BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

BY ORDER OF THE AIR FORCE PAMPHLET 91-215 SECRETARY ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Attachment 7<br />

SUPERVISE AND REVIEW DETAILS AND EXAMPLES<br />

A7.1. Introduction. Management is moving a task or an organization toward a goal. To move toward a<br />

goal you must have three things. You must have a goal, you must know where you are in relation to that<br />

goal, and you must have a plan to reach it. An effective set of risk matrices provides two of the elements.<br />

A7.2. In regard to ORM, indicators should provide information concerning the success or lack of success<br />

of controls intended to mitigate a risk. These indicators could focus on those key areas identified during<br />

the assessment as being critical to minimizing a serious risk area. Additionally, matrices may be developed<br />

to generically identify operations/areas where ORM efforts are needed.<br />

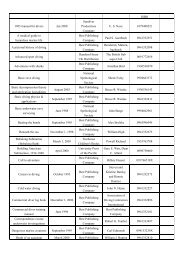

A7.3. Let’s look at a representative set of risk measures that a maintenance shop leader could use to assess<br />

the progress of his shop toward the goal of improving safety performance. Similar indicators could be<br />

developed in the areas of environment, fire prevention, security, and other loss control areas.<br />

A7.3.1. The tool control effectiveness index. Establish key indicators of tool control program<br />

effectiveness (percentage of tool checks completed, items found by QA, score on knowledge quiz<br />

regarding control procedures, etc.). All that is needed is a sampling of data in one or more of these areas.<br />

If more than one area is sampled, the scores can be weighted if desired and rolled up into a single tool<br />

control index by averaging them. See Figure A7.1 for the example.<br />

Figure A7.1. Example Tool Control Effectiveness Measurement.<br />

a. The percent of tool checks completed is 94%.<br />

b. Items found by QA. Items were found in 2% of QA inspections (98% were<br />

to standard).<br />

c. Tool control quiz score is 88%.<br />

d. If all items are weighted equally (94+98+88 divided by 3 = 93.3) then 93.3 is<br />

this quarter’s tool control safety index. Of course, in this index, high scores<br />

are desirable.<br />

A7.3.2. The protective clothing and equipment risk index. This index measures the effectiveness with<br />

which required protective clothing and equipment are being used by shop personnel. Data is collected by<br />

making spot observations periodically during the work day. Data are recorded on a check sheet and are<br />

rolled-up monthly. The index is the percent safe observations of the total number of observations made as<br />

illustrated at Figure A7.2.<br />

Figure A7.2. Example Safety Observation Measurement.<br />

TOTAL OBSERVATIONS: 27 SAFE OBSERVATIONS: 21<br />

The protective clothing and equipment safety index is 78 (21 divided by 27 = 78%).<br />

In this index high scores are desirable.<br />

113