BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A2.A.3. <strong>THE</strong> OPERATIONS ANALYSIS AND FLOW DIAGRAM<br />

A2.A.3.1. FORMAL NAME. The operations analysis<br />

A2.A.3.2. ALTERNATIVE NAMES. The flow diagram, flow chart, operation timeline<br />

A2.A.3.3. PURPOSE. The operations analysis (OA) provides an itemized sequence of events or a<br />

diagram (in the case of the flow diagram) depicting the major events of an operation. The purpose of this<br />

flow of events is to assure that all elements of an operation are evaluated for potential sources of risk. This<br />

overcomes a major weaknesses of traditional risk management which tends to immediately focus effort on<br />

one or two aspects of an operation that intuitively are identified as risky to the exclusion of other aspects<br />

that may actually be riskier. The operations analysis also guides the allocation of risk management<br />

resources over time as an operation unfolds event by event in a systematic manner.<br />

A2.A.3.4. APPLICATION. The operations analysis or flow diagram is used in virtually all risk<br />

management applications to include the most time critical. It responds to the key risk management<br />

question “What am I facing here and from where can risk arise?”<br />

A2.A.3.5. METHOD. Whenever possible the operations analysis is taken directly from the product<br />

produced by the personnel planning an operation. It is difficult to imagine planning an operation without<br />

identifying the key events in a time sequence. If for some reason such a list is not available, then the<br />

analyst creates it using the best available understanding of the operation. A key issue is the level of detail.<br />

The best practice is to break the operation down into time sequenced segments that have strongly related<br />

tasks and activities. This is normally well above the detail of individual tasks. The examples provided in<br />

paragraph A2.A.3.8. are good guides to the level of detail appropriate. It may be appropriate to break<br />

aspects of an operation that are obviously higher risk down into more detail than less risky areas. The<br />

output product of an OA is the major events of an operation in sequence with or without time checks. An<br />

alternative to the operations analysis is the flow diagram. The flow diagram converts the list of events of<br />

the operations analysis into a diagram using the well established procedures of the flow diagram.<br />

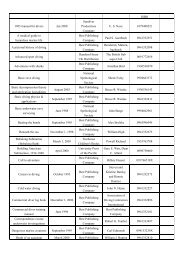

Commonly used symbols are provided at Figure A2.1. Consider putting the steps of the process on index<br />

cards or stick back note paper. This lets you rearrange the diagram without erasing and redrawing, making<br />

it easy to reconfigure the diagram and encouraging contributions.<br />

39