Synthesis instructions as PDF file for printing - kriemhild

Synthesis instructions as PDF file for printing - kriemhild

Synthesis instructions as PDF file for printing - kriemhild

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NOP http://www.oc-praktikum.de<br />

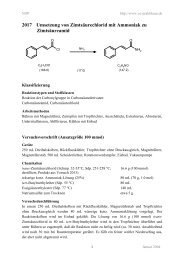

5013 <strong>Synthesis</strong> of 2,6-dimethyl-4-phenyl-1,4-dihydropyridine-<br />

3,5-dicarboxylic acid diethyl ester<br />

NH 4 HCO 3<br />

+<br />

+ 2<br />

O<br />

OC 2 H 5<br />

1<br />

H 5 C 2 O<br />

O O<br />

OC 2 H 5<br />

H O O CH3 H3C N<br />

H<br />

CH3 + 4 H2O CH5NO3 C7H6O C6H10O3 C19H23O4N + CO2 (79.1) (106.1) (130.1)<br />

(329.4)<br />

Literature<br />

Hinkel, L. E., Ayling, E. E. Morgan, W. H., J. Chem. Soc., 1931, 1835<br />

Cl<strong>as</strong>sification<br />

Reaction types and substance cl<strong>as</strong>ses<br />

reaction of the carbonyl group in aldehydes, reaction of the carbonyl group in ketones,<br />

Hantzsch synthesis, ring closure reaction<br />

carboxylic acid ester, aldehyde, ketone, heterocycle, aromatics<br />

Work methods<br />

microwave-<strong>as</strong>sisted reaction, heating under reflux, filtering, evaporating with rotary<br />

evaporator, stirring with magnetic stir bar, draining of g<strong>as</strong>es<br />

Instruction (batch scale 100 mmol)<br />

Equipment<br />

Microwave system ETHOS 1600, 500 mL two-neck fl<strong>as</strong>k, 50 mL round bottom fl<strong>as</strong>k,<br />

magnetic stirrer, magnetic stir bar, reflux condenser, gl<strong>as</strong>s tube (40 cm, NS 29), adapter with<br />

ground gl<strong>as</strong>s joint and hose coupling, suction fl<strong>as</strong>k, 2 w<strong>as</strong>h bottles, Buechner funnel (diameter<br />

6 cm), rotary evaporator, desiccator<br />

Substances<br />

benzaldehyde (bp 179 °C) 10.6 g (10.1 mL, 100 mmol)<br />

acetoacetic acid ethyl ester (bp 180 °C) 28.6 g (27.8 ml, 220 mmol)<br />

ammonium hydrogen carbonate 9.88 g (125 mmol)<br />

ethanol (bp 78 °C) 100 mL<br />

tert-butyl methyl ether (bp 55 °C) 40 mL<br />

March 2006

NOP http://www.oc-praktikum.de<br />

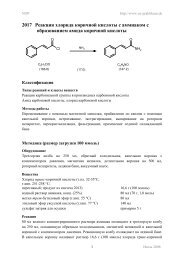

Reaction<br />

The reaction apparatus consists of a 500 mL two-neck fl<strong>as</strong>k with magnetic stir bar, electronic<br />

temperature control and reflux condenser. The reflux condenser is connected with an adapter<br />

with ground gl<strong>as</strong>s joint and hose coupling and a hose <strong>for</strong> draining of the g<strong>as</strong>es <strong>for</strong>ming during<br />

reaction. The hose is connected with an empty safety w<strong>as</strong>h bottle which is connected with a<br />

w<strong>as</strong>h bottle, filled with about 300 mL of water.<br />

10.6 g (10.1 mL, 100 mol) benzaldehyde, 28.6 g (27.8 mL, 220 mmol) acetoacetic acid ethyl<br />

ester, 9.88 g (125 mmol) ammonium hydrogen carbonate and 40 mL ethanol are filled in the<br />

reaction fl<strong>as</strong>k. The reaction apparatus is installed with the gl<strong>as</strong>s tube in the micro wave system<br />

(see "Technical <strong>instructions</strong>: Standard refluxing apparatus <strong>for</strong> micro wave systems") and<br />

treated <strong>for</strong> 40 minutes: The mixture is heated with 900 W in 2 minutes to 80 °C and this<br />

temperature is kept <strong>for</strong> 20 minutes with 400 W, then with 700 W with a temperature ramp in<br />

3 minutes from 80 °C to 88 °C until continuously refluxing and this temperature is kept <strong>for</strong><br />

15 minutes with 500 W. Afterwards the reaction mixture is further stirred <strong>for</strong> 30 minutes<br />

without additional energy supply.<br />

Work up<br />

Until its complete crystallization the cooled reaction mixture is kept in the cooler overnight<br />

where the crude product crystallizes <strong>as</strong> light-yellow solid material. The crude product is finely<br />

chopped in the fl<strong>as</strong>k and sucked off over a Buechner funnel. On the Buechner funnel it is<br />

w<strong>as</strong>hed with 10 mL, 20 mL and 10 mL ethanol and sucked off.<br />

A second product fraction can be gained from the filtrate:<br />

The solvent is evaporated from the filtrate at the rotary evaporator and the remaining oily<br />

crystalline p<strong>as</strong>te is stirred with 30 mL tert-butyl methyl ether <strong>for</strong> 15 minutes. The solid<br />

material is filtered over a folded filter paper and w<strong>as</strong>hed repeatedly with 10 mL tert-butyl<br />

methyl ether. The yellowish residue is transferred in a 50 mL fl<strong>as</strong>k and stirred with 20 mL<br />

ethanol <strong>for</strong> 15 minutes, then sucked off over a Buechner funnel, w<strong>as</strong>hed with less ethanol and<br />

sucked off again.<br />

The two product fractions are dried in the desiccator at reduced pressure.<br />

Yield (total): 21.1 g (64.1 mmol, 64%); mp 156-158 °C; GC-purity of both fractions 100%.<br />

The first product fraction is colourless and finely crystalline, the second pale-yellow.<br />

Comments<br />

An aquaeous solution of ammonia w<strong>as</strong> not used <strong>for</strong> the reaction since a high water<br />

concentration in the system is disadvantageous <strong>for</strong> the reaction. From the used ammonium<br />

hydrogen carbonate in the temperature area of 80 °C the ammonia necessary <strong>for</strong> the reaction<br />

is rele<strong>as</strong>ed. A larger excess of ammonia does not lead to an incre<strong>as</strong>e in yield.<br />

2<br />

March 2006

NOP http://www.oc-praktikum.de<br />

W<strong>as</strong>te management<br />

Recycling<br />

The evaporated ethanol is collected and redistilled.<br />

W<strong>as</strong>te disposal<br />

W<strong>as</strong>te Disposal<br />

tert-butyl methyl ether filtrate organic solvents, halogen free<br />

ethanol filtrates and w<strong>as</strong>hing solutions organic solvents, halogen free<br />

Time<br />

2 - 3 hours (without drying time)<br />

Break<br />

Be<strong>for</strong>e work-up<br />

After isolation of the first product fraction<br />

Degree of difficulty<br />

E<strong>as</strong>y<br />

Analytics<br />

GC<br />

Sample preparation:<br />

50 mg of a sample are dissolved in 1 mL dichlormethane from which 3 µL are injected.<br />

GC-conditions:<br />

column: HP-5; length 30 m, internal diameter 0.32 mm, film 0.25 µm<br />

inlet: split injection 194:1<br />

carrier g<strong>as</strong>: H2, pre-column pressure 31 kPa<br />

oven: 3 min isotherm at 50 °C, afterwards with 8 °C/min to 320 °C<br />

detector: 300 °C<br />

Percent concentration w<strong>as</strong> calculated from peak are<strong>as</strong>.<br />

GC of the pure product<br />

Retention time of the product = 29 min. No impurities were detected.<br />

3<br />

March 2006

NOP http://www.oc-praktikum.de<br />

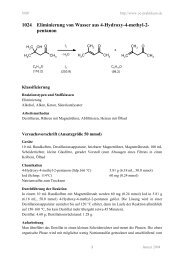

1 H NMR spectrum of the product (300 MHz, CDCl3)<br />

7.3<br />

7.0<br />

7.2<br />

(ppm)<br />

7.1<br />

6.0<br />

5.0<br />

H 5 C 2 O<br />

9<br />

8<br />

4.1<br />

(ppm)<br />

4.0<br />

(ppm)<br />

δ (ppm) Multiplicity Number of H Assignment<br />

1.22 t 6 CH2-CH3<br />

2.32 s 6 CH3 (at the ring)<br />

4.08 m 4 CH2-CH3<br />

4.99 s 1 4-H<br />

5.72 s 1 NH<br />

7.07-7.30 m 5 CH arene<br />

4.0<br />

O O<br />

3<br />

10<br />

7<br />

4<br />

1<br />

H C 2<br />

3 N 6 CH3 H<br />

11<br />

12<br />

5<br />

3.0<br />

OC 2 H 5<br />

4<br />

2.0<br />

1.0<br />

March 2006

NOP http://www.oc-praktikum.de<br />

13 C NMR spectrum of the product (300 MHz, CDCl3)<br />

160<br />

140<br />

120<br />

100<br />

(ppm)<br />

δ (ppm) Assignment<br />

167.65 C=O<br />

147.76 C-7<br />

143.87 C-2, C-6<br />

127.99, 127.82 C-8, C-12, C-9, C11<br />

126.09 C-10<br />

104.14 C-3, C-5<br />

59.72 O-CH2-<br />

39.62 C-4<br />

19.55 CH3 at the ring<br />

14.24 CH3-CH2-<br />

76.5-77.5 solvent<br />

80<br />

5<br />

60<br />

40<br />

H 5 C 2 O<br />

20<br />

9<br />

8<br />

O O<br />

3<br />

10<br />

7<br />

4<br />

1<br />

H3C 2 N 6 CH3 H<br />

11<br />

12<br />

5<br />

OC 2 H 5<br />

March 2006

NOP http://www.oc-praktikum.de<br />

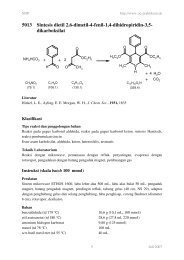

IR-spectrum of the product (KBr)<br />

%T<br />

16,6<br />

16<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

8<br />

7<br />

6,4<br />

3340,57<br />

3057,97<br />

2898,55<br />

3239,13 2985,50<br />

Hantzsch-Synthese<br />

Zielprodukt<br />

1689,27<br />

4000,0 3000 2000 1500 1000 450,0<br />

cm-1<br />

1653,14<br />

1486,94<br />

6<br />

1454,42<br />

(cm -1 ) Assignment<br />

3340 N-H- valence<br />

3080, 3060 C-H-valence, arene<br />

2985, 2900 C-H-valence, alkane<br />

1690 C=O-valence, ester<br />

1655 C=C-valence, alkene<br />

1490 C=C-valence, arene<br />

1324,35<br />

1371,32<br />

1248,48<br />

1299,06<br />

1165,38<br />

1208,74<br />

1122,02<br />

1049,76<br />

1020,86<br />

1089,51<br />

829,37<br />

735,43<br />

771,56<br />

702,91<br />

500,58<br />

637,87<br />

March 2006