April - Library

April - Library April - Library

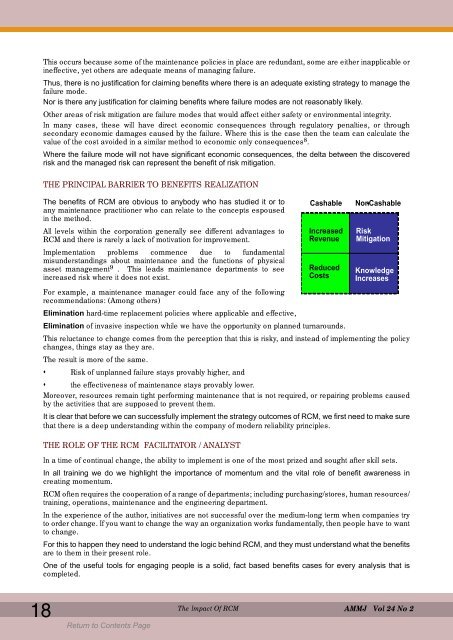

This occurs because some of the maintenance policies in place are redundant, some are either inapplicable or ineffective, yet others are adequate means of managing failure. Thus, there is no justification for claiming benefits where there is an adequate existing strategy to manage the failure mode. Nor is there any justification for claiming benefits where failure modes are not reasonably likely. Other areas of risk mitigation are failure modes that would affect either safety or environmental integrity. In many cases, these will have direct economic consequences through regulatory penalties, or through secondary economic damages caused by the failure. Where this is the case then the team can calculate the value of the cost avoided in a similar method to economic only consequences 8 . Where the failure mode will not have significant economic consequences, the delta between the discovered risk and the managed risk can represent the benefit of risk mitigation. THE PRINCIPAL BARRIER TO BENEFITS REALIZATION The benefits of RCM are obvious to anybody who has studied it or to any maintenance practitioner who can relate to the concepts espoused in the method. All levels within the corporation generally see different advantages to RCM and there is rarely a lack of motivation for improvement. Implementation problems commence due to fundamental misunderstandings about maintenance and the functions of physical asset management 9 . This leads maintenance departments to see increased risk where it does not exist. For example, a maintenance manager could face any of the following recommendations: (Among others) Elimination hard-time replacement policies where applicable and effective, Elimination of invasive inspection while we have the opportunity on planned turnarounds. This reluctance to change comes from the perception that this is risky, and instead of implementing the policy changes, things stay as they are. The result is more of the same. • Risk of unplanned failure stays provably higher, and • the effectiveness of maintenance stays provably lower. Moreover, resources remain tight performing maintenance that is not required, or repairing problems caused by the activities that are supposed to prevent them. It is clear that before we can successfully implement the strategy outcomes of RCM, we first need to make sure that there is a deep understanding within the company of modern reliability principles. THE ROLE OF THE RCM FACILITATOR / ANALYST In a time of continual change, the ability to implement is one of the most prized and sought after skill sets. In all training we do we highlight the importance of momentum and the vital role of benefit awareness in creating momentum. RCM often requires the cooperation of a range of departments; including purchasing/stores, human resources/ training, operations, maintenance and the engineering department. In the experience of the author, initiatives are not successful over the medium-long term when companies try to order change. If you want to change the way an organization works fundamentally, then people have to want to change. For this to happen they need to understand the logic behind RCM, and they must understand what the benefits are to them in their present role. One of the useful tools for engaging people is a solid, fact based benefits cases for every analysis that is completed. 18 The Impact Of RCM Cashable Non-Cashable Increased Revenue Reduced Costs Risk Mitigation Knowledge Increases AMMJ Vol 24 No 2

To be effective the task of calculating and promoting the benefits of any RCM effort should commence during the analysis period itself, and presented before implementation. REFERENCES and NOTES: 1. The issues surrounding RCM and WoL asset management are covered in more detail in “RCM- WP-002 RCM and Whole-of-Life (WoL) Asset Management” 2 Reliability-centered Maintenance, F.S. Nowlan et al, United Airlines, San Francisco, Dec 1978 3 Reliability-centered Maintenance, F.S. Nowlan et al, United Airlines, San Francisco, Dec 1978 4 Statistical Investigation of the Fatigue Life of Deep Groove Bearings, J. Lieblen and M. Zelen, Journal of Research of the National Bureau of Standards, Vol 57, No 5, November 1956. 5. Bloch, Heinz P. and Fred K. Geitner, 1994, Practical Machinery Management for Process Plants, Volume 2: Machinery Failure Analysis and Troubleshooting, 2nd Edition, Gulf Publishing Company, Houston, TX 6. Our RCM Decision Algorithm is based on Figure 17 – A Second Decision Diagram Example, page 49, SAE JA1012, 2002-01 7. Human error is discussed in detail in white paper RCM-WP-003 Introducing Human Error. 8. Cost avoidance calculation methods are available in Handout RCM-HO-002 Calculating Costs Avoided, inspired by the work of Steve Soos from Meridium on this subject. 9. The Role of the Maintenance Manager, Daryl Mather, 2008: (RCM-WP-004) • Design effective maintenance policy • Execute them as efficiently as possible • Collect relevant data for higher confidence decisions Daryl Mather is the Founder and Principal Consultant of Reliability Success Pty Ltd. He can be contacted on: dmather@reliabilitysuccess.com, or via the website at www.reliabilitysuccess.com THE MOST POWERFUL TOOL IN YOUR BELT Easy to use, web-based enterprise CMMS software SOFTWARE FEATURES ¥ WORK ORDER TRACKING ¥ ASSET MANAGEMENT ¥ PREVENTATIVE MAINTENANCE ¥ SPARE PARTS INVENTORY ¥ SERVICE REQUESTS ¥ CALENDAR SCHEDULING ¥ SECURITY ACCESS GROUPS ¥ MOBILE WORKFLOW ¥ KPI DASHBOARDS ¥ CUSTOM REPORT WRITER Old paper work orders Þlling up Þle cabinets, preventative maintenance reminders from a year ago, spare parts going missing. Sound like a nightmare? Welcome to a day in the life of so many maintenance personnel using out-dated CMMS technology. Maintenance Connection is a leading provider of solutions that make sense allowing you to manage maintenance, not software. 1300 135 002 e. sales@mcaus.com.au w. www.mcaus.com.au Software Solutions for Maintenance Professionals Combine our productivity-enhancing feature set with unparalleled customer service, and that ÒotherÓ CMMS can become nothing more than a bad dream. Talk with a Maintenance Connection Account Manager today about getting started with a transition that will make your CMMS the most powerful tool in your belt, leaving you with more time for getting on with the jobs that matter.

- Page 1 and 2: The AMMJ is Sponsored and Supported

- Page 3 and 4: info@infratherm.com.au Introducing

- Page 5 and 6: 6 10 20 22 30 AMMJ Maintenance Engi

- Page 7 and 8: AMMJ Maintenance Enginering and Eng

- Page 9 and 10: Locate electrical problems Detect p

- Page 11 and 12: technology means that experienced t

- Page 13 and 14: 2011 RELIABILITY AND APOLLO ROOT CA

- Page 15 and 16: Do our people get smarter when they

- Page 17: existing strategy in place, the tea

- Page 21 and 22: AMMJ Surge Protection Devices 21 to

- Page 23 and 24: AMMJ Lessons Learnt In 45 Years of

- Page 25 and 26: AMMJ Lessons Learnt In 45 Years of

- Page 27 and 28: AMMJ Lessons Learnt In 45 Years of

- Page 29 and 30: AMMJ Lessons Learnt In 45 Years of

- Page 31 and 32: Vol 24 No 2 AMMJ to preventative ma

- Page 33 and 34: Vol 24 No 2 AMMJ - Reduce equipment

- Page 35 and 36: Vol 24 No 2 AMMJ • MaintiMizer is

- Page 37 and 38: Vol 24 No 2 AMMJ CMMS/EAM DESCRIPTI

- Page 39 and 40: AMMJ Fit at 50 39 The enormous cost

- Page 41 and 42: AMMJ Fit at 50 41 analog signals. T

- Page 43 and 44: AMMJ Fit at 50 43 Figure 10 ABB Tra

- Page 45 and 46: AMMJ 0.87ms i.e. 13.051ms divided b

- Page 47 and 48: AMMJ Figure 6 Envelope spectrum obt

- Page 49 and 50: AMMJ Due to variable compliance eff

- Page 51 and 52: Technical Short Feature: Machinery

- Page 53 and 54: Maintenance News Penny Melrose, Dat

- Page 55 and 56: Maintenance News deviation from the

- Page 57 and 58: Seminar 1 Duration - 1 Day The Why,

- Page 59 and 60: Len Bradshaw - Seminars 1 & 2 Len B

- Page 61: And you thought we just made bearin

This occurs because some of the maintenance policies in place are redundant, some are either inapplicable or<br />

ineffective, yet others are adequate means of managing failure.<br />

Thus, there is no justification for claiming benefits where there is an adequate existing strategy to manage the<br />

failure mode.<br />

Nor is there any justification for claiming benefits where failure modes are not reasonably likely.<br />

Other areas of risk mitigation are failure modes that would affect either safety or environmental integrity.<br />

In many cases, these will have direct economic consequences through regulatory penalties, or through<br />

secondary economic damages caused by the failure. Where this is the case then the team can calculate the<br />

value of the cost avoided in a similar method to economic only consequences 8 .<br />

Where the failure mode will not have significant economic consequences, the delta between the discovered<br />

risk and the managed risk can represent the benefit of risk mitigation.<br />

THE PRINCIPAL BARRIER TO BENEFITS REALIZATION<br />

The benefits of RCM are obvious to anybody who has studied it or to<br />

any maintenance practitioner who can relate to the concepts espoused<br />

in the method.<br />

All levels within the corporation generally see different advantages to<br />

RCM and there is rarely a lack of motivation for improvement.<br />

Implementation problems commence due to fundamental<br />

misunderstandings about maintenance and the functions of physical<br />

asset management 9 . This leads maintenance departments to see<br />

increased risk where it does not exist.<br />

For example, a maintenance manager could face any of the following<br />

recommendations: (Among others)<br />

Elimination hard-time replacement policies where applicable and effective,<br />

Elimination of invasive inspection while we have the opportunity on planned turnarounds.<br />

This reluctance to change comes from the perception that this is risky, and instead of implementing the policy<br />

changes, things stay as they are.<br />

The result is more of the same.<br />

• Risk of unplanned failure stays provably higher, and<br />

• the effectiveness of maintenance stays provably lower.<br />

Moreover, resources remain tight performing maintenance that is not required, or repairing problems caused<br />

by the activities that are supposed to prevent them.<br />

It is clear that before we can successfully implement the strategy outcomes of RCM, we first need to make sure<br />

that there is a deep understanding within the company of modern reliability principles.<br />

THE ROLE OF THE RCM FACILITATOR / ANALYST<br />

In a time of continual change, the ability to implement is one of the most prized and sought after skill sets.<br />

In all training we do we highlight the importance of momentum and the vital role of benefit awareness in<br />

creating momentum.<br />

RCM often requires the cooperation of a range of departments; including purchasing/stores, human resources/<br />

training, operations, maintenance and the engineering department.<br />

In the experience of the author, initiatives are not successful over the medium-long term when companies try<br />

to order change. If you want to change the way an organization works fundamentally, then people have to want<br />

to change.<br />

For this to happen they need to understand the logic behind RCM, and they must understand what the benefits<br />

are to them in their present role.<br />

One of the useful tools for engaging people is a solid, fact based benefits cases for every analysis that is<br />

completed.<br />

18<br />

The Impact Of RCM<br />

Cashable Non-Cashable<br />

Increased<br />

Revenue<br />

Reduced<br />

Costs<br />

Risk<br />

Mitigation<br />

Knowledge<br />

Increases<br />

AMMJ Vol 24 No 2