May - Library

May - Library May - Library

Course One Planned Maintenance And Maintenance People The What, When and Who of Maintenance 1 . Maintenance Activities • The different activities performed in maintenance emergency, corrective, preventive, predictive, condition based, proactive, and designing for maintenance. • The pre-planning process in maintenance • Shutdown Maintenance - the dangers 2 . Consequences of Good or Bad Maintenance • The direct and indirect costs of Maintenance. • What do you cost and what are you worth. • Effect of too little or too much planned maintenance. • Duties of proving due care of your assets. • Are “competent” people planning and doing the maintenance work. Discussion 1: Have your organisations the corre c t mix of maintenance activities. Do you identify re a l maintenance costs and respond to those costs 3 . Inspections & Condition Based Maintenance • What inspection and preventive/predictive techniques are now available in maintenance. • How often should you perform inspections and condition based maintenance activities. • Increasing the effectiveness of inspection and condition based maintenance activities. Discussion 2: What techniques for inspections & Condition Monitoring are used in your plant. Are they successful. If not why not. 4 . Maintenance Planning and Contro l • The different processes and techniques involved with maintenance planning and control. • The functions performed by a computerised maintenance management system. 5 .The People and Stru c t u res In Maintenance • People - The most important assets in maintenance. • The different organisational structures used for maintenance activities. • Restructured maintenance; flexibility and team based structures. • What motivates people to work with the company rather than against it. • Are teams achievable in your organization? How far can you go. • Utilising non maintenance resources. • TPM - Total Productive Maintenance. • Administrative responsibilities for teams. • Recruitment and Reward methods. • Maintenance Outsourcing/Contracting. • A range of Case Studies on people issues in Maintenance. Discussions 3: Are your organisations using the right people and structures in maintenance? Successes and failures in people issues. Who should attend? Planners, Team Leaders, Team Members, Supervisors, Tradesmen, Operations Personnel, Technicians, Engineers, Systems Managers, and others interested in maintenance of plant and assets. Each course costs AUS $660.00 per delegate per day (Inclusive of GST) 1

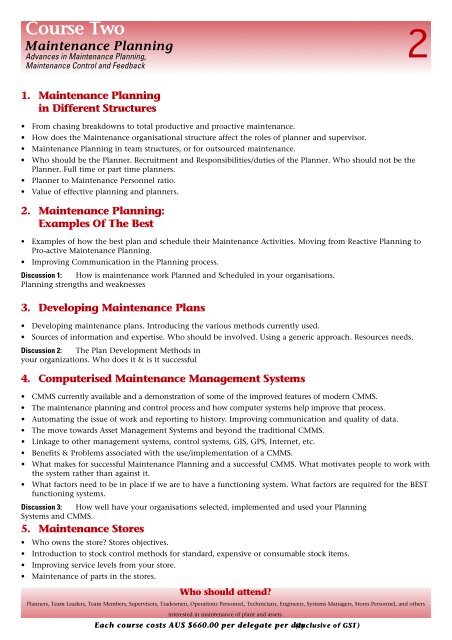

Course Two Maintenance Planning Advances in Maintenance Planning, Maintenance Control and Feedback 1 . Maintenance Planning in Diff e rent Stru c t u res • From chasing breakdowns to total productive and proactive maintenance. • How does the Maintenance organisational structure affect the roles of planner and supervisor. • Maintenance Planning in team structures, or for outsourced maintenance. • Who should be the Planner. Recruitment and Responsibilities/duties of the Planner. Who should not be the Planner. Full time or part time planners. • Planner to Maintenance Personnel ratio. • Value of effective planning and planners. 2 . Maintenance Planning: Examples Of The Best • Examples of how the best plan and schedule their Maintenance Activities. Moving from Reactive Planning to Pro-active Maintenance Planning. • Improving Communication in the Planning process. Discussion 1: How is maintenance work Planned and Scheduled in your organisations. Planning strengths and weaknesses 3 . Developing Maintenance Plans • Developing maintenance plans. Introducing the various methods currently used. • Sources of information and expertise. Who should be involved. Using a generic approach. Resources needs. Discussion 2: The Plan Development Methods in your organizations. Who does it & is it successful 4 . Computerised Maintenance Management Systems • CMMS currently available and a demonstration of some of the improved features of modern CMMS. • The maintenance planning and control process and how computer systems help improve that pro c e s s . • Automating the issue of work and reporting to history. Improving communication and quality of data. • The move towards Asset Management Systems and beyond the traditional CMMS. • Linkage to other management systems, control systems, GIS, GPS, Internet, etc. • Benefits & Problems associated with the use/implementation of a CMMS. Who should attend? Planners, Team Leaders, Team Members, Supervisors, Tradesmen, Operations Personnel, Technicians, Engineers, Systems Managers, Stores Personnel, and others interested in maintenance of plant and assets. Each course costs AUS $660.00 per delegate per day (Inclusive of GST) 2 • What makes for successful Maintenance Planning and a successful CMMS. What motivates people to work with the system rather than against it. • What factors need to be in place if we are to have a functioning system. What factors are required for the BEST functioning systems. Discussion 3: How well have your organisations selected, implemented and used your Planning Systems and CMMS. 5 . Maintenance Stores • Who owns the store ? S t o res objectives. • I n t roduction to stock control methods for standard, expensive or consumable stock items. • I m p roving service levels from your store . • Maintenance of parts in the stores.

- Page 36 and 37: For example, one of the most celebr

- Page 38 and 39: MERIT draws data from the Marine’

- Page 40 and 41: d i s c re p a n c y. The short par

- Page 42 and 43: p roblems, and getting their ideas

- Page 44 and 45: M E X M A I N T E N A N C E M A N A

- Page 46 and 47: system performance and efficiency.

- Page 48 and 49: CMMS DETAILS - Functionality C H A

- Page 50 and 51: Fax: (905) 844-0347 Email: mcudmore

- Page 52 and 53: Typical cost of the CMMS software S

- Page 54 and 55: Available as a stand-alone system.

- Page 56 and 57: Ivara EAM Company: Ivara Corporatio

- Page 58 and 59: Small site: $3,000 Medium Site: $40

- Page 60 and 61: MicroMain’s CMMS and modules are

- Page 62 and 63: Available as a stand-alone system.

- Page 64 and 65: Towards An Intelligent Holonic Main

- Page 66 and 67: 1200 1000 800 600 400 200 Breakdown

- Page 68 and 69: Figure 8a: Membership function of F

- Page 70 and 71: Decision Making Grid (DMG) Decision

- Page 72 and 73: Table 1 What type of industry does

- Page 74 and 75: Table 9 Can your condition based mo

- Page 76 and 77: KEY WHAT WHY Check packing to see i

- Page 78 and 79: • Laser range of 20m (40m diamete

- Page 80 and 81: systems, and provided the turn-key

- Page 82 and 83: (RCA), and risk based inspection (R

- Page 85: Maintenance 2004 Seminars Course On

- Page 89 and 90: The seminar is presented by Len Bra

- Page 91 and 92: E F F I C I E N C Y Maintenance Exp

- Page 93 and 94: To speed registration, please provi

- Page 95 and 96: SHUTDOWNS AND TURNAROUNDS Day One:

- Page 97: Separately Bookable Post-Conference

Course Two<br />

Maintenance Planning<br />

Advances in Maintenance Planning,<br />

Maintenance Control and Feedback<br />

1 . Maintenance Planning<br />

in Diff e rent Stru c t u res<br />

• From chasing breakdowns to total productive and proactive maintenance.<br />

• How does the Maintenance organisational structure affect the roles of planner and supervisor.<br />

• Maintenance Planning in team structures, or for outsourced maintenance.<br />

• Who should be the Planner. Recruitment and Responsibilities/duties of the Planner. Who should not be the<br />

Planner. Full time or part time planners.<br />

• Planner to Maintenance Personnel ratio.<br />

• Value of effective planning and planners.<br />

2 . Maintenance Planning:<br />

Examples Of The Best<br />

• Examples of how the best plan and schedule their Maintenance Activities. Moving from Reactive Planning to<br />

Pro-active Maintenance Planning.<br />

• Improving Communication in the Planning process.<br />

Discussion 1: How is maintenance work Planned and Scheduled in your organisations.<br />

Planning strengths and weaknesses<br />

3 . Developing Maintenance Plans<br />

• Developing maintenance plans. Introducing the various methods currently used.<br />

• Sources of information and expertise. Who should be involved. Using a generic approach. Resources needs.<br />

Discussion 2: The Plan Development Methods in<br />

your organizations. Who does it & is it successful<br />

4 . Computerised Maintenance Management Systems<br />

• CMMS currently available and a demonstration of some of the improved features of modern CMMS.<br />

• The maintenance planning and control process and how computer systems help improve that pro c e s s .<br />

• Automating the issue of work and reporting to history. Improving communication and quality of data.<br />

• The move towards Asset Management Systems and beyond the traditional CMMS.<br />

• Linkage to other management systems, control systems, GIS, GPS, Internet, etc.<br />

• Benefits & Problems associated with the use/implementation of a CMMS.<br />

Who should attend?<br />

Planners, Team Leaders, Team Members, Supervisors, Tradesmen, Operations Personnel, Technicians, Engineers, Systems Managers, Stores Personnel, and others<br />

interested in maintenance of plant and assets.<br />

Each course costs AUS $660.00 per delegate per day (Inclusive of GST)<br />

2<br />

• What makes for successful Maintenance Planning and a successful CMMS. What motivates people to work with<br />

the system rather than against it.<br />

• What factors need to be in place if we are to have a functioning system. What factors are required for the BEST<br />

functioning systems.<br />

Discussion 3: How well have your organisations selected, implemented and used your Planning<br />

Systems and CMMS.<br />

5 . Maintenance Stores<br />

• Who owns the store ? S t o res objectives.<br />

• I n t roduction to stock control methods for standard, expensive or consumable stock items.<br />

• I m p roving service levels from your store .<br />

• Maintenance of parts in the stores.