Updated CSC plated containers<br />

Existence of equipment as requested<br />

Checking good condition of the goods, containers / packaging, pallet, etc..<br />

* Required fields only in case of bulk (tanks…)<br />

dELAT<br />

E

<strong>LOADING</strong> OR UN<strong>LOADING</strong> <strong>POINT</strong> CARGA DESCARGA<br />

CHECKLIST DURING <strong>LOADING</strong> / UN<strong>LOADING</strong> SI NO NA SI NO NA<br />

Driver out of the cab, but in the near (in case ADR)<br />

Presence of a qualified operator during loading / unloading<br />

No smoking X<br />

* No leaks around the valves and accessories<br />

* Appropriate speed filling / emptying<br />

* Loading arms or hoses without tensions<br />

* In case of storms, rain / wind, wáter, ensure that no dust, etc, entry through the loading<br />

dome<br />

* Monitor maximum degree of filling (can fail automation)<br />

* Take sample and / or counter sample<br />

CHECKLIST AFTER <strong>LOADING</strong> / UN<strong>LOADING</strong><br />

* When the tank is empty, turn off the pump / compressor.<br />

* Checking total discharging of the tank.<br />

* All discharging valves and charging overtures - even if not used during discharge -<br />

properly closed<br />

* Discharge hose free of product and pressure<br />

* Depressurization / degassing tank (if applicable).<br />

* Discharge and compensation valves of the facility, closed<br />

* Discharge and compensation valves of the tank, closed<br />

* No leaks around the valves and accessories<br />

In case of partial unloading of packaged goods, ensure that the remaining charge is secure.<br />

* All charging valves and charging dome - even if not used during charging - properly<br />

closed<br />

* Arm / load line free of product. Collectors of the vehicle empty.<br />

* To seal all charging domes and discharging valves<br />

* Place a product and date label on discharge valves<br />

* Provide analysis report if the delivery / order required<br />

* Save counter sample labeled in the warehouse.<br />

Exterior packaging no dents or traces of products. Tanks without product residues adhering<br />

Stowage and packaged load securing on the vehicle.<br />

Carry load as quantity requested respecting Gross Weigth<br />

Checking internal pressure if appropriate.<br />

* All waste product removed from outside the vehicle.<br />

* Ground cable disconnected (if ADR).<br />

Transport unit / tank / packaging properly labeled / marked<br />

Wheel chocks removed. Side and rear door vehicle / container closed.<br />

<strong>SHIPPING</strong> <strong>UNIT</strong><br />

EXIT<br />

Documentation vehicle, exit.<br />

Control of the loading, not exceed Gross Weigth.<br />

Delivery of Transport documents (case ADR)<br />

Another transport documentation.<br />

Unloading exceeding goods, if necessary.<br />

* Required fields only in case of bulk (tanks…)<br />

SINGLE TANK<br />

Filling degree:<br />

%<br />

DIFFERENT<br />

COMPARTMENTS<br />

%<br />

%<br />

%<br />

%<br />

%<br />

COMMENTS:………………………………………………………………………………………<br />

…………………………………………………………………………………………………………<br />

…………………………………………………………………………………………………………<br />

…………………………………………………………………………………………………………<br />

SIGNATURE OPERATOR / <strong>LOADING</strong>- UN<strong>LOADING</strong><br />

RESPONSIBLE / (name and surname)<br />

DOCUMENTACION RECEIVED<br />

CONFORMITY DRIVER SIGNATURE (name and surname)