FLOOR HEATING ++ Lecture 2c

FLOOR HEATING ++ Lecture 2c

FLOOR HEATING ++ Lecture 2c

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>FLOOR</strong> <strong>HEATING</strong> <strong>++</strong><br />

<strong>Lecture</strong> <strong>2c</strong><br />

• Bjarne W. Olesen, Ph.D.<br />

• Professor,<br />

• International Center for Indoor Environment<br />

and Energy<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 1<br />

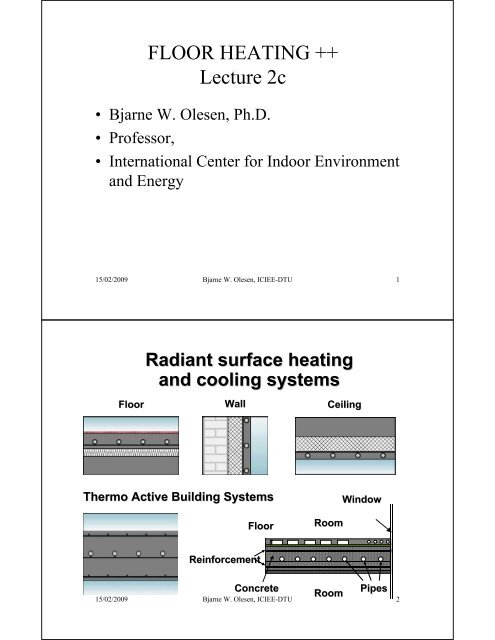

Radiant surface heating<br />

and cooling systems<br />

Floor Wall<br />

Thermo Active Building Systems<br />

Floor<br />

Reinforcement<br />

Ceiling<br />

Room<br />

Window<br />

Concrete Room<br />

Pipes<br />

Room<br />

Pipes<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 2

Determination of Heating and<br />

Cooling Capacity<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 3<br />

STANDARDS<br />

• prEN 1264-2, 2007: Prove methods for the determination of the thermal<br />

output of floor eating systems using calculation and<br />

test methods<br />

– EN 1264-1, 1999: Floor heating: Systems and components - Part 1 :<br />

Definitions and symbols<br />

– EN 1264-3, 1999: Floor heating: Systems and components - Part 3 :<br />

Dimensioning<br />

– EN 1264-4, 2001: Floor heating: Systems and components - Part 4:<br />

Installation<br />

• prEN 1264-5, 2007: Heating and cooling surfaces embedded in floors,<br />

ceilings and walls — Determination of thermal output and<br />

cooling output<br />

• EN15377-1, 2007: Embedded water based surface heating and cooling<br />

systems: Determination of the design heating and<br />

cooling capacity<br />

• EN15377-2, 2007: Embedded water based surface heating and cooling<br />

systems: Design, Dimensioning and Installation<br />

• EN15377-3, 2007: Embedded water based surface heating and cooling<br />

systems: Optimizing for use of renewable energy sources<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 4

SURFACE <strong>HEATING</strong> AND<br />

COOLING<br />

Heat transfer coefficient<br />

Heating<br />

Cooling<br />

11,0<br />

7,0<br />

Floor<br />

6,0<br />

11,0<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 5<br />

8,0<br />

Ceiling<br />

Floor heating and Ceiling cooling: q = 8,92 (θ S,m - θ i ) 1,1<br />

Wall heating and Wall cooling: q = 8 ( θ S,m - θ i )<br />

Ceiling heating: q = 6 ( θ S,m - θ i )<br />

Floor cooling q = 7 ( θ S,m - θ i )<br />

Where<br />

q is the heat flux in W/m2<br />

θS,m is average surface temperature<br />

is room design temperature (operative)<br />

θ i<br />

8,0<br />

11,5<br />

10,5<br />

9,5<br />

8,5<br />

7,5<br />

6,5<br />

5,5<br />

Wall<br />

SURFACE <strong>HEATING</strong> AND<br />

COOLING<br />

Heat transfer coefficient<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 6<br />

W/m 2 K

SURFACE <strong>HEATING</strong> AND<br />

COOLING<br />

Max. - Min. Surface temperature<br />

Heating Cooling<br />

29<br />

20<br />

Floor<br />

35<br />

20<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 7<br />

27<br />

17<br />

Perimeter<br />

40<br />

17<br />

Ceiling<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

Wall<br />

MAXIMUM <strong>HEATING</strong> AND<br />

COOLING CAPACITY<br />

Heating<br />

Cooling<br />

99<br />

42<br />

Floor<br />

165<br />

42<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 8<br />

42<br />

99<br />

Perimeter<br />

160<br />

72<br />

Ceiling<br />

200<br />

180<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Wall<br />

o C<br />

W/m 2

Universal single power function<br />

(EN1264)<br />

<strong>FLOOR</strong> <strong>HEATING</strong><br />

• CALCULATION OF THE HEAT OUTPUT W/m²<br />

• System factor B will depend on type of system and type of pipe<br />

System constant~ 6.5 - 6.7 Factors<br />

Temperature difference<br />

(Room - water)<br />

m<br />

B T<br />

m<br />

D<br />

T D u<br />

Ba aaat Floor covering Pipe spacing Pipe diameter Screed covering<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 9<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 10<br />

m<br />

u<br />

<strong>HEATING</strong> CAPACITY<br />

• Floor covering a B, spacing a T, and covering<br />

a D factors in tables<br />

• mT = 1- T/0.075 (T = Pipe spacing, m)<br />

• mu = 100 ( 0.045 - su )(su = covering thickness, m)<br />

• mD= 250 ( D-0.020 ) (D = Pipe diameter, m )<br />

w

Table A.1 : Floor covering factor a B depending on the thermal resistance R ,B of the floor covering<br />

and the thermal conductivityE of the screed for type A and C systems<br />

R ,B<br />

(m2K/W) 0 0,05 0,10 0,15<br />

E<br />

(W/(m.K)) a B<br />

2,0 1,196 0,833 0,640 0,519<br />

1,5 1,122 0,797 0,618 0,505<br />

1,2 1,058 0,764 0,598 0,491<br />

1,0 1,000 0,734 0,579 0,478<br />

0,8 0,924 0,692 0,553 0,460<br />

0,6 0,821 0,632 0,514 0,433<br />

NOTE : The floor covering factor a B may be determined with<br />

the following equation:<br />

a<br />

B<br />

1 su,0<br />

<br />

u,<br />

0<br />

<br />

1 su,<br />

0<br />

R<br />

<br />

E<br />

,<br />

B<br />

where = 10,8 W/m2K;u,0 = 1 W/m.K; s u,0 = 0,045 m<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 11<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 12

<strong>HEATING</strong> CAPACITY<br />

1.50<br />

1.00<br />

0.50<br />

0.00<br />

FACTOR FOR <strong>FLOOR</strong> COVERING, a B<br />

0.49<br />

0.46<br />

0.15<br />

0.1<br />

0.60<br />

0.55<br />

m 2 K/W<br />

0.76<br />

0.69<br />

0.05<br />

1.06<br />

0.92<br />

1.20<br />

0.80<br />

Screed<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 13<br />

COOLING CAPACITY<br />

• Total factor for the following example<br />

• 17 mm pipe<br />

• 45 mm concrete above pipes<br />

1<br />

• Concrete ~ 1,2 W/mK<br />

0,8<br />

0,6<br />

0,4<br />

0,2<br />

0<br />

300<br />

0,42<br />

0,52<br />

T, mm<br />

150<br />

0,57<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 14<br />

0,77<br />

0,66<br />

75<br />

0,96<br />

0<br />

0,01<br />

0,1 Rb, m 2 K/W

COOLING CAPACITY<br />

• Cooling capacity in W/m²for the following example<br />

• 17 mm PEX-pipe<br />

• 45 mm concrete above pipes 50<br />

• Concrete ~ 1,2 W/mK<br />

• Space temperature 26 °C 40<br />

•<br />

•<br />

Supply water temperature 14 °C<br />

30<br />

Return water temperature 19 W/m°C 20<br />

2<br />

10<br />

0<br />

300<br />

20<br />

25<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 15<br />

Heat exchange [W/m2]<br />

T mm<br />

150<br />

ALUMINUM HC device: Floor Heating & Cooling (type B), R=0.01~0.1,<br />

T=150 & 300<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

T=150, R=0.01<br />

T=150, R=0.1<br />

T=300, R=0.01<br />

T=300, R=0.1<br />

27<br />

37<br />

75<br />

32<br />

46<br />

0,1<br />

0,01<br />

R b m 2 K/W<br />

Heating/ cooling capacity, EN1264<br />

and EN 15377<br />

-15 -10 -5 0 5 10 15 20 25 30<br />

Heating/cooling medium differential temperature ΔθH=θH-θi [°C]<br />

Figure 4.17 Heat exchange between the surface (with ceramic tiles, wooden<br />

parquets or carpet R?B=0.1 and no covering R?B=0) and the space when aluminium<br />

heat conductive device used<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 16

Thermal resistance methods<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 17<br />

Pipes embedded in a<br />

massive concrete layer<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 18

Thermal resistance method<br />

<br />

v<br />

R t<br />

R 1<br />

R 2<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 19<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 20<br />

<br />

<br />

c<br />

q 1<br />

q 2<br />

s 1<br />

s 2<br />

Capillar tubes

v R t<br />

Thermal resistance<br />

methods<br />

R 1<br />

R 2<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 21<br />

<br />

Thermal resistance method<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 22<br />

<br />

<br />

<br />

c<br />

s <br />

2

Thermal resistance method<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 23<br />

q K Δθ<br />

i<br />

K H <br />

Thermal resistance<br />

methods<br />

H<br />

H H i<br />

H<br />

W/m<br />

²<br />

is the differential temperature of the heating/cooling<br />

medium<br />

equivalent coefficient of thermal<br />

conductivity<br />

/( RHC<br />

R ) W/m²<br />

C<br />

KH 1<br />

i<br />

Total thermal resistance between the heat source and the<br />

conducting layer<br />

m² °C/W<br />

T<br />

RHC T<br />

RR<br />

T<br />

RR<br />

, con RU<br />

R<br />

2<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 24<br />

R HC<br />

CL<br />

R i<br />

R e

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 25<br />

Finite Element Method<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 26

Laboratory testing<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 27<br />

UNIFORMITY OF <strong>FLOOR</strong> SURFACE<br />

TEMPERATURE<br />

Maximum<br />

Mean<br />

Minimum<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 28

W/ 2 m<br />

RADIANT <strong>FLOOR</strong> COOLING<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 29<br />

155<br />

135<br />

115<br />

95<br />

75<br />

55<br />

35<br />

15<br />

COOLING CAPACITY<br />

CALCULATED CAPACITY IN AN ATRIUM<br />

WITH DIRECT SUNSHINE ON THE <strong>FLOOR</strong><br />

107<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 30<br />

129<br />

148<br />

25 20 15<br />

Supply water temperature, o C

Floor surface temperature<br />

Heating/ cooling capacity, EN1264 and EN 15377<br />

Heat exchange [W/m2]<br />

ALUMINUM HC device: Floor Heating & Cooling (type B), R=0.01~0.1,<br />

T=150 & 300<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

T=150, R=0.01<br />

T=150, R=0.1<br />

T=300, R=0.01<br />

T=300, R=0.1<br />

-15 -10 -5 0 5 10 15 20 25 30<br />

Heating/cooling medium differential temperature ΔθH=θH-θi [°C]<br />

Figure 4.17 Heat exchange between the surface (with ceramic tiles, wooden<br />

parquets or carpet R?B=0.1 and no covering R?B=0) and the space when aluminium<br />

heat conductive device used<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 31<br />

Floor covering<br />

Heat supply<br />

Pipe distance<br />

T water-average –t room<br />

Diagram for<br />

17x2 mm pipe<br />

45 mm screed<br />

= 1,2 W/mK<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 32

Water flow rate<br />

Pressure drop<br />

Water<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 33<br />

The design supply water<br />

temperature is determined<br />

according to the room with the<br />

highest heat load or with the highest<br />

heat resistance of the floor covering.<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 34

Calculation of the water supply temperature<br />

Heat resistance of the floor covering R ,B = 0,15 m 2 K/W<br />

Pipe spacing 15 cm<br />

Design heat loss 80 W/m 2<br />

From the dimensioning diagram<br />

Difference between average water temperature and room:<br />

H = 28,9 K<br />

Average water temperature:<br />

HM= 20°C + 28,9 K = 48,9 °C<br />

Temperature difference (supply-return) for the critical room: EN1264 = 5 K<br />

Design supply water temperature:<br />

Vdim = HM + /2 = 48,9°C +2,5 K = 51,4 °C<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 35<br />

80 W/m 2<br />

FB= 27,3 °C<br />

0,15m 2 K/W<br />

Diagram for<br />

dimensioning<br />

H<br />

HM<br />

= 28,9°C<br />

= 48,9 °C<br />

Vausl = 51,4 °C<br />

Boundary<br />

conditions<br />

S å = 45 mm<br />

å = 1,2 W/mK<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 36

DIMENSIONING AND<br />

DESIGN<br />

• Pipe diameter<br />

• Pipe spacing<br />

• Pipe layout<br />

• Water flow rate<br />

• Pipe circuits<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 37<br />

Kombizone<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 38<br />

RL<br />

VL

Perimeter and occupied space<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 39<br />

Occupied space<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 40<br />

RL<br />

VL<br />

RL<br />

VL<br />

RL<br />

VL

VL<br />

RL<br />

Cover as much surface as possible<br />

Possible solution<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 41<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 42

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 43<br />

Joints in the concrete<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 44<br />

R<br />

L<br />

V<br />

L

Example<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 45<br />

Correction for covered<br />

surface<br />

Floor area<br />

Korrektur af<br />

Normvarmetabet<br />

Største varmestrøm<br />

Bad tages ikke med<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 46

Tilslutningsledninger<br />

Varmeafgivel se [W/m]<br />

egen varmekreds<br />

gennemgående<br />

Total rørlængde<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 47<br />

15<br />

14<br />

13<br />

12<br />

11<br />

10<br />

9<br />

Forbindelses rör<br />

45 46 47 48 49 50 51 52 53 54 55 56 57 58<br />

Dimensionerende fremlöbstemperatur [°C]<br />

45 mm Beton, Ü = 1,2 W/mK<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 48

q<br />

r<br />

Vandstrøm:<br />

Water flow<br />

<br />

0,<br />

86<br />

c <br />

TFTR TF<br />

TR<br />

qr: Water Vandstrøm flow l/h<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 49<br />

<br />

<br />

c: Vands varmefylde Wh/kgC<br />

Specific heat capacity<br />

Φ: Heat Varmeydelse supply W<br />

Tryktabsdiagramdiagram<br />

for 17 x 2 mm rør<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 50

14<br />

Water flow rate<br />

Pressure drop 14 x 2 mm<br />

pipe<br />

Pressure drop<br />

Water<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 51<br />

5 1 / 4<br />

Valve<br />

position<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 52

Valve position<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 53<br />

INSTALLATION<br />

• Floor systems<br />

• Wall systems<br />

•Ceilingsystems<br />

• TABS Thermo Active Building Systems<br />

• Pre-fabrication<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 54

1. Screed-concrete 2. Pipe<br />

3. Plastic foil<br />

4. Insulation 5. Acoustic insulation<br />

6. PE foil<br />

7. covering 8. Concrete slab<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 55<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 56

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 57<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 58

Radiant surface heating<br />

and cooling systems<br />

Floor Wall<br />

Thermo Active Building Systems<br />

Floor<br />

Reinforcement<br />

Ceiling<br />

Room<br />

Window<br />

Concrete Room<br />

Pipes<br />

Room<br />

Pipes<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 59<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 60

Calculation methods<br />

1. Rough sizing method based on a standard<br />

calculation of the cooling load (accuracy 20-30%).<br />

To be used based on the knowledge of the peak<br />

value for heat gains (section 5.1)<br />

2. Simplified method using diagrams for sizing<br />

based on 24 hours values of heat gains (accuracy<br />

15-20%, section 5.2).<br />

3. Simplified model based on finite difference<br />

method (accuracy 10-15%). Detailed dynamic<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 61<br />

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 62

15/02/2009 Bjarne W. Olesen, ICIEE-DTU 63