April - Library

April - Library

April - Library

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

AMMJ Lessons Learnt In 45 Years of Condition Monitoring 2<br />

Case study 7<br />

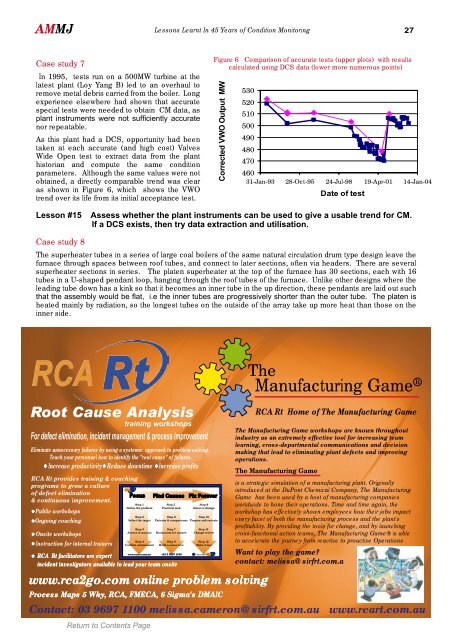

In 1995, tests run on a 500MW turbine at the<br />

latest plant (Loy Yang B) led to an overhaul to<br />

remove metal debris carried from the boiler. Long<br />

experience elsewhere had shown that accurate<br />

special tests were needed to obtain CM data, as<br />

plant instruments were not sufficiently accurate<br />

nor repeatable.<br />

As this plant had a DCS, opportunity had been<br />

taken at each accurate (and high cost) Valves<br />

Wide Open test to extract data from the plant<br />

historian and compute the same condition<br />

parameters. Although the same values were not<br />

obtained, a directly comparable trend was clear<br />

as shown in Figure 6, which shows the VWO<br />

trend over its life from its initial acceptance test.<br />

Lesson #15 Assess whether the plant instruments can be used to give a usable trend for CM.<br />

If a DCS exists, then try data extraction and utilisation.<br />

Case study 8<br />

460<br />

31-Jan-93 28-Oct-95 24-Jul-98 19-Apr-01 14-Jan-04<br />

The superheater tubes in a series of large coal boilers of the same natural circulation drum type design leave the<br />

furnace through spaces between roof tubes, and connect to later sections, often via headers. There are several<br />

superheater sections in series. The platen superheater at the top of the furnace has 30 sections, each with 16<br />

tubes in a U-shaped pendant loop, hanging through the roof tubes of the furnace. Unlike other designs where the<br />

leading tube down has a kink so that it becomes an inner tube in the up direction, these pendants are laid out such<br />

that the assembly would be flat, i.e the inner tubes are progressively shorter than the outer tube. The platen is<br />

heated mainly by radiation, so the longest tubes on the outside of the array take up more heat than those on the<br />

inner side.<br />

Eliminate unnecessary failures by using a systemic approach to problem solving.<br />

Teach your personnel how to identify the "root cause" of failures.<br />

Increase productivity Reduce downtime Increase profits<br />

RCA Rt provides training & coaching<br />

programs to grow a culture<br />

of defect elimination<br />

& continuous improvement.<br />

Public workshops<br />

Ongoing coaching<br />

Onsite workshops<br />

Instruction for internal trainers<br />

Focus Find Causes Fix Forever<br />

Step 1<br />

Define the problem<br />

Step 2<br />

Select the target<br />

Step 3<br />

Assess & monitor<br />

Step 4<br />

Confirm containment<br />

Step 5<br />

Practical look<br />

Step 6<br />

Patterns & comparisons<br />

Step 7<br />

Brainstorm for causes<br />

Step 8<br />

Build a cause tree<br />

RCA Rt facilitators are expert<br />

incident investigators available to lead your team onsite<br />

Step 9<br />

Select a change<br />

Step 10<br />

Prepare and execute<br />

Step 11<br />

Change review<br />

Step 12<br />

Make it last<br />

www.rcart.com.au +61 3 9697 1100 Copyright<br />

Figure 6 Comparison of accurate tests (upper plots) with results<br />

calculated using DCS data (lower more numerous points)<br />

Corrected VWO Output MW<br />

530<br />

520<br />

510<br />

500<br />

490<br />

480<br />

470<br />

www.rca2go.com online problem solving<br />

Process Maps 5 Why, RCA, FMECA, 6 Sigma's DMAIC<br />

Date of test<br />

The<br />

R<br />

Manufacturing Game<br />

RCA Rt Home of The Manufacturing Game<br />

The Manufacturing Game workshops are known throughout<br />

industry as an extremely effective tool for increasing team<br />

learning, cross-departmental communications and decision<br />

making that lead to eliminating plant defects and improving<br />

operations.<br />

The Manufacturing Game<br />

is a strategic simulation of a manufacturing plant. Originally<br />

introduced at the DuPont Chemical Company, The Manufacturing<br />

Game has been used by a host of manufacturing companies<br />

worldwide to hone their operations. Time and time again, the<br />

workshop has effectively shown employees how their jobs impact<br />

every facet of both the manufacturing process and the plant's<br />

profitability. By providing the tools for change, and by launching<br />

cross-functional action teams, The Manufacturing Game® is able<br />

to accelerate the journey from reactive to proactive Operations<br />

Want to play the game?<br />

contact: melissa@sirfrt.com.a<br />

Contact: 03 9697 1100 melissa.cameron@sirfrt.com.au www.rcart.com.au