April - Library

April - Library

April - Library

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Short Feature:<br />

Machinery Troubleshooting - First Impressions<br />

When troubleshooting a machinery problem, whether for an<br />

unusual vibration problem or a component failure such as a bearing<br />

or seal, first impressions from the initial machinery inspection are<br />

very important. Any troubleshooting exercise should begin with<br />

a thorough investigation of machine history - process, design,<br />

operation, maintenance, and all available machine details. These<br />

first impressions are necessary to make sure the troubleshooting<br />

team is fully armed with important data and minimize the chances<br />

of a misdiagnosis.<br />

Many people new to the troubleshooting process have a<br />

tendency to immediately pick up tools and start working. A better<br />

approach is to put the tools down and collect first impressions.<br />

While they might not immediately reveal the problem, they may<br />

identify a number of issues that are impacting overall reliability.<br />

Recommendations for these initial inspections include:<br />

1. Overall cleanliness - Good housekeeping often reveals that machinery maintenance practices are held<br />

to a higher standard. Look beyond dust to the condition of the base and foundation, piping supports, seal<br />

leaks, etc., for evidence of maintenance practices or environmental factors that negatively impact reliability.<br />

What are the expectations that a field repair can be conducted without introducing contaminants that will<br />

shorten the life of the replacement parts?<br />

2. More detailed machine inspection - Start with the machine base and look for obvious signs of decay<br />

or improper anchoring. Move up to the feet and inspect the shims and hold-down bolts. Poor practices at<br />

the base often reveal a lack of quality of other repairs. Move to the shaft and drive (i.e., couplings, belts,<br />

etc.) and look for evidence of shaft damage, improper coupling assembly, and incorrect key length. While<br />

issues with these areas may not be the cause of the current problem, improvements made with the required<br />

repairs will improve machinery reliability.<br />

3. If running, perform a basic vibration check - Use a simple tool such as a coin with serrated edges to obtain<br />

an impression of relative machinery movement if the machine is still running. While vibration measurements<br />

tend to focus on the bearings, with coin in hand, start at the base and work up to the bearing locations to feel<br />

for unusual movement. Pay close attention to boundaries and connections such as the base-to-foundation,<br />

machine feet-to-base, and all piping and conduit. A simple condition such as a loose base-bolt can have a<br />

dramatic impact on the machine.<br />

4. Keep detailed notes of the initial impressions – They will provide a comprehensive and professional report<br />

on improvements that will impact the life and reliability of the machine. While at the machine site, inspect<br />

other equipment in the area for similar issues and carefully present this information to the stakeholders.<br />

While no one likes to have their flaws revealed, a good presentation of steps that can be followed to<br />

positively impact machinery will be well received.<br />

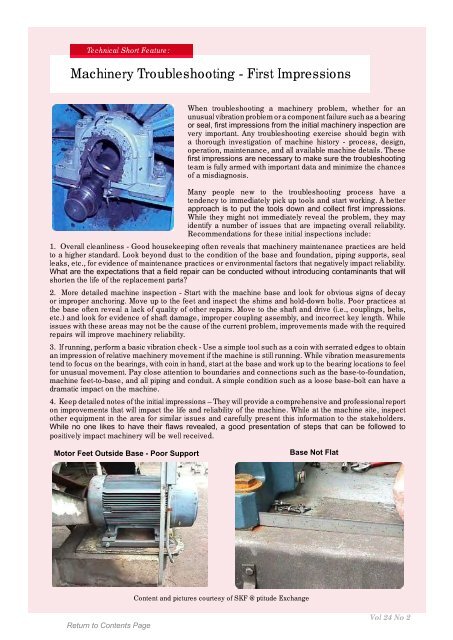

Motor Feet Outside Base - Poor Support<br />

Content and pictures courtesy of SKF @ptitude Exchange<br />

Base Not Flat<br />

Vol 24 No 2