BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

the sequence indicated, however it is important for the user to become familiar with them and choose the<br />

best combination for a particular situation.<br />

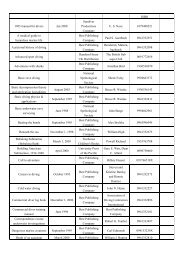

Figure 6. The Primary Family of Hazard Identification Tools.<br />

SEVEN PRIMARY HAZARD IDENTIFICATION TOOLS<br />

<strong>THE</strong> OPERATIONS ANALYSIS<br />

<strong>THE</strong> PRELIMINARY HAZARD ANALYSIS<br />

<strong>THE</strong> WHAT IF TOOL<br />

<strong>THE</strong> SCENARIO PROCESS TOOL<br />

<strong>THE</strong> LOGIC DIAGRAM<br />

<strong>THE</strong> CHANGE ANALYSIS<br />

<strong>THE</strong> CAUSE AND EFFECT TOOL<br />

20.2. There are many additional tools that can help identify hazards. One of the best is through a group<br />

process involving representatives directly from the workplace. Most people want to talk about their jobs,<br />

therefore a simple brainstorming process with a facilitator is often very productive. The following is a<br />

partial list of other sources of hazard identification information:<br />

20.2.1. Mishap Reports: These can come from within the organization, from tenants, within the chain of<br />

command, from outside the chain (other bases, wings, MAJCOMs, etc.), other services, DoD agencies,<br />

etc. Obviously, a missionized identification is the best, for it represents corporate memory applicable to the<br />

local workplace, cockpit, mission, etc. Other sources might be medical reports, maintenance records, and<br />

fire and police reports.<br />

20.2.2. Unit Personnel: Relevant experience is arguably the best source of hazard identification.<br />

Reinventing the wheel each time an operation is proposed is neither desired nor efficient. Seek out those<br />

with whom you work who have participated in similar operations and solicit their input.<br />

20.2.3. Outside Experts: Look to those outside your organization for expert opinions or advice. Possible<br />

sources of help include Safety, Quality Assurance, manufacturers, depots, and other bases.<br />

20.2.4. Current Guidance: A wealth of relevant direction can always be found in the guidance that<br />

governs our operations. Consider regulations, operating instructions, checklists, briefing guides, syllabi,<br />

FCIFs, SOPs, NOTAMs, and policy letters.<br />

20.2.5. Evaluation and inspection reports: Functional and IG visits provide important feedback and<br />

written documentation on local process management.<br />

20.2.6. Surveys: These can be unit generated. Target an audience and ask some very simple questions<br />

related to such topics as: What will your next mishap be? Who will have it? What task will cause it?<br />

When will it happen? The survey can be a powerful tool because it pinpoints people in the workplace with<br />

first hand knowledge of the job. Often, first line supervisors in the same workplace do not have as good an<br />

understanding of risk as those who confront it every day.<br />

20.2.7. Inspections: Inspections can consist of spot checks, walk throughs, checklist inspections, site<br />

surveys, and mandatory inspections. Utilize people in the workplace to provide input beyond the standard<br />

third-party inspection.<br />

17